Abstract

The asymmetrical alicyclic dianhydride 3,4-dicarboxy-1,2,3,4-tetrahydro-6-methyl-1-naphthalene succinic dianhydride (MTDA, II) was synthesized from 4-methylstyrene and maleic anhydride under nitric oxide catalysis with a yield >70%. A series of semi-alicyclic polyimides (PIs) (PI–IIa∼PI–IId) were prepared by a one-step high temperature polycondensation procedure from MTDA and various aromatic diamines. For comparison, another series of PIs (PI–Ia∼PI–Id) were prepared from the analogous dianhydride 3,4-dicarboxy-1,2,3,4-tetrahydro-1-naphthalene succinic dianhydride (TDA, I) and the same diamines. The asymmetrical molecular structure of MTDA endowed the derived PIs with good solubilities in common solvents and high optical transparencies in the ultraviolet and visible light regions by decreasing the intramolecular or intermolecular interactions of the polymer chains. The flexible and tough PI films exhibited good thermal stability up to 400 °C and showed glass transition temperatures in the range of 204–271 °C. The PI films exhibited good optical transparency with transmittances >80% at 400 nm, a cut-off wavelength <300 nm and a refractive index <1.54.

Similar content being viewed by others

Introduction

As one important group of high performance polyimides (PIs), alicyclic PIs have attracted significant attention from both the scientific and technical viewpoints over the past several decades.1, 2, 3 After many years of basic research and development, alicyclic PIs have found applications in many new industries and technologies such as advanced opto-electronic fabrication, high-quality displays and the information industry.4 Compared with their aromatic analogues, alicyclic PIs usually possess good combined properties including superior optical transparency, lower dielectric constants and dissipation factors, and acceptable thermal and thermal-mechanical stabilities at elevated temperatures.

Commercial alicyclic PIs are usually synthesized from alicyclic dianhydrides and aromatic diamines depending on the desired characteristics of the resulting PIs.5, 6, 7, 8 For instance, alicyclic PIs based on 1,2,3,4-cyclobutane tetracarboxylic dianhydride or 2,3,5-tricarboxycyclopentaneacetic dianhydride have been successfully commercialized as alignment layers for the fabrication of thin film transistor driven active matrix liquid crystal display devices.9, 10, 11 Colorless PI films derived from 1,2,4,5-cyclohexane tetracarboxylic dianhydride have also been applied in optical fiber communications and solar energy fields.12

Although alicyclic PIs have received a great deal of attention for high-tech applications, several obstacles must be overcome to enable their further development, in particular, their high cost and difficult synthesis. Matsumoto et al.13 summarized the synthetic pathways of alicyclic dianhydrides. Severe reaction conditions such as photoirradiation or high-pressure oxidation with nitric acid or ozone are often used in the synthesis of the dianhydrides. Thus, a low-cost synthetic route to obtain alicyclic monomers is highly desired to enable the development of high performance alicyclic PIs. Among various commercially available alicyclic dianhydrides, 3,4-dicarboxy-1,2,3,4-tetrahydro-1-naphthalene succinic dianhydride or tetralin dianhydride (TDA) has been widely utilized to develop high performance PIs, including highly soluble PIs,14 orienting layers for liquid crystal alignment15 and ultrafiltration membranes.16 The asymmetrical tetralin moiety in TDA endows the PIs with good combined properties. Furthermore, as previously reported, TDA is easily prepared at a large scale by a low-cost route using styrene and maleic anhydride as the starting materials and oxygen-containing gas as the catalyst.17

As part of our systematic work aimed at developing high-performance alicyclic PI optical polymers, this work reports the synthesis of a new methyl-substituted TDA dianhydride, 3,4-dicarboxy-1,2,3,4-tetrahydro-6-methyl-1-naphthalene succinic dianhydride (MTDA, II). Further, MTDA was polymerized with several aromatic diamines to afford four PIs, PI–IIa∼PI–IId. The effects of the structure of MTDA on the solubility, thermal stability and optical properties of the PIs were evaluated in detail.

