Abstract

Hydrogel materials show promise for diverse applications, particular as biocompatible materials due to their high water content. Despite advances in hydrogel technology in recent years, their application is often severely limited by inadequate mechanical properties and time-consuming fabrication processes. Here we report a rapid hydrogel preparation strategy that achieves the simultaneous photo-crosslinking and establishment of biomimetic soft–hard material interface microstructures. These biomimetic interfacial-bonding nanocomposite hydrogels are prepared within seconds and feature clearly separated phases but have a strongly bonded interface. Due to effective interphase load transfer, biomimetic interfacial-bonding nanocomposite gels achieve an ultrahigh toughness (138 MJ m−3) and exceptional tensile strength (15.31 MPa) while maintaining a structural stability that rivals or surpasses that of commonly used elastomer (non-hydrated) materials. Biomimetic interfacial-bonding nanocomposite gels can be fabricated into arbitrarily complex structures via three-dimensional printing with micrometre-level precision. Overall, this work presents a generalizable preparation strategy for hydrogel materials and acrylic elastomers that will foster potential advances in soft materials.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All the data and relevant information are available within the Article and its Supplementary Information. Additional raw data generated in this study are available from the corresponding authors upon request. Source data are provided with this paper.

References

Zhang, Y. S. & Khademhosseini, A. Advances in engineering hydrogels. Science 356, eaaf3627 (2017).

Li, J. et al. Tough adhesives for diverse wet surfaces. Science 357, 378–381 (2017).

Lutolf, M. P. et al. Synthetic matrix metalloproteinase-sensitive hydrogels for the conduction of tissue regeneration: engineering cell-invasion characteristics. Proc. Natl Acad. Sci. USA 100, 5413–5418 (2003).

Zhao, X. Multi-scale multi-mechanism design of tough hydrogels: building dissipation into stretchy networks. Soft Matter 10, 672–687 (2014).

Rauner, N. et al. Enzymatic mineralization generates ultrastiff and tough hydrogels with tunable mechanics. Nature 543, 407–410 (2017).

Gong, J. P., Katsuyama, Y., Kurokawa, T. & Osada, Y. Double-network hydrogels with extremely high mechanical strength. Adv. Mater. 15, 1155–1158 (2003).

Sun, J. Y. et al. Highly stretchable and tough hydrogels. Nature 489, 133–136 (2012).

Gong, J. P. Why are double network hydrogels so tough? Soft Matter 6, 2583–2590 (2010).

Ritchie, R. O. The conflicts between strength and toughness. Nat. Mater. 10, 817–822 (2011).

Sun, T. L. et al. Physical hydrogels composed of polyampholytes demonstrate high toughness and viscoelasticity. Nat. Mater. 12, 932–937 (2013).

Mredha, M. T. I. et al. A facile method to fabricate anisotropic hydrogels with perfectly aligned hierarchical fibrous structures. Adv. Mater. 30, 1704937 (2018).

Means, A. K. & Grunlan, M. A. Modern strategies to achieve tissue-mimetic, mechanically robust hydrogels. ACS Macro Lett. 8, 705–713 (2019).

Nakajima, T. et al. Synthesis and fracture process analysis of double network hydrogels with a well-defined first network. ACS Macro Lett. 2, 518–521 (2013).

Hua, M. et al. Strong tough hydrogels via the synergy of freeze-casting and salting out. Nature 590, 594–599 (2021).

Lin, S. et al. Anti-fatigue-fracture hydrogels. Sci. Adv. 5, eaau8528 (2019).

Lin, P., Ma, S., Wang, X. & Zhou, F. Molecularly engineered dual-crosslinked hydrogel with ultrahigh mechanical strength, toughness, and good self-recovery. Adv. Mater. 27, 2054–2059 (2015).

Yu, C. et al. Photopolymerizable biomaterials and light-based 3D printing strategies for biomedical applications. Chem. Rev. 120, 10695–10743 (2020).

Harrington, M. J., Masic, A., Holten-Andersen, N., Waite, J. H. & Fratzl, P. Iron-clad fibers: a metal-based biological strategy for hard flexible coatings. Science 328, 216–220 (2010).

Wegst, U. G. K., Bai, H., Saiz, E., Tomsia, A. P. & Ritchie, R. O. Bioinspired structural materials. Nat. Mater. 14, 23–36 (2014).

