Abstract

Room-temperature bismuth telluride (Bi2Te3) thermoelectrics are promising candidates for low-grade heat harvesting. However, the brittleness and inflexibility of Bi2Te3 are far reaching and bring about lifelong drawbacks. Here we demonstrate good pliability over 1,000 bending cycles and high power factors of 4.2 (p type) and 4.6 (n type) mW m−1 K−2 in Bi2Te3-based films that were exfoliated from corresponding single crystals. This unprecedented bendability was ascribed to the in situ observed staggered-layer structure that was spontaneously formed during the fabrication to promote stress propagation whilst maintaining good electrical conductivity. Unexpectedly, the donor-like staggered layer rarely affected the carrier transport of the films, thus maintaining its superior thermoelectric performance. Our flexible generator showed a high normalized power density of 321 W m−2 with a temperature difference of 60 K. These high performances in supple thermoelectric films not only offer useful paradigms for wearable electronics, but also provide key insights into structure–property manipulation in inorganic semiconductors.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

Source data are provided with this paper. Any additional material is available from the corresponding authors upon reasonable request.

References

Zhu, T. et al. Compromise and synergy in high-efficiency thermoelectric materials. Adv. Mater. 29, 1605884 (2017).

Zhao, W. et al. Magnetoelectric interaction and transport behaviours in magnetic nanocomposite thermoelectric materials. Nat. Nanotechnol. 12, 55–60 (2017).

He, J. & Tritt, T. M. Advances in thermoelectric materials research: looking back and moving forward. Science 357, eaak9997 (2017).

Jiang, B. et al. High-entropy-stabilized chalcogenides with high thermoelectric performance. Science 371, 830–834 (2021).

Poudel, B. et al. High-thermoelectric performance of nanostructured bismuth antimony telluride bulk alloys. Science 320, 634–638 (2008).

Hu, L. P., Zhu, T. J., Liu, X. H. & Zhao, X. B. Point defect engineering of high-performance bismuth-telluride-based thermoelectric materials. Adv. Funct. Mater. 24, 5211–5218 (2014).

Lu, Y. et al. Ultrahigh performance PEDOT/Ag2Se/CuAgSe composite film for wearable thermoelectric power generators. Mater. Today Phys. 14, 100223 (2020).

Yoo, B. et al. Electrodeposition of thermoelectric superlattice nanowires. Adv. Mater. 19, 296–299 (2007).

Bae, E. J., Kang, Y. H., Jang, K. S., Lee, C. & Cho, S. Y. Solution synthesis of telluride-based nano-barbell structures coated with PEDOT:PSS for spray-printed thermoelectric generators. Nanoscale 8, 10885–10890 (2016).

An, H., Pusko, M., Chun, D., Park, S. & Moon, J. In situ synthesis of flexible hybrid composite films for improved thermoelectric performance. Chem. Eng. J. 357, 547–558 (2019).

Wang, L. et al. Exceptional thermoelectric properties of flexible organic–inorganic hybrids with monodispersed and periodic nanophase. Nat. Commun. 9, 3817 (2018).

Jin, Q. et al. Flexible layer-structured Bi2Te3 thermoelectric on a carbon nanotube scaffold. Nat. Mater. 18, 62–68 (2018).

Fu, L. et al. High-performance bismuth antimony telluride thermoelectric membrane on curved and flexible supports. ACS Energy Lett. 6, 2378–2385 (2021).

Mu, X. et al. Enhanced electrical properties of stoichiometric Bi0.5Sb1.5Te3 film with high-crystallinity via layer-by-layer in-situ growth. Nano Energy 33, 55–64 (2017).

Lima, M. S. L. et al. High power factor in epitaxial Mg2Sn thin films via Ga doping. Appl. Phys. Lett. 119, 254101 (2021).

Kong, D., Zhu, W., Guo, Z. P. & Deng, Y. High-performance flexible Bi2Te3 films based wearable thermoelectric generator for energy harvesting. Energy 175, 292–299 (2019).

Shang, H. et al. High-performance Ag-modified Bi0.5Sb1.5Te3 films for the flexible thermoelectric generator. ACS Appl. Mater. Interfaces 12, 7358–7365 (2020).

Zheng, Z. H. et al. Harvesting waste heat with flexible Bi2Te3 thermoelectric thin film. Nat. Sustain. 6, 180–191 (2023).

Liu, W. S., Jie, Q., Kim, H. S. & Ren, Z. F. Current progress and future challenges in thermoelectric power generation: from materials to devices. Acta Mater. 87, 357–376 (2015).

Hendricks, T., Caillat, T. & Mori, T. Keynote review of latest advances in thermoelectric generation materials, devices, and technologies 2022. Energies 15, 7307 (2022).

