Abstract

Coupling two different semiconductors to form composite photocatalysts is an extremely significant technique for environmental remediation. Here, a one-step in-situ precipitation method has been developed to prepare amorphous silver silicate/carbonate (AgSiO/Ag2CO3) nanoparticles (NPs) composites, which are well dispersed sphere-like particles with the sizes of around ~50–100 nm. The high-efficiency photocatalytic activities under visible light (VL) have been carefully evaluated, and the AgSiO/Ag2CO3 NPs composites exhibit selective photocatalytic degradations on Methylene Blue (MB) and Rhodamine B (RhB). The maximum degradation rate for MB can reach ~99.1% within ~40 min under VL irradiation, much higher than that of RhB (~12%) in the same condition, which can be ascribed to (I) the smaller molecule size of MB than that of RhB, (II) the fast charge separation between AgSiO NPs and Ag2CO3 NPs, abundant heterojunction interfaces as well as fully exposed reactive sites. These composites are proposed to be an example for the preparation of other silicate composite photocatalysts for practical applications in environmental remediation.

Similar content being viewed by others

Introduction

Photocatalytic technology has become one of the most promising green technology as it can degrade organic pollutants in water to produce non-toxic substances such as CO2, H2O and so on with no secondary pollution, mild reaction conditions, and low energy consumption1,2,3. Especially, semiconductor photocatalysts have attracted wide attention in the field of environmental purification and a lot of achievements have been achieved4,5. Among them, silver carbonate (Ag2CO3) has received great research interests, but is restricted by its photocorrosion and lower photocatalytic degradation efficiency2. Therefore, it is significantly worthy to make great efforts to solve the problem for the real industrial application. Recently, it has been reported that introducing an electron acceptor in the photocatalytic reaction system can efficiently restrain the photocorrosion3. The silicates have been found to be the effective one6,7, which can not only enhance the photogenerated charge transfer but also broaden the spectral response range6,7,8. Furthermore, the excited electron–hole pairs can readily transfer between the particles due to the internal polar electric field in the silicate NPs. Among them, silver silicate (AgSiO) has been one of the most famous silicates due to its good stability, high efficiency, nontoxicity, low cost, and it has row band gap which can extend the large of light absorption8. Therefore, visible-light-driven photocatalysts can be exploited by coupling AgSiO with Ag2CO3 NPs. Furthermore, the heterojunctions by coupling them favor the separation of photogenerated electron-hole pairs resulting in the improvement of the photocatalytic activity9,10.

In this paper, AgSiO/Ag2CO3 composites with different ratios have been successfully synthesized by an in-situ method. The final samples with different molar ratios of SiO3 2− and CO3 2− exhibit the optimal photocatalytic activities. Besides, the selective photodegradation of two cationic dyes Methylene Blue (MB), Rhodamine B (RhB), and two another anionic dyes Methyl Orange (MO) and Congo Red (Cr) have been carefully investigated11. Finally, the photocatalytic mechanisms of these AgSiO/Ag2CO3 composites are carefully discussed.

Experimental Sections

Preparation of the amorphous silver silicates (AgSiO)

The AgSiO was synthesized via an in-situ method. For a typical synthesis, 0.2 M AgNO3 (40 mL) was added into 0.1 M Na2SiO3·9H2O (40 mL) under continuously stirring for 1.0 h. The precipitates were collected and washed with distilled water and ethanol, and finally dried at room temperature.

Preparation of the silver carbonate (Ag2CO3)

0.2 M AgNO3 (40 mL) was slowly drop by drop added into 0.1 M NaHCO3 (20 mL) under continuously stirring for 1.0 h. The precipitates were collected and washed with distilled water and ethanol, and finally dried at room temperature.

Preparation of the amorphous silver silicate/carbonate heterostructure (AgSiO/Ag2CO3)

The AgSiO/Ag2CO3 composites were synthesized via an in-situ precipitation method. In a typical synthetic procedure, 0.1 M Na2SiO3·9H2O (40 mL) were added to 0.1 M NaHCO3 (20 mL) under stirring for 5 min. Then, 0.2 M AgNO3 (40 mL) was slowly added to the mixture under stirring for 1.0 h. The precipitates were collected and washed with distilled water and ethanol, and dried at room temperature. The AgSiO/Ag2CO3 composites prepared with different molar ratios of Na2SiO3·9H2O and NaHCO3 in 40, 60, 80, 100 and 120 ml are denominated as AgSiO/Ag2CO3-2:1, AgSiO/Ag2CO3-3:1, AgSiO/Ag2CO3-4:1, AgSiO/Ag2CO3-5:1, and AgSiO/Ag2CO3-6:1, respectively.

