Abstract

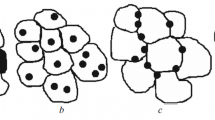

A range of Al2O3-Cr and Al2O3-Cr/Ni composites have been made using either pressureless sintering in the presence of a graphite bed or hot pressing. Examination of the microstructures shows that they are fully dense (typically 98–99% of the theoretical density) and that the micrometre-scale metallic particles remain discrete and homogeneously dispersed in all composites. All of the hot pressed specimens had higher flexural strengths than the sintered materials. Within each processing route, the composites had slightly lower strength values than the equivalent monolithic alumina specimens. This was attributed to weak interfacial bonding. Fracture toughness behaviour was investigated using indentation and double cantilever beam methods. All of the composites were found to be tougher than the parent alumina and to show resistance-curve behaviour. For the composites, maximum fracture toughness values were 5–6 MPa m1/2 (about double the value for alumina) for process zone sizes of a few millimetres, although steady state was not reached in the limited number of specimens tested. Examination of fracture surfaces and indentation cracks showed that the toughening potential of the metal particles was not exploited to any significant extent. This was mainly due to weak metal-Al2O3 interfaces, but also because of carbon embrittlement of the metallic particles in which chromium was the major constituent.

Similar content being viewed by others

References

E. BREVAL, Z. DENG, S. CHIOU and C. G. PANTANO, J. Mater. Sci. 27(1992) 1464.

E. BREVAL and C. G. PANTANO, ibid. 27 (1992) 5463.

W. H. TUAN and R. J. BROOK, Journal of the European Ceramic Society 6 (1990) 31.

X. SUN and J. YEOMANS, J. Amer. Ceram. Soc. 79 (1996) 2705.

T. SEKINO, T. NAKAJIMA, S. UEDA and K. NIIHARA, ibid. 80 (1997) 1139.

R.Z. CHEN and W. H. TUAN, Journal of the European Ceramic Society 19 (1999) 463. 5235

J. LU, L. GAO, J. SUN, L. GUI and J. GUO, Materials Science and Engineering, A 293(2000) 223.

M. LIEBERTHAL and W. D. KAPLAN, ibid. A302 (2001) 83.

S.-T. OH, M. SANDO and K. NIIHARA, J. Amer. Ceram. Soc. 81 (1998)3013.

Idem., Scripta Mater. 39 (1998) 1413.

J. L. GUICHARD, O. TILLEMENTand A. MOCELLIN, J. Mater. Sci. 32 (1997) 4513.

P. A. TRUSTY and J. A. YEOMANS,Journal of the European Ceramic Society 18 (1998) 495.

CH. LAURENT, A. PEIGNEY, O. QUÉNARD and A. ROUSSET, Sil. Ind. 63 (1998) 77.

J. L. GUICHARD, O. TILLEMENT and A. MOCELLIN, Journal of the European Ceramic Society 18 (1998) 1743.

W.B CHOU and W. H. TUAN, Journal of the European Ceramic Society 15 (1995) 291.

O. SBAIZERO and G. PEZZOTTI, Journal of the European Ceramic Society 20 (2000) 1145.

M. NAWA, T. SEKINO and K. NIIHARA, J. Mater. Sci. 29 (1994) 3185

J. LU, L. GAO, J. GUO and K. NIIHARA, Materials Research Bulletin 35 (2000) 2387.

D.E. ALDRICH and M. J. EDIRISINGHE, J. Mater. Sci. Lett. 17 (1998) 965.

S-T. OH, T. SEKINO and K. NIIHARA, Journal of the European Ceramic Society 18 (1998) 31.

S-T. OH, J-S. LEE, T. SEKINO and K. NIIHARA, Scripta Mater. 44 (2001) 2117.

T. SEKINO and K. NIIHARA, Nanostructured Materials 6 (1995) 663.

Idem., J.Mater. Sci. 32 (1997) 3943.

Y. S. TOULOUKIAN, R. K. KIRBY, R. E. TAYLOR and P.D. DESAI (Eds.) in “Thermophysical Properties of Matter, ” The TPRC Data Series, Vol. 12: Thermal Expansion—Metallic Elements and Alloys (Plenum, New York, 1975) p. 61.

Y. S. TOULOUKIAN, R. K. KIRBY, R.E. TAYLOR and T. Y. R. LEE (Eds.) in “Thermophysical Properties of Matter, ” The TPRC Data Series,Vol. 13: Thermal Expansion—Non-Metallic Solids (Plenum, New York, 1977) p. 176.

K. M. LIANG, G. ORANGE and G. FANTOZZI, J. Mater. Sci. 25 (1990) 207.

P. A. TRUSTY, Ph. D.thesis, University of Surrey, UK, 1994.

A. H. SULLY, E. A. BRANDES and K. W. MITCHELL,Journal of the Institute of Metals 81 (1952/1953) 585.

C. GANDHI and M. F. ASHBY, ActaMetallurgica 27 (1979) 1565.

B. C. ALLEN, D. J. MAYKUTH and R. I. JAFFEE, Transactionof the Metallurgical Society of AIME 227 (1963) 724.

R. E. CAIRNS JR. and N. J. GRANT,ibid. 230(1964) 1150.

H. L. WAIN and S. T.M. JOHNSTONE, Journal of the Institute of Metals 83 (1954/1955) 133. Received 4 December 2001 and accepted 18 July 2002 5236

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Ji, Y., Yeomans, J.A. Microstructure and mechanical properties of chromium and chromium/nickel particulate reinforced alumina ceramics. Journal of Materials Science 37, 5229–5236 (2002). https://doi.org/10.1023/A:1021000318894

Issue Date:

DOI: https://doi.org/10.1023/A:1021000318894