Abstract

The thermodynamic stability of chromium in the Cr0, Cr2+, and Cr3+ oxidation states considering various F− ion coordination compounds was investigated in molten LiF–NaF-KF (FLiNaK) eutectic salt. Potential fluoride ion activity (F− and CrF3−) diagrams were constructed to predict the most stable Cr oxidation states as a function of anion activity, solvation state of chromium ions and potential at 600 °C. The Gibbs free energies of these compounds were estimated by utilizing a combined cyclic voltammetry – Nernst theory analysis approach in FLiNaK salt. To verify the constructed diagrams, X-ray diffraction was utilized after exposure of Cr at various applied potentials to determine whether compounds detected in solidified FLiNaK salts agreed with thermodynamic calculations. This work aims to identify key thermodynamic factors that are significant to chromium corrosion for molten salt nuclear reactor applications. The F− stability region spans the entire region where spontaneous corrosion of Cr occurs. Cr may be oxidized to Cr2+ and Cr3+ in the presence HF (due to moisture as an impurity) spontaneously except some conditions of p1/2H2/aHF etc. This situation is not changed qualitatively for various states of solvation between oxidized Cr solute in F− solvent and this aspect is substantially similar for the two cases (pair 1: Cr0/CrF3−/ CrF63−; pair 2: Cr0/CrF42−/CrF52−) considered in this work.

Similar content being viewed by others

Introduction

Molten salt reactor (MSR) has been recognized as a promising system for generation IV nuclear reactor with improved safety and performance1. Compared to the conventional light–water reactor (LWR), molten fluoride salts (e.g., LiF–NaF–KF, LiF–BeF2 eutectic) operate in the temperature range between 600 °C and 900 °C and replace water as the medium to dissolve dissolved fissile materials1 and transfer heat; in other words, molten fluoride salts can serve as both the solvents for the reactor fuel and coolant2,3. The research and commercial development of MSR reactor center on solving technical problems that are deleterious to the safety and sustainability of this technology including reactor materials; and thus, the corrosion of metallic structural components should be addressed4,5.

Fundamentally, the corrosion of metallic elements in MSRs has been posited to occur by electrochemical processes governed by mixed potential theory where the thermodynamic driving force for oxidative corrosion is determined by the difference in the Gibbs free energies of reaction between the reduction half-cell or cathodic reactions of the oxidants in the molten fluoride salts, coupled with anodic half-cell reactions associated with transition metals used in structural materials. Herein, we consider the Croxidation half-cell reactions producing oxidized chromium-fluoride compounds6. These are in turn based on the free energy of formation (ΔGf0) of the relevant reactants and products. However, these free energies may vary depending upon the specific Cr oxidation states and possible F− coordination complexes that may form (e.g., CrF2, CrF3, FeF2)7,8,9. For instance, it has recently been argued that Cr2+ can exist as CrF3− or CrF42− and Cr3+ may exist as CrF52−, CrF63−, and Cr5F172− states in molten fluorides at 700 °C10.

The origins of the oxidants can range from moisture impurities11 (the cause of the dissolved hydrofluoric acid corrosion12), dissolved cations associated with metallic elements that originally were contained in air pre-formed oxides13, to the corrosion products themselves11, such as reduction of Cr in CrF3 or CrF2 compounds originally generated from Cr metal corrosion11,14,15. In technological applications, corrosion may result from differences in mixed potentials established by cold legs relative to hot legs16,17,18,19. Chromium is a common alloying element for various candidate MSR reactor materials including alloys that exhibit good corrosion resistance in aqueous systems4. Since molten fluoride salt is a non-oxide forming environment with high solubility for oxygen and most oxides9,13,20, the use of a protective Cr2O3 barrier layer is not suitable for this application21. This is further exacerbated by the fact that the ΔGf0 of chromium difluorides (CrF2) is lower than those of iron and nickel fluorides (other major alloying elements)1,8, and therefore Cr is predicted to exhibit the highest thermodynamic driving force for corrosion relative to candidate oxidizers discussed above. This is evidenced by phenomena such as selective Cr dissolution along grain boundaries7,22,23.

Nevertheless, our understanding of the electrochemical corrosion process involved with Cr metal and its alloys in the molten salt is limited. The question remains open which oxidation state (Cr2+ or Cr3+) is pertinent during Cr containing alloy corrosion. Thermodynamic predictions8 suggest that Cr has a high driving force to dissolve to the Cr2+ state due to the lower Gibbs free energy of the reaction producing CrF2 (reaction 1). Direct dissolution to the Cr3+ state (reaction 2) has not been reported as a predominant reaction step6. Moreover, it is posited that the resultant Cr2+ state will then be converted to the Cr3+ state through the disproportionation reaction (reaction 3) in which Cr metal is redeposited on its surface24.

where (ms) indicates a dissolved species in molten salt.

Recent progress in molten fluoride electrochemistry offers additional insights that help to interpret the corrosion mechanism of Cr. Wang et al. performed a detailed electrochemical study on a Pt wire electrode in a LiF–NaF-KF eutectic salt with the addition of CrF2 at 600 °C25. The X-ray diffractogram of the salt mixture quenched from 600 °C revealed the presence of crystalline CrF3− and CrF63− phases, corresponding to the chromium oxidation state of Cr2+ and Cr3+ ions, respectively25. A recent computational study by Winner et al. shows the solvated states of CrF3− and CrF42− are possible for Cr2+. Moreover, CrF52−, CrF63−, and Cr5F172− are possible for Cr3+ in molten fluorides at 700 °C10. However, it is unclear which solvated structure will form naturally during the spontaneous corrosion process. Nevertheless, fluoride solvation should be considered in understanding the mechanism of Cr corrosion. Thus, reactions 1–3 can be modified to reactions 4–9 through the following. It is noted that only reaction steps that involve the transfer of 1 mole of e− is considered to be the Cr2+/Cr3+ conversion reaction:

Oxidation from Cr0 to Cr2+:

Oxidation from Cr0 to Cr3+:

Oxidation from Cr2+ to Cr3+:

Based on the literature, the prior approach to understand the thermodynamics of molten fluoride salt corrosion centers on (1) systematically ranking the Gibbs free energies of possible half-cell reactions (\(\Delta {{{\mathrm{G}}}}_{{{\mathrm{r}}}}^0\)) and associated half-cell reaction potentials (E)8, and (2) developing phase stability diagrams, which depict regions of stable phases as a function of chemical compound activities (e.g., aCrF2, aCrF3, aLiO2), partial pressures of oxygen (PO2) and/or fluorine gas (PF2), and/or potential (E)7,11,13,26,27. While the goal is to predict the most favorable reaction, both approaches have not considered the Cr–F solvation phenomenon reported in recent literature10, which is critical since it affects the potential range over which thermodynamic stability of Cro, Cr2+ and Cr3+ is obtained. This, in turn, affects corrosion. In addition, these stability, or predominance, diagrams have limited flexibility since the oxidizing chemical potential is sometimes expressed as gaseous partial pressure (e.g., PO2). In molten salt corrosion, it is a thermodynamic variable rather than measurable or quantitative property, making it difficult to determine the exact point which Cr locates in a phase stability, or predominance, diagram. This provides a literature gap and an opportunity to develop potential-activity diagrams that can be utilized to predict under what conditions Cr is oxidized or immune to dissolution as a function of electrode potential and fluoride ion activities (two measurable, quantitative properties) analogous to a classical Pourbaix diagram28.