Characterization

Powder X-ray diffraction (XRD) patterns were collected using a D/MAX2500 V diffractometer equipped with Cu K α radiation (λ = 1.5418 Å). The morphologies of the materials were observed using a FEI QUANTA FEG 250 field emission scanning electron microscope (SEM). The structural information of the samples was measured with the standard KBr disk method by a Fourier transform spectrophotometer (FT-IR, Avatar 370, thermo Nicolet). X-ray photoelectron spectroscopy (XPS) was carried out on ESCALAB250 with Mg K α as the source and the C1s peak at 284.6 eV as an internal standard. UV-vis diffuse reflection spectroscopy (DRS) was recorded with a Shimadzu UV-2500 spectrophotometer using BaSO4 as the reference. The Brunauer–Emmett–Teller (BET) specific surface areas were explored by nitrogen adsorption in a Micromeritics Tristar II 3020 nitrogen adsorption–desorption apparatus in accordance with the Barret–Joyner–Halenda (BJH) technique from the N2 adsorption isotherms.

Photocatalytic tests

Photocatalytic degradation experiments were conducted in a photocatalytic reactor equipped with a 420 nm cut-off filter and a 500 W Xe lamp as the light source. For the photocatalytic reaction, the photocatalysts (20 mg) were mixed into a MB and RhB solution (50 mL, 10 mg/L). To guarantee the adsorption-desorption counterpoise, the mixed solution was stirred for 60 min in the darkness. Then, the solution was illuminated by VL and a small portion of the suspension (~3.0 mL) was sampled at 10 min illumination spacing. The catalytic efficiency was tested by using a UV-vis spectrophotometer (UV-2500, Shimadzu) for the degradation of RhB and MB.

Results and Discussion

A facile in-situ precipitation method was designed to synthesize AgSiO/Ag2CO3 nanoparticles as illustrated in Fig. 1. The chemical reaction process can be described as follows:

By adding AgNO3 to the NaHCO3 solution, the CO3 2− present in the solution will react with the added Ag+ by electrostatic interaction to produce Ag2CO3. Then, the fixed Ag+ cations will further react with SiO3 2− to generate AgSiO with the addition of Na2SiO3 solution, resulting in the formation of AgSiO/Ag2CO3 5,6,7.

The XRD patterns of pure AgSiO, Ag2CO3 and AgSiO/Ag2CO3 composites are shown in Fig. 2. The broad peak at about 34° could be indexed to the (−124) and (−115) planes for pure AgSiO in Fig. 2A, suggesting its amorphous structure6. For the pure Ag2CO3 NPs (Fig. 2B), the positions and intensities of the diffraction peaks are well matched with the standard JCPDS card2,3,11. The XRD pattern of AgSiO/Ag2CO3 composites is shown in Fig. 2A. Obviously, the diffraction peaks of AgSiO and Ag2CO3 NPs can be clearly found in curve and without any other peaks. The peaks of Ag2CO3 decreased with increasing AgSiO contents, and the characteristic peak intensity of AgSiO increases with the increase of the AgSiO contents, indicating that AgSiO/Ag2CO3 composites with high purity have been successfully synthesized by an in-situ precipitation1,8.

FTIR spectra of AgSiO, Ag2CO3 and AgSiO/Ag2CO3 composites were recorded as shown in Fig. 3. In comparison to pure AgSiO, the absorption bands of AgSiO/Ag2CO3 composites obtained at around ~705 cm−1, ~893 cm−1, ~1382 cm−1, and ~1451 cm−1 are attributed to CO3 2− in Ag2CO3 1,10. Compared with pure Ag2CO3, strong absorption band at around ~1382 cm−1 is found for AgSiO/Ag2CO3 composites, which belongs to the Si-O-Si stretching vibrations8. Moreover, there is also another shoulder peak indexed to the Si-O-Si bonds at ~1630 cm−1, which confirms the successful introduction of AgSiO in the composites. Nevertheless, the characteristic peak located at ~1382 cm−1 shifts to higher wavenumbers (Fig. 3). The observed blue shift in the composites after introducing AgSiO (Fig. 3) indicates the weakened bond strengths of Si-O-Si owing to the conjugation between Ag2CO3 and AgSiO8,12. This result demonstrates the strong interfacial coupling effect in the AgSiO/Ag2CO3 composites. Compared with the aggregated or large-size nanoparticles, the nature of AgSiO nanoparticles on Ag2CO3 acted as nano-islands can facilitate the formation of the heterojunction interfaces and guarantee the higher contact areas13,14. Both characters are essentials to promote photocatalytic activity and to enhance the separation efficiency of photogenerated charges.

