Abstract

Fatty alcohols have been identified as promising organic phase change materials (PCMs) for thermal energy storage, because of their suitable temperature range, nontoxicity and can be obtained from both natural and synthetic sources. Like all other organic PCMs, octadecanol (OD) as PCM suffers from low thermal conductivity (TC). In this work, to enhance its TC, it was grafted on the functionalized MWCNT and were used as a conductive filler to enhance overall thermal properties of OD in a composite PCM (CPCMs) structure. The OD/OD-g-MWCNT sample showed better dispersion within the composites and the presence of additional OD boosted the overall heat storage enthalpy compared to that of plane composite sample with OD/MWCNT. In a non-quantitative approach, it was observed that, any increase in grafting ratio of OD increases the heat storage enthalpy of the composites. The heat storage enthalpy of (267.7 J/g) OD/OD-g-MWCNT(4:1)-5wt% composite PCM had reached very close to the heat storage enthalpy value of pure OD (269.3 J/g), and much higher than that of OD/MWCNT-5wt% (234.5 J/g). Champion sample i.e. OD/OD-g-MWCNT (4:1)-5wt%, showed good heat storage enthalpy, cycling performance, thermal stability and TC enhancement by 262.5%.

Similar content being viewed by others

Introduction

Thermal energy is one of the major sources of natural green energy. Various methods have been developed to utilize this energy efficiently into our energy mix. Among these methods, phase change material (PCM) based latent heat storage has gained considerable attention, mainly, due to its simplicity, higher efficiency, and wide ranges of PCMs1,2. Among the different PCMs, inorganic PCMs have been heavily studied, due to their good thermal conductivity (TC) and heat of fusion. However, these materials suffers from supercooling, phase separation behavior, corrosive to metals, and also has toxicity3,4. On the other hand, organic PCMs showed better prospects in several thermal energy storage (TES) applications, mainly due to their good storage capacity, nontoxicity, and environmental safety5,6. These materials based heat storage technologies are getting applications in smart and green buildings, electronic devices, and so on7,8,9.

Among the different organic PCMs, fatty alcohols have received scant attention, though these alcohols can be obtained from both natural and petroleum sources; they are nontoxic and have suitable melting temperate for low temperature heat storage. Only a handful of reports exist where, fatty alcohols are studied for their TES properties10,11. Like other organic PCMs, they also suffer from low TC and leakage issues. So various materials, such as carbon-based materials, metal foams etc., were incorporated to improve the TC. Huang et al.12, prepared myristyl alcohol based composite PCMs (CPCMs) with nickel and copper foams by vacuum melting infiltration method. The heat storage enthalpy of CPCMs was decreased by 3–29%, while their TC was improved by 1.80-7.51 times compared with that of pure myristyl alcohol. In another work, they13 added carbon fiber to cetyl alcohol/high-density polyethylene composite to enhance its TC. TC value of the shape-stabilized CPCM was nearly 1.25 and 1.22 times higher than the CPCM without carbon fiber, respectively in liquid and solid state. In another similar work, Tang et al.14 prepared form-stable CPCM with stearyl alcohol and high density polyethylene. Here, they used expanded graphite as a TC enhancer. This CPCM showed a constant melting temperature of 57 °C with heat storage enthalpy of 200 J/g and enhanced TC by 240% with addition of just 3% expanded graphite. Wang et al.15 prepared 1-octadecanol (OD)/graphene oxide (1.5 wt%) CPCM by self-assembly method and improved its TC value by 1.5 times compared to that of pure OD. In another study, Tang et al.16 adsorbed OD in hierarchical porous polymer and prepared shape-stable CPCM. They were able to achieve nearly 75% of adsorption and observed 29.8% drop of the heat storage enthalpy value than that of the pure OD.

