Abstract

This study investigates the potential of surface-patterned membranes in replacing the conventional feed spacer-assisted filtration process. Two types of surface patterns, namely diamond (D) and honeycomb (HC), were utilized in the fabrication of the surface-patterned membranes. These membranes showed larger effective membrane area and higher average porosity when compared to the flat PES membrane. The D-Patterned and HC-Patterned membranes achieved pure water flux of 76.6 ± 16.9 and 88.3 ± 17.4 L m−2 h−1, respectively, which was higher than the flat PES membrane with and without the use of feed spacers. Furthermore, the patterned membranes reported lower natural organic matter (NOM) fouling in short and long-term filtration experiments and higher flux recovery ratio (FRR), indicating their superior anti-fouling performance over the PES membrane when using feed spacers. Overall, the simple fabrication technique, higher permeability, and excellent anti-fouling performance of the surface-patterned membranes render them suitable for potentially replacing the current configuration used in spacer-assisted filtration processes.

Similar content being viewed by others

Introduction

Pressure-driven membrane filtration processes play an important role in the production of drinking water from different sources which can help to alleviate the global water shortage1. The sustainable operation of these processes requires minimizing their energy consumption and improving their operational lifetime2. One key obstacle in achieving this is related to the inevitable membrane fouling that can negatively affect the performance of the filtration process3. Membrane fouling happens when different undesired substances are deposited on the surface and inside the pores of the membrane due to complex chemical or physical interactions4. This complicated phenomenon leads to drastic water flux decline unless the applied pressure is continuously increased which in turn, raises the energy consumption5. The severity of membrane fouling can be reduced using different techniques including physical and chemical cleaning, pre-treatment, and modification of membrane surface, among others6,7,8. Nevertheless, these techniques are often costly, require safe handling of cleaning chemicals, and become ineffective in restoring the optimal performance of the membrane after several cleaning cycles9. Alternatively, hydrodynamic methods that control the behavior of feed flow near the membrane surface, can alleviate membrane fouling without the need for chemical and physical treatments10. Two different approaches have been used to achieve this in membrane filtration processes. The first approach involves the use of nano or micro-sized patterns on the membrane surface fabricated using the so-called Template-based Micromolding (TBµM) such as Phase Separation Micromolding (PSµM), Solution Casting Micromolding (SCµM), Nanoimprint Lithography (NIL), etc11. Such patterns can improve the anti-fouling performance of the membranes by enhancing turbulence that can eventually reduce the interaction between the membrane surface and foulants. For example, Maruf et al. used the NIL to create grating patterns with an average height of 0.10–0.12 μm on ultrafiltration (UF) membrane12. The patterned UF membrane reported slightly lower clean water flux (i.e., 2.80% less than the flat membrane) due to the tightening of the pore structure that occurred after the NIL process. Nevertheless, it had lower Bovine serum albumin (BSA) fouling when compared to the flat membrane which was attributed to the back diffusion of the BSA as a result of localized turbulence and/or increased shear stresses12,13. Won et al. used a modified PSµM to fabricate pyramid or prism surface-patterned Microfiltration (MF) membranes with ~8.00–10.00 μm features14. In their study, the patterned membranes exhibited higher water flux (~20.0% larger than the flat membrane) and increased resistance to microbial adhesion due to the induced local turbulence. In another study, Baramblu et al. fabricated wavy membrane surface using wavy flow channel to help in generating local mixing and swirling flows near the membrane surface15. This led to lower membrane fouling and ~34.0% improvements in clean water flux when compared to the flat membrane. Similar observations were reported in other studies found in the literature16,17,18,19,20,21. Notwithstanding these advancements, the surface-patterned membranes remain prone to defects during the process of membrane patterning. Additionally, prolonged exposure to high-pressure filtrations can cause the gradual loss of these nanoscale and/or microscale patterns over time due to the inherent elasticity of the membranes.

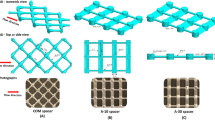

The second approach to hydrodynamically battle fouling is to use feed spacers. Conventional spacers often come in diamond (D) or square nets with filaments crossing or embedded in each other. Their role is to separate the membranes and create the feed flow channel in the Spiral Wound Membrane (SWM) modules. They also promote mixing near the membrane surface, aiding in fouling mitigation22. However, this enhanced mixing is often limited to the narrow open areas between spacer filaments and the membrane surface23. Additionally, at the membrane/spacer contact line and immediate vicinity, mass-transfer coefficients are almost zero leading to a higher concentration polarization (CP) effect and undesirable fouling23. Elevated feed channel pressure (FCP) drop is also another inevitable drawback of using feed spacers that leads to higher energy requirements for the filtration processes24. Additionally, stiff spacers can damage the membrane surface during SWM module manufacturing or high-pressure filtrations. Extensive research has been carried out in this area to tackle such issues through geometrical modification of the feed spacer, modeling and simulation, and more recently, 3D printing of innovative spacers with sophisticated designs24,25,26,27. For example, Gu et al. used computational fluid dynamics (CFD) simulations to study twenty different geometries of feed spacers by varying the spacer’s filament angle and configuration26. Their results showed that fully woven feed spacers with a mesh angle of 60.0° can reduce the CP effect and enhance mass transfer more effectively than other configurations. Nonetheless, a higher FCP drop was observed for this configuration compared to its non-woven counterpart26. Some studies focused more on optimizing the filament thickness and orientation while others utilized 3D printing techniques to create new feed spacer geometries compared to the conventional D and net feed spacers28,29,30,31. For instance, Sreedhar et al. used 3D printing to create feed spacers geometries based on triply periodic minimal surfaces (TPMS)32. The novel feed spacers reported 38.0% mass transfer enhancement, lower FCP drop, and reduced fouling when compared to commercial D feed spacers32.

Despite the significant improvements reported in many of these studies, the feed spacer contact area with the membrane surface and immediate vicinity (i.e., near-zero mass transfer region) and the spacer’s high stiffness are still major challenges. In fact, research on this topic has faced several criticisms since it continuously fails in addressing the aspect of incorporating these innovative/modified spacers into SWMs, especially the possibility of damaging the membrane surface during rolling into the SWM modules33. This is more evident in some spacer designs with sharp edges and lower agility that can damage the flexible membrane, in particular the sensitive selective surface layer33.

In this study, we combine the two hydrodynamic approaches used in fouling mitigation (i.e., surface patterning and feed spacers) to create an efficient membrane filtration process without the use of feed spacers. This is achieved through the fabrication of polyethersulfone (PES) membranes with macro-scale surface patterns that resemble the most commonly used feed spacers, the D feed spacer (Fig. 1). Additionally, a more innovative geometry (i.e., HC) was also used to create a honeycomb surface-pattered membrane. These surface-patterned membranes have a larger surface area than flat-sheet membranes resulting in a higher effective membrane filtration area for the same cell size. Furthermore, since the entire patterned membrane is used for filtration, the near-zero mass transfer regions commonly found in the conventional spacer-assisted filtration processes were minimized. These surface-patterned membranes are effective in producing turbulence and reducing foulant accumulation on the membrane surface, akin to the role played by the feed spacer in the conventional spacer-assisted filtration process, which help in reducing membrane fouling. Lastly, the surface-patterned membranes possess decent mechanical stability that prevents the gradual loss of their patterns over time during membrane filtration. For comparison, HC and D feed spacers were 3D-printed and tested with flat-sheet PES membranes. All membranes were tested for short and long-term fouling using natural organic matter (NOM) from synthetic aqueous solutions at neutral pH. Thermal and mechanical (i.e., flexible) properties of the patterned membranes were also analyzed. A series of DI water and NOM filtrations were carried out and FRR was determined. Furthermore, the patterned membranes were investigated via a series of characterizations including, porosity (ε; %) analysis, mean effective pore size (μP; nm) analysis, and surface morphologies, among others.