The UV-vis diffuse reflectance spectra of AgSiO/Ag2CO3 composites together with pure AgSiO and Ag2CO3 are shown in Fig. 3. The light absorption edge of Ag2CO3 is measured to be ~480 nm, and mainly absorptions are ultraviolet light14. In addition, the peak at 520 nm can be indexed to the Ag nanocrystals. Therefore, we can see that a broad absorption ranging from ~480 to ~750 nm is detected, which is due to the generation of Ag nanocrystals15,16. The AgSiO/Ag2CO3 composites exhibit the stronger absorption than that of the Ag2CO3 NPs in both the visible and ultraviolet light region17. Obviously, the introduction of AgSiO can significantly enhance the absorption in the visible-light region and can even extend to near-infrared region, which is attributed to the SPR of Ag nanoparticles. It is inferred that the heterojunction of AgSiO/Ag2CO3 composites results in significantly decreased interfacial contact barrier and strengthened electronic coupling of the semiconductors to generate more photogenerated electrons/holes with improved photocatalytic performance18,19.

The surface chemical compositions of AgSiO, Ag2CO3 and AgSiO/Ag2CO3-5:1 composite were investigated by XPS (Fig. 4). The full-scan XPS spectra of pure AgSiO, Ag2CO3 and AgSiO/Ag2CO3-5:1 composite (Figure S1) indicate the presence of Ag, Si, O in AgSiO, Ag, C, O in Ag2CO3 and Ag, Si, O, C in AgSiO/Ag2CO3-5:1 composite, respectively15. Figure 4A depictes the Si 2p peak of AgSiO/Ag2CO3-5:1 composite. The divided peaks located at ~96.9, ~102.8 and ~101 eV can be indexed into Ag 4 s, Si 2p1/2 and Si 2p3/2, respectively6. Figure 4B shows two XPS peaks located at ~368.1 eV and ~374.1, which can be indexed to Ag 3d5/2 and Ag 3d3/2 of pure AgSiO, Ag2CO3 and the AgSiO/Ag2CO3-5:1 composite16,17. These two peaks can be further divided into four peaks, ~368.1 and ~374.1 eV for Ag+ 3d5/2 and 3d3/2, and ~368.8 and ~374.7 eV for Ag0 3d5/2 and 3d3/2, respectively. The peaks at ~368.8 and ~374.7 eV confirm the existence of metallic Ag0 in our AgSiO/Ag2CO3-5:1 composite. The carbon element in AgSiO is mostly ascribed to the adventitious hydrocarbon from XPS itself. Therefore the strength of C 1 s obeys the decreasing order of Ag2CO3 > AgSiO/Ag2CO3 > AgSiO20. Figure 4D demonstrates that O 1 s peak in AgSiO/Ag2CO3 contains two distinguishable shoulders in the spectrum, demonstrating that two chemical states of oxygen are present on the surface21. The O 1 s peak at ~530.18 eV can be ascribed to O in AgSiO. Another peak at ~531.93 eV is attributed to O in AgSiO and Ag2CO3 19.

The morphologies of Ag2CO3, AgSiO and AgSiO/Ag2CO3 with different ratios are shown Fig. 5. It can be observed that Ag2CO3 are composed of microcubes with the length of ~1.0–5.0 μm in Fig. 5A 22. Figure 5B clearly shows that the AgSiO samples are sphere-like particles with the sizes of ~50–100 nm22,23. Figure 5C–F indicate that the morphologies of AgSiO/Ag2CO3 with different ratios are similar to AgSiO24. The presence of SiO2− in the sources has great effects on the final morphology of composite. The particle sizes of the composite decrease with the increase addition of SiO2−. Furthermore, most particles are non-agglomerated and the sizes are mostly less than 100 nm, demonstrating that the samples are really nanosized cluster compounds24. The intimate contact between AgSiO and Ag2CO3 will strengthen the photogenerated charge separation and transfer25. Compared with traditional aggregated or large contact structures, this AgSiO/Ag2CO3 composites can not only provide more surface active sites for sequential photocatalytic reactions, but also shorten the migration distance of photogenerated charges10.

The HRTEM images in Figure S2(A,B) show that the size of AgSiO/Ag2CO3 NPs is of 10 to 20 nm. The lattices of AgSiO/Ag2CO3 NPs are clearly visible in the HRTEM images. The close interface between the AgSiO and Ag2CO3 nanoparticles reveals the formation of nano-heterojunction26. From the figure, we can see that Ag2CO3 is uniformly packaged by an amorphous AgSiO, limiting the growth of Ag2CO3 27. Figure S2(B) shows the lattice spacing of uniformly dispersed Ag2CO3 nanoparticles. The lattice fringes of 0.275 nm is in agreement with the spacings of the (−101) plane of Ag2CO3 and consistent with JCPDS Card No. 26–033928. No lattice fringes of AgSiO can be observed. This kind of heterojunction, which is favorable for the transport of photoexcited carriers, is formed between AgSiO and Ag2CO3 29. Mainwhile, the composites can be further characterized by element mapping and EDS images (Fig. 6), where the Ag, Si, O and C elements are homogeneously distributed over the whole profile30,31,32. From the above results, we can expect that the strong interfacial coupling effect between AgSiO and Ag2CO3 will promote photogenerated electron-hole pairs separation and transfer, and thus further enhance the photocatalytic performance of AgSiO/Ag2CO3 composites33.