Barthelat, F., Yin, Z. & Buehler, M. J. Structure and mechanics of interfaces in biological materials. Nat. Rev. Mater. 1, 16007 (2016).

Wang, Z. et al. Stretchable materials of high toughness and low hysteresis. Proc. Natl Acad. Sci. USA 116, 5967–5972 (2019).

Song, P. et al. Granular nanostructure: a facile biomimetic strategy for the design of supertough polymeric materials with high ductility and strength. Adv. Mater. 29, 1704661 (2017).

Song, N., Gao, Z. & Li, X. Tailoring nanocomposite interfaces with graphene to achieve high strength and toughness. Sci. Adv. 6, eaba7016 (2020).

Thoniyot, P. et al. Nanoparticle-hydrogel composites: concept, design, and applications of these promising, multi-functional materials. Adv. Sci. 2, 1400010 (2015).

Haraguchi, K. & Takehisa, T. Nanocomposite hydrogels: a unique organic-inorganic network structure with extraordinary mechanical, optical and swelling/de-swelling properties. Adv. Mater. 14, 1120–1124 (2002).

Necas, J., Bartosikova, L., Brauner, P. & Kolář, J. Hyaluronic acid (hyaluronan): a review. Vet. Med. 53, 397–411 (2008).

Ellis-Davies, G. C. R. Neurobiology with caged calcium. Chem. Rev. 108, 1603–1613 (2008).

Chen, M., Zhong, M. & Johnson, J. A. Light-controlled radical polymerization: mechanisms, methods, and applications. Chem. Rev. 116, 10167–10211 (2016).

Moad, G. & Rizzardo, E. in Nitroxide Mediated Polymerization: from Fundamentals to Applications in Materials Science Vol. 19 (ed. Gigmes, D.) Ch. 1, 1–44 (Royal Society of Chemistry, 2016).

Kamata, H., Akagi, Y., Kayasuga-Kariya, Y., Chung, U. I. & Sakai, T. ‘Nonswellable’ hydrogel without mechanical hysteresis. Science 343, 873–875 (2014).

Zhao, X. Designing toughness and strength for soft materials. Proc. Natl Acad. Sci. USA 114, 8138–8140 (2017).

Kim, B. et al. A comparison among Neo-Hookean model, Mooney-Rivlin model, and Ogden model for chloroprene rubber. Int. J. Precis. Eng. Manuf. 13, 759–764 (2012).

Hoyle, C. E. & Bowman, C. N. Thiol-ene click chemistry. Angew. Chem. Int. Ed. 49, 1540–1573 (2010).

Killops, K. L., Campos, L. M. & Hawker, C. J. Robust, efficient, and orthogonal synthesis of dendrimers via thiol-ene “click” chemistry. J. Am. Chem. Soc. 130, 5062–5064 (2008).

Yang, C., Yin, T. & Suo, Z. Polyacrylamide hydrogels. I. Network imperfection. J. Mech. Phys. Solids 131, 43–55 (2019).

Zhong, M. et al. Quantifying the impact of molecular defects on polymer network elasticity. Science 353, 1264–1268 (2016).

Bai, R., Yang, J. & Suo, Z. Fatigue of hydrogels. Eur. J. Mech. A Solids 74, 337–370 (2019).

Chen, Q., Liang, S. & Thouas, G. A. Elastomeric biomaterials for tissue engineering. Prog. Polym. Sci. 38, 584–671 (2013).

Paul, C. Hydrogels for soft machines. Adv. Mater. 21, 743–756 (2009).

Grigoryan, B. et al. Multivascular networks and functional intravascular topologies within biocompatible hydrogels. Science 364, 458–464 (2019).

Lee, A. et al. 3D bioprinting of collagen to rebuild components of the human heart. Science 365, 482–487 (2019).

Smith, P. A. & Yeomans, J. A. Benefits of fiber and particulate reinforcement. Mater. Sci. Eng. 2, 133–154 (2009).

Kim, J. et al. Fracture, fatigue, and friction of polymers in which entanglements greatly outnumber cross-links. Science 374, 212–216 (2021).

