Abstract

Gas-bearing property evaluation and main controlling factor analysis have remained a concern in shale gas research. The application of principal component analysis, an important mathematical statistical method, in gas-bearing property evaluation and main controlling factor analysis of the Longmaxi shale in the Weirong area, Sichuan Basin, was examined. The Longmaxi shale exhibits high heterogeneity, manifested in the organic matter abundance, mineral composition, and pore structure. Seven geological factors, including the temperature, pressure, TOC content, clay content, brittle mineral content, pore volume, and specific surface area (SSA), were selected in principal component analysis. Four principal components with geological significance, such as mineral composition, formation condition, pore structure, and organic matter abundance, were extracted through principal component analysis, and further constituted a comprehensive factor. Shale gas-bearing properties were evaluated according to the score of the comprehensive factor. The Longmaxi shale could be identified as exhibiting good, medium, and poor gas-bearing properties based on the comprehensive factor scores of these samples. According to each geological factor’s contribution to the comprehensive factor, combined with geological analysis, it could be considered that gas-bearing properties are primarily controlled by pore volume, SSA, and clay content, followed by TOC content, brittle mineral content, temperature and pressure.

Similar content being viewed by others

Introduction

Organic-rich shale is both a source rock and unconventional reservoir1. As an unconventional natural gas reservoir, shale can not only store free gas but can also adsorb gas2,3. Gas adsorption is an important property of shale reservoirs, and adsorbed and free gas fractions jointly largely account for the shale gas content and production4,5. Free gas is commonly distributed in large inorganic and organic pores and microcracks, whereas adsorbed gas generally occurs on the walls of organic pores and clay mineral pores with large specific surface areas6. In addition, heterogeneity is an inherent attribute of shale reservoirs, which is manifested in sedimentary facies and lithofacies at the macrolevel and mineral composition, organic geochemical characteristics, and pore structure at the microlevel7. Shale heterogeneity can lead to significant differences in gas-bearing properties.

The shale gas-bearing property is an essential index for shale gas exploration potential evaluation and sweet spot prediction8,9. The evaluation objects in regard to the shale gas-bearing property can be classified into three types, namely, total gas content evaluation, evaluation of the adsorbed gas or free gas content, and gas saturation evaluation10,11. The evaluation methods for the shale gas-bearing property can be classified into three types, including the experiment/field testing method12,13,14,15,16, geophysical method17,18,19, and mathematical statistical method20,21. For example, Chen et al.18 evaluated shale gas-bearing properties and predicted the spatial distribution based on well log interpretation and seismic multiple-attribute analysis. In addition, Tang et al.20 first combined principal component analysis and gray relational analysis to determine the main controlling factors of the free gas and adsorbed gas contents and then used multiple regression analysis to establish a quantitative relationship between the free gas content, adsorbed gas content and main controlling factors to realize shale gas-bearing evaluation. Similarly, Chen et al.21 applied isotopic geochemical proxies in shale gas content prediction. In another work, Li et al.22 used the methane isothermal adsorption experiment and field gas desorption methods to obtain the adsorbed gas content and total gas content, respectively. Similarly, Xiao et al.23 calculated the adsorbed gas content and total gas content according to the Langmuir adsorption model and gas state equation and recovered the total gas content based on the AMOCO method, indicating that the calculated gas content suitably agreed with the recovered gas content.

Effective evaluation of the shale gas-bearing property has remained a concern. Literature review revealed that various experimental tests or geophysical methods were the most commonly used to evaluate gas-bearing properties. The experimental test method provides the advantages of convenient operation and intuitive results, but due to the limitations of the corresponding experimental temperature and pressure conditions, the in situ gas content cannot be directly obtained24. The advantage of a geophysical method is that this approach can widely evaluate shale gas-bearing properties. However, the disadvantage of this method is that the accuracy of the evaluation results depends on the quality of logging or seismic data25. Compared to the first two methods, the mathematical statistical method is simpler, more straightforward and more widely applicable. Although the accuracy of the evaluation model depends on whether the number of statistical samples is sufficient and whether the geological factors are comprehensively considered, these problems can be overcome via the addition of samples and geological factors. Thus, this study examined the application of principal component analysis, a mathematical statistical method, in shale gas-bearing evaluation of the Longmaxi Formation in the Weirong area, southern Sichuan Basin. In contrast to other mathematical statistical methods, such as multiple regression, this method is more comprehensive and can simultaneously realize gas-bearing evaluation and main controlling factor analysis. Moreover, this study provides a feasible method for intelligent evaluation of shale gas-bearing properties.

Geological setting

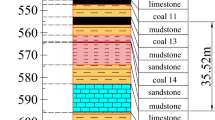

The Weirong block is located in the southern Sichuan Basin (Fig. 1). The basement of the Sichuan Basin comprises Middle and Upper Proterozoic strata, on which Sinian to Jurassic strata were successively deposited except for the lack of Devonian and Carboniferous strata. The Longmaxi Formation contains a set of marine shales deposited during the early Silurian26. The Longmaxi Formation can be divided into two members based on the lithology and biological characteristics27. The first member of the Longmaxi Formation (S1l1) comprises gray black and black carbonaceous shale, with abundant graptolite and radiolarian fossils. The lithology of the second member (S1l2) primarily indicates dark gray and grayish-green shale and silty shale, and biological fossils are underdeveloped. Vertically, the lithological change in the Longmaxi Formation indicates a trend whereby the sand content gradually increases and the clastic grain size increases from the bottom up, reflecting the change in the sedimentary environment from deep to shallow-water shelf environments. The Longmaxi Formation was uplifted and denuded in a large area during the late Silurian. This formation is mainly distributed in the east, south, and southwest of the Sichuan Basin, with a residual area of approximately 14.4 × 104 km2. The burial depth of the Longmaxi Formation in the Weirong area ranges from approximately 3000–3500 m. The thickness of the organic-rich shale of S1l1 ranges from 80 to 90 m, which is the focus of shale gas exploration. Exploration and drilling results suggest that the Longmaxi Formation in the Weirong block is generally subject to a high pressure, and the pore fluid pressure coefficient varies between ~ 1.94 and 2.0528, which provides suitable conditions for shale gas preservation but also causes great difficulties in fracturing development of shale gas.