Surface area, pore size and pore volume parameters for pure AgSiO, pure Ag2CO3 and AgSiO/Ag2CO3 composites were also investigated. The porosity of the AgSiO/Ag2CO3 composites sample is clearly enhanced. According to Figure S3, all the materials except for Ag2CO3 show a narrow pore size distribution with the average diameter of d > 2 nm13,34. With further increase of the AgSiO content, the adsorbed volume drops obviously indicating that the enhancement in adsorption volume is not driven solely by the small particles6,13,35. The surface areas of the different AgSiO/Ag2CO3 composites and pure AgSiO and Ag2CO3 are also calculated as shown in Fig. 7B for a better understanding of the composite nanostructure. It can be seen that the surface area of Ag2CO3 is ~11.4 m2·g−1. With further increasing of the amount of the AgSiO, the surface area values of the AgSiO/Ag2CO3 composites increase obviously. The surface area of AgSiO/Ag2CO3-6:1 composite can be achieved ~107.9 m2·g−1. Although the AgSiO/Ag2CO3-5:1 composite specific surface area isn’t the largest, the degradation is best, which can be attributed to its heterogeneous structure.

(A) N2 adsorption–desorption is otherms and pore size distribution curves calculated for AgSiO/Ag2CO3-5:1 composite; (B) surface area values of (1) Ag2CO3, (2) AgSiO, (3) AgSiO/Ag2CO3-2:1 composite,(4) AgSiO/Ag2CO3-3:1 composite, (5) AgSiO/Ag2CO3-4:1 composite, (6) AgSiO/Ag2CO3-5:1 composite and (7) AgSiO/Ag2CO3-6:1 composite.

Photocatalytic tests

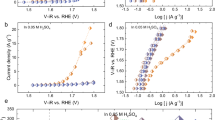

The photocatalytic activities of pure AgSiO, Ag2CO3 and AgSiO/Ag2CO3 composites with different ratios under VL irradiation are shown in Fig. 8. The degradation reaches as ~99.1% under VL irradiation within ~40 min (Fig. 8A,B). The degradation of RhB is only ~12% in the same condition (Fig. 8C,D)36,37.

(A) The photocatalytic activities of the as-prepared photocatalysts for the degradation of MB under VL irradiation; (B) the rate constants of the as-prepared photocatalysts for the degradation of MB; (C) the photocatalytic activities of the as-prepared photocatalysts for the degradation of RhB under VL irradiation; (D) the rate constants of the as-prepared photocatalysts for the degradation of RhB.

All AgSiO/Ag2CO3 composites exhibit higher photocatalytic activities than either AgSiO or Ag2CO3 with the order of AgSiO/Ag2CO3-5:1 > AgSiO/Ag2CO3-6:1 > AgSiO/Ag2CO3-4:1 > AgSiO/Ag2CO3-3:1 > AgSiO/Ag2CO3-2:1 > AgSiO > Ag2CO3, indicating the positive effect of AgSiO contents on enhancing the photocatalytic activities of the composites8,37. Full degradation of MB can be observed within ~40 min by VL irradiation in the presence of AgSiO/Ag2CO3-5:1 composite (Fig. 8A), illustrating the significantly improved photocatalytic activity of the AgSiO/Ag2CO3 composites36. However, further increment of proportion (AgSiO/Ag2CO3-6:1) results in decreased photocatalytic activity, which may be attributed to the recombination of photogenerated electrons and holes, and thenthe photocatalytic efficiency is restrained38.

Figure 9 shows the variation of the absorption spectra of MB under VL irradiation by AgSiO/Ag2CO3-5:1 composite. The characteristic peak intensities of MB gradually decrease by prolonging the irradiation time, and the adsorption peaks disappear within ~40 min irradiation12,39. The corresponding optical photographs of MB degradation using different photocatalysts under different irradiation times are collected and displayed in Fig. 9B. The color of MB gradually becomes lighter by prolonging the irradiation time, it can be seen that the color of AgSiO/Ag2CO3-5:1 composite becomes transparent while pure color for AgSiO and Ag2CO3 turns into azury40. The variation of the absorption spectra of RhB under VL irradiation by AgSiO/Ag2CO3-5:1 composite is shown in Fig. 9C. The characteristic peak intensities of RhB gradually decreased by prolonging the irradiation time, and the adsorption peaks became constant within ~40 min irradiation indicating the very slow degradation of RhB12,38. These corresponding optical photographs of RhB degradation using different photocatalysts under different irradiation times are in Fig. 9D, showing that the color of RhB almost keeps unchanged.

