Abstract

The method explained in this paper for quantitative evaluation of fatigue limit for materials containing defects is based on the experimental evidences that inhomogeneities and micro-notches can be treated like cracks. First, the basic concept of the √area parameter model is explained introducing the various data obtained by the first author's group for over last 15 years. Evidences are shown that small cracks, defects and nonmetallic inclusions having the same value of the square root of projection area, √area, have the identical influence on the fatigue limit regardless of different stress concentration factors. Various applications of these concepts to various defect types and microstructural inhomogeneities are shown. Since the estimation of fatigue strength is related to the estimation of the size of maximum defects occurring in a piece, the methods for searching the defects and the quality control of materials with respect to inclusion or defect rating as well as their statistical implications are discussed.

Similar content being viewed by others

References

Murakami, Y. and Endo, T., “Effect of small defects on the fatigue strength of metals,” Int. J. Fatigue 2, 23–30, (1980).

Murakami, Y. and Endo, M., “Effect of hardness and crack geometries on DKth of small cracks emanating from small defects,” In: The Behavior of Short Fatigue Cracks, (K.J. Miller and E.R. de Los Rios, Eds.), MEP, London, 275–293, (1986).

Murakami, Y. and Endo, M., “Effect of defects, inclusions and inhomogeneities on fatigue strength,” Int. J.Fatigue 16, 163–181, (1994).

Murakami, Y., Metal Fatigue: Effects of Small Defects and Nonmetallic Inclusions, Yokendo Ltd, Tokyo, 1993.

Kitagawa, H. and Takahashi, S., “Applicability of fracture mechanics to very small cracks or the cracks in the early stage,” Proc. 2nd Int. Conf. Mech. Behavior Mater—ICM2, Boston, 627–631, (1976).

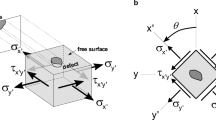

Murakami, Y., “Analysis of Stress Intensity Factors of modes I, II and III for inclined surface cracks of arbitrary shape,” Engng. Fract. Mech. 22, 101–114, (1985).

Miller, K.J., “The short crack problem,” Fatigue Fract. Engng. Mater. Struct. 5, 223–232, (1982).

Toryiama, T. and Murakami, Y., “The √area parameter model for evaluation of effects of various artificial defects and mutual interaction of small defects at the fatigue limit,” J. Soc. Mater. Sci. Japan 42, 1160–1166, (1993).

Murakami, Y., Toryiama, T., Koyasu, Y., and Nishida, S., “Effects of chemical composition of nonmetallic inclusions on the fatigue strength of high strength steels,” Tetsu-to-Hagane, Iron and Steel Inst. of Japan 79, 678–684, (1993).

Murakami, Y., Kodama, S., and Konuma, S., “Quantitative evaluation of effects of non-metallic inclusions on fatigue strength of high strength steels I: basic fatigue mechanism and evaluation of correlation between the fatigue fracture stress and the size and location of non-metallic inclusions,” Int. J. Fatigue 11(5), 291–298, (1989).

Duckworth, W.E. and Ineson, E., “The effects of externally introduced alumina particles on the fatigue life of En24 steel,” Clean Steel, Iron Steel Inst. Spec. Rep. 77, 87–103, (1963).

Murakami, Y. and Usuki, H., “Quantitative evaluation of effects of non-metallic inclusions on fatigue strength of high strength steels II: fatigue limit evaluation based on statistics for extreme value of inclusion size,” Int. J. Fatigue 11(5), 299–307, (1989).

Murakami, Y., Toryiama, T., and Coudert, E.M., “Instructions for a new method of inclusion rating and correlation with the fatigue limit,” J. Testing. Eval. 22, 318–326, (1994).

Murakami, Y., “Inclusion rating by statistics of extreme value and its application to fatigue strength prediction and quality control of materials,” J. Res. Natl. Standard 99, 345–351, (1994).

Gumbel E.J., Statistics of Extremes, Columbia University Press, New York, 1957.