It is still challenging to minimize the loss of the overall heat storage enthalpy capacity, when a conducting filler with higher TC is introduced to improve the thermal properties of the organic PCMs17,18. In this regard, several attempts have been made to enhance TC without adversely affecting the heat storage enthalpy of PCMs. Mu and Li19 grafted lauric acid with graphene aerogel by an esterification reaction. The TC value of this composite was increased by 352.1% and 32.6% compared with that of pure lauric acid and lauric acid/graphene aerogel, respectively. The melting enthalpy and freezing enthalpy of the composite was found to be 207.3 J/g and 205.8 J/g, respectively. Xiao et al.20 dispersed carbon nanotubes (CNT), oxidized-CNT and grafted-CNT into palmitic acid at a mass ratio of 1:100. The latent heat of palmitic acid/grafted-CNT even exceeded that of pure PA and also showed higher TC. Tu et al.21 grafted polyethylene glycol on graphene oxide and introduced into the polyethylene glycol to achieve enhanced graphene oxide dispersion and heightened the mobility of the PEG chains. The heat storage enthalpy and thermal conductivity were enhanced compared to that of the composite with only graphene oxide. Li et al.22 grafted three different polyalcohols octanol, tetradecyl alcohol and stearyl alcohol on the functionalized CNT and mixed with paraffin to prepare the CPCMs. They observed polyalcohols with higher number of carbon gave better TC but lower heat storage enthalpy. However, the grafted PCMs showed better dispersion than that of pure CNT within paraffin due to reduction of the length of the CNT after the grafting and improved compatibility.

In most of the previous reports, it was observed that the direct mixing of carbon-based nano fillers within fatty acids and fatty alcohols was resulted an ununiformed dispersion, which eventually affected thermal property. There are very few attempts, where some organic PCMs were grafted on the carbon-based nano fillers, but still they did not study the effect of the grafting amount, besides; investigate the cycling TES reliability of the resulting CPCM. Even in all these cases, the modified conductive filler was incorporated in to the other kind of PCMs than that of the grafted one. Therefore, to have better compatibility, to achieve better dispersion in the both solid and liquid state, to improve thermal properties of OD, it was grafted on the functionalized multi-walled carbon nanotube (MWCNT) in three different grafting ratios (1:1, 2:1 and 4:1) by a two-step chemical treatment process. The grafted and non-grafted MWCNT were subsequently used as conductive fillers with pure OD in 5 wt% to achieve novel kinds of CPCMs. This supposed to give a homogeneous dispersion of the prepared conductive filler within the CPCM in both liquid and solid state. It was also expected to achieve a better TC, good heat storage enthalpy, thermal stability and cycling TES properties. Thermal properties of the CPCM with grafted MWCNT (OD/OD-g-MWCNT) were also compared with that of CPCM with pure MWCNT (OD/MWCNT) and even with fatty alcohol included-CPCMs previously reported in literature. The produced CPCM samples showed superior thermal properties as well as reliable cycling TES properties.

Experimental

Materials

1-Octadecanol (OD; purity degree 95%) selected as organic PCM was procured from Sigma-Aldrich. Thionly chloride and nitric acid (HNO3) were purchased from BDH Chemicals Ltd, and used as received. MWCNT was purchased from cheap tube USA, and used without any modification.

Synthesis of OD-g-MWCNT pre-composites

Carboxylation of MWCNT. In a typical process described elsewhere23, MWCNT (5 g) and 350 mL of HNO3 solution (60% v/v) were mixed in a 500 mL round bottom (RB) flask and sonicated for 3 h. The flask content was refluxed at 120 °C for 12 h and then cooled at room temperature. The product was vacuum filtrated using microporous membrane with pore size of 0.22 µm. The filtrate was washed thoroughly with de-ionized water until neutral pH was achieved. Finally, the functionalized MWCNT were dried in vacuum oven to a constant weight at 60 °C.

Conversion of MWCNT-COOH to MWCNT-COCl

Carboxyl functionalized MWCNT (4 g) and thionly chloride (60 mL) were mixed slowly at room temperature in a 250 mL- RB flask. Then, the reaction mixture was refluxed at 80 °C for 24 h. Finally, thionly chloride was distilled off using a liquid nitrogen trap, and the product was washed with de-ionized water to obtain acyl chloride-functionalized MWCNT (MWCNT-COCl).

OD-grafted MWCNT (OD-g-MWCNT) pre-composite

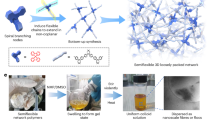

At first, OD was melted on a temperature-controlled heater at 65 °C and combined with MWCNT-COCl at weight ratio of 1:1. This mixture was refluxed at 75 °C for 48 h while stirring. After cooling to room temperature, the product was washed with de-ionized water to remove any unreacted OD. Finally, obtained OD-g-MWCNT(1:1) pre-composite was dried in vacuum oven at 60 °C for 12 h. Two other pre-composites were synthesized at 2:1 and 4:1 weight ratios of OD and MWCNT-COCl under the same reaction conditions described as above. The reaction route used in the synthesis of functionalized MWCNT and OD-g-MWCNT pre-composites is illustrated in Fig. 1.

