Abstract

Tetracycline (TC) is a widely used antibiotic that adversely affects ecosystems and, therefore, must be removed from the environment. Owing to their strong ability to oxidise pollutants, including antibiotics, and selectivity for these pollutants, an improved oxidation method based on sulphate radicals (SO4·−) has gained considerable interest. In this study, a novel technique for removing TC was developed by activating peroxymonosulphate (PMS) using a ZnFe2O4 catalyst. Using the co-precipitation method, a ZnFe2O4 catalyst was prepared by doping zinc into iron-based materials, which increased the redox cycle, while PMS was active and facilitated the production of free radicals. According to electron paramagnetic resonance spectroscopy results, a ZnFe2O4 catalyst may activate PMS and generate SO4·−, HO·, O2·−, and 1O2 to eliminate TC. This research offers a new method for creating highly effective heterogeneous catalysts that can activate PMS and destroy antibiotics. The study proposes the following degradation pathways: hydroxylation and ring-opening of TC based on the products identified using ultra-performance liquid chromatography-mass spectrometry. These results illustrated that the prepared ZnFe2O4 catalyst effectively removed TC and exhibited excellent catalytic performance.

Similar content being viewed by others

Introduction

Recently, due to the rapid development of industry, more and more antibiotic pollutants are discharged into the water body, resulting in increasingly serious water pollution. Tetracycline (TC) is a widely used antibiotic in medical and livestock farming1. However, a significant amount of TC is released into the environment and is not absorbed by humans or animals, resulting in increased microbial resistance and harmful impacts on ecological system2,3. TC levels as high as 20 mg/L have been reported in aquaculture wastewater, and recently, TC has been detected in drinking water4,5. Therefore, effective methods for the removal of TC from aqueous solutions have become a matter of urgent concern.

In recent years, antibiotics have been removed from water using various methods such as adsorption, biodegradation6, photodegradation7,8, and advanced oxidation processes (AOPs)9. The conventional methods such as adsorption and membrane processes often have some limitations including production of secondary pollutants, high cost and tedious process. The use of AOPs, in which large organic molecules are converted into small organic molecule compounds and even H2O and CO2, is the most effective method for removing TC10,11.Advanced oxidation process based on peroxymonosulfate (PMS) activation emerged as one of the most promising technologies for antibiotics remediation.

SO4·− has a higher oxidation potential, longer duration, and wider pH range compared to HO· produced via the Fenton reaction12. Generally, persulfates such as PMS or peroxydisulfate (PDS) are used to produce SO4·–13,14,15. PMS with an asymmetric structure exhibits a stronger oxidation performance than PDS with a solid symmetric framework16. Therefore, PMS is widely used in radical sulphate-based AOPs, which are typically facilitated by using metal-containing catalysts (Co, Fe, Cu, and Mn)17,18,19,20,21,22. However, highly effective, reliable, and recyclable heterogeneous catalysts for practical applications are still required. Heterogeneous catalyst is preferred as PMS activator compared to homogeneous catalyst due to the ease of catalyst recovery, minimum release of secondary pollutant and the potential to operate under such extreme conditions (high pressure and high temperature).

Among the transition-metal-based catalysts, Fe-based catalysts are frequently utilised to trigger PMS because of their high effectiveness, safety, non-toxicity, and low price. Fe-based catalysts that can activate PMS to breakdown organic pollutants include magnetic Fe3O4, α-Fe2O3, γ-Fe2O3, and δ-FeOOH23. Although low valence Fe2+ and Fe0 are readily oxidised, the slow cycle of Fe2+/Fe3+ results in low PMS activation efficiency24. Therefore, to eliminate these negative effects, bimetallic oxide catalysts have been proposed as substitutes for improving catalytic activity and stability. In the past, there were many studies on the degradation of organic pollutants by persulfate using Fe–Mn, Fe–CO bimetallic oxides as catalysts20,22,24, but the leaching of CO and Mn ions will cause secondary pollution to the environment, therefore, this study focused on environmental pollution-free Fe–Zn bimetallic oxide catalysts.