Experimental procedures

Materials

Styrene and 4-methylstyrene were purchased from Tokyo Chemical Industry Co., Ltd., Tokyo, Japan (TCI) and used as received. It is unnecessary to remove inhibitors from these chemicals. Maleic anhydride was obtained from Beijing Yili Fine Chemicals (Beijing, China) and used as received. 4,4′-Oxydianiline (ODA) (from TCI), 1,4-bis(4-aminophenoxy)benzene (APB) (from TCI), 2,2-bis[(4-aminophenoxy)phenyl]propane (BAPP) (from TCI) and 2,2-bis[(4-aminophenoxy)phenyl]hexafluoropropane (BDAF) (from Beijing POME Sci. Technol. Co. Ltd., Beijing, China) were recrystallized from ethanol and dried under vacuum at 80 °C overnight prior to use. N-methyl-2-pyrrolidinone (NMP), N,N-dimethylacetamide, cyclopentanone, tetrahydrofuran and other solvents were purified by distillation prior to use. The other commercially available reagents were used without further purification.

Measurements

Inherent viscosity was measured using an Ubbelohde viscometer with a 0.5-g dl−1 NMP solution at 25 °C. Absolute viscosity was measured using a Brookfield DV-II+ Pro viscometer (Brookfield Engineering Laboratories, Inc., Middleboro, MA, USA) at 25 °C. Fourier-transform infrared spectra were obtained using a Tensor 27 Fourier transform spectrometer. UV-vis spectra were recorded on a Hitachi U-3210 spectrophotometer (Hitachi, Ltd., Tokyo, Japan) at room temperature. The cut-off wavelength was defined as the point in the spectrum where the transmittance drops <1%. Prior to testing, PI samples were dried at 100 °C for 1 h to remove the absorbed moisture. Nuclear magnetic resonance spectra (1H NMR and 13C NMR) were obtained on an AV 400 spectrometer (Bruker Daltonics Inc., Billerica, MA, USA) operating at 400 MHz in dimethyl sulphoxide (DMSO)-d6 or CDCl3. Differential scanning calorimetry (DSC) and thermogravimetric analysis were recorded on a TA-Q series thermal analysis system (TA Instruments, New Castle, DE, USA) at heating rates of 10 °C min−1 and 20 °C min−1 in nitrogen or air, respectively. The tensile properties were tested on an Instron 3365 tensile apparatus with 80 × 10 × 0.05 mm3 specimens in accordance with GB1447-83 at a drawing rate of 2.0 mm min−1. Gel permeation chromatography measurements were performed using a Waters 1515 high-performance liquid chromatography pump (Waters Association Inc., Milford, MA, USA) equipped with a Waters 2414 refractive index detector. Two Waters Styragel HR 4 columns kept at 35±0.1 °C were used with high-performance liquid chromatography grade tetrahydrofuran as the mobile phase at a flow rate of 1.0 ml min−1.

Solubility was determined as follows: 1.5 g of the PI resin was mixed with 8.5 g of the tested solvent at room temperature (15 wt% solid content), which was then mechanically stirred under nitrogen for 24 h. The solubility was determined visually as three grades: completely soluble (++), partially soluble (+) and insoluble (−). The complete solubility is defined as the point where a homogenous and clean solution is obtained without any phase separation, precipitation or gel formation.