Here, OD was melted on a temperature-controlled heater at 65 °C and mixed with OD-g-MWCNT (1:1) in percentage mass ratio of 95/5. The obtained sol-gel compositions were mixed by a temperature-controlled shaker at 200 rpm for 30 min to get homogenous dispersions. The composites were cooled at room temperature and then grounded for characterization and further use. Same procedure was used for the preparation of other composites with 5 wt% OD-g-MWCNT pre-composite with grafting ratio of 2:1, 4:1 and pure MWCNT. The final CPCMs containing 5 wt% grafted and non-grafted MWCTs were sealed as OD/OD-g-MWCNT(1:1)-5wt%, OD/OD-g-MWCNT(2:1)-5wt%, OD/OD-g-MWCNT(4:1)-5wt% and OD/MWCNT-5wt%. The photograph images of OD, MWCNT, the synthesized OD-g-MWCNT pre-composites and prepared CPCMs, OD/OD-g-MWCNT-5wt% and OD/MWCNT-5wt% are shown in Fig. 2.

Dispersion stability experiment

The pre-weighed amount of OD was melted at 65 °C in glass tubes. OD-g-MWCNT and MWCNT pre-composites were added to the melted OD at 5 wt% of the total weight of the composite samples. The composite samples, OD/OD-g-MWCNT-5wt% and OD/MWCNT-5wt%, were mixed using a mini centrifuge at 100 rpm for 15 min to obtain homogenous distribution. Then, in order to observe the dispersion stability, both composite samples were maintained at 65 °C for 1 h without stirring.

Characterization

Grafting of OD with the functionalized MWCNT was studied by FTIR spectroscopy (Perkin Elmer, 16 F PC FTIR) technique. It was also used to investigate the chemical structures of pure OD, MWCNT, OD-g-MWCNT pre-composites, OD/OD-g-MWCNT-5wt% and OD/MWCNT-5wt% as CPCMs. The spectra were taken in the wavelength range of 4000-400 cm−1. The surface morphologies of the CPCMs were studied by scanning electron microscopy (SEM) (LEO 440 model). The samples were coated with gold to provide electrical conductivity. The crystalline structures of the CPCMs were studied using a XRD instrument (PANalytical X’-Pert3 model) with Cu (Kα = 1.5406 Å) irradiation at a step size of 0.0131°.

The phase change temperatures and heat storage enthalpy of pure OD, prepared pre-composites and CPCMs were measured using a differential scanning calorimetry (DSC) (Hitachi-DSC 7020 model) at a heating/cooling rate of 3 °C/min. This measurement was repeated three times and the mean deviation in phase change temperatures and heat storage enthalpy values were determined (minor deviation of ± 0.12 °C and minor error of ±1.03% were determined). Thermal degradation temperatures of OD, pre-composites and CPCMs were determined at heating ramp of 10 °C/min by thermal gravimetric analysis (TGA) (Perkin-Elmer model) at 30-600 °C. The temperature measurement for each sample was also taken three times and the mean deviation was determined as ±1.5 °C.

The TCs of pure OD, pre-composites and CPCMs were measured using a thermal properties analyzer (Decagon KD2 pro Devices, Inc., USA). The measurements were conducted at 20 ± 1 °C by using KS1. sensor with the maximum discrepancy of ±10% W/m K. To minimize inaccuracy, the measurements were repeated three times at 10 minutes intervals.

To investigate the effect of thermal cycling on the chemical structures, crystalline phases and TES properties of the synthesized CPCMs, a thermal cycling test was carried out using a thermal cycler (BIOER TC-25/H model). Throughout the test, the samples were melted and solidified repeatedly until targeted cycling number of 500 was achieved. After the cycling test, FTIR, XRD and DSC analyses of these CPCMs were performed again to compare results obtained for the fresh CPCM samples.