Materials and methods

Source rock and reservoir parameters

The Longmaxi shale samples from well WY1, WY11, and WY23 were analyzed for experimental data in the Experimental Research Center of Wuxi Research Institute of Petroleum Geology, SINOPEC. TOC measurement, X-ray diffraction (XRD) analysis, porosity test, low-pressure nitrogen adsorption was carried out on sixty-one samples, respectively. The TOC content, mineral composition, porosity, pore structure parameters of these shale samples were obtained. Twelve samples were prepared for kerogen microscopic examination to analyze the organic matter type. Eight samples were tested for bitumen reflectance to obtain organic matter maturity. Forty-two samples were performed on a gas chromatograph to obtain the composition of natural gas. Three samples were measured for the carbon isotopic composition of methane. For the specific operation process of the above experiment, please refer to Han et al.32, Pei et al.33, and Wu et al.34.

Total gas content measurement

The field desorption method directly measures the gas content of sixty-one shale samples. The core just taken out from the wellhead was quickly put into the desorption tank for shale gas natural desorption. When shale gas desorption, the mud circulation temperature is adopted for the first 3 h to simulate the gas desorption during coring. Then the temperature in the next 6–8 h is set to 110 °C. At this temperature, the residual gas is ignored. The desorbed gas volume was observed and recorded at different times. The gas desorption ends when the reading change of high-precision flowmeter is no more than 0.1 cm3. The lost gas volume was recovered by the USBM method. The measured desorption gas volume and calculated loss gas volume add up to the total gas content.

Principal component analysis

Principal component analysis, a mathematical statistical method, involves the reduction in the dimensions of multiple variables35. The principle of this method entails the transformation of numerous possibly correlated variables into fewer linearly uncorrelated variables through orthogonal transformation36. The transformed variables are referred to as principal components, which can effectively reflect the information of the original variables. This study used principal component analysis to evaluate shale gas-bearing properties. The influencing factors of gas-bearing properties can be divided into three types: the first type includes gas generation conditions, such as the organic matter abundance and maturity; the second type includes gas storage conditions, such as the pore volume and specific surface area; and the third type includes gas preservation conditions, such as the formation pressure and fault development degree37,38,39,40. Combined with the actual geological features of the Longmaxi shale, seven original variables, including the temperature, pressure, TOC, clay content, brittle mineral content, pore volume, and specific surface area (SSA), were considered. The steps of principal component analysis are as follows:

-

1.

Primitive variable Xb (b = 1, 2, …, 7) can be standardized as Yb (b = 1, 2, …, 7) to reduce dimensions and eliminate order of magnitude differences among the various primitive variables, Eqs. (1)–(3).

$$y_{{{\text{ab}}}} = \frac{{x_{ab} - \overline{x}_{b} }}{{s_{b} }},a = 1,2, \cdots ,61;\;\;b = 1,2, \ldots ,7$$(1)$$\overline{x}_{b} = \frac{1}{61}\sum\limits_{a = 1}^{61} {x_{ab} } ,\;\;b = 1,2, \ldots ,7$$(2)$$s_{b} = \sqrt {\frac{{\sum\nolimits_{a = 1}^{61} {(x_{ab} - \overline{x}_{b} )^{2} } }}{60}} ,\;\;b = 1,2, \ldots ,7$$(3)where xab is the value of the a-th sample of the b-th variable, \(\overline{x}_{{\text{b}}}\) is the mean value of 61 samples of the b-th variable, sb is the standard deviation of the 61 samples of the b-th variable, and yab is the value of the a-th sample of the b-th variable after standardization.

-

2.

The correlation coefficient matrix R = (rab)7×7 of the standardized data matrix Y = (yab)61×10 can be calculated based on Eq. (4).

$$r_{ab} = \frac{1}{60}\sum\limits_{k = 1}^{61} {y_{ka} y_{kb} } ,a = 1,2, \cdots ,7;\;\;b = 1,2, \ldots ,7$$(4)where rab is the correlation coefficient between the a-th and b-th variables, raa = 1, and rab = rba.

-

3.

The eigenvalue λb (b = 1, 2, …, 7; λ1 ≥ λ2 ≥ … ≥ λ7 ≥ 0) and standard orthogonal eigenvector βb (b = 1, 2, …, 7) of the correlation coefficient matrix R = (rab)7×7 can be obtained. The information contribution rate δb (b = 1, 2, …, 7) and cumulative contribution rate αb (b = 1, 2, …, 7) of λb (b = 1, 2, …, 7) can be calculated according to Eqs. (5)–(6). For αk ≥ 0.90, this indicates that the first k new variables can fully express the information of the original variables. Thus, k principal components Fb (b = 1, 2, …, k; k ≤ 7) can be extracted.

$$\delta_{b} = \frac{{\lambda_{b} }}{{\sum\nolimits_{a = 1}^{7} {\lambda_{a} } }},\;\;b = 1,2, \ldots ,7$$(5)$$\alpha_{k} = \frac{{\sum\nolimits_{b = 1}^{k} {\lambda_{b} } }}{{\sum\nolimits_{a = 1}^{7} {\lambda_{a} } }},1 \le k \le 7,k \in Z$$(6) -

4.