Wang, Y. et al. Flexible thermoelectric materials and generators: challenges and innovations. Adv. Mater. 31, 1807916 (2019).

Tan, M., Liu, W. D., Shi, X. L., Sun, Q., & Chen, Z. G. Minimization of the electrical contact resistance in thin-film thermoelectric device. Appl. Phys. Rev. 10, 021404 (2023).

Li, X., Cai, K. F., Gao, M. Y., Du, Y. & Shen, S. Recent advances in flexible thermoelectric films and devices. Nano Energy 89, 106309 (2021).

Zhang, Z. et al. Conjugated polymers for flexible energy harvesting and storage. Adv. Mater. 30, e1704261 (2018).

Wan, C. et al. Ultrahigh thermoelectric power factor in flexible hybrid inorganic–organic superlattice. Nat. Commun. 8, 1024 (2017).

Lu, Y. et al. Ultrahigh power factor and flexible silver selenide-based composite film for thermoelectric devices. Energy Environ. Sci. 13, 1240–1249 (2020).

Jiang, C. et al. Ultrahigh performance polyvinylpyrrolidone/Ag2Se composite thermoelectric film for flexible energy harvesting. Nano Energy 80, 105488 (2021).

Ding, Y. et al. High performance n-type Ag2Se film on nylon membrane for flexible thermoelectric power generator. Nat. Commun. 10, 841 (2019).

An, C. J., Kang, Y. H., Song, H., Jeong, Y. & Cho, S. Y. High-performance flexible thermoelectric generator by control of electronic structure of directly spun carbon nanotube webs with various molecular dopants. J. Mater. Chem. A 5, 15631–15639 (2017).

Lu, Y. et al. Enhanced-performance PEDOT:PSS/Cu2Se-based composite films for wearable thermoelectric power generators. ACS Appl. Mater. Interfaces 13, 631–638 (2021).

Tian, R. et al. A solution-processed TiS2/organic hybrid superlattice film towards flexible thermoelectric devices. J. Mater. Chem. A 5, 564–570 (2017).

Xu, Q. et al. Conformal organic–inorganic semiconductor composites for flexible thermoelectrics. Energy Environ. Sci. 13, 511–518 (2020).

Liang, J. et al. Flexible thermoelectrics: from silver chalcogenides to full-inorganic devices. Energy Environ. Sci. 12, 2983–2990 (2019).

Xu, S. et al. Computation-guided design of high-performance flexible thermoelectric modules for sunlight-to-electricity conversion. Energy Environ. Sci. 13, 3480–3488 (2020).

Jurado, J. P. et al. Solar harvesting: a unique opportunity for organic thermoelectrics? Adv. Energy Mater. 9, 1902385 (2019).

Sun, T. et al. Stretchable fabric generates electric power from woven thermoelectric fibers. Nat. Commun. 11, 572 (2020).

Peng, J. & Snyder, G. J. A figure of merit for flexibility. Science 366, 690–691 (2019).

Ni, D. et al. Free-standing highly conducting PEDOT films for flexible thermoelectric generator. Energy 170, 53–61 (2019).

Saeidi-Javash, M., Kuang, W. Z., Dun, C. C. & Zhang, Y. L. 3D conformal printing and photonic sintering of high-performance flexible thermoelectric films using 2D nanoplates. Adv. Funct. Mater. 29, 1901930 (2019).

Sun, S. et al. Direct atomic-scale observation of ultrasmall Ag nanowires that exhibit fcc, bcc, and hcp structures under bending. Phys. Rev. Lett. 128, 015701 (2022).

Thonhauser, T., Jeon, G. S., Mahan, G. D. & Sofo, J. O. Stress-induced defects in Sb2Te3. Phys. Rev. B 68, 205207 (2003).

Fu, X. et al. Improving deformability of Sb2Te3 layered material by dislocation climb at anti-phase boundary. Scr. Mater. 135, 10–14 (2017).

Zhu, B. et al. Realizing record high performance in n-type Bi2Te3-based thermoelectric materials. Energy Environ. Sci. 13, 2106–2114 (2020).

Carle, M., Pierrat, P., Lahalle-Gravier, C., Scherrer, S. & Scherrer, H. Transport properties of n-type Bi2(Te1-xSex)3 single crystal solid solutions (x ≤ 0.05). J. Phys. Chem. Solids 56, 201–209 (1994).

Shin, S. et al. High-performance screen-printed thermoelectric films on fabrics. Sci. Rep. 7, 7317 (2017).