(A) The absorption spectra of MB degraded by AgSiO/Ag2CO3-5:1 composite under VL irradiation; (B) the corresponding digital photograph of MB degraded by AgSiO/Ag2CO3-5:1 composite under VL irradiation; (C) the absorption spectra of RhB degraded by AgSiO/Ag2CO3-5:1 composite under VL irradiation; (D) the corresponding digital photograph of RhB degraded by AgSiO/Ag2CO3-5:1 composite under VL irradiation; Absorption spectra (E) and corresponding digital photograph (F) of RhB and MB degraded by AgSiO/AgCO3-5:1 composite under VL irradiation.

The selective photocatalytic phenomenon of the AgSiO/Ag2CO3-5:1 composite was examined by photodegradation of MB and RhB38. The absorptions peaks of MB located at ~664 nm almost disappear after irradiation within ~40 min. However, the absorption peaks of RhB located at ~554 nm doesn’t change too much (Fig. 9)39. As for two cationic dyes MB and RhB, we speculate that the discrepancy in adsorption capacities among them can be ascribed to the molecule size29,35. That is, because the size of MB molecules is smaller than those of RhB, MB can be intercalated into the space, while RhB are too large to intercalate into the NPs37.

Similarly, we used MB&MO, MO&RhB and MO&CR mixture dyes to further research the selectivity of the material. As shown from the figure S4, When AgSiO/Ag2CO3 composites were added into the binary mixtures, respectively, the characteristic peaks of cationic dyes MB disappeared quickly, while the characteristic peaks of all anionic dyes remained unchanged41. These results demonstrated excellent selective removal of cationic dyes over anionic dyes due to the electrostatic effect11,12.

Photocatalytic mechanism

The electrons and holes produced by photocatalysis have strong reduction and oxidation capacities. The main active species of different photocatalysts may vary due to their different band structure and phase compositions10,38. Thus, to explore the mechanism of the high photocatalytic activities and to assess the contribution of the reactive species, trapping experiments of reactive species were conducted using ethylenediaminetetraacetate (EDTA-2Na), iso-propyle alcohol (IPA) and N2 as h+ and OH− and e− scavengers, respectively10,16. By adding scavengers into the degradation solutions, the reactive species in the degradation process can be revealed. As shown in Fig. 10, the degradation rate decreases clearly to ~8.8% in the presence of EDTA-2Na (h+ scavenger) and the degradation rate is ~98% in the absence of scavengers, which indicates that h+ is the major reactive specie for MB degradation (Fig. 10A,B)8,40. Introducing IPA displays a significant effect on the Kapp. It decrease from ~0.102 min−1 to ~0.055 min−1 (Fig. 10C), suggesting that the radical is also a dominant reactive species. And the degradation rate decreases obviously to ~53% and ~66% in the presence of N2 (O2− scavenger) and AgNO3 (e− scavenger), which suggests that O2− and e− is the partly reactive species for MB degradation (Fig. 10D,E). Through Fig. 10F, we can visually see that the O2−, e− and h+ are reactive species42.

The recyclability of the photocatalysts is significant factors in their practical applications. Figure 11A indicates that the recyclability for AgSiO/Ag2CO3-5:1 composite. After six successive cycles, AgSiO/Ag2CO3-5:1 composite still possesses ~89% degradation rate of MB after ~40 min VL irradiation, indicating its high recyclability30,39,43. The results indicate that the incorporation of AgSiO with Ag2CO3 photocatalyst successfully improves the VL photocatalytic performance and restrains the photocorrosion in a large level13,44. To further comprehend the separation and recombination of electron-hole pairs in pure AgSiO, Ag2CO3 and AgSiO/Ag2CO3 composites, the photocurrent test is carried out under visible light33. In this study, electrochemical and photoelectrochemical measurements were performed in 1 M Na2SO4 electrolyte solution in a three-electrode quartz cell. Pt sheet was used as a counter electrode and Hg/Hg2Cl2/sat. KCl was used as a reference electrode. The pure AgSiO, Ag2CO3 and AgSiO/Ag2CO3 composites on ITO was used as the working electrode for investigation. The photoelectrochemical response was recorded with a CHI 660E electrochemical system33. The photocurrent-potential plots of these samples are shown in Fig. 11B. The figure shows the obvious photocurrent intensity of different samples under illumination by 250 lumens LED for 30 second intervals. The best photocurrent intensity (0.7 μA·g−1) of AgSiO was obtained when the applied potential is 1.3 V. And the best photocurrent intensity of Ag2CO3 was 1.2 μA·g−1. However, the photocurrent intensity was improved to 1.8 μA·cm−1 with the same applied potential after a heterojunction formed form AgSiO and Ag2CO3, which was three times greater than pure Ag2CO3. This phenomenon reveals that the AgSiO/Ag2CO3 heterostructures possess a larger carrier concentration than the pure AgSiO and Ag2CO3 NPs, and more electron-hole pairs are generated for the charge separation process45. These results of the photocurrent tests are in agreement with the results of the photodegradation of MB. The obvious photocurrent demonstrates that the interfacial charge separation between AgSiO and Ag2CO3 NPs exists in this composite46.