Principal component Fb (b = 1, 2, …, k; k ≤ 7) is the product of eigenvector βb (b = 1, 2, …, k) and standardized variable Yb (b = 1, 2, …, 7) (Eq. (7)). The comprehensive score (E) can be calculated based on Eq. (8).

$$F_{b} = \beta_{b1} Y_{1} + \beta_{b2} Y_{2} + \cdots + \beta_{b7} Y_{7} ,\;\;b = 1,2, \ldots ,k$$(7)$$E = \sum\limits_{b = 1}^{k} {\delta_{b} } F_{b}$$(8)

Workflow

This study was conducted in four steps (Fig. 2). The first step was the establishment of a geological database of the Longmaxi shale and selection of geological variables, including the formation temperature and pressure, clay content, brittle mineral content, pore volume, specific surface area, and TOC content. The second step entailed the substitution of values of these geological variables of the Longmaxi shale samples into SPSS software for principal component analysis. The principle and steps of principal component analysis are described in “Principal component analysis” section. Four principal components were extracted through principal component analysis, constituting a comprehensive factor. The comprehensive score of each shale sample and weight coefficient of each variable of the comprehensive factor could also be obtained. Based on the results of principal component analysis, third and fourth steps were performed. In the third step, the gas-bearing property could be evaluated based on the calculated comprehensive scores. Shale samples with high comprehensive scores exhibit good gas-bearing properties. Moreover, the gas content in shale could be quantitatively predicted by establishing a relationship between the comprehensive score and gas content. In the fourth step, the weight coefficient of each variable of the comprehensive factor could be determined, reflecting the relative impact of this factor on the gas-bearing property. Combining the weight coefficients of each variable with geological analysis, the main controlling factors of the gas-bearing property could be further determined.

Results and discussion

Establishment of a geological database

Organic geochemical characteristics

The kerogen macerals of the Longmaxi shale samples mainly include sapropelic amorphous and planktonic alginite but hardly include vitrinite. The type index (TI) value ranges from 78.22 to 100, indicating that the organic matter in the Longmaxi shale is dominated by type I kerogen (Table 1). The bitumen reflectance (Rb) of the Longmaxi shale ranges from 2.72 to 3.22%, and the equivalent vitrinite reflectance (Ro) ranges from 2.08 to 2.39%, demonstrating that the Longmaxi shale has generally entered the stage of overmature thermal evolution (Table 1). The results of gas chromatographic analysis reveal that methane is the main component of shale gas, with a methane content ranging from 73.82 to 97.72% and a drying coefficient higher than 95%. The stable carbon isotope composition of methane (δ13C1‰) ranged from approximately − 31.9‰ to − 35.8‰. According to the δ13C1‰ and shale gas composition results (Fig. 3a), it could be determined that the organic parent material is lipoid, which is consistent with the results of kerogen microscopic examination. Moreover, δ13C1‰ can provide information on the maturity of organic matter. Stahl41, Schoell42, and Chen et al.43 established quantitative relationships between δ13C1‰ and Ro for oil-type gas. Based on these relationships, the Longmaxi shale can be classified as generally overmature, with Ro exceeding 2.0% (Fig. 3b). The Longmaxi shale exhibits a TOC content ranging from 0.06 to 6.04 wt% (averaging 2.06 wt%), indicating a suitable shale hydrocarbon generation potential (Supplementary Table 1).

(a) Relationship between the carbon isotope composition of methane and hydrocarbon composition of natural gas generated by lipoids (modified after Stahl and Carey46 and Li et al.47). (b) Relationship between δ13C1‰ and Ro for oil-type gas (modified after Chen et al.43). The carbon isotopic composition of methane is mainly distributed between the ordinates corresponding to the two horizontal dotted lines. The maturity of the Longmaxi shale is distributed within the range between the abscissa corresponding to the two vertical dotted lines.

Ro is calculated with the following equation: Ro = 0.618Rb + 0.444. The type index can be calculated with the following equation TI = 100 × a + 100 × b1 + 50 × b2 + 10 × c1 − 75 × c2 − 100 × d45, where a is the percentage of sapropelite, b1 is the percentage of resinite in exinite, b2 is the percentage of other exinite components, c1 is the percentage of perhydrous vitrinite, c2 is the percentage of normal vitrinite, and d is the percentage of inertinite. A blank column indicates that no data are measured. A dash indicates that the data value is zero.

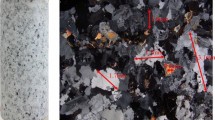

Mineral compositions

The XRD analysis shows that the Longmaxi shale mainly contains clay minerals and quartz, and their average contents are 42.3% and 33.9%. Dolomite, calcite, pyrite, and feldspar are not abundant, with average contents of 8.4%, 7.7%, 3.5%, and 3.3%, respectively. Clay minerals are dominated by illite/ smectite mixed layer and illite. Illite/smectite mixed-layer accounts for 32.0–60.0% of clay minerals, with an average of 48.7%, whereas illite make up 33.0–50.0%, with an average of 41.6%. Chlorite and kaolinite account for only a small proportion of clay minerals. The Longmaxi shale primarily contains two lithofacies, namely argillaceous shale and argillaceous-siliceous mixed shale (Fig. 4). The argillaceous shale has more clay and silica minerals and less carbonate, with their contents in the range of 48.0–61.0% (average of 52.9%), 21.0–44.0% (average of 37.7%), and 1.0–20.0% (average of 4.1%), respectively. By contrast, the argillaceous-siliceous mixed shale contains less clay and silica minerals and more carbonate minerals, with their contents in the range of 28.0–47.0% (averaging 37.3%), 29.0–45.0% (averaging 36.6%) and 7.0–30.0% (averaging 21.3%).