The objective of this work is to understand and predict the conditions for oxidative Cr corrosion in molten fluorides. This work aims to investigate Cr corrosion in LiF–NaF–KF (FLiNaK) eutectic salt, applicable to a MSR reactor29. Thermodynamic analysis was carried out based on applicatrion of the Nernst potential to predict the predominant phase of charged, solvated ions as a function of fluoride ions activity and potential (the theory is discussed in detail in “Methods”). Electrochemical measurement coupled with X-ray diffraction (XRD) were utilized to verify the predicted thermodynamic stability regions for Cr0, Cr2+, and Cr3+ stability in FLiNaK salts at 600 °C.

Results and discussion

Cyclic voltammograms of Pt in FLiNaK–CrF3 salts

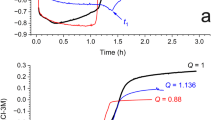

Figure 1 shows the cyclic voltammograms on a Pt wire in FLiNaK salts with the additions of 1.0 wt% and 0.42 wt% of CrF3 at 600 °C. In Fig. 1a, no Cr was present and the potassium fluoride (KF) reduction reaction was observed at the cathodic terminal of the scan, and its equilibrium potential (EKF/K) was marked in both Fig. 1a, b. It is noted that all potential reported in this work will be referenced from this measured EKF/K potential value. Hence, the reference potential used in this study is a quasi-reference EKF/K potential. The method to obtain this value is further illustrated in “Methods”. In Fig. 1c, two redox couples were observed pertaining to the Cr/Cr2+ and Cr2+/Cr3+ redox reactions. It is noted that no particular species (e.g., CrF2, CrF3, CrF3−, CrF63−) were assigned to describe the Cr2+ or Cr3+ oxidation state. The electrochemical behavior of the Pt wire in FLiNaK salts with either CrF2 or CrF3 additions have been extensively studied by multiple authors14,15,25,27,30. It was reported that both redox reactions exhibit quasi-reversibility. The Nernst potential of Cr/Cr2+ (ECr/Cr2+) and Cr2+/Cr3+ (ECr2+/Cr3+) redox pairs may be approximated at the midpoints between the oxidation and reduction peaks31,32, which are marked the red dotted lines in both Fig. 1b, c.

(a) shows the cyclic voltammogram before and after the addition of (b) 1.0 wt% and (c) 0.42 wt% of CrF3 at 600 °C. a, b indicate the equilibrium potential of KF reduction (EKF/K). The red dotted lines in (b) and (c) show the approximate experimentally determined equilibrium redox potential of Cr/Cr2+ redox couples (ECr/Cr2+).

However, in Fig. 1c, it can be seen that the Cr3+/Cr2+ reduction peak was very shallow. This peak cannot be clearly distinguished for a given weight percent of CrF3 added33,34 (such as in Fig. 1b), making it difficult to precisely determine its peak potential and current. The smaller peak current and shallower peak shape may be due to the combined effects of the lower diffusivity of Cr3+ (an order of magnitude lower than that of Cr2+ at 600 °C in FLiNaK salts25), and when the reduction reaction occurs not only on the Pt surface but elsewhere in the bulk molten salt24.

Concentration of CrF2 and CrF3 in FLiNaK

Upon the addition of CrF3 in FLiNaK salts, it was expected that deposited Cr particles and CrF2 would be formed by the disproportionation reaction (reaction 3) as observed by Liu et al.24 Determining the exact concentration of CrF2 and CrF3 in FLiNaK salts is important to the thermodynamic analysis used in the later part of this work. Given that the Cr/Cr2+ and Cr2+/Cr3+ reactions are quasi-reversible14,25,30,35,36,37,38, the Randles–Ševcik relation (Eq. (10)) was used to estimate the concentration of ionic species at a known scan rate and peak current densities:

where ip is the peak current density; n is the moles of electrons transferred; A is the area; Cb is bulk concentration; v is the scan rate; D is the diffusivity; R is the university gas constant 8.314 J K−1 mol−1; T is temperature To approximate the concentration of Cr2+ species in our FLiNaK–CrF3 salt, the ratio of peak current densities associated with Cr/Cr2+ and Cr2+/Cr3+ reactions were determined, yielding:

where \({{{\mathrm{i}}}}_{{{{\mathrm{Cr}}}}/{{{\mathrm{Cr}}}}2 + }^{{{{\mathrm{peak}}}}}\) and \({{{\mathrm{i}}}}_{{{{\mathrm{Cr}}}}2 + /{{{\mathrm{Cr}}}}3 + }^{{{{\mathrm{peak}}}}}\) are the peak current densities in the CV associated with the Cr/Cr2+ and Cr2+/Cr3+ oxidation peaks, and DCr2+ and DCr3+ are the diffusivities of Cr2+ and Cr3+ related species, which were reported by Wang and Zhang25 to be 2.55 × 10−5 and 7.74 × 10−6 cm2 s−1 in FLiNaK salts at 600 °C. Using the disproportionation reaction (3) as the basis for stoichiometric conversion, the resulting ratio of Cr2+ to Cr3+ concentration when Cr3+ is added can also be expressed as:

where x represents the moles reacted. Using Eqs. (11) and (12), the concentration of Cr2+ and Cr3+ species as a function of initial CrF3 concentration (\({{{\mathrm{C}}}}_{{{{\mathrm{CrF}}}}_3}^0\)) can be obtained as shown in Fig. 2a. Both Cr2+ and Cr3+ species follow a linear relationship with C0CrF3 as shown in Eqs. (13) and (14):

The percent conversion of initial CrF3 to Cr2+ species was computed and shown in Fig. 2b. The red line marks the solubility limit of CrF3 in FLiNaK salts, which was calculated to be 0.3 wt% by Yin et al.39. Prior to CrF3 saturation, the percent conversion increased and plateaued when 0.42 wt% of CrF3 was introduced, which is consistent with thermodynamic prediction39. Upon saturation, it was determined that about 7.71% of CrF3 was converted to CrF2, close to the percent conversion value reported by Peng et al.36.