The refractive index of the PI film formed on a 3-inch silicon wafer was measured at room temperature with a prism coupler (Metricon Corporation, Pennington, NJ, USA, model PC-2010) equipped with a He-Ne laser light source (wavelength: 632.8 nm). The in-plane (nTE) and out-of-plane (nTM) refractive indices were determined using linearly polarized laser light parallel (transverse electric, TE) and perpendicular (transverse magnetic, TM) polarizations to the film plane, respectively. The nTE/nTM birefringence (Δn) was calculated as the difference between nTE and nTM. The average refractive index (nav) was calculated according to equation (1):

Monomer synthesis

3,4-Dicarboxy-1,2,3,4-tetrahydro-6-methyl-1-naphthalene succinic dianhydride (MTDA, II)

Into a 500 ml three-necked flask equipped with a mechanical stirrer, a gas inlet and a condenser, 43.75 g (0.446 mol) of maleic anhydride, 80.60 g (0.682 mol) of 4-methylstyrene and 0.1138 g (0.5 mmol) of 2,5-di-tert-butyl hydroquinone were added. Nitrogen was first introduced to remove the air from the system. Then nitric oxide was introduced from a gas inlet placed under the surface of the reaction solution. The reaction mixture was heated to 120 °C and maintained for 5 h under a nitric oxide atmosphere. The resulting red-brown nitrogen oxide gas was trapped by passing it through an aqueous solution of 20 wt% sodium hydroxide. An orange precipitate formed during the reaction. After the reaction, the mixture was cooled to room temperature and then 60 ml of acetonitrile was added. The reaction mixture was heated to reflux for another 0.5 h. Then, 60 ml of toluene was added and the reaction mixture was cooled to room temperature. The produced white needle crystals were collected by filtration, and the solid was washed with toluene and petroleum ether in succession. After vacuum drying at 80 °C for 24 h, the pure MTDA was obtained as white crystals. The yield was 51.44 g (73.4%).

Melting point: 229 °C (DSC peak temperature). Fourier-transform infrared (FT IR) (KBr, cm−1): 2941, 1855, 1778, 1506, 1412, 1223, 1076 and 916. 1H-NMR (DMSO-d6, p.p.m.): 7.35 (s, 1H), 7.15–7.13 (m, 1H), 7.10–7.09 (m, 1H), 4.56–4.54 (d, 1H), 4.12–4.10 (m,1H), 3.83–3.81 (m, 1H), 3.18–3.13 (m, 1H), 3.09 (m, 1H), 2.82–2.78 (m, 1H), 2.32 (s, 3H), 1.97–1.95 (m, 1H) and 1.86–1.85 (m, 1H). 13C NMR (DMSO-d6, p.p.m.): 175.8, 175.3, 173.8, 172.4, 138.1, 135.0, 131.8, 130.5, 129.9, 127.7, 45.1, 44.2, 36.4, 32.3, 26.4 and 22.0. MS (EI, m/e, percentage of relative intensity): 142 (M+−172, 100). Elemental analysis: calculated for C17H14O6: C, 64.97%, H, 4.49%; found: C, 64.32%, H, 4.44%.

3,4-Dicarboxy-1,2,3,4-tetrahydro-1-naphthalene succinic dianhydride (TDA, I)

This dianhydride was synthesized from styrene and maleic anhydride through a similar route to the route used for MTDA. The product was obtained as white crystals. The yield was 48.41 g (72.3%).

Melting point: 199 °C (DSC peak temperature). Fourier-transform infrared (KBr, cm−1): 2966, 1861, 1780, 1493, 1405, 1229, 1058 and 928. 1H-NMR (DMSO-d6, p.p.m.): 7.69-7.67 (d, 1H), 7.38–7.27 (m, 2H), 7.20–7.19 (d, 1H), 4.67–4.64 (d, 1H), 3.73–3.58 (m, 2H), 3.40–3.33 (m, 1H), 2.85–2.80 (m, 2H) and 2.12–2.07 (m, 2H). 13C NMR (DMSO-d6, p.p.m.): 173.8, 173.5, 172.1, 170.8, 136.4, 129.5, 128.4, 128.1, 127.5, 127.4, 42.8, 42.1, 37.3, 36.7, 32.8 and 26.2. MS (EI, m/e, percentage of relative intensity):128 (M+−172, 100). Elemental analysis: calculated for C16H12O6: C, 64.00%, H, 4.03%; found: C, 64.10%, H, 4.03%.