Lithofacies classification of the Longmaxi shale in the Weirong area (modified after Yuan et al.48).

Pore structure characteristics

Nitrogen adsorption/desorption isotherms for twelve shale samples retrieved from two wells are shown in Fig. 5. These isotherms are characterized by an obvious hysteresis loop and Point B. The adsorption isotherm is convex under a low relative pressure, caused by monolayer coverage. When the adsorption isotherm is almost linear with the relative pressure, the single-layer adsorption process ends, and multilayer adsorption begins. The adsorption isotherm reveals a slightly concave trend under a high relative pressure and does not reach the limiting uptake. Then, the relative pressure drops, and the desorption isotherm does not coincide with the adsorption isotherm, forming a hysteresis loop associated with capillary condensation in pores. Based on the IUPAC classification49, the nitrogen adsorption/desorption isotherms belong to type IV isotherms, and the hysteresis loops are mainly of the H2 and H3 types. The information reflected by the isotherm shape indicates that the Longmaxi shale contains abundant mesopores, mainly ink bottle-shaped and slit-like pores.

The change rate of the pore volume and SSA of the Longmaxi shale with the pore diameter is shown in Fig. 6. The pore volume obviously changes when the pore diameter ranges from 0.6 to 1.0 nm and 2.0 to 10.0 nm. The SSA obviously varies within the 0.6–1.0 nm pore size range. Thus, the pore size of the Longmaxi shale primarily ranges from 0.6 to 1.0 nm and 2.0 to 10.0 nm. In addition, a quantitative description of the pore structure can be obtained from the generated nitrogen adsorption/desorption isotherms. The pore volume and SSA of the shale range from 0.011 to 0.046 cm3/g (averaging 0.026 cm3/g) and 6.304 to 37.011 m2/g (averaging 20.009 m2/g), respectively (Supplementary Table 1). The pore volume of mesopores is the largest, with a mean value of 0.015 cm3/g, followed by micropores and macropores, with average values of 0.008 cm3/g and 0.003 cm3/g, respectively. Micropores exhibit the largest SSA, with an average value of 15.385 m2/g. In contrast, mesopores and macropores exhibit a smaller specific area. The average SSA values of mesopores and macropores are 4.585 m2/g and 0.039 m2/g, respectively.

Application of principal component analysis

Seven factors, including the TOC content, temperature, pressure, pore volume, specific surface area, clay content, and brittle mineral content, were selected from the geological database for principal component analysis (Supplementary Table 1). These factors are related to gas-bearing properties, and these data are easy to obtain. The results of principal component analysis are reliable since the Kaiser–Meyer–Olkin (KMO) value is 0.73, which is greater than 0.6, and the significance of Bartlett’s test of sphericity is lower than 0.05. Four principal components were extracted, namely, FAC1, FAC2, FAC3, and FAC4. Each principal component is a linear combination of the original variables. The weight coefficients of each variable of these four principal components are listed in Table 2. FAC1, FAC2, FAC3, and FAC4 captured 33.9%, 32.8%, 25.6%, and 7.1%, respectively, of the total variability. FAC1, FAC2, FAC3, and FAC4 could explain 99.4% of the total variability. Thus, we used these four principal components to evaluate the gas-bearing property. FAC1 exhibited a positive relationship with the brittle mineral content but was negatively correlated with the clay content (Fig. 7a). FAC2 was positively correlated with the temperature and pressure (Fig. 7a). FAC3 attained a positive relationship with the pore volume and specific surface area (Fig. 7b). FAC4 was positively correlated with the TOC content (Fig. 7b). Based on these observations, FAC1–FAC4 could reflect geological significance well and could be interpreted as the mineral composition, formation condition, pore structure, and organic matter abundance, respectively. A comprehensive factor (CFAC) was obtained based on FAC1, FAC2, FAC3, and FAC4. The scores of FAC1, FAC2, FAC3, FAC4, and CFAC of each sample were calculated according to Eqs. (9)–(13), the eigenvectors of all standardized variables in Eqs. (9)–(13) are listed in Table 2, and the results are provided in Table 3. The weight coefficients of each variable of CFAC are listed in Table 2. The first three factors contributing the most to CFAC were the pore volume, SSA, and clay content (Table 2).

where X1–X7 are standardized variables; X1 denotes the formation temperature, K; X2 denotes the formation pressure, MPa; X3 denotes TOC, wt%; X4 denotes the pore volume, cm3/g; X5 denotes the pore surface area, m2/g; X6 denotes the clay content, %; and X7 denotes the brittle mineral content, %.