Results and discussion

3D printing accuracy and replica molds reusability

The 3D printing accuracy of both spacers and replica molds was assessed by measuring the difference between the designed dimensions in the CAD file and the 3D-printed counterpart (i.e., deviation from design (DfD)). The results shown in Fig. 2a revealed that the DfD was <4.00% for all 3D-printed spacers and molds. For instance, the highest DfD was observed in the 3D-printed D and HC feed spacers filament’s diameter which was around 2.82 ± 0.04% and 3.45 ± 0.06%, respectively. The level of accuracy achieved by this 3D printing process exceeds what has been previously reported in the literature for similar FDM 3D-printed feed spacers34,35. Moreover, in Fig. 2c, an insignificant difference was observed between the different surface-patterned membranes. This demonstrates the reusability of the replica molds which can be attributed to the protective parafilm layer applied on these molds before the polymer blend solution casting. The parafilm acts as a barrier separating the 3D-printed PLA mold from the aggressive NMP solvent used in preparing the polymer blend solution.

a Measured dimensions of 3D-printed spacers/molds and their deviation from design (DfD); b actual images of the 3D printed spacers and molds; c measured average diameter of intrusions in the patterned membranes; d actual and CAD images of the patterned membranes. Error bars represent the standard deviation between ten reported values.

Structural characterization of the fabricated membranes

The surface and cross-sectional morphologies of the fabricated membranes are critical aspects in understanding their performance. Therefore, the top, bottom, and cross-sectional surface morphologies of the fabricated membranes were examined using SEM, and the results are summarized in Fig. 3. All membranes showed porous top surfaces with slightly larger pores in the D-Patterned and HC-Patterned membranes and significantly more porous patterns (Fig. 3a). This surface was referred to as the “top surface” since it will be facing the feed side throughout the UF experiments whereas, during the non-solvent induced phase separation (NIPS) process, it will be in contact with the mold itself (i.e., bottom surface), thus resulting in a more porous surface36.

a Top and bottom surface morphologies; b Cross-sectional surface morphologies of the flat and surface-patterned membranes. Membranes’ thicknesses: control PES membrane ≈ 294 µm, D-Patterned membrane ≈ 1522 µm, and HC-Patterned membrane ≈ 1494 µm. The top 1st and top 2nd SEM images in the D-Patterned and HC-Patterned are taken on the inter-pattern’s space and the pattern’s intersection, respectively.

The side exposed to the nonsolvent during the NIPS process (i.e., bottom surface in Fig. 3a) showed a very dense, defect-free surface with significantly smaller pores37. This can be explained by the thermodynamic instability of the polymer solution in the presence of PVP which results in immediate demixing at the nonsolvent/polymer solution interface38. This leads to the formation of a denser thin layer (i.e., skin layer) at the top surface with nanopores and a sublayer with finger-like voids as shown in the magnified cross-sectional image in Fig. 3b37. In contrast, the solvent (i.e., NMP) and PVP within the replica mold take a longer time to diffuse through the entire membrane towards the nonsolvent, leading to the formation of a second sublayer with macro-voids and more open structure (Fig. 3b)39,40. This delayed demixing is more evident in the patterns in both the HC-Patterned and D-Patterned membranes as they will be the last to achieve complete precipitation. Such extended duration causes the formation of a porous sponge-like structure with more open pores in the second sublayer skeleton as shown in the cross-sectional images in Fig. 3b41. Lastly, the EDS spectrum of the flat and patterned membranes shows a typical spectrum of PES membranes with S, C, and O elements peak at around Kα = 2.31, 0.28, and 0.53 keV, respectively (Supplementary Fig. 1).

To further understand the change in pore size and intrinsic porosity of the fabricated membranes, the average porosity (ε; %) and molecular weight cut-off (MWCO) were measured and the results are displayed in Fig. 4a. As can be seen from the figure, the ε increased from 38.4 ± 2.9% in the flat PES membrane to 46.1 ± 3.6% and 49.4 ± 3.2% in the D-Patterned and HC-Patterned membranes, respectively. Moreover, the ANOVA test results showed that the ε values of both the D-Patterned and HC-Patterned membranes were statistically different than the ε of flat PES membrane. The MWCO increased from around 390 kDa in the flat PES membrane to 860 and 880 kDa in the D-Patterned and HC-Patterned membranes, respectively. Similarly, the mean effective pore size (μP) increased from 15.4 ± 2.2 nm in the flat PES membrane to 24.1 ± 2.5 and 23.5 ± 2.5 nm in the D-Patterned and HC-Patterned membranes, respectively, as calculated from the Supplementary Fig. 2. These results are comparable to the reported results for PES and other ultrafiltration (UF) membranes in the literature42,43,44,45,46. The incorporation of surface patterns on the PES membrane has a noticeable impact on its morphology and structure. The presence of patterns slows down the phase inversion rate during the NIPS process, which hinders the advancement of the finger structures from the interface between the polymer solution and the non-solvent towards the bottom surface. This slower phase inversion rate results in a porous, sponge-like structure with more open pores in the sublayer skeleton, which eventually leads to increased average porosity and pore size of the formed membranes40. This is also evident from the pore size distribution curve presented as a probability density function that showed a broader pore distribution for both D-Patterned and HC-Patterned membranes (Supplementary Fig. 2d). Overall, larger pore size allows larger molecules to pass through the membrane, resulting in larger MWCO of the surface-patterned membranes.

The hydrophilicity of the fabricated membranes was determined through static and dynamic water contact angle (WCA) measurements as well as the membrane surface free energy (-ΔGSL)47. Lower WCA and higher -ΔGSL values indicate higher hydrophilicity of the membrane surface which can improve the water permeation and antifouling properties47. In general, the hydrophilicity of a surface is determined by its chemical composition and the degree to which it can interact with wetting liquid molecules. Both D-Patterned and HC-Patterned membranes reported slightly lower WCA and higher -ΔGSL than the flat PES membrane as shown in Fig. 4b, c. However, these results were statistically not different than the WCA result of flat PES membrane. All membranes are made of PES and therefore, there will be no change in the chemical composition between different membranes. Nevertheless, the slight improvement in the hydrophilicity of the surface-patterned membrane is possibly related to their higher porosity. This creates additional sites where capillary forces can assist in water molecule infiltration, leading to enhanced water uptake by the membrane and ultimately resulting in improved hydrophilicity48.