Based on experimental results, Fig. 12 depicts a diagrammatic sketch for photocatalytic mechanism. Under VL irradiation, AgSiO can absorb VL, leading to the excitation of e− to the conduction band (CB) and whilst keeping h+ in the valence bands (VB)2,7. For AgSiO/Ag2CO3 heterojunctions, the photogenerated e− on the CB of AgSiO can easily migrate to the CB of Ag2CO3 while the photogenerated h+ in the VB of Ag2CO3 migrates to AgSiO19. That is to say, the appropriately aligned band edges of AgSiO and Ag2CO3 indicates that the migration of effective photogenerated charges can occur via the heterojunctions with strong interfacial coupling effect in the composite47. The migration of photogenerated charges limit the transmission of photogenerated e− and h+ on different sides, which reduces the recombination rate of photogenerated electron-hole pairs and improves the abundance and stability of photogenerated charge in the composite6,7. At the same time, the isolated photogenerated charges promote the production of reactive oxidative species, i.e. •O2− and •OH, which are responsible for degrading MB confirmed by Fig. 12 26,48,49.

Conclusions

In summary, a facile in-situ precipitation method has been designed and developed to synthesize a series of AgSiO/Ag2CO3 composites with the sizes in the range of 100 nm. The as-synthesized AgSiO/Ag2CO3-5:1 composite shows superior VL photocatalytic activities, and the degradation of MB reach as ~99.1% under VL irradiation within ~40 min, which can be ascribed to the synergetic effect between AgSiO and Ag2CO3, including the maximum heterojunction interface with intimate contact, enhanced photogenerated charge separation efficiency, fully exposed reactive sites as well as excellent VL response in the composite. For the selectivity for degradation, we speculate that the discrepancy in degradation capacities among the two anionic dyes can be ascribed to the molecule size. This work will give insights into the importance of rational design of heterojunction systems, and provide a potential method for the construction of efficient heterojunction photocatalysts with controllable sizes and space distributions.

References

Shi, L., Liang, L., Wang, F., Liu, M. & Sun, J. Enhanced visible-light photocatalytic activity and stability over g-C3N4/Ag2CO3 composites. J. Mater. Sci. 50, 1718–1727 (2015).

Li, Y. et al. Preparation and enhanced visible light photocatalytic activity of novel g-C3N4 nanosheets loaded with Ag2CO3 nanoparticles. Nanoscale 7, 758–764 (2015).

Panthi, G. et al. Electrospun composite nanofibers of polyacrylonitrile and Ag2CO3 nanoparticles for visible light photocatalysis and antibacterial applications. J. Mater. Sci. 50, 4477–4485 (2015).

Xu, X., Zhai, T., Shao, M. & Huang, J. Anodic formation of anatase TiO2 nanotubes with rod-formed walls for photocatalysis and field emitters. Phys. Chem. Chem. Phys. 14, 16371–16376 (2012).

Dai, G., Yu, J. & Liu, G. A new approach for photocorrosion inhibition of Ag2CO3 photocatalyst with highly visible-light-responsive reactivity. J. Phy. Chem. C 116, 15519–15524 (2012).

Liu, J. et al. Anchoring of Ag6Si2O7 nanoparticles on α-Fe2O3 short nanotubes as a Z-scheme photocatalyst for improving their photocatalytic performances. Dalton T. 45, 12745–12755 (2016).

Lou, Z. et al. Ag6Si2O7: a silicate photocatalyst for the visible region. Chem. Mater. 26, 3873–3875 (2014).

Zhang, S. et al. Hybrid 0D-2D nanoheterostructures: in-situ growth of amorphous silver silicates dots on g-C3N4 nanosheets for full spectrum photocatalysis. ACS Appl. Mater. Inter. 8, 35138–35149 (2016).

Zheng, Y., Lin, L., Ye, X., Guo, F. & Wang, X. Helical graphitic carbon nitrides with photocatalytic and optical activities. Angew. Chem. Int. Edit. 53, 11926–11930 (2014).

Mehraj, O., Mir, N. A., Pirzada, B. M., Sabir, S. & Muneer, M. In-situ anion exchange synthesis of AgBr/Ag2CO3 hybrids with enhanced visible light photocatalytic activity and improved stability. J. Mol. Catal. A: Chem. 395, 16–24 (2014).

Yang, H. et al. Constructing the novel ultrafine amorphous iron oxyhydroxide/g-C3N4 nanosheets heterojunctions for highly improved photocatalytic performance. Sci. Rep. 7, 8686 (2017).