Estimating the Gibbs free energy of formation of solvated chromium fluorides

Figure 3 shows the experimental Cr/Cr2+ Nernst potential (ECr/Cr2+) indicated by symbols versus the calculated Cr2+ concentration (Eq. (13)) on a logarithmic scale. The solid line is a fit to the data that can be fitted against Eq. (15). Between 0.11 and 0.27 wt% CrF3 addition, the ECr/Cr2+ potential exhibits a positive linear relationship with the log-scale concentration, which is consistent with the general Nernst expression of the (Cr ⇌ Cr2+ + 2e−) half-cell redox reaction:

At 0.42 wt% and 1.00 wt%, the ECr/Cr2+ potentials measured were similar. This was likely related to the saturation of CrF3 in FLiNaK when concentrations greater than the solubility limit of 0.3 wt% of CrF3 was introduced39, resulting in the formation of distinct K2CrF5 or K3CrF6 phases in FLiNaK39. When the solubility limit is exceeded, the FLiNaK salt remains at a constant relative concentration of Cr2+ and Cr3+ in the FLiNaK salts, in which case the measured ECr/Cr2+ potential values will not change.

The linear region in Fig. 3 can be fitted and extrapolated to determine the standard electrode potential (E0Cr/Cr2+) using the y-intercept of Eq. (16). Using a similar electrochemical approach27, Massot et al. reported that γCr2+ (activity coefficient of Cr2+) to be close to unity in LiF–NaF salts at 700 °C27. In this work, E0Cr/Cr2+ was found to be −3.41 \({\rm{V}}_{{\rm{F}}_{2}/{\rm{F}}^{-}}\), which is similar to −3.35 \({\rm{V}}_{{\rm{F}}_{2}/{\rm{F}}^{-}}\) the pure compound reference state value of CrF2 from the thermochemical database (HSC Chemistry software 6.1)27. Using Eqs. (17) and (18) to relate E0Cr/Cr2+ to \(\Delta {{{\mathrm{G}}}}_{{{\mathrm{f}}}}^0\) of Cr2+, the \(\Delta {{{\mathrm{G}}}}_{{{\mathrm{f}}}}^0\) of Cr2+ was calculated to be −657.7 kJ/mol F−, which is similar to the literature value of \(\Delta {{{\mathrm{G}}}}_{{{\mathrm{f}}}}^0\) of CrF2 reported in Table 140.

In molten fluorides, the Cr2+ oxidation state can also possibly exist in the forms of CrF3− or CrF42− species10. To obtain their \(\Delta {{{\mathrm{G}}}}_{{{\mathrm{f}}}}^0\) values, the half-cell redox reactions of Cr/CrF3− and Cr/CrF42− were first separately considered. To determine the precise E0Cr/Cr2+ standard electrode potentials pertaining to the Cr/CrF3− (\({{{\mathrm{E}}}}_{{{{\mathrm{Cr}}}}/{{{\mathrm{CrF}}}}_3^ - }^0\)) and Cr/CrF42− (\({{{\mathrm{E}}}}_{{{{\mathrm{Cr}}}}/{{{\mathrm{CrF}}}}_4^{2 - }}^0\)) solvated states, we can consider the Nernst expression for reactions 4 and 5:

Assuming that (i) the activity coefficient of Cr2+ ions in FLiNaK salts is unity8,27, (ii) the activity coefficient of F− ions is unity in FLiNaK salt since the F− ions do not form complexes or a separate phase with Li+, Na+ and K+ ions8,9,41, (iii) and the concentration of F− ions is 49.3 M based on stoichiometric calculation (i.e., log(aF−) = 1.693). The intercept of Eq. (16) can be related to that in Eqs. (19) and (20), resulting in the relations:

Using these relations, the formal potentials of each Cr2+ solvated species may be estimated. The integers presented in Eqs. (21) and (22) are a function of the stoichiometric moles of F− ions consumed, which is different depending on the solvated structure. For clarity purposes, the calculation of these standard potentials assumes that only one solvated state contributes to the Cr/Cr2+ redox reaction. In this work, the \({{{\mathrm{E}}}}_{{{{\mathrm{Cr}}}}/{{{\mathrm{CrF}}}}_3^ - }^0\) and \({{{\mathrm{E}}}}_{{{{\mathrm{Cr}}}}/{{{\mathrm{CrF}}}}_4^{2 - }}^0\) are found to be −3.848 and −3.994 \({\rm{V}}_{{\rm{F}}_{2}/{\rm{F}}^{-}}\), which are equivalent to the \(\Delta {{{\mathrm{G}}}}_{{{\mathrm{f}}}}^0\) values of −742.6 and −770.9 kJ/mol, respectively.

The method presented relies on identifying both the oxidation and reduction potentials of a redox reaction. However, it was previously mentioned that the reduction peak of Cr3+/Cr2+ was shallow, and could yield erroneous Nernst potentials.Therefore, the experimental–theoretical method utilized above may not yield reliable result when estimating the \(\Delta {{{\mathrm{G}}}}_{{{\mathrm{f}}}}^0\) of CrF52− and CrF63− species in this case.

An alternative approach was used. With UV-Vis absorption spectroscopy24 correlated with cyclic voltammetry measurements36, it was reported that the Cr2+ and Cr3+ states can coexist in equilibrium, saturated condition, upon the addition of CrF2 or CrF3 salts in FLiNaK. In Fig. 2b, it was found that 7.71% of Cr3+ was converted to Cr2+ species, which is similar to the value reported by Peng et al.36 and Zhang et al.25. Upon CrF3 saturation, it is fair to assume that the ratio of Cr2+/Cr3+ activities (i.e., \({{{\mathrm{a}}}}_{{{{\mathrm{CrF}}}}_3^ - }\)/\({{{\mathrm{a}}}}_{{{{\mathrm{CrF}}}}_6^{3 - }}\) or \({{{\mathrm{a}}}}_{{{{\mathrm{CrF}}}}_4^{2 - }}\)/\({{{\mathrm{a}}}}_{{{{\mathrm{CrF}}}}_5^{2 - }}\)) were 0.0814.

Consider the Nernst equations for reactions 8 and 9:

With a Cr2+/Cr3+ equilibrium activity ratio of 0.0814 and log(aF−) of 1.693, Eqs. (23) and (24) can be simplified to the forms:

In this case, the standard or formal potentials of reactions 8 and 9 can be experimentally determined by measuring the redox potential of ECr2+/Cr3+ when FLiNaK salt is saturated with CrF3. In this work, ECr2+/Cr3+ was found to be +1.43 VKF/K or −3.77 \({\rm{V}}_{{\rm{F}}_{2}/{\rm{F}}^{-}}\). \({{{\mathrm{E}}}}_{{{{\mathrm{CrF}}}}_6^{3 - }/{{{\mathrm{CrF}}}}_3^ - }^0\) and \({{{\mathrm{E}}}}_{{{{\mathrm{CrF}}}}_5^{2 - }/{{{\mathrm{CrF}}}}_4^{2 - }}^0\) were found to be −3.081 and −3.667 \({\rm{V}}_{{\rm{F}}_{2}/{\rm{F}}^{-}}\), respectively. Using Eq. (18) and the \(\Delta {{{\mathrm{G}}}}_{{{\mathrm{f}}}}^0\) values of CrF3− and CrF42− previously determined, the \(\Delta {{{\mathrm{G}}}}_{{{\mathrm{f}}}}^0\) of CrF52− and CrF63− were calculated to be −1124.7 and −1039.9 kJ/mol, respectively. The summary of the \(\Delta {{{\mathrm{G}}}}_{{{\mathrm{f}}}}^0\) of solvated chromium fluorides is shown in Table 2. It is noted that Eqs. (21) and (22) were used to calculate the \(\Delta {{{\mathrm{G}}}}_{{{\mathrm{f}}}}^0\) in the case of solvated CrF3− or CrF42 species using data presented by Massot et al.27. The result of this work yields a similar value as compared in Table 2.