In this study, ZnFe2O4 catalyst was synthesised using the co-precipitation reaction, and its performance in TC degradation was evaluated. The primary goals of this study were to (1) investigate the physicochemical characteristics of the catalyst and discuss its catalytic effectiveness in PMS systems, (2) investigate the effect of various environmental conditions on TC degradation, and (3) examine the reactive oxygen species generated in the ZnFe2O4/PMS system and elucidate the TC degradation process. Our study provides a new perspective on finding improved, inexpensive, and eco-friendly catalysts.

Methods

Materials

PMS (KHSO5·0.5KHSO4·0.5K2SO4), iron hexahydrate chloride (FeCl3·6H2O), zinc chloride (ZnCl2), TC, sodium chloride (NaCl), sodium carbonate (Na2CO3), and sodium dihydrogen phosphate (NaH2PO4) were supplied by Aladdin Industrial Co., Ltd. Hydrochloric acid (HCl), ethanol, and sodium hydroxide (NaOH) were purchased from Guangzhou Chemical Reagent Co. Deionied water (DI) was used throughout the experiment. All reagents were of the lowest analytical quality.

Synthesis of ZnFe2O4

Using a co-precipitation method, ZnFe2O4 was synthesised. First, FeCl3·6H2O and ZnCl2 were ultrasonically dispersed in 50 mL of DI water for 30 min. The resultant mixture was then placed in a water bath at 50 °C and stirred magnetically. NaOH was added to the solution until the pH reached 9, and the suspension was continuously stirred and maintained at 50 °C for 1 h. The ZnFe2O4 composites were then centrifuged, separated, and washed with ethanol and ultrapure water to reach a pH of 7. The obtained composites were dried at 60 °C for 24 h, pulverised, passed through an 80-mesh sieve, and then calcined at 600 °C for 2 h under N2 gas.

Characterization of the catalyst

The X-ray diffraction (XRD) pattern were measured between 5 and 80° at 40 kV and 250 mA. The morphology of the ZnFe2O4 composites was obtained using scanning electron microscopy (SEM; TESCAN MIRA LMS) equipped with energy-dispersive X-ray spectroscopy (EDS). X-ray photoelectron spectroscopy (XPS) was performed using a Thermo Scientific K-Alpha photoelectron spectrometer system.

Catalytic activity test

To evaluate the catalytic performance and reusability of ZnFe2O4, we determined its TC removal efficiency. To achieve an equilibrium between adsorption and desorption, the catalyst (0.2 g/L) was uniformly suspended in the TC solution (20 mg/L) at 25 °C and continuously shaken for 30 min. To initiate the catalytic oxidation, PMS was introduced into the reaction solution. We collected 2 mL of sample solutions at a time, filtered them through a 0.22 mm membrane, and measured their TC content using an ultraviolet–visible spectrophotometer at 360 nm. An ultra-performance liquid chromatography-mass spectrometry (UPLC-MS) system was used to identify the TC oxidation intermediates. Reactive oxygen species (ROS) were detected using electron paramagnetic resonance (EPR). After the reaction, the catalyst was collected, washed with ethanol and water, and used in a subsequent cycle to determine its suitability for reuse.

Results and discussion

Characterization of catalysts

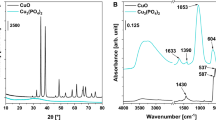

The XRD pattern of the prepared catalyst matched that of cubic spinel ZnFe2O4 (JCPDS file No. 22-1012), indicating the presence of ZnFe2O4 crystals (Fig. 1). Six diffraction peaks were observed at 2θ = 18.19°, 29.92°, 35.26°, 42.84°, 45.45°, and 62.21°, which corresponded to the (111), (220), (311), (400), (511), and (440) planes of the ZnFe2O4, respectively, indicating its high surface purity and good crystallinity.

The SEM was used to examine the surface morphology and particle size distribution of ZnFe2O4. Figure 2 shows an SEM image of a synthetic ZnFe2O4 catalyst at various magnifications. Evidently, ZnFe2O4 nanoparticles with hexagonal and spherical structures are uniformly dispersed. After the reaction, the surface pores of the catalyst become larger.The homogenous distribution of the ZnFe2O4 particles may help in establishing contact between the catalyst and oxidant, facilitating the activation of PMS25. Moreover, the surface of ZnFe2O4 contains several pores, which help adsorb TC on the catalyst surface.