Polymer synthesis and film preparation

The general procedure for the synthesis of PIs can be illustrated by the preparation of PI–IIa. Into a 250-ml three-necked, round-bottomed flask equipped with a mechanical stirrer, a Dean-Stark trap and a nitrogen inlet, ODA (2.0024 g, 10 mmol) was dissolved in m-cresol (10 g) to give a clear solution. Then MTDA (3.1429 g, 10 mmol) was added in one batch, and an additional volume of m-cresol (10 g) was added to wash the residual dianhydride and adjust the solid content of the reaction system to 20 wt%. After stirring under nitrogen for 1 h, a mixture of toluene (36 ml) and isoquinoline (catalytic amount) was then added. The reaction mixture was heated to 180 °C and maintained for 6 h. During the reaction, the toluene–water azeotrope was distilled out of the system and collected in the Dean-Stark trap. After cooling to room temperature, the viscous solution was carefully poured into an excess of ethanol to yield a silky resin. The resin was collected and dried at 80 °C in vacuo for 24 h. The yield was 5.00 g (96%).

PI–IIa resin (1.5 g) was dissolved in NMP (8.5 g) at room temperature to afford a 15-wt% solution. The solution was filtered through a 0.45-μm Teflon syringe filter to remove any undissolved impurities. Then the solution was spin-coated onto a clean silicon wafer or quartz substrate. The thickness of the PI film was controlled by regulating the spinning rate. PI–IIa films with thicknesses ranging from 10 to 100 μm were obtained by thermally baking the solution in a nitrogen flow according to the following heating procedure: 80 °C per 2 h, 150 °C per 1 h, 200 °C per 1 h and 250 °C per 1 h.

The other PI resin and films were prepared according to a similar procedure as mentioned above.

Results and Discussion

Monomer synthesis

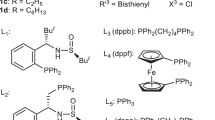

Scheme 1 shows the synthetic procedure for MTDA and TDA. The target compounds were synthesized by the Diels–Alder reactions of styrene (for TDA) or 4-methylstyrene (for MTDA) and maleic anhydride, followed by the rearrangement reaction of the intermediate. (Methyl)styrene was used as both the reactant and the solvent. In the literature, TDA has been synthesized from styrene and maleic anhydride with a molar ratio of 2.1:1.17 Toluene and flowing air (15 l h−1) were used as the solvent and catalyst, respectively. The obtained TDA dianhydride has to be purified by recrystallization from a toluene/acetone mixture to remove the oxidized byproducts. In our experiments, the reductive nitric oxide was used instead of the oxidative air. The obtained dianhydrides have good purities and can be used directly for polymerization. These products can also be further purified by dissolution in a good solvent of acetonitrile and then precipitated slowly by adding the poor solvent toluene, although this may result in a slight reduction of yield. This reaction can be easily expanded to a large scale and we have successfully synthesized several hundred grams per batch.

Figure 1 shows the FT IR spectra of the dianhydrides, in which the characteristic bands of the carbonyl groups in the anhydride moiety of MTDA were clearly observed at 1855 and 1778 cm−1. In addition, the characteristic absorption of the methyl group appeared at 2941 cm−1 for MTDA. The 13C NMR and two dimensional 1H–13C heteronuclear single-quantum coherence spectra of MTDA are illustrated in Figure 2, together with the assignments of the observed resonances. As depicted in Figure 2a, 17 signals are clearly revealed; among these, 10 carbons induce signals in the DEPT-135 measurements because of their attached protons. This result is consistent with the proposed structure. In Figure 2b, the absorptions of the protons agreed well with those of the corresponding carbon signals. Interestingly, the two pairs of protons in the methylene groups (H3,3′ and H6,6′) exhibited individual absorptions in the 1H NMR spectrum owing to the slightly different chemical environments of the protons in the dianhydride. The protons in the aromatic ring (H12, H13 and H15) appeared at the lowest field in the spectrum.