The synergistic improvements in hydrophilicity and average porosity were reflected in the pure water flux of the patterned membranes during the UF experiments. Both D-Patterned and HC-Patterned membranes reported water flux of 76.6 ± 16.9 and 88.3 ± 17.4 L m−2 h−1, respectively, compared to 52.5 ± 6.3 L m−2 h−1 in the case of the flat PES membrane (Fig. 4d). These enhancements in water flux can also be related to the improved turbulence in the boundary layer near the membrane surface by the HC and D patterns24,30. It is generally known that using feed spacers can improve the mass transfer across the membrane due to the created turbulence near the membrane surface. For example, using the D and HC 3D-printed feed spacers with the flat PES membrane led to 12.6% and 30.5% improvements in the water flux, respectively, compared to the PES membrane alone (i.e., empty feed channel) (Fig. 4d). The superiority of HC Spacers over the D Spacer is mainly attributed to the higher and well-distributed shear stress generated near the surface of the membrane compared to less intense and less uniform shear stresses in the D spacer49,50. Furthermore, the HC Spacers can cause frequent fluctuations in crossflow velocity leading to improved local mass transfer50. For these reasons, larger water permeation was observed in the HC-Patterned membrane compared to the D-Patterned membrane as shown in Fig. 4d. Another reason for the higher water permeation in the patterned membranes compared to both flat PES and spacer-assisted membrane filtrations is attributed to the increase in their effective surface area. For instance, D-Patterned and HC-Patterned membranes exhibited ≈32.0% and ≈29.0% larger effective surface area, respectively, compared to the flat PES membrane. Analogous observations were reported in the literature for micro-patterned membranes40,51.

Mechanical and thermal analyses were carried out to evaluate the impact of patterns on the PES membrane properties. These properties have a direct impact on the membrane’s lifetime and stable performance under harsh operating conditions52. As can be observed in Fig. 5a, both patterned membranes reported higher elongation-at-break (EAB) values than the flat PES membrane. This provides significant evidence that the introduction of patterns on the membrane surface didn’t compromise the PES membranes’ elasticity. Therefore, the patterned membranes can be simply wrapped around (Fig. 5c, d) and stacked in a similar way to the SWM module. The higher EAB values of the patterned membranes can be related to the presence of a sponge-like structure in the membrane as seen earlier from the SEM images. This layer has higher mechanical integrity, thus providing the patterned membranes with improved elastic properties53,54.

The thermal decomposition behavior of the patterned membranes showed no obvious changes compared to the flat PES membrane, despite the slight improvement in the decomposition temperature (Td) (Fig. 5b). This confirmed the thermal stability of the patterned membranes, thus their suitability for UF experiments. The decomposition stages of the PES polymer are discussed in detail elsewhere in the literature55.

Pressure drop evaluation

The pressure loss across the feed channel is a significant factor in the pressure-driven membrane filtration processes as it has a direct correlation with the amount of energy consumed in the process. Figure 6 shows the pressure drop in mbar when using the patterned membranes and 3D-printed feed spacers in UF experiments. This pressure drop was also calculated for the spacer-less channel using the PES membrane alone and used as a reference in determining the pressure drop increase shown in Fig. 6b. The use of feed spacers is almost always accompanied by an increase in the feed channel pressure drop due to the resistance encountered by the fluid while flowing over the spacer’s filaments30,56. As displayed in Fig. 6a, the pressure drops observed when using the 3D-printed feed spacers (i.e., D and HC Spacers) were higher than the patterned membranes over the entire crossflow velocity range. This can be attributed to the presence of back vortices and turbulent eddies created near the solid spacer filament and between the inter-filament spacing at higher crossflow velocities as illustrated in Fig. 6c57,58. These eddies create pockets of low pressure and create additional obstacles for the fluid to navigate around the spacer’s filament which causes the fluid to slow down and eventually, leads to increased pressure drop. On the other hand, the porous patterns in the patterned membranes reduce the fluid resistance by allowing part of the fluid to pass through the porous membrane. This causes drag reduction due to the formation of finite velocity at the porous patterned surfaces and delays the fluid separation as it promotes the formation of turbulent boundary layers on the patterns. The presence of a turbulent boundary layer retains higher kinetic energy compared to a laminar boundary layer, leading to reduced shear stress at the fluid-surface interface and resulting in lower pressure and frictional drags. These factors reduce the formation of turbulent eddies and back vortices, thus causing a lower pressure drop than the solid 3D-printed feed spacers. This is also evident from the pressure drop increase shown in Fig. 6b when compared to the pressure drop in the spacer-less channel. For instance, at a crossflow velocity of 0.88 m s−1, the pressure drop increases for the D-Patterned, HC-Patterned, D Spacer, and HC Spacer were 18.8, 6.25, 25.1, and 12.5%, respectively. Increasing the crossflow velocity to 1.47 m s−1 led to a further increase in the pressure drop to as high as 23.5, 11.8, 35.3, and 32.4% for the D-Patterned, HC-Patterned, D Spacer, and HC Spacer, respectively. Furthermore, the HC-Patterned membrane exhibited a smaller impact of crossflow velocity on the pressure drop compared to the other tested membranes. This can be attributed to the unique surface pattern and geometry of the HC-Patterned membrane, which could affect the flow dynamics and the interaction between the fluid and the membrane surface. HC patterns can provide better shear stress distribution and turbulence within the region enclosed by the HC pattern itself. For instance, in a comparison between HC and D spacers made by Park et al., numerical results showed that the HC spacer exhibits lower shear stress near the spacer’s filaments and higher magnitude of turbulence in the space enclosed by the spacer’s filaments50. Similarly, Yanar et al. showed that HC spacer design enables the shear stress on the membrane surface to be more equally and effectively distributed compared to commercially available spacer49. Although the relationship between shear stress distribution and pressure drop can be complex and dependent on many other factors, pressure drop is significantly affected by energy dissipation due to fluid shearing on the membrane59. Therefore, better distribution of shear stress can reduce the energy dissipation and eventually, reduce the impact of crossflow velocity on pressure drop. It is worth mentioning that the pressure drops observed during the spacer-less feed channel experiment (i.e., using PES membrane only) is related to the geometrical properties of the filtration setup shown in Supplementary Fig. 6.

Membrane fouling, long-term durability, and fouling reversibility

Synthetic NOM solution with different concentrations was used to evaluate the fouling behavior of the fabricated membranes. Figure 7a shows the relative flux of all fabricated membranes during the filtration experiment using a low-foulant NOM solution. It can be seen that the HC and D-Patterned membranes exhibited the lowest flux decline compared to the 3D-printed HC and D spacers. For instance, by the end of the first hour of filtration, the HC and D-Patterned membranes reported a flux decline of around 58.0 and 71.0%, respectively (Fig. 7b). On the other hand, filtration using the 3D-printed HC and D spacers reported a flux decline of around 73.0 and 78.0%, respectively. The highest flux decline of 85.0% was observed when using the PES membrane alone. At the end of the 6-hr experiment, the HC-Patterned membrane showed the highest relative flux (i.e., lowest flux decline) of around 22.0% compared to 9.80 and 4.40% in the HC Spacer and PES membrane, respectively. These trends indicate that membrane fouling initially occurs due to pore blockage and then continues as a result of additional cake layer formation in the later stages60. Analogous trends were observed when using high-foulant NOM solution during the filtration experiment over an extended duration (Supplementary Fig. 4b). However, the fabricated membranes were exposed to more severe fouling (i.e., flux decline) caused by the higher NOM-calcium complexation. Overall, the patterned membranes and PES membrane with 3D-printed feed spacers reported superior performance over the PES membrane alone in both fouling experiments. This can be explained by the formation of turbulent eddies and back vortices at the center of the cell as shown in Fig. 7c. The incoming feed splits into several streams by the spacer’s/pattern’s intersection and then merges to form small-scale eddies and back vortices, which ultimately transit to the turbulent regime. This turbulence pushes the NOM foulants away from the membrane surface back into the bulk solution and reduces their interaction with the membrane57,61. Furthermore, in the patterned membranes, the improved anti-fouling performance over the 3D-printed feed spacers can be attributed to the difficulty of forming strong cake layers on the patterns due to the higher shear stress gradient that often exists as a result of the no-slip boundary condition (Fig. 7c). Several studies reported higher shear forces at the patterns’ peaks and the formation of vortices in the immediate vicinity, thus, alleviating the formation of a strong fouling layer on these patterns18,51,62,63. The superior performance of the HC-Patterned membrane over the D-Patterned membrane can be related to the improved shear stress distribution and turbulence generated near the membrane surface and within the region enclosed by the HC pattern. This was proven numerically by Park et al. where the unique geometry of the HC spacer led to a higher magnitude of turbulence in the areas enclosed by the filaments49,50. It is worth mentioning that the patterned membranes also showed a noticeably lower initial flux as shown in Supplementary Fig. 4a. The reason for this is related to the patterned membranes’ larger pore size which makes them more susceptible to blockage and constriction at the start of the NOM filtration, thus having a greater impact on the initial flux64.