Stability of Cr2+ and Cr3+ in molten fluorides

The Nernst equations for key redox reactions involving CrF3, CrF3−, CrF42−, CrF52−, CrF63−, and Cr species are listed in Table 3. The predominance region of each possible reaction product considered in Table 4 is plotted as a function of potential versus the F− (Fig. 4) and the CrF3− (Fig. 5) activities on a logarithmic scale. The solid lines indicate equilibrium boundaries between the species considered. Given the complexity arising from the consideration of all solvated states, two pairs of solvated species (pair 1: Cr0/CrF3−/CrF63−; pair 2: Cr0/CrF42−/CrF52−) were first independently considered.

a Considers the CrF3− and CrF63− species and (b) the CrF42− and CrF52− solvated states. The red, blue, and green dots at log(aF−) = 1.693 mark the potentials for XRD results presented in Fig. 6. All Cr–F species were assumed to have an activity of 10−6 M.

Figure 4a, b illustrates the potential log(aF−) diagrams for pair 1: Cr0/CrF3−/CrF63− (Fig. 4a) and for pair 2: Cr0/CrF42−/CrF52− (Fig. 4b) species in molten fluorides at 600 °C. The activities of all Cr ionic species were assumed be 10−6 M. All potentials displayed are with respect to the evolution of fluorine gas (F2/F−), whose potential value is calculated from the Nernst equation of reaction 27 (Table 3). The red vertical line at log(aF−) = 1.693 indicates the fluoride activity corresponding to the FLiNaK salts. The blue and orange dashed line indicates the potential window of molten FLiNaK salts defined by reactions 27 and 28. The black dotted-dash line indicates the HF reduction reaction (reaction 29) at the various ratios of p1/2H2/aHF:

In Fig. 4a, the CrF3− ions exist in a relatively narrow stability region, ~150 mV wide at the FLiNaK salt composition (red line). Above −3.284 \({\rm{V}}_{{\rm{F}}_{2}/{\rm{F}}^{-}}\), the CrF63− species (+2 oxidation state) is predicted to be most thermodynamically stable. This behavior remains consistent in the range of log(aF-) studied. It is also noted that the equilibrium potential given by the Nernst potential for hydrogen evolution (reaction 29) exists at potentials above that CrF3−/CrF63− oxidation reaction (8), indicating the oxidizing power of HF towards spontaneous anodic dissolution of Cr leading to formation of solvated Cr2+ and Cr3+. In Fig. 4b, the stability regions of Cr, CrF42−, and CrF52− species are shown. As the log(aF−) increases, the stability region of CrF42− species widens, and then oxidized to CrF52− through reaction 9. To verify which one of these situations actually exists when Cr is exposed to FLiNaK systems at 600 °C, high purity Cr was potentiostatically polarized to −5, −4, −3.2 \({\rm{V}}_{{\rm{F}}_{2}/{\rm{F}}^{-}}\) in FLiNaK salts at the same temperature (marked as the green, blue, red dots in Fig. 4). The composition of the solidified residual salts was analyzed with XRD. This will be discussed in the next section.

Figure 4 predicts that Cr would remain as the Cr0 state (in the “immunity” region) when it is polarized at or below −5 \({\rm{V}}_{{\rm{F}}_{2}/{\rm{F}}^{-}}\), and undergo active corrosion to either CrF3− or CrF52− state at −4 \({\rm{V}}_{{\rm{F}}_{2}/{\rm{F}}^{-}}\), and either CrF52− or CrF63− state at −3.2 \({\rm{V}}_{{\rm{F}}_{2}/{\rm{F}}^{-}}\). Potentiostatic hold experiments coupled with XRD were used to verify these predictions. Figure 5 shows the XRD of FLiNaK salts after Cr was potentiostatically polarized to −3.2 \({\rm{V}}_{{\rm{F}}_{2}/{\rm{F}}^{-}}\) for 50 h, −4 \({\rm{V}}_{{\rm{F}}_{2}/{\rm{F}}^{-}}\) for 50 h, and −5 \({\rm{V}}_{{\rm{F}}_{2}/{\rm{F}}^{-}}\) for 1 h.

In the pure solidified FLiNaK (Fig. 5a), the XRD patterns reveal diffraction peaks of KF, LiF and NaF with KF peaks sharing the highest percent intensity. When Cr metal was held at −5 \({\rm{V}}_{{\rm{F}}_{2}/{\rm{F}}^{-}}\) for 1 h, no significant mass loss of Cr was observed. However, the XRD pattern (Fig. 5b) of the tested salts shows low-intensity diffraction peaks corresponding to the presence of NaCrF3 (peak 4) and KCrF3 (peak 9) species. The presence of Cr may be attributed to the dissolution of a native Cr2O3 oxide film at the beginning of the experiment. It is noted that large cathodic reduction current density (>1 A/cm2) was observed after 1 h of potentiostatic hold (not shown) at this potential. This may either be due to formation of H2 bubbles from HF reduction or the reduction of potassium on the Cr surface.

Figure 5c, d shows the XRD patterns of FLiNaK salts where a Cr coupon was potentiostatically polarized at −4 VKF/K or −3.2 \({\rm{V}}_{{\mathrm{F}}_{2}/{\mathrm{F}}^{-}}\) for 50 h, respectively. In Fig. 5c, the presence of NaCrF3 (peak 4) and KCrF3 (peak 9) species were identified, corroborating with thermodynamic prediction. In Fig. 5d, the NaCrF3 (peak 4), KCrF3 (peak 9), K2NaCrF6 (peak 7), K3CrF6 (peak 8), Li2NaCrF6 (peak 10) compounds were identified, confirming the existence of both CrF3− and CrF63− states. The CrF3− likely formed during the solidification of FLiNaK and maintained a thermodynamic equilibrium with the CrF63− state24. The K2NaCrF6, K3CrF6, Li2NaCrF6 compounds suggest that the Cr3+ ion has a coordination number 6 at the temperature studied.

Results obtained are in a good correlation with literature data and previous work on compound prediction reported in Ab-initio simulations10. In all potentials studied, no CrF52− related compounds were detected. This indicates that the Cr/Cr2+ and Cr2+/Cr3+ seen in Fig. 1 likely correspond to the Cr/CrF3− and CrF3−/CrF63− redox couples.