In addition, the elemental analytical results also revealed the successful preparation of the target dianhydrides.

Polymer synthesis

As shown in Scheme 2, PI–Ia∼d and PI–IIa∼d were prepared by a one-step, high-temperature polycondensation procedure in m-cresol solution at a temperature of 180 °C. White or pale-yellow fibrous PI resins were obtained quantitatively, with inherent viscosities of 0.55∼0.76 dl g−1 for TDA-PIs (PI–Ia∼d) and 0.43∼0.68 dl g−1 for MTDA-PIs (PI–IIa∼d) (Table 1). These values indicate that the current PIs possess moderate-to-high molecular weights. The average numerical molecular weight of the PI resins can be increased by subsequent thermal baking at elevated temperatures. For instance, PI–IId (MTDA-BDAF) resin exhibited a numerical molecular weight value of 17,733 g mol−1, which increased to 20,189 g mol−1 after thermal baking of the resin solution at temperatures up to 250 °C. Apparently, a post-polymerization occurs in the curing process of the PI. Flexible and tough PI films were obtained by casting the solutions in NMP, followed by baking at elevated temperatures from 80 to 250 °C. All the films exhibited good tensile properties. For instance, PI–IIa showed a tensile strength of 84 MPa, an elongation at breakage of 7.0% and a tensile modulus of 2.5 GPa.

Figure 1 compares the FT IR spectra of the dianhydrides and the PIs. The characteristic absorptions of the carbonyls in TDA (1861 cm−1) and MTDA (1855 cm−1) disappear in the spectra of PI–Ia and PI–IIa, respectively. Instead, the absorptions at 1780 and 1720 cm−1 arising from the asymmetric and symmetric carbonyl stretching vibrations of the imide groups are observed in both of the PIs. Additionally, the absorption at 1381 cm−1 is assigned to the C–N stretching vibration of the imide structure. A typical 1H NMR spectrum of PI–IIa (MTDA-ODA) is shown in Figure 3. The spectrum is clearly divided into two parts. One part consists of the aliphatic, alicyclic and methyl protons in the upfield region, which ranged from 1.85 to 4.56 p.p.m.; the other part contains the aromatic protons in the dianhydride moiety (H9, H10 and H11) and the diamine moiety (H12 and H13), which ranged from 7.09 to 7.35 p.p.m. Similarly, the two pairs of protons in the methylene groups (H2,3 and H5,6) exhibited individual absorptions in the spectrum because of the different chemical environments of the protons in the polymer.

Solubility

Table 1 summarizes the solubility of the PIs synthesized here. All the PIs were easily soluble in polar aprotic solvents (NMP and N,N-dimethylacetamide), m-cresol and γ-butyrolactone at a concentration of 15 wt%. Among the PIs, PI–IIc (MTDA-BAPP) and PI–IId (MTDA-BDAF) showed the best solubility owing to the synergistic effects of the bulky tetralin moiety, the pendant methyl substituent and the flexible ether and isopropylidene or hexafluoroisopropylidene linkages. The PIs were wholly soluble in tetrahydrofuran and dichloromethane at room temperature. Under the same conditions, PI–Ic (TDA-BAPP) and PI–Id (TDA-BDAF) were only partially soluble in dichloromethane. The enhancement of the solubility of MTDA-PIs can be attributed to the looser packing of the molecular chains induced by the lateral methyl group.

We further investigated the effects of solvents on the solubility of the PIs. Figure 4 illustrates the correlations between the absolute viscosities (η) and solid contents of PI–IIa (MTDA-ODA) in NMP and γ-butyrolactone. Although PI–IIa was soluble in both of the tested solvents, the η values were quite different. For instance, at the same solid content of 25 wt%, PI–IIa had an η value of 8.40 Pascal·second (Pa·s) in NMP, much lower than that in γ-butyrolactone (53.2 Pa·s). Thus, for practical applications, NMP is better suited for use in developing a soluble MTDA-PI solution with a high solid content and a relatively low viscosity. When comparing polymers made with the same diamine, the solubility of MTDA-PI is greater than that of its TDA-PI analogues. For instance, as mentioned above, PI–IIa (MTDA-ODA) showed an η value of 8.40 Pa·s in NMP at a solid content of 25 wt%. However, under the same conditions, PI–Ia (TDA-ODA) exhibited a much higher η value (42.6 Pa·s), indicating its lower solubility in this solvent.