TC degradation in various systems

The degradation of tetracycline under different Fe-based catalysts was illustrated in Table 1. TC removal efficiency was higher (63%) than other Fe-based catalysts, when Fe–Zn catalysts was employed in the same reaction conditions. So, the TC removal efficiencies were investigated in various systems to evaluate the catalytic effectiveness of ZnFe2O4-activated PMS for TC degradation (Fig. 3a). ZnFe2O4 alone was found to remove 15% of TC within 30 min because of TC adhering to the large surface area of the catalyst. Despite being a powerful oxidant (E = 1.82 V), PMS alone could remove only 30% of the TC in a 60-min period due to insufficient catalyst for PMS activation and oxygen radical production. The TC removal efficiencies of Fe2O3 and ZnO as catalysts were 60% and 66%, respectively, demonstrating that both ZnO and Fe2O3 can activate PMS. However, the TC degradation efficiency could reach 78% in ZnFe2O4/PMS system, indicating its improved catalytic performance.

Catalytic activity and reaction parameter effects

The effects of the catalyst amount, PMS addition amount, and starting pH on TC decomposition were investigated to determine the catalytic oxidation efficiency of ZnFe2O4. The TC degradability improved as the catalyst quantity was increased from 0.1 to 0.5 g L−1, as shown in Fig. 3b. With a catalyst concentration of 0.1 g L−1, 53% TC was removed in 60 min. This is attributed to the increased number of active sites available for PMS activation as the catalyst dose increases to facilitate TC degradation26. When the catalyst concentration was increased to 0.2 g L−1, TC removal increased to 78% in 60 min. However, no discernible improvement was observed on further increasing the catalyst amount to 0.5 g L−1, which may be attributed to the ability of the catalyst to bind excess radicals that tend to aggregate27,28,29,30. Figure 3c shows the effect of the PMS concentration on the TC removal efficiency. Using 20 mg L−1 PMS, the TC elimination was 42% within 60 min and reached to 78% when using 100 mg L−1 PMS. This could be because increasing the PMS concentration increases the contact between PMS and the catalyst, thus producing more free radicals31. Nevertheless, the effectiveness of TC elimination decreased when the PMS concentration was increased further. Because the excess PMS could quench SO4·− and HO· to form SO5·− (Eqs. 1 and 2) with weak oxidation ability32, the produced SO4·− or SO5·− should also have a self-quenching ability (Eqs. 3 and 4)33,34,35,36. Therefore, in future studies, 100 mg/L PMS should be used as the optimal concentration.

A key factor influencing TC removal is the initial pH of the reaction solution. Figure 3d shows that the TC removal efficiencies within 60 min were 85%, 81%, 78%, 73%, and 64% at different pH values of 3.0, 5.0, 7.0, 9.0, and 11.0, respectively. According to these findings, ZnFe2O4-activated PMS could dissolve PMS over a broad pH range, and its removal effectiveness decreased with increasing pH. Generally, SO4·−, which can be manufactured in large quantities for TC degradation, is the primary active species under acidic conditions (Eqs. 5 and 6)37,38. However, SO4·− tends to react with OH− to form HO· under alkaline conditions (Eq. 7)39. To dissociate TC chemical bonds, the oxidative potential of the HO· radical should be smaller than that of the SO4·− radical. A higher concentration of OH− can also cause HO· to interact with OH−, resulting in radical annihilation and reduced TC degradation efficiency.

Effects of different anions on TC degradation

Water and wastewater contain various inorganic anions that affect tetracycline removal. Therefore, the effects of Cl−, \({\text{CO}}_{3}^{2}\), and \({\text{H}}_{{2}} {\text{PO}}_{{4}}^{ - }\) on the rate of TC degradation in the ZnFe2O4/PMS system were studied. Figure 4a shows that 1 mM of Cl− had a slight effect on TC degradation; however, 5–10 mM of Cl− could improve TC removal efficiency to 87%. Furthermore, high levels of Cl− may transfer electrons to PMS, resulting in sulphate radicals and superabundant chlorine species (Eqs. 8 and 9)40,41,42,43, which may participate in the TC degradation process44.

Moreover, increasing the \({\text{CO}}_{{3}}^{{{2}{-}}}\) concentration from 1 to 10 mM facilitated TC breakdown (Fig. 4b). This might be attributed to the activation of asymmetrically structured PMS by \({\text{CO}}_{{3}}^{{{2}{-}}}\), thus producing more reactive free radicals (Eq. 10)45,46,47.