Results and Discussions

Chemical structure characterization

The FTIR spectra of the synthesized MWCNT-COOH, MWCNT-COCl and OD-g-MWCNT (1:1) are given in Fig. 3. In the spectrum of MWCNT-COOH, the broad peak in between at 3250 and 3650 cm−1 confirms the presence of hydroxyl (–OH) groups present in MWCNT22. The absorption peak at 1690 cm−1 represents the stretching of C=O bond of –COOH group as the symmetric and asymmetric stretching vibrations of COOH were appeared at 1471 and 1359 cm−1, respectively24. In addition, the peaks appeared at 958 and 829 cm−1 are assigned to vibration of –OH groups25. In the spectrum of MWCNT-COCl, the absorption peak at 1776 cm−1 is related with the stretching vibration of C=O of acid chloride. The absorption peaks at 1328 and 639 cm−1 confirmed the presence of C–O and C–Cl stretching of acid chloride functionalized MWCNT. The peak at 1736 cm−1 is attributed to the stretching of C=O, which is from OD-g-MWCNT. On the other hand, in the spectrum of OD-g-MWCNT pre-composite, the intensity of –OH absorption peak between at 3250 and 3650 cm−1 was significantly decreased after grafting. However, a small peak seen in this range is associated with the vibration of –OH groups of OD, which were not grafted with MWCNT-COCl. Moreover, the peaks detected at 2924 and 2836 cm−1 are identified with the stretching vibration of -CH2 and -CH3 groups that come from OD. All these confirms that the OD was successfully grafted on the MWCNT22.

The FTIR spectra of pure OD, OD/OD-g-MWCNT(1:1)-5wt%, OD/OD-g-MWCNT(2:1)-5wt%, OD/OD-g-MWCNT(4:1)-5wt% and OD/MWCNT-5wt% composites are presented in Fig. 4. It is clear from the spectra that there is no additional peak in the spectrum of the CPCMs after mixing of OD with the grafted or non-grafted MWCNT. Slight shifts in the wavenumbers of some absorption peaks were observed for the CPCMs compared to that of pure OD, which can be due to physical interactions or could be identified as capillary and surface tension forces among them11,22,23.

On the other hand, to investigate the effect of the grafted or non-grafted MWCNT on the crystal structure of the OD, the XRD analysis was conducted. Figure 5 shows the XRD analysis results obtained for OD/OD-g-MWCNT(1:1)-5wt%, OD/OD-g-MWCNT(2:1)-5wt%, OD/OD-g-MWCNT(4:1)-5wt% and OD/MWCNT-5wt% composites. All the typical diffraction peaks of OD is visible around 6°, 20°, 21.5°, 22°, and 24.5°, the doublet around 24.5° may be due the MWCNT15. Since the amount of the nanotubes is quite low, it is difficult to get the separate distinguishable peak of them11,17,22.

Surface morphology and dispersion stability

Surface morphology and distribution of the MWCNT within the CPCMs were investigated by SEM analysis. The obtained SEM images are presented in Fig. 6(a). As seen from the images of the OD/OD-g-MWCNT composites, the phase intensity of the grafted MWCNT on the surface of OD was decreased with decreasing its grafting ratio. The nanotubes were dispersed uniformly throughout the surface of OD and no agglomeration was observed. The uniformity of MWCNT in grafted or mixed state creates heat transfer network, which could provide effective heat conduction paths throughout the CPCM21,22.

Figure 6(b) shows the images of the dispersion stability of OD/OD-g-MWCNT-5wt% and OD/MWCNT-5wt% composite samples at 65 °C after 1 h-standby period. As clearly seen, some parts of MWCNT in the OD/MWCNT-5wt% sample began to precipitate while the sample OD/OD-g-MWCNT-5wt% maintained its stable suspension. These results indicate that grafted MWCNT created more stable suspension with melted OD compared to the pure MWCNT. It is probably a result of relatively stronger colloidal attractions between OD-g-MWCNT and OD. The similar observation was reported for the acid modified carbon nanotubes/erythritol composite suspension26.

TES properties of the synthesized pre-composites and CPCMs

The DSC results of the synthesized OD-g-MWCNT pre-composite samples are presented in Fig. 7. It was observed that, the phase change temperatures of OD-g-MWCNT (1:1), OD-g-MWCNT (2:1) and OD-g-MWCNT (4:1) somewhat decreased by 1.1, 1.0 and 0.9 °C for melting phase change and 2.4, 0.6 and 1.3 °C for freezing phase change in comparison with that of pure OD. These irregularly shifts could be resulted because of its conversion to new chemical structures. Both heat storage capacities measured for melting and freezing of all grafted samples are quite low, due to very small amount of OD present in the grafted samples. However, both heat storage capacities increased with the increasing amount of OD in the grafted samples.