Zhang, B. et al. Dual-dynamic interpenetrated networks tuned through macromolecular architecture. Polym. Chem. 10, 6290–6304 (2019).

Ducrot, E. et al. Toughening elastomers with sacrificial bonds and watching them break. Science 344, 186–189 (2014).

Dunlop, J. W. C., Weinkamer, R. & Fratzl, P. Artful interfaces within biological materials. Mater. Today 14, 70–78 (2011).

Freedman, B. R. et al. Degradable and removable tough adhesive hydrogels. Adv. Mater. 33, 2008553 (2021).

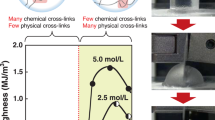

Zou, X. et al. Viscoelasticity and structures in chemically and physically dual-cross-linked hydrogels: insights from rheology and proton multiple-quantum NMR spectroscopy. Macromolecules 50, 9340–9352 (2017).

Acknowledgements

We thank Q. Shan, H. Li and X. Guo at Shanghai Jiao Tong University for technical assistance and F. Wang and P. Sun at Nankai University for the NMR characterization of gels. This work was financially supported by the National Key Research and Development Program of China (2019YFA0110500, L.Z. and Q.L.; 2021YFC2701400, Q.L.; 2019YFA0904800, L.Z.), the National Natural Science Foundation of China (22022506, Q.L.; 32121005, L.Z.; 21937004, L.Z.) and the Interdisciplinary Program of Shanghai Jiao Tong University (YG2022ZD017, Q.L.; YG2022ZD009, L.Z.), as well as the Young Leading Scientists Cultivation Plan supported by the Shanghai Municipal Education Commission (ZXWH1082101, Q.L.).

Author information

Authors and Affiliations

Contributions

L.Z. and Q.L. conceived the ideas. B.B., L.Z. and Q.L. were responsible for the experimental concept, design and data analysis. B.B., L.Z. and Q.L. wrote the manuscript. B.B., Q.Z., Y.Z. (Y. Zhang), R.Z., K.L., C.S. and B.C. prepared the materials, performed the mechanical tests and analysed the data. Y.Z. (Y. Zheng), T.C. and C.X. evaluated the cytotoxicity and biocompatibility of the materials and analysed the data. J.W., T.W. and S.T. employed finite element modelling and analysed the data. B.B., K.Y., Y.S. and Y.H. performed the 3D printing. B.B. and Q.Z. performed the structural characterization and analysed the data. L.Z. and Q.L. provided financial support and supervised all aspects of this work. All authors commented on the manuscript and its revisions.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Materials thanks Jeremiah Johnson and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data

Extended Data Fig. 1 The reaction mechanism between o-nitrobenzyl alcohol (NB) groups and methacrylate groups in the presence of LAP.

a, The reaction between nitrosobenzene and LAP in methanol was confirmed by UV-vis spectroscopy. b, The PEGNB in methanol was first irradiated to give PEGNO. LAP (two equivalents) was then added, and the solution was subsequently irradiated. Alternatively, the PEGNB and LAP (two equivalents) in methanol were directly irradiated. c, The reaction between d-NB and LAP in methanol was characterized by HPLC. d, ESR spectra of the reaction products formed between d-NB and LAP (2 equivalents). The ESR signals were recorded immediately after irradiation (left) and 20 minutes later (right) to verify the formation of persistent nitroxides. e, The structural formula and LC-MS spectra of the product (the d-NB nitroxide abstracting a hydrogen). This product was formed by the reaction between d-NB (20 mM) and LAP (20 mM) in methanol under 395-nm light irradiation. f, The general structural formula and corresponding LC-MS spectra of the photo-polymerization products formed by photo-polymerization of d-NB (1 eq), 2-hydroxyethyl methacrylate (10 eq), and LAP (2 eq) in methanol solution. The n represents the polymerization degree of 2-hydroxyethyl methacrylate. We conducted these experiments to study the details of the reaction between NB groups and methacrylate in the presence of LAP. This reaction mechanism can be divided into two steps: in the first step, NB groups underwent the typical photolytic reaction and were converted to o-nitrosobenzaldehyde groups, which reacted with the LAP radicals to yield the persistent nitroxides (Extended Data Fig. 1a–e). The reaction between NB groups and LAP was thorough and occurred quickly (Extended Data Fig. 1c). In the second step, the nitroxides captured the carbon-centered radicals formed by the polymerization of methacrylate (Extended Data Fig. 1f).

