Abstract

In the field of phase transformations in steels, much attention has been paid to the transformation of austenite into diverse product phases but, until recently not much work has been done on the formation of austenite during heating. There are few published models dealing with the transformation of eutectoid or hypoeutectoid steels with a starting microstructure which is a mixture of ferrite and pearlite.

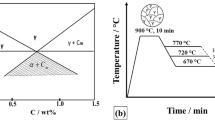

The aim of the present work was to use phase transformation theory to develop a model for austenite formation which takes into account the chemical composition and microstructure of the steel studied, and thermal history experienced. Classic nucleation theory and diffusion-controlled growth equations are used to determine the progressive transformation of the different phases into austenite.

A phase transformation model with sound physical basis as the one presented in this work can be used to determine the effects of various parameters in the reaction involved, like microstructure (grain size, pearlite spacing), composition, heating rate and others. Another direct application of this model is the generation of CHT (continuous heating transformation) diagrams for specific steels, which are a useful reference in research, as well as in many industrial processes.

Similar content being viewed by others

References

R. Mancini and C. Budde, Acta Materialia 47 (1999) 2907.

R. C. Reed, T. Akbay, Z. Shen, J. M. Robinson and J. H. Root, Materials Science and Engineering A 256 (1998) 152.

R. C. Reed, Z. Shen, T. Akbay and J. M. Robinson, ibid. A232 (1997) 140.

G. A. Roberts and R. F. Mehl, Transactions of the A.S.M. 31 (1943) 613.

T. Akbay and C. Atkinson, J. Mater. Sci. 31 (1996) 2221.

Idem., ibid. 31 (1996) 5004.

T. Akbay, R. C. Reed and C. Atkinson, Acta Metallurgica et Materialia 47 (1994) 1469.

A. Ali and H. K. D. H. Bhadeshia, J. Mater. Sci. 28 (1993) 3137.

C. Atkinson and T. Akbay, Acta Materialia 44 (1996) 2861.

C. Atkinson, T. Akbay and R. C. Reed, Acta Metallurgica Materialia 43 (1995) 2013.

N. C. Law and D. V. Edmonds, Metallurgical Transactions A 11A (1980) 33.

G. R. Speich, A. Szirmae and M. J. Richards, Transactions of the Metallurgical Society of A.I.M.E. 245 (1969) 1063.

J. R. Yang and H. K. D. H. Bhadeshia, Materials Science and Engineering A 131 (1991) 99.

J. R. Yang and C. Y. Huang, Materials Chemistry and Physics 35 (1993) 168.

C. R. Brooks, “Principles of the Austenitization of Steels” (Elsevier Applied Science, London, 1992).

A. Jacot, M. Rappaz and R. C. Reed, Acta Materialia 46 (1998) 3949.

A. Jacot and M. Rappaz, ibid. 45 (1997) 575.

Idem., ibid. 47 (1999) 1645.

F. G. Caballero, C. Capdevila and C. GarcÍa de AndrÉs, Scripta Materialia 42 (2000) 1159.

C. GarcÍa de AndrÉs, F. G. Caballero, C. Capdevila and H. K. D. H. Bhadeshia, ibid. 39 (1998) 791.

M. Hillert, in “Decomposition of Austenite by Diffusional Processes,” edited byV. F. Zackay and H. I. Aaronson, (Interscience, New York, 1962) p. 197.

C. M. Sellars, Quantitative Metallography, Technical Report, Escuela Superior de Ingenieros Industriales de San Sebastian, 1981.

L. C. Chang and H. K. D. H. Bhadeshia, Materials Science and technology 11 (1995) 874.

J. W. Christian, “Theory of Transformations in Metals and Alloys, Part I” (Pergamon Press, Oxford, 1975).

S. J. Jones and H. K. D. H. Bhadeshia, Metallurgical and Materials Transactions A 28A (1997) 2005.

C. Zener, Transactions of the A.I.M.E. 203 (1955) 619.

L. Kaufman, E. V. Clougherty and R. J. Weiss, Acta Metallurgica 11 (1963) 323.

H. I. Aaronson, H. A. Domian and G. M. Pound, Transactions of the A.I.M.E. 236 (1966) 768.

Idem., ibid. 236 (1966) 753.

S. M. Hodson, “MTDATA-Metallurgical and Thermochemical Databank” (National Physical Laboratory, Teddington, UK, 1989).

A. Prat, X. Tort-Martorell and P. Grima, “Estadística teórica y Aplicada: Entregas 1 a 4” (C.P.D.A., Universitat Politècnica de Catalunya, Barcelona, 1992).

T. Sourmail, Neuromat Ltd., Models manager, 2000.

D. J. C. Mackay, in “Mathematical Modelling of Weld Phenomena 3,” edited by H. Cerjak (The Institute of Materials, London, 1997) p. 359.

D. J. C. Mackay, “vised neural networks.” available at http://wol.ra.phy.cam.ac.uk/mackay/.

J. Crank, “The Mathematics of Diffusion” (Oxford University Press, Oxford, 1975).

M. Avrami, Journal of Chemical Physics 7 (1939) 1103.

Idem., ibid. 8 (1940) 212.

Idem., ibid. 9 (1941) 177.

J. W. Cahn, Acta Metallurgica 4 (1956) 449.

M. T. Hagan, H. B. Demuth and M. Beale, “Neural Network Design” (PWS Publishing, Boston, 1996).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Gaude-Fugarolas, D., Bhadeshia, H.K.D.H. A model for austenitisation of hypoeutectoid steels. Journal of Materials Science 38, 1195–1201 (2003). https://doi.org/10.1023/A:1022805719924

Issue Date:

DOI: https://doi.org/10.1023/A:1022805719924