During the corrosion of Cr, the activities of CrF3− and CrF63− species in the FLiNaK salts are expected to increase over an exposure period. Therefore, it is useful to consider the change in thermodynamic driving forces (Table 3) with respect to the activities of CrF3− and CrF63− ions under a defined constant of log(aF−) where (log(49.3) = 1.693 for FLiNaK).

Figure 6 shows the potential-activity diagrams considering the predominant phases of Cr, CrF3−, and CrF63− species as a function of log(aCrF3−) and potential. The equilibrium potential between Cr and CrF3− ions was computed from reaction 4 and exhibits a linear relationship with log(aCrF3−). The blue circular symbols shown in Fig. 6 are the experimental half-cell Nernst potential reported in Fig. 3, which are closely follow but slightly different from the thermodynamic predictions. Nevertheless, the boundary of these stability regions is sensitive to the \(\Delta {{{\mathrm{G}}}}_{{{\mathrm{f}}}}^0\) of solvated chromium fluorides (Table 2) utilized to construct these potential-activity diagrams. The use of cyclic voltammetry provides a relatively straightforward method to estimate these \(\Delta {{{\mathrm{G}}}}_{{{\mathrm{f}}}}^0\) values, but the method is sensitive to errors. For example, the uncertainties could be related to the use of quasi EKF/K potential, temperature distributions or natural convection effects during molten salt electrochemistry measurement or because the Nernst potential theory cannot completely describe the potential for the quasi-reversible reactions31.

The blue dot indicates the experimental equilibrium redox potential of the Cr/Cr2+ half-cell reactions reported in Fig. 4.

Before reaching the CrF3 solubility limit in FLiNaK salts, the CrF3−/CrF63− equilibrium line shows a linearly decreasing potential with F- ion activity consistent with the prediction of the Nernst equation. When the solubility limit is reached, the ratio of CrF3− to CrF63− activities is assumed to be 0.0814 calculated assuming the 7.71% conversion shown in Fig. 2b. Therefore, the Nernst potential is a straight horizontal line since an equilibrium ratio was enforced. It is noted that the equilibrium potential of CrF3−/CrF63− reactions in Fig. 6 is lower than that in Fig. 4a. This is because the CrF3−/CrF63 activity ratio (Fig. 2b) was considered when constructing the potential log(aCrF3−) diagram; whereas all Cr ion activities were assumed to be 10−6 M in Fig. 4a, b.

One observation is that as the p1/2H2/aHF ratio increases, the equilibrium potential of HF/H2 reaction decreases and approaches to that of the CrF63−/CrF3− reduction. As the CrF3− activity increases, the stability region of CrF3− E-aCrF3- phase space becomes smaller. Practically, based on the estimated \(\Delta {{{\mathrm{G}}}}_{{{\mathrm{f}}}}^0\), the Cr/CrF3− boundary will not intersect with that of the CrF3−/CrF63−. Therefore, thermodynamic prediction indicates that the corrosion of Cr may always take place first through the direct dissolution to Cr2+ state in the form of CrF3−, and CrF63− will then be formed electrochemically in either within the FLiNaK salts or Cr surface.

Ramifications towards spontaneous corrosion of Cr in FLiNaK

The diagrams (Figs. 4 and 6) indicate that the KF is oxidized at all potentials where Cr is oxidized to Cr2+ and Cr3+. The F− stability region spans the entire region where spontaneous corrosion of Cr occurs. Cr may be oxidized to Cr2+ and Cr3+ in the presence HF (due to moisture impurity) spontaneously except some extreme combinations of p1/2H2/aHF etc. This situation is not changed qualitatively for different solvation of oxidized Cr with F− and this aspect is substantially similar for the two cases (pair 1: Cr0/CrF3−/CrF63−; pair 2: Cr0/CrF42−/CrF52−) considered in this work. Cr may be oxidized by HF and may be oxidized by other sufficiently noble metal impurities (not shown).

It is important to note that Figs. 4 and 6 are conventional thermodynamic stability fields that assume full reversibility of electrochemical reactions, uniform distribution of concentration, and chemical equilibrium between species. Readers must take caution when applying these principles to analyze actual complex corrosion system involving both kinetic and thermodynamic factors. Work is still ongoing to further verify and optimize the accuracy of potential-activity diagrams in molten fluoride salts, for example to theoretically calculate the Gibbs free energy of formation of solvated compounds in molten fluorides. The thermodynamic prediction presented here are consistent with literature the experimental findings of Liu et al.24 and an ample number of electrochemical studies in FLiNaK salts14,25,30,35,36,37,38. The potential-activity diagram developed in this work is also useful to help understanding the corrosion thermodynamics and kinetics of metallic alloys in molten fluoride salts, which will be illustrated in our future work.

Main results

-

The Gibbs free energy of formation of CrF3−, CrF42−, CrF52−, and CrF63− solvated chromium compounds were extracted from the analysis of cyclic voltammetry data on Pt wire in FLiNaK–CrF3 salts at 600 °C. Based on classical thermodynamics including the Nernst equation, a E-log(aF-) analogous to a Pourbaix diagram was constructed for two systems: (i) Cr/CrF3−/CrF63− (ii) Cr/CrF42−/CrF52− pertinent to Cr exposure in molten fluoride salts.

-

To validate the prediction, a Cr coupon was potentiostatically held at selected potentials corresponding to the different thermodynamic stability regions, and the solidified salts were analyzed using X-ray diffraction. Experimental XRD results confirmed that the Cr/CrF3−/CrF63− described Cr corrosion thermodynamics in FLiNaK salts at 600 °C, while CrF42− or CrF52− compounds were not detected by XRD.

-

A E-log(\({\rm{a}}_{{{\rm{CrF}}_3}^{-}}\)) diagram based on the Cr/CrF3−/CrF63− system was also developed to predict the most thermodynamically favorable oxidation state for Cr corrosion. The prediction shows that the direct dissolution from Cr to CrF3− via a +2 charge is favored over all reasonable values of aHF. F− complexation assuming Cr/CrF3−/CrF63− compared to CrF42− or CrF52 produces E-aHF diagrams which are similar but have distinct differences.

-

The E-log(aF-) diagram indicates that the K is oxidized to K+ existing as KF at all potentials where Cr is oxidized to Cr2+ and Cr3+. The F− stability region spans the entire region where spontaneous corrosion of Cr occurs. Cr may be oxidized to Cr2+ and Cr3+ in the presence HF (due to moisture impurity) spontaneously except for some conditions of p1/2H2/aHF etc. This situation is not changed qualitatively for various states of solvation between oxidized Cr solute in F− solvent and this aspect is similar for the two cases (pair 1: Cr0/CrF3−/ CrF63−; pair 2: Cr0/CrF42−/CrF52−) considered in this work.