Similarly, Fig. 4c shows that H2PO4- degrades TC rapidly, which may be due to the transformation of SO4·− into the more reactive H2PO4·− as shown in(Eqs. 11 and 12)48.

Reusability of ZnFe2O4 in catalytic reaction

The most crucial factor in practical applications is the capacity of the catalyst to be reused. To investigate the reusability of ZnFe2O4, four cycling runs were performed under ideal experimental conditions. As shown in Fig. 5, the TC degradation efficiencies reduced from 77 to 66% in 60 min after 4 cycles, indicating the good reusability of the ZnFe2O4 catalyst. A minor metal ion overflow on the catalyst may have decreased its activity. Furthermore, TC decomposition may have been hampered by intermediate products absorbed by the catalyst49.

Catalytic mechanism

To explore the catalytic mechanism of ZnFe2O4, ROS involved in the ZnFe2O4/PMS system were investigated using EPR spectroscopy. DMPO was used to capture SO4·−, HO·, and O2·− using spin trapping, and TEMP was used to detect 1O2. As shown in Fig. 6a, the DMPO-HO· and DMPO- SO4·− adducts showed their characteristic peaks when the time was increased from 0 to 10 min. Moreover, the DMPO-O2·− adduct signal in Fig. 6b indicates that O2·− may also be involved in TC degradation. Moreover, the TEMP-1O2 adduct signal was detected at 10 min, implying the presence of 1O2 in the reaction (Fig. 6c). These findings demonstrated that PMS might be triggered by ZnFe2O4 producing some active substance that removes TC.

XPS was used to analyse changes in Zn and Fe valence states in untreated and treated ZnFe2O4 catalysts to further investigate their role in PMS activation. The C 1s, O 1s, Fe 2p, and Zn 2p peaks of both new and used catalysts in Fig. 7 indicate the good stability of ZnFe2O4. The peaks at 284.8, 530.8, 711.5, and 1021.6 eV in Fig. 7a correspond to C 1s, O 1s, Fe 2p, and Zn 2p, respectively. Table 2 shows the relative element contents before and after the reaction. The C 1s orbital in the samples before and after the reaction has similar components, which can be identified as C–O, C–C, O=C–O, and C=O based on the peak patterns and binding energies of 286.3, 284.8, 288.9, and 287.2 eV, respectively (Fig. 7b and Table 3). In Fig. 7c, the energy difference between the spin–orbit splitting peaks (2p3/2 and 2p1/2) is approximately 23 eV, and the spectral peak area ratio (2p3/2:2p1/2) is approximately 2:1. The energy position of Zn 2p spectral peaks and the database suggest that 1021.9 eV should correspond to ZnO. Based on the Fe 2p spectrum in Fig. 7d, the Fe species in the catalyst should be Fe3+ with the lowest peak intensity at 708.9 eV. The peaks at 714.5 and 719.3 eV are surface and satellite peaks of the catalyst, respectively, whereas those at 710.0, 711.0, 712.0, and 713.0 eV correspond to the four typical multiple cleavages of Fe3+ with relative contents listed in Table 4. Based on these results, the valence states of Fe and Zn in the catalyst have not changed substantially. However, following the reaction, the carbon content rose, whereas the concentrations of Fe and Zn decreased. Although the catalyst contains only Fe3+, its content at a low binding energy increased after the reaction.

Degradation pathways of TC

To elucidate the TC decomposition process, the main products were qualitatively analysed using the ESI Q Orbitrap HRMS. Figure 8 shows the possible degradation pathways discussed below. The initial compound (TC) has an ion peak at m/z 445, corresponding to the proton-ionised form of [M + H]+. The first possible reaction pathway involves the formation of the m/z 461 product via oxidative hydroxylation of the “A” ring of TC, m/z 477 via hydroxylation of the “D” ring, and m/z 449 via oxidative “D” ring opening and removing the carbonyl group. Further oxidation could occur when the C–C bonds are broken and side chains are removed to yield m/z 378 and 394. In addition, m/z 366 could be obtained via the oxidative ring opening of the “B” ring. The second possible reaction pathway involves the formation of product m/z 461 via hydroxylation of the “D” ring, product m/z 495 via the “D” ring opening, and products m/z 376 and 422 via oxidative breaking of the C–C bonds. The product m/z 366 was then obtained by oxidising the “B” ring and removing the carboxyl group. The third possible reaction channel involves the TC breakdown via the C–N bond and demethylation of dimethylamine to procure m/z 431, the hydroxylation of the “A” ring of TC to obtain m/z 463, and the oxidative opening of the “D” ring to procure m/z 364. The splitting of the rings to form tiny molecules of acids and amines, as well as H2O, CO2, \({\text{NO}}_{3}^{ - }\), and \({\text{NH}}_{{4}}^{ + }\), indicate oxidative breakdown and complete degradation of the compounds.