Gas-bearing property evaluation

The measured gas content in the Longmaxi shale samples ranges from 0.31 to 5.32 m3/t. In general, shale with a gas content < 2 m3/t can be regarded as exhibiting poor gas-bearing properties, shale with a gas content ranging from 2 to 4 m3/t exhibits medium gas-bearing properties, and shale exhibits high gas-bearing properties given a gas content > 4 m3/t. In this study, the measured gas content in the Longmaxi shale samples was used to verify the principal component analysis results. The findings suggest that the comprehensive score obtained via principal component analysis is positively correlated with the measured gas content (Fig. 8). Therefore, the comprehensive score of principal component analysis can also be used to effectively evaluate the Longmaxi shale gas-bearing properties. A linear relationship between the comprehensive score and shale gas content was further established. The comprehensive scores corresponding to gas contents of 2 m3/t and 4 m3/t are − 0.209 and 0.788, respectively. Thus, shale with a score < − 0.209 can be evaluated as exhibiting poor gas-bearing properties, shale with a score ranging from − 0.209 to 0.788 exhibits medium gas-bearing properties, and shale with a score > 0.788 exhibits good gas-bearing properties. Gas-bearing property evaluation of a single well reveals that the results based on principal component analysis suitably agree with those based on the measured gas content, with the coincidence rates for wells WY11 and WY23 reaching 80.8% and 77.1%, respectively (Fig. 9). In addition, apparent differences in gas-bearing properties between these two wells are observed. Well WY11 exhibits poor gas-bearing properties, whereas the gas-bearing properties of well WY23 are primarily medium to good. This phenomenon may occur because the geological factors influencing the gas-bearing properties in these two wells are quite different.

Verification of the gas-bearing property evaluation results based on the comprehensive score of the Longmaxi shale samples by the measured gas content. (a) Gas-bearing property evaluation results for well WY11; (b) gas-bearing property evaluation results for well WY23. *Indicates that the gas-bearing property is evaluated by the comprehensive score. **Indicates that the gas-bearing property is evaluated based on the measured gas content.

Main controlling factors of the gas-bearing properties

The main controlling factors affecting the shale gas-bearing properties were revealed via principal component analysis. The above indicates that the geological factors contributing to the comprehensive factor include the pore volume, SSA, clay content, temperature, pressure, TOC content, and brittle mineral content, with the pore volume, SSA, and clay content yielding the greatest contribution (Table 2). Except for the clay content, which negatively contributes to the comprehensive factor, the other geological factors positively contribute to the comprehensive factor. Moreover, geological analysis reveals that most of these geological factors attain good relationships with the measured gas content, especially SSA, pore volume, TOC, brittle mineral content, and clay content (Fig. 10). The positive correlations among SSA, pore volume and gas content reflect the control of the pore structure on the gas-bearing properties (Fig. 10a,b), which is also shown in previous literature50. The pore volume and SSA primarily provide the occurrence space of free and adsorbed gas, respectively51. The larger the pore volume and SSA are, the more conducive these conditions to shale gas enrichment, which often indicates good gas-bearing properties52. Consistent with previous studies53,54, the TOC content exerts a positive effect on the gas content in this study (Fig. 10c), as reflected by the gas supply and storage. On the one hand, a high TOC content reflects a high gas generation potential, which is the premise of good gas-bearing properties. On the other hand, the TOC content is positively related to SSA (Fig. 10d), indicating that the organic pores developed within the organic matter provide a very large SSA for adsorbed gas. In addition, it has been revealed in previous studies that organic pores notably contribute to the pore volume in regard to free gas55,56. A change in mineral composition can also lead to a difference in shale gas-bearing properties. The brittle mineral content is positively correlated with the gas content (Fig. 10e), while the clay mineral content is positively correlated with the gas content (Fig. 10f). There are primary intergranular pores, dissolved pores, and microcracks related to brittle minerals, which are conducive to the storage of shale gas, especially free gas22. In contrast, plastic clay minerals can be compressed and deformed under the action of stress and can increasingly fill pores, which is not conducive to pore preservation57. Therefore, a mineral composition with a high brittle mineral content and low clay content improves the gas-bearing property of shale. Finally, based on the results of principal component analysis and geological analysis, the main controlling factors of shale gas-bearing properties are pore volume, SSA, and clay mineral content. The secondary controlling factors are TOC content, brittle mineral content, temperature and pressure. Since temperature and pressure are external factors, this study will not focus on them.

Influencing factors of shale gas-bearing properties. The correlations between SSA and shale gas content (a), between pore volume and shale gas content (b), between TOC content and shale gas content (c), between TOC content and SSA (d), between brittle mineral content and shale gas content (e), and between clay content and shale gas content (f), respectively.

Statistical analysis demonstrates that the Longmaxi shale samples with good gas-bearing properties exhibit TOC values of 1.94–6.04 wt% (avg. 4.17 wt%), SSA values of 21.846–37.011 m2/g (avg. 29.032 m2/g), pore volume values of 0.020–0.046 m3/g (avg. 0.035 m3/g), and brittle mineral contents of 49–75% (avg. 65%). The Longmaxi shale samples with medium gas-bearing properties exhibit TOC values of 1.23–4.57 wt% (avg. 2.33 wt%), SSA values of 10.659–34.301 m2/g (avg. 23.002 m2/g), pore volume values of 0.018–0.046 m3/g (avg. 0.029 m3/g), and brittle mineral contents of 41–79% (avg. 56%). The Longmaxi shale samples with poor gas-bearing properties exhibit TOC values of 0.06–2.39 wt% (avg. 0.97 wt%), SSA values of 6.304–22.429 m2/g (avg. 12.967 m2/g), pore volume values of 0.011–0.036 m3/g (avg. 0.019 m3/g), and brittle mineral contents of 33–63% (avg. 44%). It is thus clear that the Longmaxi shale samples with good gas-bearing properties exhibit a high TOC content, large pore space, and high brittle mineral content. In contrast, shale with poor gas-bearing properties exhibits the opposite trend (Fig. 11).