Methods

Setup, sample, and salt preparation

High purity Cr rectangular sheet (99.995%, Alfa Aesar) with the dimension 20 × 1.5 × 3 mm were used. Coupons were metallographically prepared to 1200 grit surface finish using silicon carbide polishing papers. The FLiNaK salt was prepared by weighing LiF (99.85%, Fisher Scientific), NaF (99.99%, Fisher Scientific), KF (99.5%, Fisher Scientific) into the stoichiometric ratio of 46.5, 11.5, and 42 mol%, respectively. Prior to mixing, these salts were dried in a vacuum furnace for 48 h at 100 °C, and then transferred to a N2-filled glove box with controlled O2 and H2O levels below <0.1 ppm. Nevertheless, during this transfer process, it is expected that the salts could absorb water from moist air during transfer (relative humidity of the laboratory was about 30%). In all, 30 g of FLiNaK salt were used for each experiment. The mass ratio of salt to Cr coupon is approximately equivalent to 0.03 g of FLiNaK/g of Cr.

The setup to perform electrochemical measurement is shown in Fig. 7. All measurements were carried out in a N2-filled glove box in a modified muffle furnace at 600 °C. A glassy carbon crucible (99.999%, Fisher Scientific) was used as both the salt container and counter electrode, and a Pt wire was used as a Pt/PtO/O2− quasi-reference electrode based on a controlled oxygen level. The working electrode was either a Cr coupon spot welded to a Ni200 wire or a platinum wire (99.997%, Alfa AesarTM). All the electrodes were fed through an alumina tube and placed in a quartz tube to ensure sturdy connections. A Gamry interface 1000 potentiostat was used to perform electrochemical tests. To minimize impurities pertaining to residual water moisture or oxygen, prior to the insertion of test electrodes, the salt mixture was heated to 600 °C for 3 h under the flow of ultra-high purity N2 gas (99.999%).

Reference potential determination

For a more meaningful and reliable comparison between thermodynamic prediction and electrochemistry results, the electrode potential was represented relative to both the potassium fluoride reduction (reaction 27, KF/K) and fluorine gas evolution (reaction 28, F2/F−).

The redox potential for reaction 27 can be experimentally measured using a cyclic voltammetry technique performed on a Pt wire in molten fluoride salts27. This method has also been utilized by Massot et al.27, Shay et al.42, and Wang et al.33. The technique involves polarizing the Pt wire to a cathodic (negative) direction until a sharp increase in reduction current corresponding to KF reduction is detected, and the scan is reversed to oxidize the K deposited on the Pt wire surface. An example cyclic voltammogram is shown in Fig. 1a. The equilibrium potential of reaction 27 was estimated at the position between the oxidation peak (KF/K). Once the KF/K potential was known, the F2/F− potential was be calculated using the Nernst equation (in FLiNaK salts where log(aF−) = 1.693, EKF/K = −5.206 \({\rm{V}}_{{\rm{F}}_{2}/{\rm{F}}^{-}}\)).

Thermodynamic analysis

In this project, a systematic thermodynamic analysis was carried out to predict the most favorable reaction for Cr dissolution as a function of potential and fluoride ion activities. Firstly, consider a general, reversible, half-cell electrochemical reaction in molten fluorides as shown:

where x describes the number of fluoride ions reacted per atom of Cr. The Nernst Equation for reaction 30 can be represented by the Nernst equations as43:

where \({{{\mathrm{E}}}}_{{{{\mathrm{M}}}}/{{{\mathrm{MF}}}}_{{{\mathrm{n}}}}^{{{{\mathrm{x}}}} + }}\) is the Nernst potential (or equilibrium redox potential), R is the universal gas constant, T is the temperature in K, n is the number of electrons transferred to complete the reaction shown one time, F is the Faraday’s constant of 96,500 coulombs/mol of e-, ai (=\({\upgamma}_{{{\mathrm{i}}}}\,{{{\mathrm{C}}}}_{{{\mathrm{i}}}}\)) is the ion activity, and \({{{\mathrm{E}}}}_{{{{\mathrm{M}}}}/{{{\mathrm{MF}}}}_{{{\mathrm{n}}}}^{{{{\mathrm{x}}}} + }}^0\) is the standard electrode potential of the half-cell reaction. The \({{{\mathrm{E}}}}_{{{{\mathrm{M}}}}/{{{\mathrm{MF}}}}_{{{\mathrm{n}}}}^{{{{\mathrm{x}}}} + }}^0\) can be related to \(\Delta {{{\mathrm{G}}}}_{{{\mathrm{f}}}}^0\) through Eqs. (17) and (18) (see introduction).

Table 1 shows the \(\Delta {{{\mathrm{G}}}}_{{{\mathrm{f}}}}^0\) of potassium and chromium-fluoride compounds obtained from Barin et al.40. Since the melting point of KF, CrF2, CrF3 is higher than 600 °C, the \(\Delta {{{\mathrm{G}}}}_{{{\mathrm{f}}}}^0\) at supercooled state was used instead. This is calculated by the summation of their solid state \(\Delta {{{\mathrm{G}}}}_{{{\mathrm{f}}}}^0\) and the fusion energy (\(\Delta {{{\mathrm{G}}}}_{{{\mathrm{F}}}}^0\))6,44 obtained by the following equations:

where the subscript “l” is liquid phase and “s” is solid phase. The values of \({{{\mathrm{H}}}}_{{{{\mathrm{l}}}},{{{\mathrm{F}}}}}^0\), \({{{\mathrm{H}}}}_{{{{\mathrm{s}}}},{{{\mathrm{F}}}}}^0\), \({{{\mathrm{S}}}}_{{{{\mathrm{l}}}},{{{\mathrm{F}}}}}^0\), \({{{\mathrm{S}}}}_{{{{\mathrm{s}}}},{{{\mathrm{F}}}}}^0\) values were obtained from the FactSage 8.0 SGTE pure substances database (v13.1)45. It is noted that the \(\Delta {{{\mathrm{G}}}}_{{{\mathrm{f}}}}^0\) of fluoride ion (F−) is assumed to be 0 and the partial pressure of fluorine gas (F2) is assumed to be 1 atm so reaction 28 can be a reference for other electrochemical reactions. To ensure the reliability of the \(\Delta {{{\mathrm{G}}}}_{{{\mathrm{f}}}}^0\) values used in this work, the \(\Delta {{{\mathrm{G}}}}_{{{\mathrm{f}}}}^0\) values from various thermodynamic databases are listed in Table 4. It is noted that these values represent the condition at T = 0 K. The \(\Delta {{{\mathrm{G}}}}_{{{\mathrm{f}}}}^0\) values from Barin et al.40 are consistent with Yoo1 and with two open source thermodynamic databases: Open Quantum Materials Database (OQMD)46,47 and Materials Project (MP)34. The method to convert the formation energy reported in OQMD and MP, from eV/atom to the standard unit of kJ/mol, can be found in the work of Lany et al48.