Extended Data Fig. 2 Microscopic structure of the BIN hydrogels with different Rw values.

AFM phase images of dried BIN gels. Rw values were 0.10 (a), 0.14 (b), 0.18 (c), 0.20 (d), and 0.26 (e). To investigate how the increased fraction of HAMA enhances the strength of the BIN gels, phase mapping was conducted via AFM. When the fraction of HAMA increased in BIN gels, the hard granules became larger in general.

Extended Data Fig. 3 Mechanism investigation for the rupture of HAMA particles.

HAADF and BF images of unstretched and stretched tBIN gels. Samples were dried before testing. The stretch ratio was about 15 for this gel. The Rw was 0.10. Note that the thickness of the samples was 100 nm in the STEM test, thus the observed HAMA particles in the HAADF and BF images were sparser as compared to the AFM phase images. The unstretched and stretched gels (back to original length after stretching) were characterized by STEM. After sufficient stretching, the density of HAMA particles (bright regions in the HAADF images) was notably reduced. Additionally, in the stretched gel, there were dispersive bright regions that were relatively weaker in brightness (marked with blue arrows), which belong to the ruptured HAMA particles. These phenomena agreed well with the AFM observations (Fig. 3b).

Extended Data Fig. 4 Finite element modelling.

a, FE mesh with 180,384 CPS4R elements and 16,308 COH2D4 elements. b, FE predictions of the stress distribution in sBIN gels with NB grafting degree of 0.7 (left) and 2.1 (right) when they ruptured. Both of their Rw values were set to 0.20. The FE predictions indicated that the stronger interface led to higher fracture strength of the BIN gels. A widely accepted hyperelastic model (Ogden model) was adopted.

Extended Data Fig. 5 Interfacial chemistry of the gels with different functional groups.

a, Schematics of the structural differences between the BIN gels and gels based on PEGMA, PEGAA, and PEGSH. Theoretically, BIN gels can also be synthesized when the PEG chains are functionalized with groups that can couple the transient radicals on HAMA granules, such as methacrylate (MA), acrylate (AA), and thiol (SH) groups. However, the relatively lower kinetic constants of the coupling reactions in these systems (Supplementary Table 4) and the instability of the carbon-centred radicals (and thiol radicals) led to defects in the soft phase and a lower proportion of PEG chains bonded to the interface as a result of the self-crosslinking or radical annihilating effects, apparently decreasing the mechanical performance of these gels. b, c, Representative stress-strain curves of gels containing different functional groups, Rw was 0.08 (b) and 0.20 (c).

Extended Data Fig. 6 Structural characterization of the BIN gel and PEGMA/HAMA gel with proton multiple quantum NMR.

a, b, The 1H double quantum (DQ) build-up curves from the obtained IDQ and Iref (corresponding to the DQ and reference signal intensity) dataset for the BIN (PEGNB/HAMA) gel (a) and PEGMA/HAMA gel (b) (a representative one given its better mechanical performance than that of the PEGAA and PEGSH hydrogels) at room temperature. The Itail curve was obtained by fitting the tail of the Iref-IDQ curve, which indicates the contribution from network defects. The normalized double quantum (nDQ) build-up signal is fitted as the red line (fitting nDQ). c, The corresponding Dres (residual dipolar coupling) distribution curves obtained from the fitting on the nDQ curves. In this system, the tail signals in the MQ experiment indicate the contributions of polymer defects in the gel network. The tail signal fraction of the BIN gel (42%) was slightly lower than that of the PEGMA/HAMA gel (44.5%), indicating that the PTPC mechanism is better than methacrylate at preventing polymer defects in the gel network. Moreover, the relatively narrow Dres distribution of the BIN gel suggests that the BIN gel exhibits a more uniform network structure than the PEGMA/HAMA gel.

Extended Data Fig. 7 3D printing of BIN gels.

a, Models for 3D printing of BIN gels. b, Structure and a demonstration of mechanical properties of the printed gel. The printed gel, 10 mm in outer diameter, 7 mm in inner diameter, and 2 mm in thickness, was post-cured by exposing to 395-nm light for 30 seconds (0.5 W/cm2 power), which conferred a material that could then sustain a load of 0.5 kg. c, 3D printed conical and hollowed-out structures composed of the BIN gel material. The Rw was 0.22. These structures demonstrated the high precision and the unlimited types of patterns that can be achieved via 3D printing of BIN gels.