Guidance for shale gas exploration

In the era of big data, it is inevitable that digital and intelligent oilfields are constructed, which is very beneficial to the optimization of oilfield exploration and development decisions and improvement in economic benefits58. The Longmaxi Formation is an important shale gas-producing layer in China. After decades of research, abundant basic geological data of the Longmaxi shale are available, which provides essential support for the establishment of a vast geological database. A geological database comprises an indispensable part of digital and intelligent oilfields. How can we effectively use a comprehensive geological database to guide digital and intelligent exploration of shale gas? The answer lies in the realization of data analysis intelligence, i.e., the compilation of algorithms. Principal component analysis is a basic, simple, and efficient algorithm. In this paper, effective evaluation of shale gas-bearing properties was realized using principal component analysis, which can provide guidance for digital and intelligent shale gas exploration (Fig. 12). Specifically, four principal components with geological significance, such as the pore structure, formation condition, pore structure, and organic matter abundance, are extracted through principal component analysis in this study. The shale gas-bearing property is evaluated according to the score of the comprehensive factor comprising these four principal components. Gas-bearing property evaluation is the result of comprehensively considering the above geological factors, which are generally also considered in sweet spot prediction of shale gas59,60. Therefore, the gas-bearing property evaluation results obtained by principal component analysis can be used as a comprehensive index for shale gas sweet spot prediction. Combined with other geological indicators in the geological database, such as regional structural characteristics, shale physical properties, and surface conditions61, the superposition analysis is carried out to realize the graded evaluation of sweet spots in the study area.

Conclusions

The principal component analysis method can effectively evaluate the gas-bearing properties of the Longmaxi shale, with an accuracy of approximately 80%. Moreover, combining this method and geological analysis, the main controlling factors, namely, SSA, pore volume, and clay content, of gas-bearing properties can be determined. According to the gas-bearing characteristics, it can be considered that the Longmaxi Formation contains three levels of shale gas reservoirs with good, medium, and poor gas bearing properties. Good gas-bearing shale exhibits a gas content > 4 m3/t and a comprehensive score > 0.788, with an average TOC content of 4.17 wt%, average SSA of 29.032 m2/g, average pore volume of 0.035 m3/g, and average brittle mineral content of 65%. Medium gas-bearing shale exhibits a gas content of 2–4 m3/t and a comprehensive score of − 0.209 to 0.788, with average TOC, SSA, pore volume, and brittle mineral contents of 2.33 wt%, 23.002 m2/g, 0.029 m3/g, and 56%, respectively. Poor gas-bearing shale exhibits a gas content < 2 m3/t and a comprehensive score < − 0.209, with average TOC, SSA, pore volume, and brittle mineral contents of 0.97 wt%, 12.967 m2/g, 0.019 m3/g, and 44%, respectively.

In addition, principal component analysis can be used as an algorithm to realize intelligent analysis. The application of principal component analysis in gas-bearing property evaluation lays a foundation for intelligent shale gas exploration, which is an inevitable trend in the era of big data.

Data availability

All data generated or analyzed during this study are included in this published article.

References

Hu, T. et al. Key factors controlling shale oil enrichment in saline lacustrine rift basin: Implications from two shale oil wells in Dongpu Depression, Bohai Bay Basin. Petrol. Sci. 18, 687–711 (2021).

Memon, A. et al. Gas adsorption and controlling factors of shale: Review, application, comparison and challenges. Nat. Resour. Res. 30(1), 827–848 (2021).

Memon, A., Li, A. F., Muther, T. & Ren, X. X. An experimental study of gas sorption, adsorbed and sorbed porosity and their impact on shale gas-in-place calculations. J. Porous Media 23(10), 985–1000 (2020).

Muther, T. et al. Unconventional hydrocarbon resources: Geological statistics, petrophysical characterization, and field development strategies. J. Petrol. Explor. Prod. Technol. https://doi.org/10.1007/s13202-021-01404-x (2021).

Muther, T., Syed, F. I., Dahaghi, A. K. & Negahban, S. Contribution of gas adsorption–desorption in Marcellus shale for different fractured well configurations. J. Petrol. Explor. Prod. Technol. https://doi.org/10.1007/s13202-022-01456-7 (2022).

Xing, J. Y. et al. Classification of controlling factors and determination of a prediction model for shale gas adsorption capacity: A case study of Chang 7 shale in the Ordos Basin. J. Nat. Gas Sci. Eng. 49, 260–274 (2018).

Sun, J., Xiao, X. M. & Cheng, P. Influence of water on shale pore heterogeneity and the implications for shale gas-bearing property—A case study of marine Longmaxi Formation shale in northern Guizhou. Mar. Petrol. Geol. 134, 105379 (2021).

Daniel, J. K. R. & Bustin, R. M. Characterizing the shale gas resource potential of Devonian-Mississippian strata in the western Canada sedimentary basin: Application of an integrated formation evaluation. AAPG Bull. 92(1), 87–125 (2008).

Zhu, L. Q., Ma, Y. S., Zhang, C. M., Wu, S. G. & Zhou, X. Q. New parameters for charactering the gas-bearing properties of shale gas. J. Petrol. Sci. Eng. 201, 108290 (2021).

Ambrose, R. J., Hartman, R. C., Diaz-Campos, M. & Sondergeld, C. H. Shale gas-in-place calculations part I: New pore-scale considerations. SPE J. 17(1), 219–229 (2012).

Li, W. et al. Evaluation of gas-in-place content and gas-adsorbed ratio using carbon isotope fractionation model: A case study from Longmaxi shales in Sichuan Basin, China. Int. J. Coal Geol. 249, 103881 (2022).

Jiang, G., Chen, Z. & Hui, G. A novel model to determine gas content in naturally fractured shale. Fuel 306, 121714 (2021).