a Relative flux (J2/J1) over a short filtration period and low-foulant NOM solution; b magnified image of the first hour of low-foulant NOM filtration; c schematic illustration of the possible anti-fouling mechanisms. Relative flux curves are an average of three membrane samples. A fresh set of membranes was used in this experiment.

The initial NOM rejection was 73.8 ± 0.9, 75.3 ± 0.8, and 81.8 ± 0.5% for the D-Patterned, HC-Patterned, and PES membranes, respectively. This rejection increased to 85.5 ± 1.3, 89.6 ± 0.9, and 93.4 ± 0.7% after the first hour of operation and did not change significantly over the remaining filtration duration. Such an increase in the NOM rejection can be related to blockage of the larger pores at the start of the experiment and later on the formation of a porous cake layer on the membrane surface60,65. Therefore, the mean pore size of the membranes was affected, leading to higher NOM rejection with time. It is worth mentioning that the main NOM rejection mechanism in all membranes was size exclusion66,67. Furthermore, at the end of both 6-hr and 12-hr experiments, the HC-Patterned, D-Patterned, HC, D spacers, and PES membranes exhibited a significant flux decline. This indicated the necessity of the membrane cleaning step in an attempt to restore the original performance of the fabricated membranes. Therefore, the membrane samples used in the 6-hr NOM filtration experiment were tested under three consecutive 6-hr NOM filtration cycles. After each cycle, chemical cleaning using 2000 ppm NaOCl solution (pH = 11.0) and washing with ultrapure water were used.

The results shown in Fig. 8a, b indicated better fouling resistance in the case of the patterned membranes compared to the PES and 3D-printed feed spacers. For instance, the FRR of the D-Patterned and HC-Patterned in the first filtration cycle was 95.4 ± 0.6 and 93.4 ± 0.1%, respectively, whereas the PES membrane, D Spacer, and HC Spacer reported 86.8 ± 1.4, 88.3 ± 0.5, and 93.7 ± 1.2%, respectively (Fig. 8b). Once again, at the apex of the patterns in the patterned membranes, higher shear forces minimize the deposition of foulants on these surfaces and therefore, improve the overall anti-fouling performance. Images of the membranes after the 6-hr filtration and subsequent cleaning are shown in Supplementary Fig. 5a, b, respectively. Overall, the recovered pure water flux of all membranes decreased with filtration cycles indicating an increased percentage of irreversible fouling which is in tune with previous studies64,66. A comparison between the results reported in this study and others found in the literature is provided in Supplementary Table 1.

In Summary, this research study investigated the potential of developing an efficient spacer-less filtration process through the synthesis of surface-patterned membranes that bear resemblance to the widely employed feed spacers, such as the D feed spacer. These patterns offer several advantages for the filtration process as they enable a larger effective filtration area, (i.e., ≈29.0–32.0% larger than a flat PES membrane), which enhances water permeation. For example, the D-Patterned and HC-Patterned membranes achieved ultrapure water flux of 76.6 ± 16.9 and 88.3 ± 17.4 L m−2 h−1, respectively, compared to 52.5 ± 6.3, 59.1 ± 8.7, and 68.5 ± 15.8 L m−2 h−1 in the case of flat PES membrane, D feed spacer, and HC feed spacer. The surface patterns can also improve the anti-fouling performance of the membranes by promoting turbulence near the membrane surface, akin to the role played by the feed spacer in the conventional feed-spacer filtration process. This turbulence pushes the NOM foulants away from the membrane surface back into the bulk solution and reduces their interaction with the membrane surface. Therefore, the patterned membranes reported lower NOM fouling and flux decline over short and long-term filtration experiments when compared to the flat PES membrane, D feed spacer, and HC feed spacer. This was also attributed to higher shearing forces at the patterns’ peaks and the formation of vortices in their immediate vicinity. Furthermore, since the entire surface-patterned membranes are flexible, there will be no risks of damaging the membrane surface during manufacturing or high-pressure filtrations. Overall, our endeavor has the potential to pave the way for future advancements in the development of similar membranes for integration into actual membrane modules.

Methods

Materials and chemicals

Polyethersulfone (PES, Mw = 58,000 g mol−1) was purchased from Goodfellow Cambridge Limited, United Kingdom. Poly(vinylpyrrolidone) (PVP; Mw: 40,000 g mol−1), sodium hydroxide (NaOH; Mw: 39.99 g mol−1), hydrochloric acid (HCl; 36.0-38.5%), calcium chloride anhydrous (CaCl2; ≥93.0%), humic acid (HA; technical grade), bovine serum albumin (BSA; 66,000 g mol−1), sodium alginate (SA), 1-Methyl-2-pyrrolidone EMPLURA® (NMP; Mw: 99.1 g mol−1), absolute ethanol EMSURE®, di-sodium hydrogen phosphate EMSURE® (Na2HPO4; Mw = 141.96 g mol−1), sodium dihydrogen phosphate dihydrate EMSURE® (NaH2PO4.H2O; Mw = 156.01 g mol−1), Polyethylene glycols (PEG) with Mw of 6000, 8000, and 35,000 g mol−1, polyethylene oxide (PEO) with Mw of 300,000 and 900,000 g mol−1 were all received from Sigma-Aldrich, USA. Analytical grade sodium chloride (NaCl; Mw = 58.44 g mol−1) was acquired from Fisher Scientific. Tough black polylactic acid Ultimaker® (PLA) was provided by Precise Trading LLC, UAE. Sodium hypochlorite (NaOCl) in the form of a commercial bleach solution (5.25%) was obtained from a local supplier. All mixtures were prepared using ultrapure water produced from a Milli-Q® IQ 7015 water purification system. Non-woven polypropylene/polyethylene (PP/PE) membrane support (Novatexx 2471; thickness = 180.0 µm) was obtained from Freudenberg-Filter, Germany. All chemicals and materials were used as received.

