Abstract

Purpose. To examine the effect of particle size and morphology on aerosol dispersion using jet-milled and spray-dried mannitol particles in narrow size distributions within the respirable range.

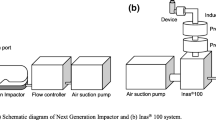

Methods. Particle size and morphology were examined by laser diffraction and scanning electron microscopy, respectively. Aerosol dispersion was examined using a cascade impactor with a preseparator operating at a flow rate of 60 L/min, using two inhaler devices: Rotahaler (low-resistance device) and Inhalator (high-resistance device). Powder flow was examined using static and dynamic methods (Carr's compressibility index and vibrating spatula, respectively).

Results. Narrow size distributions of jet-milled and spray-dried particles were produced (d50% = 1.4 to 10.3 μm, GSD = 1.8 to 2.1, and d50% = 1.6 to 7.5 μm; GSD = 1.5 to 1.9, respectively). All particles were highly crystalline. Differences in particle shape were observed between jet-milled and spray-dried particles. Higher fine particle fraction (FPF) and relative fine particle fraction (FPFrel) (greater aerosol dispersion) and lower geometric standard deviation (GSD) (less variation) were obtained using particles with d50% between 2 and 5 μm. Higher mass median aerodynamic diameter were obtained with larger d50%. Spray-dried particles produced greater aerosol dispersion compared with jet-milled particles. Greater aerosol dispersion was obtained using the Inhalator than the Rotahaler.

Conclusions. Small changes in the particle size within the 1-10-μm range produced a major impact in the aerosol dispersion of jet-milled and spray-dried particles. Even in these narrow size ranges, aggregation plays an important role in aerosol dispersion.

Similar content being viewed by others

References

P. R. Byron. Prediction of drug residence times in regions of the human respiratory tract following aerosol inhalation. J. Pharm. Sci. 75:433-438 (1986).

A. J. Hickey, N. M. Concessio, M. M. Van Oort, and R. M. Platz. Factors influencing the dispersion of dry powders as aerosols. Pharm. Tech. 8:58-82 (1994).

R. J. Malcolmson and J. K. Embleton. Dry powder formulations for pulmonary delivery. Pharm. Sci. Tech. Today. 1:394-398 (1998).

K. Masters. Spray Drying Handbook, Longman Scientific and Technical, New York, 1991, pp. 1-20.

N. Chew and H.-K. Chan. Influence of particle size, air flow and inhaler device on the dispersion of mannitol powders as aerosols. Pharm. Res. 16:1098-1103 (1999).

N. Y. K. Chew, D. F. Bagster, and H.-K. Chan. Effect of particle size, air flow and inhaler device on the aerosolisation of disodium cromoglycate powders. Int. J. Pharm. 206:75-83 (2000).

A. Chawla, K. M. G. Taylor, J. M. Newton, and M. C. R. Johnson. Production of spray dried salbutamol sulphate for use in dry powder aerosol formulation. Int. J. Pharm. 108:233-240 (1994).

M. T. Vidgren, P. A. Vidgren, and T. P. Paronen. Comparison of physical and inhalation properties of spray-dried and mechanically micronized disodium cromoglycate. Int. J. Pharm. 35:139-144 (1987).

M. D. Louey, M. M. van Oort, and A. J. Hickey. The effect of spray-drying parameters on particle size of mannitol particles. AAPS PharmSci. 3 (2001).

J. Sánchez. Colorimetric assay of alditols in complex biological samples. J. Agr. Food Chem. 46:157-169 (1998).

A. J. Hickey and N. M. Concessio. Flow properties of selected pharmaceutical powders from a vibrating spatula. Part. Part. Syst. Charact. 11:457-462 (1994).

T. M. Crowder and A. J. Hickey. An instrument for rapid powder flow measurement and temporal fractal analysis. Part. Part. Sys. Charact. 16:32-34 (1999).

C. A. Dunbar, A. J. Hickey, and P. Holzner. Dispersion and characterisation of pharmaceutical dry powder aerosols. Kona. 16:7-45 (1998).

I. Gonda. Targeting by deposition. In A. J. Hickey (ed.), Pharmaceutical Inhalation Aerosol Technology, Marcel Dekker, Inc., New York, 1992, pp. 61-82.

A. Wade and P. J. Weller. Handbook of Pharmaceutical Excipients, London Pharmaceutical Press, London, 1994.

A. R. Clark and A. M. Hollingworth. The relationship between powder inhaler resistance and peak inspiratory conditions in healthy volunteers—implications for in vitro testing. J. Aerosol Med. 6:99-110 (1993).

J. N. Staniforth. Powder flow. In M.E. Aulton (ed.), Pharmaceutics: The Science of Dosage Form Design, Churchill Livingstone, New York, 1988, pp. 600-615.

Z. Wang, M. Kwauk, and H. Li. Fluidization of fine particles. Chem. Eng. Sci. 53:377-395 (1998).

H. M. Jaeger, S. R. Nagel, and R. P. Behringer. The physics of granular matter. Physics Today 49:32-38 (1996).

J. Visser. Van der Waals and other cohesive forces affecting powder fluidization. Powder Tech. 58:1-10 (1989).

J. Visser. Particle adhesion and removal: a review. Part. Sci. Tech. 13:169-196 (1995).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Louey, M.D., Van Oort, M. & Hickey, A.J. Aerosol Dispersion of Respirable Particles in Narrow Size Distributions Produced by Jet-Milling and Spray-Drying Techniques. Pharm Res 21, 1200–1206 (2004). https://doi.org/10.1023/B:PHAM.0000033007.27278.60

Issue Date:

DOI: https://doi.org/10.1023/B:PHAM.0000033007.27278.60