O’Neill, K. T., Birt, B. & Hopper, T. Borehole measurements of adsorbed gas content in coals using stimulated diffusion nuclear magnetic resonance. Int. J. Coal Geol. 247, 103845 (2021).

Xiong, W. et al. Pressure building-up methodology to measure gas content of shale samples. J. Petrol. Sci. Eng. 186, 106678 (2020).

Li, Q. et al. Occurrence features and gas content analysis of marine and continental shales: A comparative study of Longmaxi Formation and Yanchang Formation. J. Nat. Gas Sci. Eng. 56, 504–552 (2018).

Shtepanl, E., Noll, L. A., Eloed, L. W. & Jacobs, P. M. A new regression-based method for accurate measurement of coal and shale gas content. SPE J. 13, 359–363 (2010).

Chen, Q. et al. Quantitatively determining gas content using pulsed neutron logging technique in closed gas reservoir. J. Petrol. Sci. Eng. 198, 108149 (2021).

Chen, S. et al. Predicting gas content in high-maturity marine shales using artificial intelligence based seismic multiple-attributes analysis: A case study from the lower Silurian Longmaxi Formation, Sichuan Basin, China. Mar. Petrol. Geol. 101, 180–194 (2019).

Cao, L., Chang, S. & Yao, Y. Application of seismic sedimentology in predicating sedimentary microfacies and coalbed methane gas content. J. Nat. Gas Sci. Eng. 69, 102944 (2019).

Tang, L. et al. A quantitative evaluation of shale gas content in different occurrence states of the Longmaxi Formation: A new insight from well JY-A in the Fuling Shale Gas Field, Sichuan Basin. Acta Geol. Sin-Engl. 93(2), 400–419 (2019).

Chen, Z. et al. Applying isotopic geochemical proxy for gas content prediction of Longmaxi shale in the Sichuan Basin, China. Mar. Petrol. Geol. 116, 104329 (2020).

Li, Z. et al. Gas-bearing property of the Lower Cambrian Niutitang Formation shale and its influencing factors: A case study from the Cengong block, northern Guizhou Province, South China. Mar. Petrol. Geol. 120, 104556 (2020).

Xiao, D. et al. Comparison of marine and continental shale gas reservoirs and their gas-bearing properties in China: The examples of the Longmaxi and Shahezi shales. Energy Fuel. 35, 4029–4043 (2021).

Shi, W., Wang, X., Zhang, C., Feng, A. & Huang, Z. Experimental study on gas content of adsorption and desorption in Fuling shale gas field. J. Petrol. Sci. Eng. 180, 1069–1076 (2019).

Guo, S. & Peng, Y. Determination method of shale gas content: A case study in the Ordos Basin, China. J. Petrol. Sci. Eng. 173, 95–100 (2019).

Xiao, B. et al. Geochemical characteristics of marine shale in the Wufeng Formation-Longmaxi Formation in the northern Sichuan Basin, South China and its implications for depositional controls on organic matter. J. Petrol. Sci. Eng. 203, 108618 (2021).

Wang, H., Shi, Z. & Sun, S. Biostratigraphy and reservoir characteristics of the Ordovician Wufeng Formation-Silurian Longmaxi Formation shale in the Sichuan Basin and its surrounding areas, China. Petrol. Explor. Dev. 48(5), 1019–1032 (2021).

Ma, X., Wang, H., Zhou, S., Shi, Z. & Zhang, L. Deep shale gas in China: Geological characteristics and development strategies. Energy Rep. 7, 1903–1914 (2021).

Nie, H. et al. An overview of the characteristic of typical Wufeng-Longmaxi shale gas fields in the Sichuan Basin, China. Nat. Gas Ind. B 8, 217–230 (2021).

Xiong, L. Characteristics and significance of sedimentary facies of Wufeng-Longmaxi formation shale in Weirong Shale Gas Field, southern Sichuan Basin. Petrol. Geol. Exp. 41(3), 326–332 (2019) (in Chinese with English abstract).

Xu, Z. et al. Petrophysical properties of deep Longmaxi Formation shales in the southern Sichuan Basin, SW China. Petrol. Explor. Dev. 47(6), 1183–1193 (2020).

Han, M. et al. Influence of structural damage on evaluation of microscopic pore structure in marine continental transitional shale of the Southern North China Basin: A method based on the low-temperature N2 adsorption experiment. Petrol. Sci. https://doi.org/10.1016/j.petsci.2021.10.016 (2021).

Pei, L. et al. Origin, accumulation and secondary alteration of natural gas around Qingshui Sub-sag, Liaohe Depression, China: Insights from molecular and isotopic composition. Mar. Petrol. Geol. 135, 105390 (2022).

Wu, X. et al. Constraints of molecular and stable isotopic compositions on the origin of natural gas from Middle Triassic reservoirs in the Chuanxi large gas field, Sichuan Basin, SW China. J. Asian Earth Sci. 204, 104589 (2020).

Hotelling, H. Analysis of a complex of statistical variables into principal components. J. Educ. Psychol. 24, 417–441 (1933).

Ohta, T. & Arai, H. Statistical empirical index of chemical weathering in igneous rocks: A new tool for evaluating the degree of weathering. Chem. Geol. 240(3–4), 280–297 (2007).

Esen, O., Zer, S. C., Soylu, A., Rend, A. R. & Fine, A. Geological controls on gas content distribution of coal seams in the knk coalfield, soma basin, turkey. Int. J. Coal Geol. 231, 103602 (2020).