Shu, D., Feng, F., Han, H. & Ma, Z. Prominent adsorption performance of amino-functionalized ultra-light graphene aerogel for methyl orange and amaranth. Chem. Eng. J. 324, 1–9 (2017).

Chen, F. et al. Novel ternary heterojunction photcocatalyst of Ag nanoparticles and g-C3N4 nanosheets co-modified BiVO4 for wider spectrum visible-light photocatalytic degradation of refractory pollutant. Appl. Catal. B: Environ. 205, 133–147 (2017).

Zhao, Q. et al. One-pot synthesis of Zn-doped SnO2 nanosheet-based hierarchical architectures as a glycol gas sensor and photocatalyst. CrystEngComm 17, 4394–4401 (2015).

Yu, C. et al. Enhancing the photocatalytic performance of commercial TiO2 crystals by coupling with trace narrow-band-gap Ag2CO3. Ind. Eng. Chem. Res. 53, 5759–5766 (2014).

Liu, L. et al. A stable Ag3PO4@ g-C3N4 hybrid core@ shell composite with enhanced visible light photocatalytic degradation. Appl. Catal. B: Environ. 183, 133–141 (2016).

Han, S. W., Kim, Y. & Kim, K. Dodecanethiol-derivatized Au/Ag bimetallic nanoparticles: TEM, UV/VIS, XPS, and FTIR analysis. J. Colloid Interf. SCI. 208, 272–278 (1998).

Kaushik, V. K. XPS core level spectra and Auger parameters for some silver compounds. J. Electron Spectrosc. 56, 273–277 (1991).

Yu, C., Li, G., Kumar, S., Yang, K. & Jin, R. Phase transformation synthesis of novel Ag2O/Ag2CO3 heterostructures with high visible light efficiency in photocatalytic degradation of pollutants. Adv. Mater. 26, 892–898 (2014).

Epling, W. S., Hoflund, G. B. & Salaita, G. N. Surface characterization study of the thermal decomposition of Ag2CO3. J. Phys. Chem. B 102, 2263–2268 (1998).

Dong, S. et al. Self-assembled hollow sphere shaped Bi2WO6/RGO composites for efficient sunlight-driven photocatalytic degradation of organic pollutants. Chem. Eng. J. 316, 778–789 (2017).

Jin, X., Mok, E. K., Baek, J.-W., Park, S.-H. & Hwang, S.-J. Importance of the tuning of band position in optimizing the electronic coupling and photocatalytic activity of nanocomposite. J. Solid State Chem. 230, 175–181 (2015).

Férey, G. et al. A chromium terephthalate-based solid with unusually large pore volumes and surface area. Science 309, 2040–2042 (2005).

Sun, J. et al. Bioinspired hollow semiconductor nanospheres as photosynthetic nanoparticles. Nat. Commun. 3, 1139 (2012).

Gaumet, M., Vargas, A., Gurny, R. & Delie, F. Nanoparticles for drug delivery: the need for precision in reporting particle size parameters. Eur. J. Pharm. Biophar. 69, 1–9 (2008).

Fang, S. et al. Fabrication of BiOCl@ CdS/Ag2CO3 heterojunctions with enhanced photocatalytic activity under visible-light irradiation. J. Mater. Sci.-Mater. El. 1–9 (2017).

Al-Keisy, A. et al. A ferroelectric photocatalyst Ag10Si4O13 with visible-light photooxidation properties. J. Mater. Chem. A 4, 10992–10999 (2016).

Yang, M.-Q. et al. Self-surface charge exfoliation and electrostatically coordinated 2D hetero-layered hybrids. Nat. Commun. 8, 14224 (2017).

Yu, C.-L. et al. Novel AgCl/Ag2CO3 heterostructured photocatalysts with enhanced photocatalytic performance. Rare Metals 35, 475–480 (2016).

Yu, B. et al. Preparation of electrospun Ag/g-C3N4 loaded composite carbon nanofibers for catalytic applications. Mater. Res. Express 4, 1 (2017).

Zhu, X. et al. Synthesis of novel visible light response Ag10Si4O13 photocatalyst. Appl. Catal. B: Environ. 199, 315–322 (2016).

Chen, Q., Wu, S. & Xin, Y. Synthesis of Au-CuS-TiO2 nanobelts photocatalyst for efficient photocatalytic degradation of antibiotic oxytetracycline. Chem. Eng. J. 302, 377–387 (2016).

Yang, M.-Q. et al. Ultrathin nickel boron oxide nanosheets assembled vertically on graphene: a new hybrid 2D material for enhanced photo/electro-catalysis. Mater. Horiz. 4, 885–894 (2017).

Liu, J. et al. 2D ZnO mesoporous single-crystal nanosheets with exposed {0001} polar facets for the depollution of cationic dye molecules by highly selective adsorption and photocatalytic decomposition. Appl. Catal. B: Environ. 181, 138–145 (2016).

