Abstract

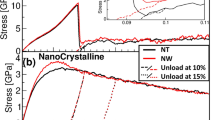

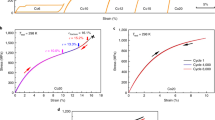

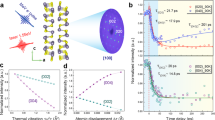

Anelastic materials exhibit gradual full recovery of deformation once a load is removed, leading to dissipation of internal mechanical energy1. As a consequence, anelastic materials are being investigated for mechanical damping applications. At the macroscopic scale, however, anelasticity is usually very small or negligible, especially in single-crystalline materials2,3. Here, we show that single-crystalline ZnO and p-doped Si nanowires can exhibit anelastic behaviour that is up to four orders of magnitude larger than the largest anelasticity observed in bulk materials, with a timescale on the order of minutes. In situ scanning electron microscope tests of individual nanowires showed that, on removal of the bending load and instantaneous recovery of the elastic strain, a substantial portion of the total strain gradually recovers with time. We attribute this large anelasticity to stress-gradient-induced migration of point defects, as supported by electron energy loss spectroscopy measurements and also by the fact that no anelastic behaviour could be observed under tension. We model this behaviour through a theoretical framework by point defect diffusion under a high strain gradient and short diffusion distance, expanding the classic Gorsky theory. Finally, we show that ZnO single-crystalline nanowires exhibit a high damping merit index, suggesting that crystalline nanowires with point defects are promising materials for energy damping applications.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Lakes, R. Viscoelastic Material (Cambridge Univ. Press, 2009).

Zener, C. Elasticity and Anelasticity of Metals (Univ. Chicago Press, 1948).

Nowick, A. S. & Berry, B. S. Anelastic Relaxation in Crystalline Solids (Academic, 1972).

Wang, Z. L. & Song, J. H. Piezoelectric nanogenerators based on zinc oxide nanowire arrays. Science 312, 242–246 (2006).

Chan, C. K. et al. High-performance lithium battery anodes using silicon nanowires. Nature Nanotech. 3, 31–35 (2008).

McAlpine, M. C. et al. High-performance nanowire electronics and photonics on glass and plastic substrates. Nano Lett. 3, 1531–1535 (2003).

Xu, F., Lu, W. & Zhu, Y. Controlled 3D buckling of silicon nanowires for stretchable electronics. ACS Nano 5, 672–678 (2011).

Takei, K. et al. Nanowire active-matrix circuitry for low-voltage macroscale artificial skin. Nature Mater. 9, 821–826 (2010).

Feng, X. L., He, R., Yang, P. & Roukes, M. L. Very high frequency silicon nanowire electromechanical resonators. Nano Lett. 7, 1953–1959 (2007).

Park, H. S., Cai, W., Espinosa, H. D. & Huang, H. Mechanics of crystalline nanowires. MRS Bull. 34, 178–183 (2009).

Richter, G. et al. Ultra high strength single crystalline nanowhiskers grown by physical vapor deposition. Nano Lett. 9, 3048–3052 (2009).

Zhu, Y., Xu, F., Qin, Q. Q., Fung, W. Y. & Lu, W. Mechanical properties of vapor–liquid–solid synthesized silicon nanowires. Nano Lett. 9, 3934–3939 (2009).

Chen, C. Q., Shi, Y., Zhang, Y. S., Zhu, J. & Yan, Y. J. Size dependence of the Young's modulus of ZnO nanowires. Phys. Rev. Lett. 96, 75505 (2006).

Wu, B., Heidelberg, A. & Boland, J. J. Mechanical properties of ultrahigh-strength gold nanowires. Nature Mater. 4, 525–529 (2005).

Chen, B. et al. Anelastic behavior in GaAs semiconductor nanowires. Nano Lett. 13, 3169–3172 (2013).

Qin, Q. et al. Recoverable plasticity in penta-twinned metallic nanowires governed by dislocation nucleation and retraction. Nature Commun. 6, 5983 (2015).

Zhu, Y. & Espinosa, H. D. An electromechanical material testing system for in situ electron microscopy and applications. Proc. Natl Acad. Sci. USA 102, 14503–14508 (2005).

Chang, T. H. & Zhu, Y. A microelectromechanical system for thermomechanical testing of nanostructures. Appl. Phys. Lett. 103, 263114 (2013).