The DSC thermograms of prepared OD/OD-g-MWCNT composites are presented in Fig. 8 and the TES data derived from these thermograms is given in Table 1. All of the CPCMs melts and solidifies in temperature range of 54.6-55.3 °C and 55.4-55.8 °C, respectively. When compared to these results with those of pure OD, it was found that the change in melting temperature of OD/OD-g-MWCNT (1:1)-5wt%, OD/OD-g-MWCNT (2:1)-5wt%, OD/OD-g-MWCNT (4:1)-5wt% and OD/MWCNT-5wt% composites were in the range of (-0.2) – (-0.9) °C and the change in freezing temperature of them was in the range of 0.7–1.1 °C. In addition, the heat storage capacities of the CPCMs increased in parallel with heat storage capacity of the corresponding pre-composite added to OD. In fact, the CPCM sample with OD-g-MWCNT (4:1) showed the highest heat storage capacity of 267.7 ± 2.7 and 263.03 ± 2.6 J/g, respectively for its melting and freezing period, which were very close to that of pure OD.

Additionally, when compared with the results obtained for the OD/MWCNT composite, its heat storage enthalpies were found to be lower than the other three CPCM samples. As it is visible from the tabulated data in Table 2, the CPCMs containing grafted and non-grafted MWCNT prepared in this work showed relatively higher heat storage capacities than those of previously reported similar PCMs15,16,19,20,22. It became clear that the grafting helped to achieve better distribution of MWCNT and the additional OD present in the grafted MWCNT also contributed to overall heat storage capacities of the PCMs.

Effect of thermal cycling on TES properties of the prepared CPCMs

The cycling TES reliability of a PCM can be considered as its TES life after its long-term utilization16,24,26. With this respect, a consecutive thermal cycle test was adapted to all prepared composite PCMs and the DSC thermograms obtained after 500 cycles were indicated in Fig. 9. By comparing the data in Table 1 and Table 3, the change in melting temperature of OD/OD-g-MWCNT (1:1)-5wt%, OD/OD-g-MWCNT (2:1)-5wt%, OD/OD-g-MWCNT (4:1)-5wt% and OD/MWCNT-5wt% composites were determined as −0.7, 0.1, 0.8 and −0.4 °C and the variation in their freezing temperatures was established by −0.2, −0.1, −0.3 and −0.4 °C, respectively. Furthermore, the heat storage capacity were reduced by 8.6, 8.0, 7.3 and 7.8 J/g for melting of the CPCMs while the heat storage capacity was diminished by 7.1, 6.7, 8.4 and 6.1 J/g for freezing of respective composite. These minor alterations proves good TES cycling stability of the prepared composite PCMs.

Effect of thermal cycling on chemical structures of the prepared CPCMs

The dependence of the chemical stability of PCM on long-term usage is one of the most imperative limits, which is worth considering during the selection stage. Accordingly, the FTIR and XRD analysis of four types of composite PCMs were repeated after 500 cycles. The results of cycled and non-cycled composite PCMs were compared in Figs. 10 and 11. As evident found from the FTIR spectrums, the profile and absorption wavenumbers of the main band peaks were nearly unchanged after the cycling process. In XRD, similar response was observed, without any new peaks. The 2θ ° values of the characteristic peaks were almost same after the cycling period. Both results confirms that all of the composite PCMs had unique cycling chemical stability.