3D printing of feed spacers and replica molds

Two different geometries for master molds inspired by the commercial D spacer and an innovative HC spacer were prepared using Autodesk® Fusion360 software (Fig. 9). Initially, feed spacers were designed and used to create intrusions in the molds shown in Fig. 9 using the split body command in the software. The width of patterns (i.e., 1.64 mm) was larger than the depth (i.e., 1.10 mm) since the parafilm coating and lateral shrinkage during the non-solvent induced phase separation (NIPS) process will result in ≈1.10 mm thick patterns. Therefore, feed spacers with 1.10 mm filament diameter (dF) were designed and used for comparisons. All Computer-aided design (CAD) files were then converted to stereolithography format (STL) and fed into Ultimaker® Cura software which is used in determining the desired 3D printing parameters and slicing and 3D models. The output file was then used to 3D-print the molds and spacers using fused deposition modeling (FDM) Ultimaker® S3 3D printer with single extrusion of tough black PLA filament. All molds and spacers were gently smoothened using sandpaper to remove any defects or sharp/rough edges. To investigate the 3D printing accuracy, three spacers and molds of each type were fabricated and dimensions (i.e., dF, pattern width, and depth) were measured at ten different points using a digital Vernier caliper. Average values were reported and deviation from the design (DfD; %) was calculated using Eq. (1):

Where davg is the average dimension in mm (either dF, pattern width, or pattern depth) of the 3D printed mold/spacer and dd is the corresponding design dimension in mm.

Fabrication of the flat and surface-patterned membranes

All membranes were prepared following the non-solvent induced phase separation (NIPS) fabrication process from a dope solution consisting of 16.0 wt% PES, 2.00 wt% PVP, and 82.0 wt% NMP68 as shown in Fig. 10. These optimum concentrations were chosen based on our previous work37,69. The PES pellets and PVP filler were first dried in a vacuum oven at 70 °C for 2 h to remove any entrapped moister. Once dried, the PVP filler (with its predetermined wt%) was dissolved in NMP for 30.0 mins under continuous stirring at room temperature (≈24.0 °C). Following that, the PES pellets were gradually added to the mixture while mixing at 400 rpm and left for 24.0 h to completely dissolve to achieve a homogenous polymer blend solution. This solution was sonicated using an ultrasonication setup (Branson Ultrasonics™, CPX3800H-E) for 30.0 mins, degassed in the same setup for 90.0 mins, and then left to rest for 24 h to remove any entrapped air bubbles. Before casting, all PLA patterned replica molds were covered with parafilm using a vacuum setup to create an insulating layer between the mold and bubble-free polymer blend solution (Fig. 10). A 600 µm edge was created on the replica mold to prevent the polymer solution from escaping during the casting process. All patterned replica molds were fixed on a glass plate and then the polymer blend solution was poured directly onto the mold and uniformly spread with a casting knife. An adequate piece of non-woven membrane support was gently placed on the cast solution to help create a less dense top layer. Lastly, the glass plate, together with the replica mold, was immediately immersed in an ethanol/ultrapure water (1:1 ratio) coagulation bath for 24 h. The patterned membranes were then released from the replica molds and washed several times with ultrapure water to remove any traces of NMP and other impurities. For comparison, a replica mold with no patterns was used to prepare flat-sheet PES membranes following the same procedure mentioned above. All prepared membranes were stored in ultrapure water until used. The membrane with a D spacer pattern was denoted as D-Patterned whereas the one with a HC spacer pattern was denoted as HC-Patterned. Furthermore, the control flat-sheet membrane was referred to as PES Membrane and was used with and without 3D-printed feed spacers. For characterization purposes only, support-free flat and patterned PES membranes were also prepared following the same steps mentioned above. A schematic illustration of the fabrication process is shown in Fig. 10.

Replica mold reusability

To assess the reusability of the replica mold, the patterned membranes were fabricated using the same mold three times. The thickness of the intrusions (i.e., diameter) at ten different locations was measured using a digital Vernier caliper for both D-Patterned and HC-Patterned membranes, and average values were reported. The deviations between the initially fabricated patterned membrane and the other two replicas were determined.

Characterization of fabricated membranes

A series of extensive characterizations were performed on both the flat-sheet and patterned membranes. High-resolution scanning electron microscope (SEM) (ThermoFischer™ Quanta 450 FEG) was used to examine the surface and cross-sectional morphologies of the fabricated membranes. Before the inspection, a thin layer of gold was applied to all membrane samples using a Ted Pella sputter coater to prevent charging and enhance surface imaging. It is worth mentioning that the surface facing the mold is used as the top surface in the filtration experiments since it has all the patterns. This surface is referred to as the top surface in the SEM images. Furthermore, the top and bottom surfaces in the D-Patterned and HC-Patterned membranes are taken on the inter-pattern’s space and the pattern’s intersection. The cross-sectional membrane samples were prepared following the freeze-fracture method using liquid nitrogen. The samples were submerged in liquid nitrogen for a certain time and gently broken using a flat-tip tweezer. Carbon tape with a strong adhesive side was used to fix all samples on the SEM stubs. The elemental composition of the produced membranes was studied using Energy Dispersive X-ray (EDS) spectroscopy at an acceleration voltage of 20.0 kV. The mechanical properties of the membranes were measured using the Universal Testing System (5965 model, Instron, US). Several sample strips measuring 65.0 × 10.0 mm (L×W) were cut using a precision film-cutting tool. Each sample was loaded onto the Instron 5960 machine and secured using rough grips where the middle section measuring 20.0 × 5.00 mm (L×W) was the only section exposed to the load. A cross-head velocity of 0.50 mm min−1 at room temperature was used in all measurements. Furthermore, the elongation at break (EAB; %) was determined as the ratio between the displacement at sample break (mm) and initial sample length exposed to load (mm). The thermal stability of the membranes was evaluated using thermogravimetric analysis (TGA) via TG 209 F3 Tarsus® (NETZSCH, Germany). The temperature range of 25–800 °C was used to measure the weight loss of membrane samples due to thermal decomposition. The samples were heated to 800 °C at a heating rate of 15.0 °C min−1 under a protective nitrogen flow of 20.0 mL min−1. Both dynamic and static water contact angles (WCA) were measured using Drop Shape Analyzer (DSA) tool (DSA 100 S, Krüss Scientific, Germany) using 10.0 μL DI water droplets ejected from a micro-syringe. The WCA was measured at three different locations in each sample and average values were reported. One-way complete statistical analysis of variance (ANOVA) test at a confidence level of 95% was applied to the results of WCA. Young-Dupre equation (Eq. (2)) was used to calculate the surface free energy (-ΔGSL) as the following37:

Where γL represents the surface tension of water (72.8 mJ m−2) and θ represents the water CA. Furthermore, the average porosity (ε; %) of all membrane samples was determined following a simple gravimetric method70,71. All samples were cut into 20.0 mm desks and dried in a vacuum oven at 70 °C for 48 h before any weight measurements. Furthermore, since the patterned membranes are not uniform in thickness due to their geometrical properties, their total volume was used in the membrane porosity calculations. This was determined from the density of the fabricated membrane which was calculated by measuring the weight of the dry flat membrane and its thickness. The average porosity was calculated using Eq. (3) and a one-way complete statistical analysis of variance (ANOVA) test at a confidence level of 95% was applied to these results.

Where VT = Am × δ for the flat membrane sample and WdP/ρF for the patterned membranes. Ww and Wd represent the weight of the wet and dry membranes (g), Am and δ are the effective membrane area (cm2) and flat membrane thickness (cm), respectively. WdP is the weight of the dry patterned membrane (g) and ρF is the density of the fabricated membrane (g cm−3). Lastly, ρG is the density of the wetting liquid (Galwick; 1.83 g cm−3).