Conclusions

The co-precipitation method was used to synthesise a highly active ZnFe2O4 catalyst, which was subsequently used as a PMS activator to degrade TC. The ZnFe2O4 catalyst was studied using XRD, SEM, and XPS. The effects of the changes in the amount of catalyst, PMS concentration, and initial pH on TC decomposition efficiency were studied under various conditions. Under the optimised reaction conditions, the TC degradation efficiency reached 78%. Inorganic anions (H2PO4–\({\text{H}}_{{2}} {\text{PO}}_{{4}}^{-}\), \({\text{CO}}_{{3}}^{{{2}{-}}}\), and Cl–) can promote TC degradation to certain extent. In the cyclic experiments, ZnFe2O4 was found to be catalytically active and stable. In addition, the EPR and XPS results revealed the presence of numerous active substances, including SO4·–, HO·, O2·–, and 1O2, in the TC mineralization process. The potential TC degradation mechanisms of the ZnFe2O4/PMS system were hypothesised to depend on the products identified by UPLC-MS. These results demonstrated that the prepared ZnFe2O4 catalyst effectively removed TC and exhibited excellent catalytic performance.

Data availability

Data is available under reasonable request to the corresponding author.

References

Kovalakova, P. et al. Occurrence and toxicity of antibiotics in the aquatic environment: A review. Chemosphere 251, 126351. https://doi.org/10.1016/j.chemosphere.2020.126351 (2020).

He, J. et al. Enhanced peroxymonosulfate activation over heterogeneous catalyst Cu0.76Co2.24O4/SBA-15 for efficient degradation of sulfapyridine antibiotic. Ecotoxicol. Environ. Saf. 216, 112189. https://doi.org/10.1016/j.ecoenv.2021.112189 (2021).

Le, S. et al. V2O5 nanodot-decorated laminar C3N4 for sustainable photodegradation of amoxicillin under solar light. Appl. Catal. B Environ. 303, 120903. https://doi.org/10.1016/j.apcatb.2021.120903 (2022).

Sun, J. et al. Synchronous removal of tetracycline and copper (II) over Z-scheme BiVO4/rGO/g-C3N4 photocatalyst under visible-light irradiation. Environ. Sci. Pollut. Res. 29, 19148–19164. https://doi.org/10.1007/s11356-021-16996-4 (2022).

Wei, J., Han, D., Bi, J. & Gong, J. Fe-doped ilmenite CoTiO3 for antibiotic removal: Electronic modulation and enhanced activation of peroxymonosulfate. Chem. Eng. J. 423, 130165. https://doi.org/10.1016/j.cej.2021.130165 (2021).

Yang, P. et al. Efficient removal of tetracycline in water by a novel chemical and biological coupled system with non-woven cotton fabric as carrier. Chin. Chem. Lett. 32, 2823–2827. https://doi.org/10.1016/j.cclet.2021.02.028 (2021).

Dang, C. et al. Pre-accumulation and in-situ destruction of diclofenac by a photo-regenerable activated carbon fiber supported titanate nanotubes composite material: Intermediates, DFT calculation, and ecotoxicity. J. Hazard. Mater. 400, 123225. https://doi.org/10.1016/j.jhazmat.2020.123225 (2020).

Ji, H. et al. 2D/1D graphitic carbon nitride/titanate nanotubes heterostructure for efficient photocatalysis of sulfamethazine under solar light: Catalytic “hot spots” at the rutile–anatase–titanate interfaces. Appl. Catal. B Environ. 263, 118357. https://doi.org/10.1016/j.apcatb.2019.118357 (2020).