Thermal degradation behavior of the prepared composite PCMs

Thermal durability of pure OD and the fabricated composite PCMs were investigated by TGA analysis. As evident in Fig. 12, pure OD demonstrated a one-step thermal degradation between 190 °C and 295 °C. In similar form, the OD/MWCNT-5wt% composite PCM degraded thermally at only one stage corresponding to temperature range of 198-306 °C, which is slightly higher than the pure OD. OD grafted MWCNT i.e. OD/OD-g-MWCNT (1:1)-5wt%, OD/OD-g-MWCNT (2:1)-5wt%, OD/OD-g-MWCNT (4:1)-5wt% composite PCM samples also shown thermal decomposition with one-step gradation. The degradation started around 243 ± 1.3 °C, 235 ± 1.6 °C and 228 ± 1.4 °C and completed at 353 ± 1.7 °C, 337 ± 1.5 °C, and 318 °C ± 1.6 for the respective composite PCMs. A shift in initial and final degradation temperature was observed for all grafted samples. In the OD/OD-g-MWCNT (1:1)-5wt%, OD/OD-g-MWCNT (2:1)-5wt%, OD/OD-g-MWCNT (4:1)-5wt% composite PCM samples, the degradation temperature moved to higher values with the lower ratios of OD in the grafted samples. This manifested that the operating temperature and the thermal degradation temperature of pure OD was extended by the addition of grafted MWCNT. Similar results were also observed for different type of composite PCMs27,28.

TC of the prepared pre-composites and composite PCMs

TC property is one of the important parameters considered during the PCM selection. PCMs with higher TC reduce the heat charging/discharging period during the operation of TES system. OD is an organic alcohol has low TC, which should be enhanced before utilization. One common approach is to add some nano particles with higher TC, like, graphite, CNT, graphene etc., to increase the TC property29,30,31. For this study, OD was grafted on the MWCNT and used as conductive filler. Pure OD has a TC value of 0.16 ± 0.01 W/m K. All other samples showed higher TC value than that of pure OD. The OD-g-MWCNT (1:1), OD-g-MWCNT (2:1), and OD-g-MWCNT (4:1) samples showed TC of 0.82 ± 0.04, 0.77 ± 0.05, and 0.69 ± 0.03 W/m K, respectively. TC value was measured as 0.57 ± 0.05, 0.76 ± 0.03, 0.61 ± 0.02, and 0.58 ± 0.04 W/m K, respectively for OD/MWCNT-5wt%, OD/OD-g-MWCNT (1:1)-5wt%, OD/OD-g-MWCNT (2:1)-5wt%, and OD/OD-g-MWCNT (4:1)-5wt% samples. The improvement in TC value in the grafted samples compared to that of pure OD is due to the presence of the MWCNTS, as expected the TC values were slowly reduces with the increasing amount of OD. The lower TC value of the OD/MWCNT-5wt% sample was mainly due to non-homogeneous distribution of MWCNTS and agglomeration as confirmed in SEM image and (Fig. 6). The TC values of the OD/OD-g-MWCNT (1:1)-5wt%, OD/OD-g-MWCNT (2:1)-5wt%, and OD/OD-g-MWCNT (4:1)-5wt% samples were higher than that of OD/MWCNT-5wt% mainly due to the better dispersion of the MWCNT within the composite structure. Again, a similar trend of reduction of the TC values were observed mainly due the increasing amount of OD in the grafted structure, but this helped to maintain the heat storage capacity of the composites very close to that of pure OD.

In Table 4, the TC results of the prepared OD/OD-g-MWCNT (4:1)-5wt% composite PCM is compared with those of grafted and non-grafted fatty alcohol included-CPCMs. As seen from the tabulated data, the CPCM prepared in this work had much superior thermal properties than the other similar reported PCMs13,14,15. Especially when compare with the reports of Wang et al.15, where the authors worked with OD and mixed with graphene oxide to improve its thermal properties. In comparison to pure OD, the reduction of melting enthalpy with the best performing composite sample was reported as 2.76 J/g15. However, in this study, the reduction of melting enthalpy was found to be 1.6 J/g, which confirms significant improvement of heat storage capacity. In case of TC, the improvement was much larger. Therefore, grafting OD on the MWCNT found to be a better option to improve its distribution within the composite structure. At the same time, it contributed towards better retention of heat storage capacity.

Conclusions

In a significant improved approach, ODs were successfully grafted on the MWCNT in different OD to MWCNT weight ratios, and was used as conductivity filler to enhance over-all thermal properties of OD for thermal energy storage. Grafting was confirmed by the FTIR and XRD analysis and the grafted sample had better dispersion and the presence of additional OD boosted the heat storage capacities of the prepared composite PCMs as compare to the sample with pure MWCNT. No additional chemical interaction was observed in the composite PCMs and it was confirmed by same FTIR and XRD analysis. Overall, all the composite PCM samples had good thermal, chemical and cycling reliability. Champion composite PCM sample, OD/OD-g-MWCNT (4:1), showed a good melting and solidification enthalpy of 267.7 and -263.6 J/g respectively, which were very close to that of pure OD. Significant enhancement of thermal conductivity was achieved, which was nearly 262.5% higher than that of pure OD. This method proves to be efficient approach to improve thermal properties of the fatty alcohol and can be useful for other organic PCMs as well. Eventually a better performing PCM can be obtained for better heat storage or heat management technology.