The mean effective pore size (μP; nm), molecular weight cut-off (MWCO; kDa) defined as the molecular weight of the solute at which the rejection is 90%, and pore size distribution of all membrane samples were evaluated using the solute separation method72,73. Further details on this method can be found in Supplementary Note 1. Briefly, different solutions consisting of 200 mg L−1 of PEG or PEO with different molecular weights were prepared and filtered through the membranes. Equation (4) was then used to calculate the solute rejection (R; %) by measuring the concentration of solute in both the feed (CF; mg L−1) and permeate (CP; mg L−1) using Total Organic Carbon (TOC) machine (Sievers InnovOx TOC Analyzer).

Pressure drop experiments

The pressure drop experiments were carried out in a lab-scale setup consisting of a 5 L feed container connected to a gear pump drive (Cole-Parmer® Inc., USA) equipped with a gear pump head (L18428, Micropump® Inc., USA), flow meter (F-55376LA, Blue-White Industries® Ltd., USA), a testing cell with 79.0 × 50.0 mm2 active membrane area (A7 Cell, Convergence Inspector, The Netherlands), and two sensitive digital pressure gauges (resolution 0.001 bar, accuracy ±1.00% F.S., range 0.00–1.00 bar). The 3D-printed spacers, flat membrane, and patterned membranes were loaded into the feed side of the cell whereas a flat porous plate was placed in the permeate channel to prevent the membrane from bending. The ultrapure water flow was varied between 0.75 to 3.00 liters per min (LPM) which corresponds to a crossflow velocity of 0.45 to 1.77 m s−1, thus covering a wide range of membrane systems operated commercially. The pressure at the feed and retentate sides (i.e., across the cell) was recorded and used in determining the pressure drop. An image of the setup is shown in Supplementary Fig. 6. The pressure drop increase percentage was also calculated relative to the pressure drop observed in the spacer-less experiment (i.e., empty feed channel) using Eq. (5)

Where PE is the pressure drop observed in the empty feed channel (mbar) and Pj is the pressure drop observed in a spacer-filled feed channel or using patterned membranes (mbar).

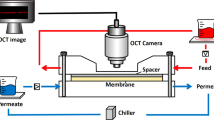

Ultrapure water flux and long/short-term fouling experiments

All UF tests were conducted using a crossflow system (UF Hydra, Convergence Inspector, The Netherlands). This system is fitted with several flow and pressure sensors, pumps, and data acquisition software. A downscaled version of the A7 Convergence Inspector cell with a membrane-active area measuring 45.0 × 30.0 mm2 was used with this system. Prior to any filtration experiments, the fabricated membranes were compacted for 2 h by filtering ultrapure water at transmembrane pressure (TMP) of 2.00 bars and feed flowrate of 7.00 L h−1. At the end of compaction, pure water flux (Jw; L m−2 h−1) was measured at 1 bar and calculated using Eq. (6):

Where Vw is the filtered water volume (L), A is the effective membrane surface area (m2), and Δt is the filtration time (hr). The effective surface area of the patterned membranes was determined using the open-source ImageJ software (NiH, USA), while for the flat membranes, it was calculated mathematically.

This pure water flux experiment was repeated three times for different membrane samples fabricated on different days and average values were reported. The pre-compacted membranes were then tested for natural organic matter (NOM) rejection as well as low-fouling short-term (i.e., 6 h) and high-fouling long-term (i.e., 12 h) filtration experiments. The synthetic NOM solution was prepared following well-described procedures in the literature74. Briefly, solutions consisting of 50.0 mg of BSA, SA, and HA dissolved in 10.0 mM phosphate buffer solution (pH = 7.00), ultrapure water, and 0.10 NaOH solution, respectively, were prepared. The HA solution pH was adjusted to 7.00 using 0.50 and 5.00 M HCl solutions to limit the ionization of ionogenic groups75. The NOM mixture was then prepared by mixing 50.0 mg L−1 of BSA, SA, and HC solutions with a solution consisting of 1.00 mM CaCl2 and 7.00 mM NaCl in ultrapure water (1:1 ratio). This solution was referred to as a low-foulant NOM solution whereas a high-foulant NOM solution was prepared using 200 mg L−1 BSA, SA, and HA solutions following the exact procedures. The NOM size distribution (Supplementary Fig. 7) was determined using a laser diffraction instrument (Malvern Mastersizer 3000, Malvern, UK). The fouling experiments were conducted such that both permeate and retentate were recirculated back to the feed tank under continuous stirring to minimize the variation in the feed solution concentration throughout the filtration duration (i.e., 6 or 12 h). The feed solution flowrate was set to 7.00 L h−1 while fixing the TMP to 1.00 bar. The flux decline was then monitored for the entire duration of the experiment and relative flux was calculated using Eq. (7):

where J2 represents the varying flux during the NOM filtration experiment in L m−2 h−1 and J1 is the initial flux (L m−2 h−1).

The NOM rejection was evaluated by measuring the TOC content of the feed solution and permeate samples collected at different times using the TOC machine analyzer. Similar to the pure water flux experiments, the low-fouling and high-fouling experiments were repeated three times for different membrane samples, and average values were reported.

Reusability of the fabricated membranes

To evaluate the reusability and antifouling behavior of the fabricated membranes, three cycles of low-fouling and chemical cleaning were carried out. The fouled membranes were cleaned by initially washing them with ultrapure water and then submersion in 2000 mg L−1 NaOCl solution (pH = 11.0) for 1 h. The membranes were then washed several times with ultrapure water and retested for pure water flux. The antifouling behavior was then evaluated by determining the flux recovery ratio (FRR; %) calculated using Eq. (8):

Where Jc represents the ultrapure water flux of the cleaned membrane (L m−2 h−1) and Jw represents the pure water flux of the pristine membrane (L m−2 h−1).

Data availability

All data generated or analyzed during this study are included in this published paper and its supplementary information files.

References

Giwa, A. et al. Biomimetic membranes: a critical review of recent progress. Desalination 420, 403–424 (2017).

Ahmed, F. E., Khalil, A. & Hilal, N. Emerging desalination technologies: current status, challenges and future trends. Desalination 517, 115183 (2021).

Goh, P. S., Lau, W. J., Othman, M. H. D. & Ismail, A. F. Membrane fouling in desalination and its mitigation strategies. Desalination 425, 130–155 (2018).

AlSawaftah, N., Abuwatfa, W., Darwish, N. & Husseini, G. A comprehensive review on membrane fouling: mathematical modelling, prediction, diagnosis, and mitigation. Water 13, 1327 (2021).

Nassrullah, H., Anis, S. F., Hashaikeh, R. & Hilal, N. Energy for desalination: a state-of-the-art review. Desalination 491, 114569 (2020).

Rahmawati, R. et al. Engineered spacers for fouling mitigation in pressure driven membrane processes: progress and projection. J. Environ. Chem. Eng. 9, 106285 (2021).

El Batouti, M., Alharby, N. F. & Elewa, M. M. Review of new approaches for fouling mitigation in membrane separation processes in water treatment applications. Separations 9, 1 (2021).

Ruigómez, I., González, E., Rodríguez-Gómez, L. & Vera, L. Fouling control strategies for direct membrane ultrafiltration: physical cleanings assisted by membrane rotational movement. Chem. Eng. J. 436, 135161 (2022).

Hacıfazlıoğlu, M. C., Parlar, İ., Pek, T. Ö. & Kabay, N. Evaluation of chemical cleaning to control fouling on nanofiltration and reverse osmosis membranes after desalination of MBR effluent. Desalination 466, 44–51 (2019).