Wei, Q. et al. Implications of geological conditions on gas content and geochemistry of deep coalbed methane reservoirs from the Panji Deep Area in the Huainan Coalfield, China. J. Nat. Gas Sci. Eng. 85, 103712 (2021).

Ge, M., Chen, K., Chen, X., Wang, C. & Bao, S. The influence factors of gas-bearing and geological characteristics of Niutitang Formation shale in the southern margin of Xuefeng Mountain ancient uplift: A case of Well Huangdi 1. China Geol. 4, 533–544 (2020).

Gasparik, M. et al. Geological controls on the methane storage capacity in organic-rich shales. Int. J. Coal Geol. 123(2), 34–51 (2014).

Stahl, W. J. Carbon and nitrogen isotopes in hydrocarbon research and exploration. Chem. Geol. 20, 121–149 (1977).

Schoell, M. The hydrogen and carbon isotopic composition of methane from natural gases of various origins. Geochim. Cosmochim. Acta. 44, 649–661 (1980).

Chen, J. et al. New equation to decipher the relationship between carbon isotopic composition of methane and maturity of gas source rocks. Sci. China Earth Sci. 64(3), 470–493 (2021) (in Chinese with English abstract).

Jacob, H. Classification, structure, genesis and practicle importance of natural solid oil bitumen (“migrabitumen”). Int. J. Coal Geol. 11, 65–79 (1989).

Xia, P. et al. Shale gas reservoir evaluation by geophysical measurements: A case study of the upper ordovician-lower silurian in the Fenggang block, Northern Guizhou Province. Acta Geol. Sin-Engl. 4, 1310–1321 (2021).

Stahl, W. J. & Carey, B. D. Jr. Source-rock identification by isotope analyses of natural gases from fields in the Val Verde and Delaware basins, west Texas. Chem. Geol. 16, 257–267 (1975).

Li, Z., Yang, Y., Feng, M. & Bu, S. Methane carbon isotope and its application in natural gas prospecting. Oil Gas Geol. 6(4), 426–433 (1985).

Yuan, Y. et al. Compositional controls on nanopore structure in different shale lithofacies: A comparison with pure clays and isolated kerogens. Fuel 303, 121079 (2021).

Sing, K. S. et al. Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity. Pure Appl. Chem. 57, 603–619 (1985).

Zhang, J. Z. et al. Pore structure characteristics of a marine-continental coal-bearing shale reservoir and its effect on the shale gas-containing property. Geochimica 50(5), 478–491 (2021) (in Chinese with English abstract).

Ross, D. J. K. & Bustin, R. M. Shale gas potential of the lower Jurassic Gordondale Member, northeastern British Columbia, Canada. B Can. Petrol. Geol. 55(1), 51–75 (2007).

Cao, T. et al. Pore evolution in siliceous shales and its influence on shale gas-bearing capacity in eastern Sichuan-western Hubei, China. J. Petrol. Sci. Eng. 208, 109597 (2022).

Li, J., Wu, Q., Jin, W., Lu, J. & Nan, Z. Logging evaluation of free-gas saturation and volume content in Wufeng-Longmaxi organic-rich shales in the Upper Yangtze Platform, China. Mar. Petrol. Geol. 100, 530–539 (2019).

Tang, X. L. et al. Lithofacies characteristics and its effect on gas storage of the Silurian Longmaxi marine shale in the southeast Sichuan Basin, China. J. Nat. Gas Sci. Eng. 28, 338–346 (2016).

Ji, L. et al. Investigation into the apparent permeability and gas-bearing property in typical organic pores in shale rocks. Mar. Petrol. Geol. 110, 871–885 (2019).

Zhang, L. et al. Heterogeneity characterization of the lower Silurian Longmaxi marine shale in the Pengshui area, South China. Int. J. Coal Geol. 195, 250–266 (2018).

Dong, T. & Harrisb, N. B. The effect of thermal maturity on porosity development in the Upper Devonian–Lower Mississippian Woodford Shale, Permian Basin, US: Insights into the role of silica nanospheres and microcrystalline quartz on porosity preservation. Int. J. Coal Geol. 217, 103346 (2020).

Korovin, I. S. & Tkachenko, M. G. Intelligent oilfield model. Procedia Comput. Sci. 101, 300–303 (2016).

Hou, L. H. et al. Quantitative assessment of the sweet spot in marine shale oil and gas based on geology, engineering, and economics: A case study from the Eagle Ford Shale, USA. Energy Strateg. Rev. 38, 100713 (2021).

Qiu, Z. & Zou, C. N. Controlling factors on the formation and distribution of “sweet-spot areas” of marine gas shales in South China and a preliminary discussion on unconventional petroleum sedimentology. J. Asian Earth Sci. 194, 103989 (2020).

Zou, C. N. et al. Geologic significance and optimization technique of sweet spots in unconventional shale systems. J. Asian Earth Sci. 178, 3–19 (2019).

Acknowledgements

The study was sponsored by the National Natural Science Foundation of China (grant number U19B6003-02) and the AAPG Foundation Grants-in-Aid program (18644937). Authors thank SINOPEC Southwest Branch Company for providing essential data and appreciate the editors and reviewers for their careful work and insightful comments.

Author information

Authors and Affiliations

Contributions

M.L. wrote the original draft, X.P. supervised the manuscript, L.X. validate the method used in the manuscript, T.H. and D.C. reviewed the manuscript, and Z.Z. and S.H. prepared all figures.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Li, M., Pang, X., Xiong, L. et al. Application of mathematical statistics to shale gas-bearing property evaluation and main controlling factor analysis. Sci Rep 12, 9859 (2022). https://doi.org/10.1038/s41598-022-13863-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-022-13863-1

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.