Thermal properties

The effects of the asymmetrical methyl-substituted tetralin structure in MTDA on the thermal stabilities of the PIs were investigated by thermogravimetric analysis and DSC measurements. Table 2 summarizes the thermal characterization of the polymers. Figure 5 depicts the thermogravimetry plots of TDA-PIs and MTDA-PIs obtained in nitrogen over a temperature range of 100–700 °C. These plots show that the current PIs possess good thermal stability with no significant weight loss up to ∼400 °C. Above 400 °C, the PIs lose their original weight rapidly, reaching a residual weight ratio in the range of 9.45–20.47% at 700 °C. The 10% weight loss temperatures (T10%) of the PIs are all >400 °C in nitrogen. This implies that the incorporation of the aliphatic or alicyclic moiety in the PIs did not reduce their thermal stabilities. Although the thermal stability of the current PIs is lower than that of common aromatic PIs, it is high enough to enable applications in microelectronic fabrication and display fields.

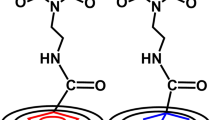

Glass transition temperature (Tg) values were obtained from the second heating scans of PI samples at a heating rate of 10 °C min−1 (Figure 6 and Table 2). All the polymers exhibit good thermal stabilities with Tg values in the range of 204–271 °C, depending on the rigidity of the aromatic diamines. For the same dianhydride, the Tg values of the PIs followed the order ODA>APB>BDAF>BAPP. Decreasing Tg generally correlated with an increasing chain flexibility. In both series, the PIs derived from BAPP and BDAF showed the lowest Tg values due to the increase in the flexibility of polymer chains arising from the flexible isopropylidene or hexafluoroisopropylidene bridges, whereas the PIs obtained from ODA had the highest values because these molecular chains contain the least flexible linkages.

Optical properties

It has been well established in the literature that the optical transparency of aromatic PI films can be efficiently improved by decreasing the formation of intra- and inter-molecular charge transfer complexes in the PI chains.18, 19 When properly designed, colorless PI films can even be obtained. Among various methodologies used to decrease charge transfer complexes formations, the introduction of an alicyclic moiety either in the dianhydride or in the diamine moiety has proven to be one of the most effective procedures.

In the present work, the MTDA-PI films were obtained as pale-yellow free-standing films. The coloration of the MTDA-PI films could be because of the phenyl ring in the tetralin dianhydride moiety, which might interact with the benzene moiety in the aromatic diamine unit forming an intermolecular charge transfer complexes. The optical properties of the films are summarized in Table 3 and the UV-vis spectra of the MTDA-PI films are illustrated in Figure 7. The PI films showed good optical transparency in the UV-vis light region, with cut-off wavelengths <300 nm and transmittances >80% at 400 nm at a thickness of 10 μm. The good optical transparency of the current PI films, on the one hand, is attributed to the asymmetrical and bulky alicyclic tetralin structure of the dianhydride unit. On the other hand, the flexible ether or (hexafluoro)isopropylidene bridges in the diamine moiety are also beneficial for improving the optical transparency of the PI films by reducing the conjugation of the PI chains. PI–Id and PI–IId, which contain trifluoromethyl groups in the polymer chains, exhibited lower cut-off wavelengths and higher optical transmittances than their CF3-free analogous PIs. The bulky and electron-withdrawing CF3 group in BDAF was presumably effective in decreasing charge transfer complexes formation through steric hindrance and the inductive effect. This low-color feature of the PI films synthesized here is extremely desirable for their application in optical devices such as transistor driven active matrix liquid crystal display devicess.