Wacławek, S. et al. Chemistry of persulfates in water and wastewater treatment: A review. Chem. Eng. J. 330, 44–62. https://doi.org/10.1016/j.cej.2017.07.132 (2017).

Hao, S.-M. et al. Hollow manganese silicate nanotubes with tunable secondary nanostructures as excellent fenton-type catalysts for dye decomposition at ambient temperature. Adv. Func. Mater. 26, 7334–7342. https://doi.org/10.1002/adfm.201603315 (2016).

Zhu, L. et al. Designing 3D-MoS2 sponge as excellent cocatalysts in advanced oxidation processes for pollutant control. Angew. Chem.-Int. Ed. 59, 13968–13976. https://doi.org/10.1002/anie.202006059 (2020).

Chen, F. et al. Catalytic degradation of ciprofloxacin by a visible-light-assisted peroxymonosulfate activation system: Performance and mechanism. Water Res. https://doi.org/10.1016/j.watres.2020.115559 (2020).

Chen, C. et al. In-situ pyrolysis of Enteromorpha as carbocatalyst for catalytic removal of organic contaminants: Considering the intrinsic N/Fe in Enteromorpha and non-radical reaction. Appl. Catal. B 250, 382–395. https://doi.org/10.1016/j.apcatb.2019.03.048 (2019).

Jia, M. et al. Magnetic heterojunction of oxygen-deficient Ti3–TiO2 and Ar-Fe2O3 derived from metal-organic frameworks for efficient peroxydisulfate (PDS) photo-activation. Appl. Catal. B-Environ. https://doi.org/10.1016/j.apcatb.2021.120513 (2021).

Zhang, L.-S. et al. carbon nitride supported high-loading Fe single-atom catalyst for activating of peroxymonosulfate to generate O-1(2) with 100% selectivity. Angew. Chem.-Int. Ed. 60, 21751–21755. https://doi.org/10.1002/anie.202109488 (2021).

Wang, L. et al. Fabrication of Co3O4-Bi2O3-Ti catalytic membrane for efficient degradation of organic pollutants in water by peroxymonosulfate activation. J. Colloid Interface Sci. 607, 451–461. https://doi.org/10.1016/j.jcis.2021.08.086 (2022).

Abdul Nasir Khan, M. et al. Metal-organic framework-derived hollow Co3O4/carbon as efficient catalyst for peroxymonosulfate activation. Chem. Eng. J. 363, 234–246. https://doi.org/10.1016/j.cej.2019.01.129 (2019).

Asif, M. B., Kang, H. & Zhang, Z. Gravity-driven layered double hydroxide nanosheet membrane activated peroxymonosulfate system for micropollutant degradation. J. Hazard. Mater. 425, 127988. https://doi.org/10.1016/j.jhazmat.2021.127988 (2022).

Chen, X. et al. PMS activation by magnetic cobalt-N-doped carbon composite for ultra-efficient degradation of refractory organic pollutant: Mechanisms and identification of intermediates. Chemosphere 287, 132074. https://doi.org/10.1016/j.chemosphere.2021.132074 (2022).

Li, Y. et al. Peroxymonosulfate activation on FeCo2S4 modified g-C3N4 (FeCo2S4-CN): Mechanism of singlet oxygen evolution for nonradical efficient degradation of sulfamethoxazole. Chem. Eng. J. 384, 123361. https://doi.org/10.1016/j.cej.2019.123361 (2020).

Sun, J. A., Wang, L., Wang, Y., Lv, W. & Yao, Y. Activation of peroxymonosulfate by MgCoAl layered double hydroxide: Potential enhancement effects of catalyst morphology and coexisting anions. Chemosphere 286, 131640. https://doi.org/10.1016/j.chemosphere.2021.131640 (2022).

Zhao, G. et al. Iron-based catalysts for persulfate-based advanced oxidation process: Microstructure, property and tailoring. Chem. Eng. J. https://doi.org/10.1016/j.cej.2020.127845 (2021).

Zhao, J. et al. Superior performance of ZnCoOx/peroxymonosulfate system for organic pollutants removal by enhancing singlet oxygen generation: The effect of oxygen vacancies. Chem. Eng. J. 409, 128150. https://doi.org/10.1016/j.cej.2020.128150 (2021).