Zou, H., Rowe, D. M. & Williams, S. G. K. Peltier effect in a co-evaporated Sb2Te3(P)–Bi2Te3(N) thin film thermocouple. Thin Solid Films 408, 270–274 (2002).

Zhang, Z. W., Wang, Y., Deng, Y. & Xu, Y. B. The effect of (00l) crystal plane orientation on the thermoelectric properties of Bi2Te3 thin film. Solid State Commun. 151, 1520–1523 (2011).

Fan, P. et al. High thermoelectric performance achieved in Bi0.4Sb1.6Te3 films with high (00l) orientation via magnetron sputtering. J. Eur. Ceram. Soc. 40, 4016–4021 (2020).

Hou, W. et al. Fabrication and excellent performances of Bi0.5Sb1.5Te3/epoxy flexible thermoelectric cooling devices. Nano Energy 50, 766–776 (2018).

Jiang, Y. et al. Direct atom-by-atom chemical identification of nanostructures and defects of topological insulators. Nano Lett. 13, 2851–2856 (2013).

Navrátil, J., Starý, Z. & Plechác̆ek, T. Thermoelectric properties of p-type antimony bismuth telluride alloys prepared by cold pressing. Mater. Res. Bull. 31, 1559–1566 (1996).

Takashiri, M., Takiishi, M., Tanaka, S., Miyazaki, K. & Tsukamoto, H. Thermoelectric properties of n-type nanocrystalline bismuth-telluride-based thin films deposited by flash evaporation. J. Appl. Phys. 101, 074301 (2007).

Xing, Y. et al. A device-to-material strategy guiding the ‘double-high’ thermoelectric module. Joule 4, 2475–2483 (2020).

Miquelot, A. et al. In- and out-plane transport properties of chemical vapor deposited TiO2 anatase films. J. Mater. Sci. 56, 10458–10476 (2021).

Bahrami, A., Schierning, G. & Nielsch, K. Waste recycling in thermoelectric materials. Adv. Energy Mater 10, 1904159 (2020).

Shafique, K., Khawaja, B., Sabir, F., Qazi, S. & Mustaqim, M. Internet of things (IoT) for next-generation smart systems: a review of current challenges, future trends and prospects for emerging 5G-IoT scenarios. IEEE Access 8, 23022–23040 (2020).

Varghese, T. et al. Flexible thermoelectric devices of ultrahigh power factor by scalable printing and interface engineering. Adv. Funct. Mater. 30, 1905796 (2020).

Lu, Z. et al. Shear induced deformation twinning evolution in thermoelectric InSb. npj Comput. Mater. 7, 111 (2021).

Lee, H. Thermoelectrics: Design and Materials (John Wiley & Sons, 2016).

Hu, S. et al. Band diagrams and performance of CdTe solar cells with a Sb2Te3 back contact buffer layer. AIP Adv. 1, 042152 (2011).

Salmon, J., Harmany, Z., Deledalle, C. A. & Willett, R. Poisson noise reduction with non-local PCA. J. Math. Imaging Vis. 48, 279–294 (2014).

Barthel, J. Dr. Probe: a software for high-resolution STEM image simulation. Ultramicroscopy 193, 1–11 (2018).

Zhang, Q., Zhang, L. Y., Jin, C. H., Wang, Y. M. & Lin, F. CalAtom: a software for quantitatively analysing atomic columns in a transmission electron microscope image. Ultramicroscopy 202, 114–120 (2019).

Shamay, Y. et al. Quantitative self-assembly prediction yields targeted nanomedicines. Nat. Mater. 17, 361–368 (2018).

Hohenberg, P. & Kohn, W. Inhomogeneous electron gas. Phys. Rev. 136, B864–B871 (1964).

Kohn, W. & Sham, L. J. Self-consistent equations including exchange and correlation effects. Phys. Rev. 140, A1133–A1138 (1965).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Zhou, Y. et al. Physics-guided co-designing flexible thermoelectrics with techno-economic sustainability for low-grade heat harvesting. Sci. Adv. 9, eadf5701 (2023).

Acknowledgements

J.H. acknowledges support from the National Natural Science Foundation of China (grant 11934007), the Science and Technology Innovation Committee Foundation of Shenzhen (grant JCYJ20200109141205978) and the Outstanding Talents Training Fund in Shenzhen (202108). L.X. acknowledges support from the Science and Technology Innovation Committee Foundation of Shenzhen (grant JCYJ20190809145205497). We thank K. Cai at Tongji University for fruitful discussion, and M. Han at Shenzhen Institute of Advanced Technology, Chinese Academy of Sciences, for support on the thermal diffusion coefficient testing. We acknowledge the assistance of SUSTech Core Research Facilities. We also thank F. Shen and S. Liu from Thermo Fisher Scientific and Z. Li from BestronST for help and discussion on the mechanical in situ TEM testing at Shanghai NanoPort.