References

Sharma, R., Ganesan, P., Tyagi, V. V., Metselaar, H. S. C. & Sandaran, S. C. Developments in organic solid-liquid phase change materials and their applications in thermal energy storage. Energy. Convers. Manag 95, 193–228 (2015).

Sun, Q. et al. Flexible phase change materials for thermal storage and temperature control. Chem. Eng. J 353, 920–929 (2018).

Mohamed, S. A. et al. A review on current status and challenges of inorganic phase change materials for thermal energy storage systems. Renew. Sustain. Energy. Rev. 70, 1072–1089 (2017).

Chen, T. et al. Fatty amines/graphene sponge form-stable phase change material composites with exceptionally high loading rates and energy density for thermal energy storage. Chem. Eng. J 382, 122831 (2020).

Kant, K., Shukla, A. & Sharma, A. Advancement in phase change materials for thermal energy storage applications. Sol. Energy Mater. Sol. Cells 172, 82–9283 (2017).

Elias, C. N. & Stathopoulo, V. N. A comprehensive review of recent advances in materials aspects of phase change materials in thermal energy storage. Energy Proc 161, 385–394 (2019).

Magendran, S. S. et al. Synthesis of organic phase change materials (PCM) for energy storage applications: A review. Nano-Struc Nano-Objects 20, 100399 (2019).

Kibria, M. A., Anisur, M. R., Mahfuz, M. H., Rahman, S. & Metselaar, I. H. S. C. A review on thermos-physical properties of nanoparticle dispersed phase change materials. Energy Convers Manag 95, 69–89 (2015).

Sarı, A., Al-Ahmed, A., Bicer, A., Al-Sulaiman, F. A. & Hekimoğlu, G. Investigation of thermal properties and enhanced energy storage/release performance of silica fume/myristic acid composite doped with carbon nanotubes. Renew. Energy 140, 779–788 (2019).

Memon, S. A., Lo, T. Y., Shi, X., Barbhuiya, S. & Cui, H. Preparation, characterization and thermal properties of Lauryl alcohol/Kaolin as novel form-stable composite phase change material for thermal energy storage in buildings. Appl. Therm. Energy 59, 336–347 (2013).

Memon, S. A., Lo, T. Y., Cuib, H. & Barbhuiya, S. Preparation, characterization and thermal properties of dodecanol/cement as novel form-stable composite phase change material. Energy Build 66, 697–705 (2013).

Huang, X., Lin, Y., Alva, G. & Fang, G. Thermal properties and thermal conductivity enhancement of composite phase change materials using myristyl alcohol/metal foam for solar thermal storage. Sol. Energy Mater. Sol. Cells 170, 68–76 (2017).

Huang, X., Alva, G., Liu, L. & Fang, G. Microstructure and thermal properties of cetyl alcohol/high density polyethylene composite phase change materials with carbon fiber as shape-stabilized thermal storage materials. Appl. Energy 200, 19–27 (2017).

Tang, Y., Lin, Y., Jia, Y. & Fang, G. Improved thermal properties of stearyl alcohol/high density polyethylene/expanded graphite composite phase change materials for building thermal energy storage. Energy Build 153, 41–49 (2017).

Wang, X., Cheng, X., Li, Y., Li, G. & Xu, J. Self-assembly of three-dimensional 1-octadecanol/graphene thermal storage materials. Sol. Energy 179, 128–134 (2019).

Tang, J. et al. 1-octadecanol@hierarchical porous polymer composite as a novel shape-stability phase change material for latent heat thermal energy storage. Appl. Energy 187, 514–522 (2017).

Lin, Y., Jia, Y., Alva, G. & Fang, G. Review on thermal conductivity enhancement, thermal properties and applications of phase change materials in thermal energy storage. Renew. Sustain. Energy Rev. 82, 2730–2742 (2018).

Qureshi, Z. A., Ali, H. M. & Khushnood, S. Recent advances on thermal conductivity enhancement of phase change materials for energy storage system: A review. Int. J. Heat Mass Trans 127, 838–856 (2018).