Liu, Y., Zhou, A., Gan, Y. & Li, X. Roles of hydroxyl and sulfate radicals in degradation of trichloroethene by persulfate activated with Fe2+ and zero-valent iron: Insights from carbon isotope fractionation. J. Hazard. Mater. 344, 98–103. https://doi.org/10.1016/j.jhazmat.2017.09.048 (2018).

Guo, B. et al. Co3O4/CoO ceramic catalyst: Bisulfite assisted catalytic degradation of methylene blue. Ceram. Int. 47, 27617–27623. https://doi.org/10.1016/j.ceramint.2021.06.186 (2021).

She, S. et al. Reusing warm-paste waste as catalyst for peroxymonosulfate activation toward antibiotics degradation under high salinity condition: Performance and mechanism study. Chem. Eng. J. 426, 131295. https://doi.org/10.1016/j.cej.2021.131295 (2021).

Cai, C. et al. Efficient degradation of bisphenol A in water by heterogeneous activation of peroxymonosulfate using highly active cobalt ferrite nanoparticles. J. Hazard. Mater. 399, 122979. https://doi.org/10.1016/j.jhazmat.2020.122979 (2020).

Luo, J. et al. Transforming goat manure into surface-loaded cobalt/biochar as PMS activator for highly efficient ciprofloxacin degradation. Chem. Eng. J. 395, 125063. https://doi.org/10.1016/j.cej.2020.125063 (2020).

Nguyen, T.-B. et al. Construction of ternary NiCo2O4/MnOOH/GO composite for peroxymonosulfate activation with enhanced catalytic activity toward ciprofloxacin degradation. Chem. Eng. J. 446, 137326. https://doi.org/10.1016/j.cej.2022.137326 (2022).

Zhu, S. et al. Magnetic Co/Fe nanocomposites derived from ferric sludge as an efficient peroxymonosulfate catalyst for ciprofloxacin degradation. Chem. Eng. J. 432, 134180. https://doi.org/10.1016/j.cej.2021.134180 (2022).

Wu, Z. et al. Efficient degradation of tetracycline by persulfate activation with Fe, Co and O co−doped g−C3N4: Performance, mechanism and toxicity. Chem. Eng. J. 434, 134732. https://doi.org/10.1016/j.cej.2022.134732 (2022).

Cao, J. et al. Degradation of tetracycline by peroxymonosulfate activated with zero-valent iron: Performance, intermediates, toxicity and mechanism. Chem. Eng. J. 364, 45–56. https://doi.org/10.1016/j.cej.2019.01.113 (2019).

Ghanbari, F., Khatebasreh, M., Mahdavianpour, M. & Lin, K.-Y.A. Oxidative removal of benzotriazole using peroxymonosulfate/ozone/ultrasound: Synergy, optimization, degradation intermediates and utilizing for real wastewater. Chemosphere 244, 125326. https://doi.org/10.1016/j.chemosphere.2019.125326 (2020).

Ghanbari, F., Wu, J., Khatebasreh, M., Ding, D. & Lin, K.-Y.A. Efficient treatment for landfill leachate through sequential electrocoagulation, electrooxidation and PMS/UV/CuFe2O4 process. Sep. Purif. Technol. 242, 116828. https://doi.org/10.1016/j.seppur.2020.116828 (2020).

Li, M. et al. Exploring degradation mechanism of tetracycline via high-effective peroxymonosulfate catalysts of montmorillonite hybridized CoFe composites and safety assessment. Chem. Eng. J. 427, 130930. https://doi.org/10.1016/j.cej.2021.130930 (2022).

Tang, L. et al. Enhanced activation process of persulfate by mesoporous carbon for degradation of aqueous organic pollutants: Electron transfer mechanism. Appl. Catal. B 231, 1–10. https://doi.org/10.1016/j.apcatb.2018.02.059 (2018).

Hussain, I. et al. Insights into the mechanism of persulfate activation with nZVI/BC nanocomposite for the degradation of nonylphenol. Chem. Eng. J. 311, 163–172. https://doi.org/10.1016/j.cej.2016.11.085 (2017).

Liu, C. et al. Coupling metal–organic frameworks and g-C3N4 to derive Fe@N-doped graphene-like carbon for peroxymonosulfate activation: Upgrading framework stability and performance. Appl. Catal. B Environ. 255, 117763. https://doi.org/10.1016/j.apcatb.2019.117763 (2019).