To predict the thermodynamic stability of Cr, the equilibrium redox reactions that are possible involving the Cr0, CrF3, CrF3−, CrF42−, CrF52−, CrF63 species must be considered. Table 3 lists the possible redox reactions and their Nernst equations. The potential window offered by molten fluorides can be defined by the reduction of potassium fluoride (reaction 27) and fluorine gas evolution (reaction 28). The Nernst potentials of possible redox reactions are computed as a function of electrochemical potential and fluoride ion activity. These results are presented in the form of a potential-activity diagram (vs. log(aF−) and log(aCrF3−)) applicable for molten fluoride salt, which is analogous to Pourbaix diagram developed for aqueous systems28.

Estimating the Gibbs free energy of solvated chromium-fluoride ions

To perform a complete thermodynamic analysis, the Gibbs free energy of formation (\(\Delta {{{\mathrm{G}}}}_{{{\mathrm{f}}}}^0\)) of various chromium-fluoride compounds (e.g. CrF3−, CrF42−, CrF52−, CrF63−) needs to be known. However not all of these values are reported in the literature. In this work, an electrochemical method was used to determine the \(\Delta {{{\mathrm{G}}}}_{{{\mathrm{f}}}}^{{{\mathrm{o}}}}\) values of these compound27. The redox electrode potentials (\({{{\mathrm{E}}}}_{{{{\mathrm{M}}}}/{{{\mathrm{MF}}}}_{{{\mathrm{x}}}}^{{{{\mathrm{n}}}} - {{{\mathrm{x}}}}}}\)) of Cr redox reactions (4–9) was determined from cyclic voltammetry performed on a platinum wire inserted in FLiNaK salts with the addition between 0.11 and 1 wt% of CrF3 (97%, Fisher Scientific) at 600 °C. The standard electrode potential (\({{{\mathrm{E}}}}_{{{{\mathrm{M}}}}/{{{\mathrm{MF}}}}_{{{\mathrm{x}}}}^{{{{\mathrm{n}}}} - {{{\mathrm{x}}}}}}^0\)) was obtained by the extrapolation of \({{{\mathrm{E}}}}_{{{{\mathrm{M}}}}/{{{\mathrm{MF}}}}_{{{\mathrm{x}}}}^{{{{\mathrm{n}}}} - {{{\mathrm{x}}}}}}\) to 1 M MFxn-x in the FLiNaK salts. The \(\Delta {{{\mathrm{G}}}}_{{{\mathrm{f}}}}^0\) of possible chromium-fluoride compounds were calculated using Eq. 1727.

Potentiostatic test and X-ray diffraction

To access the validity of thermodynamic predictions, a pure Cr coupon was potentiostatically polarized to −3.2 \({\rm{V}}_{{\rm{F}}_{2}/{\rm{F}}^{-}}\) for 50 h, −4 \({\rm{V}}_{{\rm{F}}_{2}/{\rm{F}}^{-}}\) for 50 h, −5 \({\rm{V}}_{{\rm{F}}_{2}/{\rm{F}}^{-}}\) for 1 h in FLiNaK salts at 600 °C using a Pt qusai-reference electrode and a glassy carbon crucible as a counter electrode. The details for the electrochemical setup is presented in the section “Setup, sample and salt preparation”.The phase composition of solidified salts was analyzed by XRD using the Malvern–Panalytical Empyrean diffractometer [wavelength Cu Kα (1.5405 A)]. The PDF4+ database was used as the reference data. The software HighScore Plus was used for Rietveld refinements. The peak profile was refined by pseudo-Voigt function.

Data availability

The authors declare that the data supporting the findings of this study are available within the paper. The supplementary data will be available upon reasonable request.

Change history

29 June 2022

A Correction to this paper has been published: https://doi.org/10.1038/s41529-022-00267-9

References

Yoo, J. H. Thermodynamic Data-Base for Metal Fluorides, Technical Report Number: TR-1824, (Korea Atomic Energy Research Institute) KAERI, (2001).

Dolan, T. J. Molten Salt Reactors and Thorium Energy (Woodhead Publishing, 2017).

Serp, J. et al. The molten salt reactor (MSR) in generation IV: overview and perspectives. Prog. Nucl. Energy 77, 308–319 (2014).

Wright, R. N. & Sham, T. L. Status of Metallic Structural Materials for Molten Salt Reactors. Technical Report INL/EXT-18-45171; Argonne National Laboratory & Idaho National Laboratory (2018).

Busby, J. et al. Technical Gap Assessment for Materials and Component Integrity Issues for Molten Salt Reactors. Technical Report ORNL/SPR-2019/1089; Oak Ridge National Laboratory (2019).

Guo, S. et al. Corrosion in the molten fluoride and chloride salts and materials development for nuclear applications. Prog. Mater. Sci. 97, 448–487 (2018).

Sridharan, K. & Allen, T. Molten Salts Chemistry from Lab to Application - Chapter 12: Corrosion in Molten Salts (Elsevier, 2013).

Zhang, J. et al. Redox potential control in molten salt systems for corrosion mitigation. Corros. Sci. 144, 44–53 (2018).

Baes, C. F. The chemistry and thermodynamics of molten salt reactor fuels. J. Nucl. Mater. 51, 149–162 (1974).

Winner, N. et al. Ab-initio simulation studies of chromium solvation in molten fluoride salts. J. Mol. Liq. 335, 116351 (2021).

Wang, Y. et al. Effects of the oxidants H2O and CrF3 on the corrosion of pure metals in molten (Li,Na,K)F. Corros. Sci. 103, 268–282 (2016).

Pizzini, S. & Morlotti, R. Oxygen and hydrogen electrodes in molten fluorides. Electrochim. Acta 10, 1033–1041 (1965).

Ai, H. et al. Effects of O2—additive on corrosion behavior of Fe–Cr–Ni alloy in molten fluoride salts. Corros. Sci. 150, 175–182 (2019).

Wu, W. et al. Electrochemical behaviors of Cr(III) in molten LiF-NaF-KF eutectic. Int. J. Electrochem. Sci. 13, 225–234 (2018).

Yoko, T. & Bailey, R. A. Electrochemical studies of chromium in molten LiF ‐ NaF ‐ KF (FLINAK). J. Electrochem. Soc. 131, 2590–2595 (1984).

Jordan, W. H. et al. Aircraft Nuclear Propulsion Project Quarterly Progress Report. Technical Report Number: ORNL-2221; Oak Ridge National Laboratory (1957).

Koger, J. W. Effect of FeF2 Addition on Mass Transfer in A Hastelloy N: LiF-BeF2-UF4 Thermal Convection Loop System. Technical Report Number: ORNL-TM-4188; Oak Ridge National Laboratory (1972).