Author information

Authors and Affiliations

Contributions

Y.L., Y.Z., W.W., M.H. and J.H. conceived the general idea. J.H. supervised the project. Y.L. prepared the samples and devices, carried out the measurements and characterizations and interpreted the results. Y.Z. constructed the device testing equipment, performed the finite-element simulations and analysed the data. W.W. contributed to the TEM observations, simulations and analysis. M.H. contributed to the growth and optimization of SCs. X.H., S.H. and G.L. conducted the DFT calculations. D.M., L.X., P.L., B.J., B.Z., J.F., J.S. and J.L. contributed to the TE characterizations. Q.L., Y.H. and J.Y. helped to prepare the sample for electron microscopy observations. Y.L., Y.Z., W.W., M.H. and J.H. wrote the paper. All authors discussed and commented on the results.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Nanotechnology thanks Kaiping Tai, Takao Mori and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data

Extended Data Fig. 1 STEM-EDS spectrum image and analysis of the staggered layers for p-type BST films.

a, HAADF-STEM image, overall corresponding EDS spectrum image and individual elemental Bi, Sb, Te maps of the p-type Bi0.5Sb1.5Te3 thin film. b, Intensity profiles of the staggered layers (marked in HAADF image of a) from the HAADF and elemental maps.

Extended Data Fig. 2 In situ TEM investigation of p-type BST films.

a, The protocol of FIB sample preparation for in situ mechanical TEM testing. b, The SEM image of resultant FIB sample. c, Intensity profiles of atomic columns in Te (upper) and BiSb layer (lower) in staggered layers in the marked region tracked from image i to vi in Fig. 2g. d, Strain maps for the nanostructure evolution during in situ deformation tracked from image i to vi in Fig. 2g.

Extended Data Fig. 3 Cyclic temperature dependent thermoelectric properties.

Temperature dependent thermoelectric properties of p-type samples (a, b, c) and n-type samples under three test cycles (d, e, f).

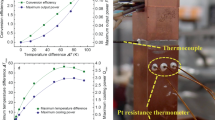

Extended Data Fig. 4 The design and performance of the Bi2Te3-based 5-pair p–n f-TEG.

a, The temperature profile of the proposed 5-pair p–n f-TEG with an optimized dimension. b, Digital photo of our f-TEG. Comparison of maximum power density (PDmax) as a function of temperature difference (c) and normalized maximum power density (PDmax×L/ΔT2) (d) among the flexible TE modules.

Supplementary information

Supplementary Information

Supplementary Notes 1–5, Figs. 1–27 and Tables 1–5.

Supplementary Video 1

In situ SEM observation of p-type Bi2Te3 film under bending.

Supplementary Video 2

In situ SEM observation of n-type Bi2Te3 film under bending.

Supplementary Video 3

Overviewing TEM observation of p-type Bi2Te3 film during in situ mechanical TEM testing.

Supplementary Video 4

HRTEM observation and the corresponding strain map during in situ deformation.

Source data

Source Data Fig. 1

Exceptional flexibility and TE performance of Bi2Te3-based films.

Source Data Fig. 2

Macroscopic, microscopic and atomic-scale in situ observations of staggered-layer-boosted flexibility for p-type BST films.

Source Data Fig. 3

DFT calculations showing the staggered-layer structure transformation in Bi2Te3 thin film.

Source Data Fig. 4

Temperature-dependent TE properties and DFT electronic band structures of the p- and n-type SCs and films.

Source Data Fig. 5

Electrical output performance of Bi2Te3-based f-TEGs.

Source Data Extended Data Fig. 1

STEM–energy-dispersive spectroscopy image and analysis of the staggered layers for p-type BST films.

Source Data Extended Data Fig. 2

In situ TEM investigation of p-type BST films.

Source Data Extended Data Fig. 3

Cyclic temperature-dependent TE properties.

Source Data Extended Data Fig. 4

The design and performance of the Bi2Te3-based five-pair p–n f-TEG.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lu, Y., Zhou, Y., Wang, W. et al. Staggered-layer-boosted flexible Bi2Te3 films with high thermoelectric performance. Nat. Nanotechnol. 18, 1281–1288 (2023). https://doi.org/10.1038/s41565-023-01457-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41565-023-01457-5

This article is cited by

-

Metavalently bonded tellurides: the essence of improved thermoelectric performance in elemental Te

Nature Communications (2024)

-

A flexible feature for the long-reigning thermoelectric champion bismuth telluride

Nature Nanotechnology (2023)