Belfort, G. Membrane modules: comparison of different configurations using fluid mechanics. J. Membr. Sci. 35, 245–270 (1988).

Heinz, O., Aghajani, M., Greenberg, A. R. & Ding, Y. Surface-patterning of polymeric membranes: fabrication and performance. Curr. Opin. Chem. Eng. 20, 1–12 (2018).

Maruf, S. H. et al. Influence of sub-micron surface patterns on the deposition of model proteins during active filtration. J. Membr. Sci. 444, 420–428 (2013).

Ding, Y., Maruf, S., Aghajani, M. & Greenberg, A. R. Surface patterning of polymeric membranes and its effect on antifouling characteristics. Sep. Sci. Technol. 52, 240–257 (2017).

Won, Y.-J. et al. Preparation and application of patterned membranes for wastewater treatment. Environ. Sci. Technol. 46, 11021–11027 (2012).

Barambu, N. U. et al. A wavy flow channel system for membrane fouling control in oil/water emulsion filtration. J. Water Process. Eng. 44, 102340 (2021).

Jung, S. Y. et al. Particle deposition on the patterned membrane surface: simulation and experiments. Desalination 370, 17–24 (2015).

Maruf, S. H., Wang, L., Greenberg, A. R., Pellegrino, J. & Ding, Y. Use of nanoimprinted surface patterns to mitigate colloidal deposition on ultrafiltration membranes. J. Membr. Sci. 428, 598–607 (2013).

Lee, Y. K., Won, Y.-J., Yoo, J. H., Ahn, K. H. & Lee, C.-H. Flow analysis and fouling on the patterned membrane surface. J. Membr. Sci. 427, 320–325 (2013).

Maruf, S. H., Greenberg, A. R., Pellegrino, J. & Ding, Y. Critical flux of surface-patterned ultrafiltration membranes during cross-flow filtration of colloidal particles. J. Membr. Sci. 471, 65–71 (2014).

Won, Y.-J. et al. Correlation of membrane fouling with topography of patterned membranes for water treatment. J. Membr. Sci. 498, 14–19 (2016).

Shang, W. et al. Understanding the influence of hydraulic conditions on colloidal fouling development by using the micro-patterned nanofiltration membrane: Experiments and numerical simulation. J. Membr. Sci. 654, 120559 (2022).

Abid, H. S., Johnson, D. J., Hashaikeh, R. & Hilal, N. A review of efforts to reduce membrane fouling by control of feed spacer characteristics. Desalination 420, 384–402 (2017).

Koutsou, C. P., Yiantsios, S. G. & Karabelas, A. J. A numerical and experimental study of mass transfer in spacer-filled channels: Effects of spacer geometrical characteristics and Schmidt number. J. Membr. Sci. 326, 234–251 (2009).

Ibrahim, Y. & Hilal, N. The potentials of 3D-printed feed spacers in reducing the environmental footprint of membrane separation processes. J. Environ. Chem. Eng. 11, 109249 (2023).

Foo, K., Liang, Y. Y. & Weihs, G. A. F. CFD study of the effect of SWM feed spacer geometry on mass transfer enhancement driven by forced transient slip velocity. J. Membr. Sci. 597, 117643 (2020).

Gu, B., Adjiman, C. S. & Xu, X. Y. The effect of feed spacer geometry on membrane performance and concentration polarisation based on 3D CFD simulations. J. Membr. Sci. 527, 78–91 (2017).

Siddiqui, A. et al. Predicting the impact of feed spacer modification on biofouling by hydraulic characterization and biofouling studies in membrane fouling simulators. Water Res. 110, 281–287 (2017).

Benjamin, J. et al. Optimizing pressure retarded osmosis spacer geometries: An experimental and CFD modeling study. J. Membr. Sci. 647, 120284 (2022).

Siddiqui, A. et al. Development and characterization of 3D-printed feed spacers for spiral wound membrane systems. Water Res. 91, 55–67 (2016).

Sreedhar, N. et al. 3D printed feed spacers based on triply periodic minimal surfaces for flux enhancement and biofouling mitigation in RO and UF. Desalination 425, 12–21 (2018).

Ali, S. M. et al. Energy efficient 3D printed column type feed spacer for membrane filtration. Water Res. 164, 114961 (2019).

Sreedhar, N. et al. Mass transfer analysis of ultrafiltration using spacers based on triply periodic minimal surfaces: effects of spacer design, directionality and voidage. J. Membr. Sci. 561, 89–98 (2018).

Sreedhar, N., Thomas, N., Ghaffour, N. & Arafat, H. A. The evolution of feed spacer role in membrane applications for desalination and water treatment: a critical review and future perspective. Desalination 554, 116505 (2023).

Yanar, N., Yang, E., Park, H., Son, M. & Choi, H. Efficacy of electrically-polarized 3D printed graphene-blended spacers on the flux enhancement and scaling resistance of water filtration membranes. ACS Sustain. Chem. Eng. 9, 6623–6631 (2021).

Tan, W. S. et al. Comparison of solid, liquid and powder forms of 3D printing techniques in membrane spacer fabrication. J. Membr. Sci. 537, 283–296 (2017).

Ho, C.-C. & Su, J. F. Boosting permeation and separation characteristics of polyethersulfone ultrafiltration membranes by structure modification via dual-PVP pore formers. Polymer 241, 124560 (2022).

Ibrahim, Y. et al. Highly selective heavy metal ions membranes combining sulfonated polyethersulfone and self-assembled manganese oxide nanosheets on positively functionalized graphene oxide nanosheets. Chem. Eng. J. 428, 131267 (2022).

Zhao, S. et al. Comparison study of the effect of PVP and PANI nanofibers additives on membrane formation mechanism, structure and performance. J. Membr. Sci. 385–386, 110–122 (2011).

Xiao, Z. et al. Slippery for scaling resistance in membrane distillation: a novel porous micropillared superhydrophobic surface. Water Res. 155, 152–161 (2019).

Asad, A., Sadrzadeh, M. & Sameoto, D. Direct micropatterning of phase separation membranes using hydrogel soft lithography. Adv. Mater. Technol. 4, 1800384 (2019).

Li, S., Cui, Z., Zhang, L., He, B. & Li, J. The effect of sulfonated polysulfone on the compatibility and structure of polyethersulfone-based blend membranes. J. Membr. Sci. 513, 1–11 (2016).

Fang, X. et al. Polyethyleneimine, an effective additive for polyethersulfone ultrafiltration membrane with enhanced permeability and selectivity. J. Membr. Sci. 476, 216–223 (2015).

Maximous, N., Nakhla, G., Wan, W. & Wong, K. Performance of a novel ZrO2/PES membrane for wastewater filtration. J. Membr. Sci. 352, 222–230 (2010).

Younas, H. et al. Super-hydrophilic and fouling resistant PVDF ultrafiltration membranes based on a facile prefabricated surface. J. Membr. Sci. 541, 529–540 (2017).

Muhamad, M. S., Salim, M. R. & Lau, W.-J. Preparation and characterization of PES/SiO2 composite ultrafiltration membrane for advanced water treatment. Korean J. Chem. Eng. 32, 2319–2329 (2015).

Mu, Y. et al. Development of highly permeable and antifouling ultrafiltration membranes based on the synergistic effect of carboxylated polysulfone and bio-inspired co-deposition modified hydroxyapatite nanotubes. J. Colloid Interface Sci. 572, 48–61 (2020).