Murakami, Y., Basic Mechanisms in Fatigue of Metals, Materials Science (P. Lukàs and J. Polaàk Eds.), Elsevier, New York, 343–350, 1988.

Murakami, Y., “Effect of small defects and nonmetallic inclusions on the fatigue strength of metals,” JSME Int. J., Ser. A 32, 167–180, (1989).

Murakami, Y., “Effects of nonmetallic inclusions on the fatigue strength of metals,” In: Micromechanics and Inhomogeneity, The Toshio Mura 65th Anniversary Volume (G. J. Weng, M. Taya and H. Abe, Eds.), Springer-Verlag, New York, 283–295, (1990).

Murakami, Y., “Effects of nonmetallic inclusions of the fatigue of high strength steels: historical overview and new quantitative evaluation,” Impact of Improved Material Quality on Properties, Product Performance, and Design, MD. 28, ASME, 89–103, (1991).

Kobayashi, M., Murakami, Y., Makino, T., Toriyama, T., Kurihara, Y., and Ebara, R., “Fatigue strength prediction of automobile suspension spring steels: explicit analysis of nonmetallic inclusions, shoot peening, decarburized layer, surface roughness and corrosion pits,”ibid., 171–183, (1991).

Natsume, Y., Miyakawa, S., Vemura, Y., and Murakami, Y., “Prediction of fatigue strength of high-speed steel based on estimation of the maximum size of inclusions,” Proc. Int. Conf. Fatigue 90, (H. Kitagawa and T. Tanaka Eds.), Honolulu, 1, 349–354, (1990).

Murakami, Y., “Effects of small defects, small cracks and nonmetallic inclusions on fatigue strength of high strength steels,” Proc. Int. Conf. Fatigue 90, In: (H. Kitagawa and T. Tanaka Eds.), Honolulu, 1, 377–382, (1990).

Endo, M., “Effects of graphite shape, size and distribution on the fatigue strength of spheroidal graphite cast irons,” J. Soc. Mater. Sci. Japan 38(433), 1139–1144, (1989).

Sakai, T., Kogo, S., and Suzuki, M., “Statistical fatigue properties of nodular cast iron in rotating bending,” J. Soc. Mater. Sci. Japan 38(434), 1268–1274, (1989).

Endo, M., “Fatigue thresholds for small cracks in spheroidal graphite cast iron,” Proc. Int. Conf. `Fatigue 90', (H. Kitagawa and T. Tanaka Eds.), Honolulu, 3, 1357–1362, (1990).

Doi, S., Harada, S., Mitsunaga, K., Yano, M., and Yasuda, H., “Fatigue behavior of spheroidal graphite ductile iron,” Proc. JSME Meeting, (900-86), 613–615, (1990).

Endo, M., “Fatigue strength prediction of nodular cast iron containing small defects,” Impact of Improved Material Quality on Properties, Product Performance, and Design, MD 28, ASME, 125–137, (1991).

Sugiyama, Y., Asami, K., and Matsuoka, S., “The quantitative evaluation method on fatigue limit of materials with defects by using ductile cast iron and its application to the fatigue limit improvement,” Proc. 69th JSME Spring Ann. Meeting A(920-17), 476–478, (1992).

Endo, M., “Fatigue strength prediction of spheroidal graphite cast irons based on the root-area parameter model,” ibid. 479–481, (1992).

Kato, Y. and Hasegawa, N., “Fatigue limits and thresholds in fatigue cracks growth of a spheroidal cast iron FCD450,” ibid. 494–496, (1992).

Beretta, S., Blarasin, A., Endo, M., Giunti, T., and Murakami, Y., “Defect tolerant design of automotive components,” Int. J. Fatigue 19, 319–333, (1997).

Kobayashi, M. and Matsui, T., “Prediction of fatigue strength of aluminum casting alloys by the Harea parameter model,” Trans. JSME, ser. A 62(594), 341–346, (1996).