Xie, M. et al. Cobalt doped g-C3N4 activation of peroxymonosulfate for monochlorophenols degradation. Chem. Eng. J. 360, 1213–1222. https://doi.org/10.1016/j.cej.2018.10.130 (2019).

Li, C.-X. et al. Insights on the pH-dependent roles of peroxymonosulfate and chlorine ions in phenol oxidative transformation. Chem. Eng. J. 362, 570–575. https://doi.org/10.1016/j.cej.2019.01.057 (2019).

Long, Y. et al. Sulfur-containing iron nanocomposites confined in S/N co-doped carbon for catalytic peroxymonosulfate oxidation of organic pollutants: Low iron leaching, degradation mechanism and intermediates. Chem. Eng. J. 404, 126499. https://doi.org/10.1016/j.cej.2020.126499 (2021).

Luo, R. et al. Singlet oxygen-dominated non-radical oxidation process for efficient degradation of bisphenol A under high salinity condition. Water Res. 148, 416–424. https://doi.org/10.1016/j.watres.2018.10.087 (2019).

Yang, S. et al. Rapid removal of tetrabromobisphenol A by α-Fe2O3-x@Graphene@Montmorillonite catalyst with oxygen vacancies through peroxymonosulfate activation: Role of halogen and α-hydroxyalkyl radicals. Appl. Catal. B Environ. 260, 118129. https://doi.org/10.1016/j.apcatb.2019.118129 (2020).

Zhou, X. et al. Tunable S doping from Co3O4 to Co9S8 for peroxymonosulfate activation: Distinguished Radical/Nonradical species and generation pathways. Appl. Catal. B Environ. 282, 119605. https://doi.org/10.1016/j.apcatb.2020.119605 (2021).

Ao, X. et al. Degradation of tetracycline by medium pressure UV-activated peroxymonosulfate process: Influencing factors, degradation pathways, and toxicity evaluation. Chem. Eng. J. 361, 1053–1062. https://doi.org/10.1016/j.cej.2018.12.133 (2019).

Liu, X., Pei, Y., Cao, M., Yang, H. & Li, Y. Highly dispersed copper single-atom catalysts activated peroxymonosulfate for oxytetracycline removal from water: Mechanism and degradation pathway. Chem. Eng. J. 450, 138194. https://doi.org/10.1016/j.cej.2022.138194 (2022).

Wang, J. & Wang, S. Effect of inorganic anions on the performance of advanced oxidation processes for degradation of organic contaminants. Chem. Eng. J. 411, 128392. https://doi.org/10.1016/j.cej.2020.128392 (2021).

Wan, Q. et al. Peroxymonosulfate activation by bimetallic modified syderolite pellets catalyst for degradation of brominobenzonitrile. Process. Saf. Environ. Prot. 165, 505–513. https://doi.org/10.1016/j.psep.2022.07.052 (2022).

Liu, Z., Gao, Z. & Wu, Q. Activation of persulfate by magnetic zirconium-doped manganese ferrite for efficient degradation of tetracycline. Chem. Eng. J. 423, 130283. https://doi.org/10.1016/j.cej.2021.130283 (2021).

Acknowledgements

This work was funded by the National Agricultural Product Quality and Safety Risk Assessment Project (GJFP20220204), Agricultural Science and Technology Innovation Program of China (ASTIP-TRIC06), the Science and Technology Project of Bijie Tobacco Branch Company (2020520500240072, 2023520500240162) and the Science and Technology Project of Chenzhou Tobacco Company of Hunan Province (No. 2019-45).

Author information

Authors and Affiliations

Contributions

X.Z. design, experiment, analysis, drafting. W.L. design, experiment, analysis, drafting. J.G. design, analysis, investigation. C.L. analysis, investigation. Y.X. analysis, investigation. X.L. analysis, investigation. D.S. conception, resources, revising. J.Z. conception, funding acquisition, revising.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zhao, X., Li, W., Gao, J. et al. Activation of peroxymonosulphate using a highly efficient and stable ZnFe2O4 catalyst for tetracycline degradation. Sci Rep 13, 13932 (2023). https://doi.org/10.1038/s41598-023-38958-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-023-38958-1

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.