Abstract

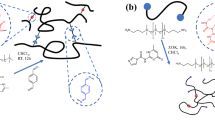

In this work, a largely miscible second-generation aliphatic polyester hyperbranched polymer (HBP) is used as a modifier in a cured epoxy amine network to explore molecular mobility in the glassy state and its impact on compressive properties. The β relaxation determined by dynamic mechanical analysis is used as a measure of short-range motion in the glassy state and is related to the compressive modulus and yield properties. The parameters explored include an increased HBP concentration, enhanced HBP, and epoxy matrix interactions through pre-reaction via a rigid covalent linkage and a modified epoxy network of flexible butanediol diglycidyl ether (BDDGE) and highly crosslinkable tetraglycidyl diamino diphenyl methane (TGDDM). The β relaxation peaks are analyzed in terms of their area, FWHM, and position (Tβ) and are observed to correlate strongly with changes in the modulus, yield stress, and strain.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Vidil T, Tournilhac F, Musso S, Robisson A, Leibler L. Control of reactions and network structures of epoxy thermosets. Prog Polym Sci. 2016;62:126–79.

Francois C, Pourchet S, Boni G, Rautiainen S, Samec J, Fournier L, et al. Design and synthesis of biobased epoxy thermosets from biorenewable resources. Comptes Rendus Chim. 2017;20:1006–16.

Tian N, Ning RC, Kong J. Self-toughening of epoxy resin through controlling topology of cross-linked networks. Polymer. 2016;99:376–85.

Wu JH, Xiao CD, Yee AF, Klug CA, Schaefer J. Controlling molecular mobility and ductile-brittle transitions of polycarbonate copolymers. J Polym Sci Part B-Polym Phys. 2001;39:1730–40.

Fei XM, Wei W, Tang YY, Zhu Y, Luo J, Chen MQ, et al. Simultaneous enhancements in toughness, tensile strength, and thermal properties of epoxy-anhydride thermosets with a carboxyl-terminated hyperbranched polyester. Eur Polym J. 2017;90:431–41.

Liu HC, Zhang JQ, Gao XX, Huang GS. Simultaneous reinforcement and toughness improvement of an epoxy-phenolic network with a hyperbranched polysiloxane modifier. Rsc Adv. 2018;8:17606–15.

Misasi JM, Jin QF, Knauer KM, Morgan SE, Wiggins JS. Hybrid poss-hyperbranched polymer additives for simultaneous reinforcement and toughness improvements in epoxy networks. Polymer. 2017;117:54–63.

Wang YM, Chen SF, Chen XC, Lu YF, Miao MH, Zhang DH. Controllability of epoxy equivalent weight and performance of hyperbranched epoxy resins. Compos Part B-Eng. 2019;160:615–25.

Cook WD, Mayr AE, Edward GH. Yielding behaviour in model epoxy thermosets—ii. Temp Depend, Polym. 1998;39:3725–33.

Mayr AE, Cook WD, Edward GH. Yielding behaviour in model epoxy thermosets—i. Effect of strain rate and composition. Polymer. 1998;39:3719–24.

Espuche E, Galy J, Gerard JF, Pascault JP, Sautereau H. Influence of cross-link density and chain flexibility on mechanical-properties of model epoxy networks. Macromol Symposia. 1995;93:107–15.

Urbaczewskiespuche E, Galy J, Gerard JF, Pascault JP, Sautereau H. Influence of chain flexibility and cross-link density on mechanical-properties of epoxy amine networks. Polym Eng Sci. 1991;31:1572–80.

Oleinik EF. Epoxy-aromatic amine networks in the glassy state structure and properties. Adv Polym Sci. 1986;80:49–99.

Heux L, Halary JL, Laupretre F, Monnerie L. Dynamic mechanical and c-13 nmr investigations of molecular motions involved in the beta relaxation of epoxy networks based on dgeba and aliphatic amines. Polymer. 1997;38:1767–78.

Heux L, Laupretre F, Halary JL, Monnerie L. Dynamic mechanical and c-13 nmr analyses of the effects of antiplasticization on the beta secondary relaxation of aryl-aliphatic epoxy resins. Polymer. 1998;39:1269–78.

Shi JF, Inglefield PT, Jones AA, Meadows MD. Sub-glass transition motions in linear and cross-linked bisphenol-type epoxy resins by deuterium line shape nmr. Macromolecules. 1996;29:605–9.

Hardis R, Jessop JLP, Peters FE, Kessler MR. Cure kinetics characterization and monitoring of an epoxy resin using dsc, raman spectroscopy, and dea. Compos Part a-Appl Sci Manuf. 2013;49:100–8.

Scherzer T. Ftir-rheo-optical characterization of the molecular orientation behaviour of amine cured epoxy resins during cyclic deformation. Polymer. 1996;37:5807–16.

Scherzer T. Characterization of the molecular deformation behavior of glassy epoxy resins by rheo-optical ftir spectroscopy. J Polym Sci Part B-Polym Phys. 1996;34:459–70.

Heinz S, Tu JW, Jackson M, Wiggins J. Digital image correlation analysis of strain recovery in glassy polymer network isomers. Polymer. 2016;82:87–92.

Ramsdale-Capper R, Foreman JP. Internal antiplasticisation in highly crosslinked amine cured multifunctional epoxy resins. Polymer. 2018;146:321–30.

Tu JW, Tucker SJ, Christensen S, Sayed AR, Jarrett WL, Wiggins JS. Phenylene ring motions in isomeric glassy epoxy networks and their contributions to thermal and mechanical properties. Macromolecules. 2015;48:1748–58.

Jin QF, Misasi JM, Wiggins JS, Morgan SE. Simultaneous reinforcement and toughness improvement in an aromatic epoxy network with an aliphatic hyperbranched epoxy modifier. Polymer. 2015;73:174–82.

Pham S, Burchill PJ. Toughening of vinyl ester resins with modified polybutadienes. Polymer. 1995;36:3279–85.

Lee SE, Jeong E, Lee MY, Lee MK, Lee YS. Improvement of the mechanical and thermal properties of polyethersulfone-modified epoxy composites. J Ind Eng Chem. 2016;33:73–9.

Matejka L, Amici Kroutilova I, Lichtenhan JD, Haddad TS. Structure ordering and reinforcement in poss containing hybrids. Eur Polym J. 2014;52:117–26.

Acknowledgements

This work was partially supported by The Australian Research Council (DP180100094).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declares that they have no conflict of interest.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Reyes, L.Q., Swan, S.R., Gan, H. et al. The role of β relaxations in controlling compressive properties in hyperbranched polymer-modified epoxy networks. Polym J 53, 393–401 (2021). https://doi.org/10.1038/s41428-020-00433-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-020-00433-3

This article is cited by

-

Reinforcing and Toughening Modification of PPC/PBS Blends Compatibilized with Epoxy Terminated Hyperbranched Polymers

Journal of Polymers and the Environment (2022)