Yao, Z. et al. Preparation, characterization, and antibacterial activity of shell waste loaded with silver. J. Mater. Sci. 48, 8580–8587 (2013).

Cui, W. et al. Microwave-assisted synthesis of Ag@AgBr-intercalated K4Nb6O17 composite and enhanced photocatalytic degradation of Rhodamine B under visible light. Chem. Eng. J. 230, 10–18 (2013).

Hou, R. et al. Coupling system of Ag/BiOBr photocatalysis and direct contact membrane distillation for complete purification of N-containing dye wastewater. Chem. Eng. J. 317, 386–393 (2017).

Shu, J. et al. One-pot synthesis of AgCl@ Ag hybrid photocatalyst with high photocatalytic activity and photostability under visible light and sunlight irradiation. Chem. Eng. J. 252, 374–381 (2014).

Ma, X. et al. Comparison of photocatalytic reaction-induced selective corrosion with photocorrosion: Impact on morphology and stability of Ag-ZnO. Appl. Catal. B: Environ. 201, 348–358 (2017).

Orge, C., Pereira, M. & Faria, J. Photocatalytic-assisted ozone degradation of metolachlor aqueous solution. Chem. Eng. J. 318, 247–253 (2017).

Liang, H., Jia, Z., Zhang, H., Wang, X. & Wang, J. Photocatalysis oxidation activity regulation of Ag/TiO2 composites evaluated by the selective oxidation of Rhodamine B. Appl. Surf. Sci. 422, 1–10 (2017).

Suyana, P. et al. Co3O4-C3N4 p-n nano-heterojunctions for the simultaneous degradation of a mixture of pollutants under solar irradiation. Environ. Sci. Nano. 4, 212–221 (2017).

Zhang, D., Li, J., Wang, Q. & Wu, Q. High {001} facets dominated BiOBr lamellas: facile hydrolysis preparation and selective visible-light photocatalytic activity. J. Mol. Catal. A 1, 8622–8629 (2013).

Gou, W., Wu, P., Jiang, D. & Ma, X. Synthesis of AgBr@ Bi2O3 composite with enhanced photocatalytic performance under visible light. J. Alloy. Compd. 646, 437–445 (2015).

Han, C., Quan, Q., Chen, H. M., Sun, Y. & Xu, Y. J. Progressive Design of Plasmonic Metal-Semiconductor Ensemble toward Regulated Charge Flow and Improved Vis-NIR-Driven Solar-to-Chemical Conversion. Small 13, 14 (2017).

Xu, K. et al. Ag-CuO-ZnO metal-semiconductor multiconcentric nanotubes for achieving superior and perdurable photodegradation. Nanoscale 9, 11574–11583 (2017).

Chen, F. et al. Facile preparation of ternary Ag2CO3/Ag/PANI composite nanorods with enhanced photoactivity and stability. J. Mater. Sci. 52, 4521–4531 (2017).

Zhang, P. et al. Synthesis of sandwich-structured AgBr@Ag@TiO2 composite photocatalyst and study of its photocatalytic performance for the oxidation of benzyl alcohols to benzaldehydes. Chem. Eng. J. 306, 1151–1161 (2016).

Yang, M.-Q., Zhang, N., Wang, Y. & Xu, Y.-J. Metal-free, robust, and regenerable 3D graphene–organics aerogel with high and stable photosensitization efficiency. J. Catal. 346, 21–29 (2017).

Acknowledgements

Financial supports from NSFC (Grant Nos 51672109, 21505050) and the Natural Science Foundation of Shandong Province (Grant No. ZR2016JL015, ZR2016FM30).

Author information

Authors and Affiliations

Contributions

C.R.Y. performed the experiments. D.X.L. and Y.H.C. performed the SEM observations and TEM observations. Z.S.W. and X.X.J. discussed and commented on the experiments and results, and wrote the paper.

Corresponding authors

Ethics declarations

Competing Interests

The authors declare that they have no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Cao, R., Yang, H., Deng, X. et al. In-situ synthesis of amorphous silver silicate/carbonate composites for selective visible-light photocatalytic decomposition. Sci Rep 7, 15001 (2017). https://doi.org/10.1038/s41598-017-15405-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-017-15405-6

This article is cited by

-

The study of TiO2/Cu2O nanoparticles as an efficient nanophotocalyst toward surface adsorption and photocatalytic degradation of methylene blue

Applied Nanoscience (2022)

-

Fabrication of Hierarchical ZnO@NiO Core–Shell Heterostructures for Improved Photocatalytic Performance

Nanoscale Research Letters (2018)

-

Fabrication of Ag-modified porous ZnMgO nanorods with enhanced photocatalytic performance

Journal of Materials Science: Materials in Electronics (2018)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.