DeVan, J. H. & Evans, III, R. B. Corrosion Behavior of Reactor Materials in Fluoride Salt Mixtures. Technical Report ORNL-TM-328; Oak Ridge National Laboratory (1962).

Jordan, W. H. et al. Aircraft Nuclear Propulsion Project Quarterly Progress Report for Period Ending Sept. 10, 1956. Technical Report Number: ORNL-2157; Oak Ridge National Laboratory (1956).

Song, Y. et al. Solubility of Cr2O3 in molten fluorides with different ZrF4 contents and fluoroacidities. J. Electrochem. Soc. 167, 023501 (2020).

Qiu, J. et al. Electrochemical study of the dissolution of oxide films grown on type 316L stainless steel in molten fluoride salt. Corros. Sci. 186, 109457 (2021).

Wang, Y., Liu, H., Yu, G., Hou, J. & Zeng, C. Electrochemical study of the corrosion of a Ni-based alloy GH3535 in molten (Li,Na,K)F at 700 °C. J. Fluor. Chem. 178, 14–22 (2015).

Zhou, W. et al. Proton irradiation-decelerated intergranular corrosion of Ni-Cr alloys in molten salt. Nat. Commun. 11, 3430 (2020).

Liu, Y. et al. Corrosion of Cr in molten salts with different fluoroacidity in the presence of CrF3. Corros. Sci. 169, 108636 (2020).

Wang, Y. & Zhang, J. Electrochemical properties of CrF2 in FLiNaK molten salt and the new analytical methods for their determination. J. Electrochem. Soc. 167, 086503 (2020).

Cramer, S. D. & Covino Jr., B. S. ASM Handbook Volume 13A: Corrosion: Fundamentals, Testing, and Protection (ASM International, 2003).

Massot, L. et al. Corrosion products electrochemical behaviour into molten lif-naf: investigation of Cr(II) system. J. Electrochem. Soc. 168, 026510 (2021).

Pourbaix, M. Atlas of Electrochemical Equilibria in Aqueous Solutions (National Association of Corrosion Engineers, 1974).

Sohal, M. S. et al. Engineering Database of Liquid Salt Thermophysical and Thermochemical Properties. Technical Report Number: INL/EXT-10-18297; Idaho National Laboratory (2010).

Ludwig, D. et al. High temperature electrochemistry of molten fluoride salt for measurement of dissolved chromium. Corros. Eng., Sci. Technol. 46, 360–364 (2011).

Elgrishi, N. et al. A practical beginner’s guide to cyclic voltammetry. J. Chem. Educ. 95, 197–206 (2018).

Hamman, C. H. et al. Electrochemistry, 2nd edition. (Wiley, 2007).

Wang, Y. Species Chemistry and Electrochemical Separation in Molten Fluoride Salt. PhD’s thesis, Virginia Polytechnic Institute and State University (2019).

Jain, A. et al. The materials project: a materials genome approach to accelerating materials innovation. APL. Materials 1, 011002 (2013).

Zakharova, V. V. et al. Electrochemistry of iron, nickel and chromium in LiF–NaF–KF (FLiNaK) eutectic melt: a cyclic voltammetry study. AIP Conf. Proc. 2313, 050039 (2020).

Peng, H. et al. Electrochemical investigation of the stable chromium species in molten FLINAK. RSC Adv. 5, 76689–76695 (2015).

Zheng, G. & Sridharan, K. Corrosion of structural alloys in high-temperature molten fluoride salts for applications in molten salt reactors. JOM 70, 1535–1541 (2018).

Doniger, W. H. & Sridharan, K. Application of voltammetry for quantitative analysis of chromium in molten 2LiF-BeF2 (FLiBe) salt. J. Electrochem. Soc. 838, 73–81 (2019).

Yin, H. et al. Thermodynamic modeling of LiF-NaF-KF-CrF3 system. J. Fluor. Chem. 209, 6–13 (2018).

Barin, I., Knacke, O. & Kubaschewski, O. Thermochemical Properties of Inorganic Substances (Springer Berlin Heidelberg, 1977).

Bieber, A. L. et al. Fluoroacidity evaluation in molten salts. Electrochim. Acta 6, 5022–5027 (2011).

Shay, N. W. Electrochemical Sensor Development for Fluoride Molten Salt Redox Control. Master’s thesis, Ohio State University (2017).

Jones, D. A. Principles and Prevention of Corrosion (Prentice Hall, 1996).

Guo, S., Shay, N., Wang, Y., Zhou, W. & Zhang, J. Measurement of europium (III)/europium (II) couple in fluoride molten salt for redox control in a molten salt reactor concept. J. Nucl. Mater. 496, 197–206 (2017).

Bale, C. W. et al. FactSage thermochemical software and databases—recent developments. CALPHAD 33, 295 (2009).

Saal, J. E. et al. Materials design and discovery with high-throughput density functional theory: the open quantum materials database (OQMD). JOM 65, 1501–1509 (2013).

Kirklin, S. et al. The open quantum materials database (OQMD): assessing the accuracy of DFT formation energies. npj Comput Mater. 1, 1–15 (2015).

Stevanović, V. et al. Correcting density functional theory for accurate predictions of compound enthalpies of formation: fitted elemental-phase reference energies. Phys. Rev. B 85, 115104 (2012).

Acknowledgements

Research primarily was supported as part of fundamental understanding of transport under reactor extremes (FUTURE), an Energy Frontier Research Center (EFRC) funded by the U.S. Department of Energy (DOE), Office of Science, Basic Energy Sciences (BES). This work was performed in the Department of Materials Science and Engineering (DMSE) in the Center for Electrochemical Science and Engineering (CESE) at the University of Virginia. Utilization of the Malvern–Panalytical Empyrean diffractometer were supported by Nanoscale Materials Characterization Facility (NMCF) with National Science Foundation (NSF) under award CHE-2102156.

Author information

Authors and Affiliations

Contributions

H.L.C. and E.R. conceived the methodology to obtain the needed thermodynamic data and designed the experiments to obtain free energies of formation and Nernst potentials. H.L.C., E.R., and J.Q. performed the experimental analysis. H.L.C. was responsible for thermodynamic analysis and diagrams construction and prepared the original draft with input from J.R.S and E.R. J.R.S. guided application of corrosion thermodynamic criteria for spontaneous corrosion with H.L.C. and E.R., edited and reviewed the manuscript. J.R.S. and P.H. conceptualized and directed the project. P.H. was responsible for funding acquisition and overall project themes within F.U.T.U.R.E. All the authors contributed to the interpretation of the experimental data and discussed the results. All authors discussed the data interpretation. All co-authors contributed during reviewing of the final manuscript. All authors approved the final version.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Chan, H.L., Romanovskaia, E., Qiu, J. et al. Insights on the corrosion thermodynamics of chromium in molten LiF-NaF-KF eutectic salts. npj Mater Degrad 6, 46 (2022). https://doi.org/10.1038/s41529-022-00251-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41529-022-00251-3