Extended Data Fig. 8 The generality of the PTPC reaction for constructing strong and tough hydrogels.

a, b, Experimental comparison of the toughness of the hydrogels comprising various linear polymers (tetra-armed poly(propylene glycol)-block-PEG (PPG-PEG), polyacrylamide (PAAm), poly(N,N-dimethylacrylamide acrylamide) (PDMAAm), polyacrylic acid (PAA), or poly(hydroxyethyl acrylate) (PHEA)) as the soft phase and HAMA as the hard phase (a); or hydrogels comprising PAAm as the soft phase and various polysaccharides (gellan gum, chitosan, alginate, carboxymethyl cellulose, or chondroitin sulfate) as the hard phase (b). In the plots, ‘MA’ and ‘NB’ indicate hydrogels fabricated with conventional radical polymerization and our PTPC reaction, respectively. The weight ratio of the soft phase to the hard phase was 15 to 1 ~ 2. Water content was 85 ± 1.5 wt%. Figure 4g and 4h follow the same settings listed above. Data in a and b are presented as mean values ± s.d. (n = 3).

Extended Data Fig. 9 Physical properties of the unfilled acrylic elastomers.

a, 2D Young’s modulus distribution of the PEANB-based acrylic elastomer, assessed with atomic force microscopy (AFM) nanomechanical mapping. b, Images of the PEANB-based acrylic elastomer before deformation (left) and after deformation (right). Due to the nanoscale phase-separated microstructures, our materials display good optical transparency (even after deformation); we want to emphasize that any macroscale heterogeneity or fillers would result in visible phase separation and optical turbidity. c, Stress-stretch curves of the PEANB-based and poly(ethyl acrylate) (PEAMA)-based acrylic elastomers. d, e, Successive loading-unloading cycling tests of the PEANB-based acrylic elastomer at a constant strain ratio of 0.23 (d) and with increasing strain ratios (e).

Supplementary information

Supplementary Information

Supplementary Figs. 1–15, Tables 1–5, video captions, raw materials and synthetic materials.

Supplementary Video 1

In situ preparation of the BIN gel (Rw = 0.20). The BIN gel is obtained within seconds.

Supplementary Video 2

Stretching process of the BIN gel (Rw = 0.08) at a deformation rate of 20 mm min–1. The video is accelerated ×10. The BIN gel shows large deformation and distinct yielding when stretched.

Supplementary Video 3

A strip-shaped sample of BIN gel (Rw = 0.20) is readily prepared but highly robust. The sample is prepared via irradiation of 395 nm light (0.5 W cm–2) within one single, simple step. It shows high elasticity and is robust enough to withstand a sudden hard pull.

Supplementary Video 4

A honeycomb-like structure fabricated with BIN gel (Rw = 0.22) via 3D printing shows an excellent mechanical performance and elasticity. Despite the micrometre-sized structure of the internal support pillars, the printed BIN gel maintains structural integrity after large and repeated deformations.

Supplementary Video 5

A honeycomb-like structure fabricated with a conventional PEG hydrogel (with 20 wt% PEG diacrylate (Mn = 700 Da), 1.2 wt% LAP and 0.1 wt% tartrazine in aqueous solution) via 3D printing shows an extremely brittle performance. The video is decelerated ×4. The printed PEG gel ruptures immediately once the deformation occurs.

Source data

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bao, B., Zeng, Q., Li, K. et al. Rapid fabrication of physically robust hydrogels. Nat. Mater. 22, 1253–1260 (2023). https://doi.org/10.1038/s41563-023-01648-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41563-023-01648-4

This article is cited by

-

Compliant Iontronic Triboelectric Gels with Phase-Locked Structure Enabled by Competitive Hydrogen Bonding

Nano-Micro Letters (2024)

-

Fatigue-resistant Hydrogels

Chemical Research in Chinese Universities (2024)

-

A portable intelligent hydrogel platform for multicolor visual detection of HAase

Microchimica Acta (2024)