Xu, F., Qin, Q. Q., Mishra, A., Gu, Y. & Zhu, Y. Mechanical properties of ZnO nanowires under different loading modes. Nano Res. 3, 271–280 (2010).

Lifshitz, R. & Roukes, M. L. Themoelastic damping in micro- and nanomechanical systems. Phys. Rev. B 61, 5600–5609 (2000).

Schaumann, G., Völki, J. & Alefeld, G. The diffusion coefficients of hydrogen and deuterium in vanadium, niobium, and tantalum by Gorsky-effect measurements. Phys. Status Solidi 42, 401–413 (1970).

Schaumann, G., Völkl, J. & Alefeld, G. Relaxation process due to long-range diffusion of hydrogen and deuterium in niobium. Phys. Rev. Lett. 21, 891–893 (1968).

McCluskey, M. D. & Jokela, S. J. Defects in ZnO. J. Appl. Phys. 106, 071101 (2009).

Zhang, X., Kulik, J. & Dickey, E. C. Diffusion in SixGe1−x/Si nanowire heterostructures. J. Nanosci. Nanotechnol. 7, 717–720 (2007).

Zhu, T. & Li, J. Ultra-strength materials. Prog. Mater. Sci. 55, 710–757 (2010).

Janotti, A. & Van de Walle, C. G. Native point defects in ZnO. Phys. Rev. B 76, 165202 (2007).

Ashby, M. F. Materials Selection in Mechanical Design (Butterworth-Heinemann, 2010).

San Juan, J., Nó, M. L. & Schuh, C. A. Nanoscale shape-memory alloys for ultrahigh mechanical damping. Nature Nanotech. 4, 415–419 (2009).

Perea, D. E. et al. Direct measurement of dopant distribution in an individual vapour–liquid–solid nanowire. Nature Nanotech. 4, 315–319 (2009).

Wang, X. et al. Growth of uniformly aligned ZnO nanowire heterojunction arrays on GaN, AlN, and Al0.5Ga0.5N substrates. J. Am. Chem. Soc. 127, 7920–7923 (2005).

Acknowledgements

Y.Z. acknowledges support from the National Science Foundation (NSF) under awards CMMI-1030637 and 1301193, and the use of the Analytical Instrumentation Facility at North Carolina State University, which is supported by the State of North Carolina and the NSF. H.G. acknowledges support from the NSF through award CMMI-1161749 and the MRSEC Program through award DMR-0520651 at Brown University. C.M. acknowledges a scholarship from the China Scholarship Council (no. 2011683006). Y.Z. thanks Y. Gu and W. Lu for providing nanowire samples and for discussions about the defect structures in these nanowires.

Author information

Authors and Affiliations

Contributions

Y.Z. conceived the idea. Y.Z. and H.G. designed the experiments and modelling. G.C., Q.Q. and F.X. performed the in situ mechanical testing. J.L., G.C. and E.C.D. performed EELS characterization. C.M. and H.H. performed the modelling and simulations. G.C., C.M., E.C.D., H.G. and Y.Z. wrote the paper. All authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary information

Supplementary Information (PDF 972 kb)

Supplementary Movie 1

Supplementary Movie 1 (WMV 8041 kb)

Supplementary Movie 2

Supplementary Movie 2 (WMV 5986 kb)

Rights and permissions

About this article

Cite this article

Cheng, G., Miao, C., Qin, Q. et al. Large anelasticity and associated energy dissipation in single-crystalline nanowires. Nature Nanotech 10, 687–691 (2015). https://doi.org/10.1038/nnano.2015.135

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nnano.2015.135

This article is cited by

-

Isogeometric analysis of architected materials and structures

Engineering with Computers (2024)

-

Room-temperature oxygen vacancy migration induced reversible phase transformation during the anelastic deformation in CuO

Nature Communications (2021)

-

Metallic nanocrystals with low angle grain boundary for controllable plastic reversibility

Nature Communications (2020)

-

Microelectromechanical Systems for Nanomechanical Testing: Displacement- and Force-Controlled Tensile Testing with Feedback Control

Experimental Mechanics (2020)

-

Parallel Nanoimprint Forming of One-Dimensional Chiral Semiconductor for Strain-Engineered Optical Properties

Nano-Micro Letters (2020)