Abstract

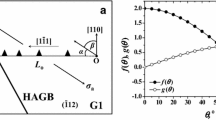

The authors discuss in detail the existing cleavage fracture model including the physical model and the statistical model. Based on the discovery that a minimum distance for initiating the cleavage fracture was revealed to have a definite physical meaning, that the stress triaxiality reaches the critical value Tc at this distance instead of that the presence of an eligible carbide crack within this distance is assured; a combined criterion for cleavage fracture, i.e. a critical plastic strain (εp ≥ εpc) for initiating a crack nucleus, a critical stress triaxiality (σ m/σ ≥ Tc) for preventing it from blunting and a critical normal stress (σyy ≥ σ) for its propagation has been proposed to substitute for the criterion of σyy ≥ σ over a ‘characteristic distance’ suggested by the RKR model. With regard to the statistical model the authors suggested that it is not necessary to describe the fracture stress distribution by Weibull function. The fracture probability at a given applied load was modified by multiplying a ‘remaining probability’ taking account of the effect of the preceding loading process.

The authors also discuss the mechanism of transition from a fibrous to a cleavage crack within the toughness transition temperature range.

Similar content being viewed by others

References

R.O. Ritchie, J.F. Knott and J.R. Rice, Journal of the Mechanics and Physics of Solids 21 (1973) 395–410.

T. Lin, A.G. Evans and R.O. Ritchie, Acta Metallurgica 34 (1986) 2205.

D. Curry and J.F. Knott, Metals Science Journal 13 (1979) 341.

F.M. Beremin, Metallurgical Transactions A 14A (1983) 1349.

C.X. Hou, Q.G. Cai, Yi Su and X.Y. Zheng, Advances in Fracture Research, Proceedings ICF 6, 2 (1984) 1415–1422.

D.J. Neville, Journal of the Mechanics and Physics of Solids 36 (1988) 443–457.

J.R. Rice and M.A. Johnson, Inelastic Behavior of Solids, Kanninen (ed.). McGraw Hill, New York (1970) 641.

R.M. McMeeking, Journal of the Mechanics and Physics of Solids 25 (1977) 357.

J.H. Chen, G.Z. Wang, C. Yan, H. Ma and L. Zhu, International Journal of Fracture 83 (1997) Pt. II.

J.H. Chen, C. Yan and J. Sun, Acta Metallurgica et Materialia 42 (1994) 251–261.

J.H. Chen, G.Z. Wang, Z. Wang, L. Zhu and Y.Y. Gao, Metallurgical Transactions 22A (1991) 2287–2296.

J.G. Chen and G.Z. Wang, Metallurgical Transactions 25A (1994) 1381–1390.

J.G. Chen and G.Z. Wang, Metallurgical Transactions 23A (1992) 509–517.

J.H. Chen, L. Zhu and H. Ma, Acta Metallurgica 38 (1990) 2527–2535.

J.H. Chen, G.Z. Wang, C. Yan, H. Ma and L. Zhu, International Journal of Fracture 83 (1997) Pt. III.

J.H. Chen, G.Z. Wang and H.J. Wang, Acta Materialia, 44 (1996) 3979–89.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Chen, J., Wang, G., Yan, C. et al. Advances in the mechanism of cleavage fracture of low alloy steel at low temperature. Part II: Fracture model. International Journal of Fracture 83, 121–138 (1997). https://doi.org/10.1023/A:1007304900578

Issue Date:

DOI: https://doi.org/10.1023/A:1007304900578