Abstract

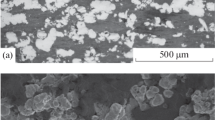

The microstructure, deformation characteristics, and electric conductivity of composites produced by explosive compaction of a copper–molybdenum powder mixture were studied. It is shown that an increase in detonation velocity during explosive treatment leads to an increase in crystal lattice microstrains and dispersivity of the block structure. This favors the plastic deformation of the particles, mainly copper particles, activation and weldability of their boundaries, which increases the conductivity of the compacts produced. Optimal conditions of explosive compaction and heat treatment for production of composites with high conductivity are found. Key words: powder mixture, planetary mill, explosive compaction, heat treatment, electric conductivity, x-ray structural analysis.

Similar content being viewed by others

REFERENCES

G. A. Shvetsov, V. I. Maly, A. G. Anisimov, et al., “High-current ARC erosion of explosively compacted Mo/Cu and W/Cu electrodes," IEEE Trans. Magnetics, 33, No. 1, 410–412 (1997).

R. Prummer, Explosivverdichtung Pulvriger Substanzen, BRD, Springer Verlag (1987).

T. S. Teslenko, “Explosive action on materials with a structure saturated with defects," Combust. Expl. Shock Waves, 27, No. 6, 134–139 (1991).

V. F. Nesterenko, Pulsed Loading of Heterogeneous Materials [in Russian], Nauka, Novosibirsk (1992).

N. N. Thadhani, E. Dunbar, and R. A. Graham, “Characteristics of shock-compressed configuration of Ti and Si powder mixture," in: High-Pressure Science and Technology, Part 2, Samara, Rossiya (1993), pp. 1307–1310.

Ya. S. Umanskii et al., Crystallography, Radiography, and Electron Microscopy [in Russian], Metallurgiya, Moscow (1982).

G. A. Shvetsov, V. I. Maly, A. V. Solovov, et al., “New materials and technologies for pulsed power research and applications," in: 12 IEEE Int. Pulsed Power Conf., Vol. 2, Monterey, California (1999), pp. 765–768.

E. G. Avvakumov, Mechanical Methods of Activating Chemical Processes [in Russian], Nauka, Novosibirsk (1979).

S. B. Zlobin, V. V. Pai, I. V. Yakovlev, and G. E. Kuz'min, “Explosive compaction of aluminum powder and the structure of compacts," Combust. Expl. Shock Waves, 36, No. 2, 256–260 (2000).

M. P. Bondar' and T. S. Teslenko, “Effect of the degree of defectness of an original material on the deformation structure formed in explosive collapse of thick-walled hollow cylinders," Combust. Expl. Shock Waves, 33, No. 6, 718–728 (1997).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Mali, V.I., Teslenko, T.S. Structure and Properties of Explosively Compacted Copper–Molybdenum. Combustion, Explosion, and Shock Waves 38, 473–477 (2002). https://doi.org/10.1023/A:1016223618707

Issue Date:

DOI: https://doi.org/10.1023/A:1016223618707