Refractive indices of the PI films at 633 nm were determined by a prism coupler. Table 3 shows the nTE, nTM, average refractive indices (nav) and birefringences (Δn) of PI films. The Δn values of the PI films were obtained as 0.0013–0.0055. These relatively small values reveal that the polymers have low polarizability and anisotropy, and that the polymer chains are preferentially oriented in the film plane. This low degree of molecular orientation of the PIs can be attributed to the existence of flexible ether linkages in the molecular chains. The nav values of the PI films were determined as 1.5120–1.5395 for TDA-PIs and 1.5065–1.5364 for MTDA-PIs, respectively. As shown in Table 3, MTDA-PI films showed slightly lower nav values, but they were still very close to those of the TDA-PI analogues. According to the Lorentz–Lorenz equation,20 the refractive index of one polymer is mainly affected by the molar refraction and molar volumes of the polymer chains. In the present case, the introduction of the bulky methyl group in MTDA-PIs slightly decreased the refractive indices of the polymers. However, this decrease is limited owing to the relatively low molar volumes of the methyl groups. In other work that will be reported in the future, the refractive indices of the PIs have been reduced by introducing a bulkier tert-butyl group.

PI–IId (MTDA-BDAF) exhibited the lowest nav value (1.5065) of the series, mainly because of its relatively lower molecular packing density induced by the synergistic effects of the bulky tetralin moiety, the pendant methyl substituent and flexible hexafluoroisopropylidene and ether linkages.

Conclusion

A series of semi-alicyclic PIs were designed and synthesized with the aim of improving their solubility in common solvents and their optical transparency in the UV-visible light region without negatively affecting their thermal stability. This goal was achieved by developing PIs from an alicyclic dianhydride MTDA and various aromatic diamines. The asymmetrical structure of MTDA interrupts the regularity of the PI molecule chains, thus enhancing the solubility of the PIs in common solvents. Meanwhile, this irregular packing of the PI chains is beneficial for the penetration of UV and visible light, resulting in good optical transparency. Finally, incorporating the bulky alicyclic tetralin moiety in the dianhydride unit did not induce a significant deterioration in the thermal stability. Therefore, the present semi-alicyclic PIs are considered to be one of the most promising optical polymers for opto- and microelectronic applications.

Synthesis of tetralin dianhydrides.

Synthesis of alicyclic polyimides (PI–Ia∼d and PI–IIa–d).

References

Matsumoto, T., Mikami, D., Hashimoto, T., Kaise, M., Takahashi, R. & Kawabata, S. Alicyclic polyimides- a colorless and thermally stable polymer for opto-electronic devices. J. Phys. Conf. Ser 187, 012005 (1–10) (2009).

Matsumoto, T. & Kurosaki, T. Soluble and colorless polyimides from bicyclo- [2.2.2]octane-2,3,5,6-tetracarboxylic 2,3:5,6-dianhydrides. Macromolecules 30, 993–1000 (1997).

Matsumoto, T. Nonaromatic polyimides derived from cycloaliphatic monomers. Macromolecules 32, 4933–4939 (1999).

Mathews, A. S., Kim, I. & Ha, C. S. Synthesis, characterization, and properties of fully aliphatic polyimides and their derivatives for microelectronics and optoelectronics applications. Macromol. Res. 15, 114–128 (2007).

Watanabe, Y., Shibasaki, Y., Ando, S. & Ueda, M. Synthesis of semiaromatic polyimides from aromatic diamines containing adamantly units and alicyclic dianhydrides. J. Polym. Sci., Part A: Polym. Chem 42, 144–150 (2004).

Liu, J. G., He, M. H., Zhou, H. W., Qian, Z. G., Wang, F. S. & Yang, S. Y. Organosoluble and transparent polyimides derived from alicyclic dianhydride and aromatic diamines. J. Polym. Sci., Part A: Polym. Chem 40, 110–119 (2002).

