Abstract

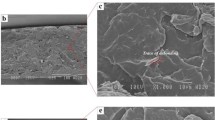

Using plant microfiber bundles with a nanometer unit web-like network, a moulded product with a bending strength of 250 MPa was obtained without the use of binders. High interactive forces seem to be developed between pulp fibers owing to their nanometer unit web-like network. In other words, the area of possible contact points per fiber are increased, so that more hydrogen bonds might be formed or van der Waals forces increased. When 2% oxidized tapioca starch, by weight, was added, the yield strain doubled and the bending strength reached 310 MPa. The starch mixed moulded product had a similar stress strain curve to that for magnesium alloy, and three to four times higher Young's modulus and bending strength values than polycarbonate and GFRP (chopped). The mouldings have a combination of environmentally friendly and high strength properties.

Similar content being viewed by others

References

D. Fengel and G. Wegener, in “WOOD—Chemistry Ultrastructure Reactions” (Walter de Gruyter, Belrin, New York, 1983) p. 93.

I. Sakurada, Y. Nukushima and T. Ito, J. Polym. Sci. 57 (1962) 651.

D. H. Page and F. El-Hosseiny, J. Pulp Pap. Sci. 9 (1983) 99.

L. H. Sperling, “Introduction to Physical Polymer Science” (John Wiley & Sons Inc., New York, 2001) p.499.

L. Lundquist, B. Marque, P. O. Hagstrand, Y. Leterrier and J.-A. E. Manson, Compos. Sci. Technol. 63 (2003) 137.

T. G. Rials, M. P. Wolcott and J. M. Nassar, J. Appl. Polym. Sci. 80 (2001) 546.

M. A. Svoboda, R. W. Lang, R. Bramsteidl, M. Ernegg and W. Stadlbauer, Mol. Cryst. Liq. Cryst. 47 (2000) 353.

X. Y. Chen, Q. P. Guo and Y. L. Mi, J. Appl. Polym. Sci. 69 (1998)1891.

J. Simonsen, Forest Prod. J. 47 (1997) 74.

O. Y. Mansour, S. Kamel and M. A. Nassar, J. Appl. Polym. Sci. 69 (1998) 845.

M. Wollerdorfer and H. Bader, Ind. Crop. Prod. 8 (1998) 105.

D. G. Hepworth, J. F. V. Vincent, G. Jeronimidis and D. M. Bruce, Compos. Part A-Appl. S. 31 (2000) 599.

F. W. Herrick, R. L. Casebier, J. K. Hamilton and K. R. Sandberg, J. Appl. Polym. Sci.: Appl. Polym. Symp. 37 (1983) 797.

T. Taniguchi and K. Okamura, Polym. Int. 47 (1998) 291.

Y. Matsuda, Sen-i Gakkaishi 56 (2000) 192.

S. Yamanaka, K. Watanabe, N. Kitamura, M. Iguchi, S. Mitsuhashi, Y. Nishi and M. Uryu, J. Mater. Sci. 24 (1989) 3141.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Yano, H., Nakahara, S. Bio-composites produced from plant microfiber bundles with a nanometer unit web-like network. Journal of Materials Science 39, 1635–1638 (2004). https://doi.org/10.1023/B:JMSC.0000016162.43897.0a

Issue Date:

DOI: https://doi.org/10.1023/B:JMSC.0000016162.43897.0a