Mu, B. & Li, M. Synthesis of novel form-stable composite phase change materials with modified graphene aerogel for solar energy conversion and storage. Sol. Energy Mater. Sol. Cells 191, 466–475 (2019).

Xiao, D. et al. Study on the phase change thermal storage performance of palmitic acid/carbon nanotubes composites. Composites Part A: Appl. Sci. Manufac 77, 50–55 (2015).

Tu, J. et al. Latent heat and thermal conductivity enhancements in polyethylene glycol/polyethylene glycol-grafted graphene oxide composites. Adv. Comp. Hybrid Mater 2(3), 471–480 (2019).

Li, M., Chen, M., Wub, Z. & Liu, J. Carbon nanotube grafted with polyalcohol and its influence on the thermal conductivity of phase change material. Energy Convers. Manag 83, 325–329 (2014).

Lee, R.-S., Chen, W.-H. & Lin, J.-H. Polymer-grafted multi-walled carbon nanotubes through surface-initiated ring-opening polymerization and click reaction. Polymer 52(10), 2180–2188 (2011).

Yang, L. et al. Thermal reliability of typical fatty acids as phase change materials based on 10,000 accelerated thermal cycles. Sustain Cities Soc 46, 101380 (2019).

Song, S., Dong, L., Chen, S., Xie, H. & Xiong, C. Stearic-capric acid eutectic/activated attapulgiate composite as form-stable phase change material for thermal energy storage. Energy Convers. Manag 81, 306–311 (2014).

Shen, S. et al. The effects of modified carbon nanotubes on the thermal properties of erythritol as phase change materials. Energy Convers. Manag 57, 41–48 (2018).

Halvaee, M. et al. Comparison of pristine and polyaniline-grafted MWCNTs as conductive sensor elements for phase change materials: thermal conductivity trend analysis. J. Appl. Polym. Sci. 134, 45389 (2017).

Zhang, Q. & Liu, J. Sebacic acid/CNT sponge phase change material with excellent thermal conductivity and photo-thermal performance. Sol. Energy Mater. Sol Cells 179, 217–222 (2018).

Fan, L.-W. et al. Effects of various carbon nanofillers on the thermal conductivity and energy storage properties of paraffin-based nanocomposite phase change materials. Appl. Energy 110, 163–172 (2013).

Fan, L.-W. et al. Non-isothermal crystallization of aqueous nanofluids with high aspect-ratio carbon nano-additives for cold thermal energy storage. Appl. Energy 138, 193–201 (2015).

Guo, S. et al. Evaluation and comparison of erythritol-based composites with addition of expanded graphite and carbon nanotubes. Appl. Energy 205, 703–709706 (2017).

Acknowledgements

The authors (A. Al-Ahmed, A. Sarı and M.A.J. Mazumder) thankfully acknowledge the Deanship of Scientific Research (DSR) of King Fahd University of Petroleum & Minerals (KFUPM), Saudi Arabia for funding, through Internal Project # IN161025.

Author information

Authors and Affiliations

Contributions

A.A.A, A. S. and M.A.J.M designed and supervised the work. A.A.A., and M.A.J.M. and I. carried out synthesis and performed FTIR, XRD analysis A.S, G.H., and F.A.A.S. performed thermal and SEM analysis. All authors analyzed and interpreted the data. All authors discussed the data and agreed to submit the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Al-Ahmed, A., Sarı, A., Mazumder, M.A.J. et al. Thermal energy storage and thermal conductivity properties of Octadecanol-MWCNT composite PCMs as promising organic heat storage materials. Sci Rep 10, 9168 (2020). https://doi.org/10.1038/s41598-020-64149-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-020-64149-3

This article is cited by

-

Multi-objective optimization of multiple droplet impacts on a molten PCM using NSGA-II optimizer and artificial neural network

Scientific Reports (2023)

-

Fabrication and applications of a microencapsulated prothioconazole based on β-cyclodextrin

Applied Nanoscience (2022)

-

Mitigation of groundwater iron-induced clogging by low-cost bioadsorbent in open loop geothermal heat pump systems

Applied Water Science (2022)

-

Accurate Measurements of the Thermal Conductivity of Hexadecan-1-ol and Octadecan-1-ol in the Solid and Liquid Phases

International Journal of Thermophysics (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.