Abstract

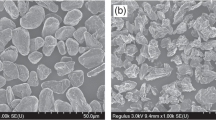

A method to drain cast porous ceramics has been conceived and established, where samples were shown to have a functionally gradient cross-section with a continuously increasing mean particle size between the two principal surfaces.

Ceramic discs approximately 45 mm in diameter, and 3.3 mm thick were cast by sedimentation. These green bodies were dried prior to sintering. Maximum sintering temperature and the length of the sintering soak time were varied for samples made from suspensions of both 5 and 10 volume percent solids. Mercury porosimetry was used to obtain the porosity and pore size distribution in each sample. Additionally, a number of atomic force microscopy (AFM) measurements were made on some samples in order to correlate bulk porous properties with those on the outside surfaces.

The results showed that as the sintering temperature increased, the densification of the bodies proceeded more rapidly. In general, the longer the sintering soak time, the denser the samples became as well. For the samples prepared at the lower temperatures however, the porosity showed less of a soak time dependence. The green body had a clustered and asymmetric microstructure, which contributed to differing degrees of localized densification and coarsening effects depending on the sintering temperature. Densification effects were more pronounced with the samples made from the more concentrated suspenisions.

There was an inverse correlation between the bulk and surface pore dimensions, attributable to the different size scales of particles in the two regions. The much finer surface layer particles were able to undergo some amount of densification while surface diffusion sintering mechanisms were primarily at work elsewhere in the structure.

Similar content being viewed by others

References

K. Darcovich and M.E. Price, J. Can. Cer. Soc. 66 (2), 141 (1997).

K. Darcovich and C.R. Cloutier, J. Am. Cer. Soc. 82 (8), 2073 (1999).

I.A. Aksay, in Advances in Ceramics, edited by J.A. Manjels and G.L. Messing (Columbus, OH: American Ceramic Society, 1984), p. 94.

A.G. Lamas, M. Almeida, and H.M.M. Diz, Ceram. Int. 19, 121 (1993).

P.M. Biesheuvel and H. Verweij, J. Membrane Sci. 156, 141 (1999).

T. Moritz, G. Werner, M. Mangler, G. Tomandl, and H. Eichler, in 9th Cimtec World Ceramics Congress.Ceramics-Getting into the 2000's, Pt.C, edited by P. Vincenzini (Faenza, Italy: Techna Srl., 1999), p. 321.

J. (III) Cesarano and I.A. Aksay, J. Am. Ceram. Soc. 71 (12), 1062 (1988).

W.-C.J. Wei, S.-U. Lu, and C.-L. Hsieh, J. Cer. Soc. Japan. 104 (4), 277 (1996).

G.K. Binnig, Phys. Scripta. T19, 53 (1987).

J. Luyten, J. Cooymans, and R. Leysen, Key Eng. Materials. 132–136, 1691 (1997).

K. Darcovich, D. Roussel, and F.N. Toll, J. Membrane Sci. 183 (2), 291 (2001).

N. Das and H.S. Maiti, J. Membrane Sci. 140, 205 (1998).

A.G. Evans, J. Am. Cer. Soc. 65 (10), 497 (1982).

K. Uematsu, M. Miyashita, J.Y. Kim, and N. Uchida, J. Am. Cer. Soc. 75 (4), 1016 (1992).

N. Das, S. Bandyopadhyay, D. Chattopadhyay, and H.S. Maiti, J. Mater. Sci. 31, 5221 (1996).

K.L. Stephanopoulos, G.E. Romanos, A.C. Mitropoulos, N.K. Kanellopoulos, and R.K. Heenan, J. Membrane Sci. 153, 1 (1999).

Z. Zeng, X. Xiao, Z. Gui, and L. Li, J. Membrane Sci. 136, 153 (1997).

H.G. Pedersen, J. Tranto, and J.W. Høj, Key Eng. Materials. 132–136, 1707 (1997).

A. Li, H. Zong, J. Gu, and G. Xiong, Prog. Natural Sci. 7 (2), 187 (1997).

Z.R. Ismagilov, R.A. Shkrabina, N.A. Koryabkina, A.A. Kirchanov, H. Veringa, and P. Pex, React. Kinet. Catal. Lett. 60(2), 225 (1997).

A. Nijmeijer, C. Huiskes, N.G.M. Sibelt, H. Kruidhof, and H. Verweij, Am. Cer. Soc. Bull. 77(4), 95 (1998).

N. Das and H.S. Maiti, J. Eur. Cer. Soc. 19(3), 341 (1999).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Darcovich, K., Toll, F. & Meurk, A. Sintering Effects on the Porous Characteristics of Functionally Gradient Ceramic Membrane Structures. Journal of Porous Materials 8, 201–210 (2001). https://doi.org/10.1023/A:1012284522672

Issue Date:

DOI: https://doi.org/10.1023/A:1012284522672