Kudo, K., Nonokawa, D., Li, J. & Shiraishi, S. Synthesis of optically active alicyclic polyimides from a chiral, nonracemic dianhydride. J. Polym. Sci., Part A: Polym. Chem 40, 4038–4044 (2002).

Fang, X. Z., Yang, Z. H., Zhang, S. B., Gao, L. X. & Ding, M. X. Synthesis and properties of polyimides derived from cis- and trans-1,2,3,4-cyclohexane tetracarboxylic dianhydrides. Polymer 45, 2539–2549 (2004).

Lee, Y. J., Kim, Y. W., Ha, J. D., Oh, J. M. & Yi, M. H. Synthesis and characterization of novel polyimides with 1-octadecyl side chains for liquid crystal alignment layers. Polym. Adv. Technol 18, 226–234 (2007).

Nishikwa, M. Development of novel polyimide alignment films for liquid crystal display televisions. J. Photopolym. Sci. Technol 124, 317–320 (2011).

Nishikawa, M., Matsuki, Y., Bessho, N., Iimura, Y. & Kobayashi, S. Characterization of polyimide liquid crystal alignment films for active matrix-LCD use. J. Photopolym. Sci. Technol. 8, 233–240 (1995).

Liu, J. G., Nakamura, Y., Ogura, T., Shibasaki, Y., Ando, S. & Ueda, M. Optically transparent sulfur-containing polyimide−TiO2 nanocomposite films with high refractive index and negative pattern formation from poly(amic acid)−TiO2 nanocomposite film. Chem. Mater 20, 273–281 (2008).

Matsumoto, T. Alicyclic polyimides: an approach from monomer synthesis. J. Synth. Org. Chem. Jpn. 62, 776–786 (2000).

Tsuda, Y., Kuwahara, R., Fukuda, K., Ueno, K. & Oh, J. M. Soluble polyimides and copolyimides based on alicyclic dianhydride having cyclohexene and tetralin moiety. Polym. J. 37, 126–132 (2005).

Lee, C. J., Woo, T. H. & Lee, M. S. Effect of alkyl side chain of soluble polyimide orienting layer on liquid crystal alignment. Mol. Cryst. Liq. Cryst. 316, 205–208 (1998).

Kim, I. C., Park, K. W. & Tak, T. M. Synthesis and characterization of soluble polyimides and its ultrafiltration membrane performances. J. Appl. Polym. Sci. 73, 907–918 (1999).

Olbrich, J. & Dorffel, J. Process for reacting maleic anhydride with vinylbenzenes. US Patent 4614808 (1986).

Ando, S., Matsuura, T. & Sasaki, S. Coloration of aromatic polyimides and electronic properties of their source materials. Polym. J. 29, 69–76 (1997).

Hasegawa, M. & Horie, K. Photophysics, photochemistry, and optical properties of polyimides. Prog. Polym. Sci. 26, 259–335 (2001).

Liu, J. G., Nakamura, Y., Shibasaki, Y., Ando, S. & Ueda, M. Synthesis and characterization of high refractive index polyimides derived from 4,4′-(p-phenylenedisulfanyl) dianiline and various aromatic tetracarboxylic dianhydrides. Polym. J. 39, 543–550 (2007).

Acknowledgements

We gratefully acknowledge the financial support from the National Natural Science Foundation of China (50403025).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Guo, Yz., Song, Hw., Zhai, L. et al. Synthesis and characterization of novel semi-alicyclic polyimides from methyl-substituted tetralin dianhydride and aromatic diamines. Polym J 44, 718–723 (2012). https://doi.org/10.1038/pj.2012.12

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2012.12

Keywords

This article is cited by

-

Synthesis and characterization of an aromatic diamine and its polyimides containing asymmetric large side groups

Polymer Bulletin (2020)

-

Synthesis and characterization of high-temperature-resistant and optically transparent polyimide coatings for potential applications in quartz optical fibers protection

Journal of Coatings Technology and Research (2019)