Zhu, L. et al. Negatively charged polysulfone membranes with hydrophilicity and antifouling properties based on in situ cross-linked polymerization. J. Colloid Interface Sci. 498, 136–143 (2017).

Xu, F. et al. How pore hydrophilicity influences water permeability? Research 2019, 2019/2581241 (2019).

Yanar, N., Son, M., Park, H. & Choi, H. Bio-mimetically inspired 3D-printed honeycombed support (spacer) for the reduction of reverse solute flux and fouling of osmotic energy driven membranes. J. Ind. Eng. Chem. 83, 343–350 (2020).

Park, S. et al. 3D printed honeycomb-shaped feed channel spacer for membrane fouling mitigation in nanofiltration. J. Membr. Sci. 620, 118665 (2021).

Won, Y.-J. et al. Factors affecting pattern fidelity and performance of a patterned membrane. J. Membr. Sci. 462, 1–8 (2014).

Ibrahim, Y., Naddeo, V., Banat, F. & Hasan, S. W. Preparation of novel polyvinylidene fluoride (PVDF)-Tin(IV) oxide (SnO2) ion exchange mixed matrix membranes for the removal of heavy metals from aqueous solutions. Sep. Purif. Technol. 250, 117250 (2020).

Yin, Q., Zhang, Q., Cui, Z., Li, W. & Xing, W. Alkali resisting polyphenylsulfone ultrafiltration membrane with tailored microstructure. Polymer 124, 128–138 (2017).

Xiang, J. et al. Effect of nonsolvent additives on PES ultrafiltration membrane pore structure. J. Appl. Polym. Sci. 136, 47525 (2019).

Abdulkarem, E., Ibrahim, Y., Naddeo, V., Banat, F. & Hasan, S. W. Development of Polyethersulfone/α-Zirconium phosphate (PES/α-ZrP) flat-sheet nanocomposite ultrafiltration membranes. Chem. Eng. Res. Des. 161, 206–217 (2020).

Picioreanu, C., Vrouwenvelder, J. S. & van Loosdrecht, M. C. M. Three-dimensional modeling of biofouling and fluid dynamics in feed spacer channels of membrane devices. J. Membr. Sci. 345, 340–354 (2009).

Kerdi, S., Qamar, A., Vrouwenvelder, J. S. & Ghaffour, N. Fouling resilient perforated feed spacers for membrane filtration. Water Res. 140, 211–219 (2018).

Koutsou, C. P., Yiantsios, S. G. & Karabelas, A. J. Direct numerical simulation of flow in spacer-filled channels: effect of spacer geometrical characteristics. J. Membr. Sci. 291, 53–69 (2007).

Koutsou, C. P. & Karabelas, A. J. A novel retentate spacer geometry for improved spiral wound membrane (SWM) module performance. J. Membr. Sci. 488, 129–142 (2015).

Jermann, D., Pronk, W., Meylan, S. & Boller, M. Interplay of different NOM fouling mechanisms during ultrafiltration for drinking water production. Water Res. 41, 1713–1722 (2007).

Maruf, S. H., Greenberg, A. R., Pellegrino, J. & Ding, Y. Fabrication and characterization of a surface-patterned thin film composite membrane. J. Membr. Sci. 452, 11–19 (2014).

Zhao, Z., Ilyas, A., Muylaert, K. & Vankelecom, I. F. J. Optimization of patterned polysulfone membranes for microalgae harvesting. Bioresour. Technol. 309, 123367 (2020).

Zhao, Z., Muylaert, K. & Vankelecom, I. F. J. Combining patterned membrane filtration and flocculation for economical microalgae harvesting. Water Res. 198, 117181 (2021).

Qu, F. et al. Ultrafiltration membrane fouling caused by extracellular organic matter (EOM) from Microcystis aeruginosa: effects of membrane pore size and surface hydrophobicity. J. Membr. Sci. 449, 58–66 (2014).

Mattaraj, S., Jarusutthirak, C. & Jiraratananon, R. A combined osmotic pressure and cake filtration model for crossflow nanofiltration of natural organic matter. J. Membr. Sci. 322, 475–483 (2008).

Kumar, M., Baniowda, H. M., Sreedhar, N., Curcio, E. & Arafat, H. A. Fouling resistant, high flux, charge tunable hybrid ultrafiltration membranes using polymer chains grafted graphene oxide for NOM removal. Chem. Eng. J. 408, 127300 (2021).

Chu, K. H. et al. Evaluation of humic acid and tannic acid fouling in graphene oxide-coated ultrafiltration membranes. ACS Appl. Mater. Interfaces 8, 22270–22279 (2016).

Hilal, N., Ismail, A. F. & Wright, C. Membrane Fabrication (CRC Press, 2015).

Ouda, M., Ibrahim, Y., Banat, F. & Hasan, S. W. Oily wastewater treatment via phase-inverted polyethersulfone-maghemite (PES/γ-Fe2O3) composite membranes. J. Water Process. Eng. 37, 101545 (2020).

Ibrahim, Y., Abdulkarem, E., Naddeo, V., Banat, F. & Hasan, S. W. Synthesis of super hydrophilic cellulose-alpha zirconium phosphate ion exchange membrane via surface coating for the removal of heavy metals from wastewater. Sci. Total. Environ. 690, 167–180 (2019).

Ouda, M. et al. Highly permeable, environmentally-friendly, antifouling polylactic acid-hydroxyapatite/polydopamine (PLA-HAp/PDA) ultrafiltration membranes. J. Clean. Prod. 330, 129871 (2022).

Abu Seman, M. N., Khayet, M. & Hilal, N. Development of antifouling properties and performance of nanofiltration membranes modified by interfacial polymerisation. Desalination 273, 36–47 (2011).

Thong, Z. et al. Novel nanofiltration membranes consisting of a sulfonated pentablock copolymer rejection layer for heavy metal removal. Environ. Sci. Technol. 48, 13880–13887 (2014).

Kumar, M., Sreedhar, N., Jaoude, M. A. & Arafat, H. A. High-flux, antifouling hydrophilized ultrafiltration membranes with tunable charge density combining sulfonated poly(ether sulfone) and aminated graphene oxide nanohybrid. ACS Appl. Mater. Interfaces 12, 1617–1627 (2020).

Alpatova, A., Verbych, S., Bryk, M., Nigmatullin, R. & Hilal, N. Ultrafiltration of water containing natural organic matter: heavy metal removing in the hybrid complexation–ultrafiltration process. Sep. Purif. Technol. 40, 155–162 (2004).

Acknowledgements

This work was jointly sponsored by the New York University Abu Dhabi (NYUAD) and Tamkeen under the NYUAD Research Institute Award (Project CG007). All the experiments were conducted using research facilities at NYUAD and the NYUAD Water Research Centre.

Author information

Authors and Affiliations

Contributions

Y.I.: Conceptualization, methodology, experimental, data analysis and curation, validation, characterization, writing the original draft. N.H.: Funding acquisition, investigation, supervision, writing—review and editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial or non-financial interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ibrahim, Y., Hilal, N. Enhancing ultrafiltration membrane permeability and antifouling performance through surface patterning with features resembling feed spacers. npj Clean Water 6, 60 (2023). https://doi.org/10.1038/s41545-023-00277-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41545-023-00277-3