Murakami, Y., Ikeda, H., and Toriyama, T., “Quantitave evaluation of effects of inhomogeneity phases on the fatigue strength of Al-Si new alloys,” Proc. Int. Conf. Mech. Behavior Mater.—ICM6, Kyoto (Japan), 433–438, (1991).

Natsume, Y., Muramatsu, T., and Miyamoto, T., “Effect of carbide crack on fatigue strength of alloy-tool steel under cold working,” Proc. JSME Meeting (900-86) 323–325, (1990).

Beretta, S. and Murakami, Y., “Statistical analysis of defects for fatigue strength prediction and quality control of materials,” Fatigue Fract. Engng. Mater. Struct. 21, 1049–1065, (1998).

Uemura, Y. and Murakami, Y., “A numerical simulation of evaluating the maximum size of inclusions to examine the validity of the metallographic determination of the maximum size of inclusions,” Trans. JSME 56, 162–167, (1990).

Takahashi, R. and Shibuya, M., “The maximum size of the planar sections of random spheres and its application to metallurgy,” Ann. Inst. Statist. Math. 48(1), 127–144, (1996).

Beretta, S. and Matteazzi, S., “Short cracks propagation in eutectoid steel wires,” Int. J. Fatigue 18, 451–456, (1996).

Beretta, S. and Boniardi, M., “Fatigue strength and surface quality of high strength eutectoid steel wires,” Int. J. Fatigue 21, 329–335, (1999).

Gladman, T., “Developments in inclusion control and their effects on steel properties,” Ironmaking and Steelmaking 19(6), 457–463, (1992).

Wanibe, Y., Itoh, T., Umezawa, K., Nagahama, H., and Nori, Y., “Application of new techniques for characterization of non-metallic inclusions,” J. Steel Research 66, 172–177, (1995).

Cybo, J., “Stereological alterations of non-metallic inclusions, fracture morphology and alloy impact strength after blowing active powders into liquid steel,” J. Steel Research 66, 167–171, (1995).

Harter, L., “Size effect in fatigue,” Application of Statistics, (P.R. Krishnaiah Ed.), North-Holland, 202–221, (1977).

Kohler, J. and Heckel, K., “Scatter and statistical size-effect at fatigue behavior of metallic specimens,” Proc. Int. Conf. Mech. Behavior Mater—ICM2, Boston (USA), 652–656, (1976).

Heckel, K. and Kra Ch., “Scatter and transferability of fatigue data at service loading,” Proc. Int. Conf.Mech. Behavior Mater—ICM6, Kyoto (Japan), 627–632, (1991).

Beretta, S., Clerici, P., and Paolini, G., “An experimental approach to size effect in rotating bending fatigue,” Proc. Symp. Fatigue Design FD'92, Helsinki (Finland), 122–133, (1992).

Bomas, H., Linkewitz, T., and Mayr, P., “Application of a weakest-link concept to the fatigue limit of hard steels,” Proc. Symp., “Statistical methods in fatigue”, Boras (Sweden). (1998).

Takahashi, R. and Shibuya, M., “Prediction of maximum size in Wicksell's corpuscle problem,” Ann. Inst.Statist. Math 50(2), 361–377, (1998).

Anderson, C.W., “The largest inclusion within a piece of steel,” Proc. Symp., “Extremes-risk and safety”, Boras (Sweden) 1998.

Beretta, S. and Murakami, Y., “A new series of software for the analysis of defects based on the statistics of extremes,” Report to NIRECO LtD, Kyushu University, Fukuoka (Japan) 1999.

Beretta, S. and Murakami, Y., “A new application of LEVD to the analysis of multiple inclusion types and the cleanliness assessment in metals,” To be submitted to Acta Materialia, (1999).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Murakami, Y., Beretta, S. Small Defects and Inhomogeneities in Fatigue Strength: Experiments, Models and Statistical Implications. Extremes 2, 123–147 (1999). https://doi.org/10.1023/A:1009976418553

Issue Date:

DOI: https://doi.org/10.1023/A:1009976418553