Abstract

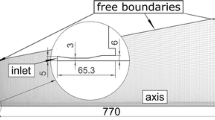

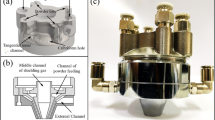

A process control chart is proposed for DC plasma spraying process based on the in-flight simulation of the injected states of the particles determined by computational fluid dynamics analysis (via FLUENT V4.3). The chart consists of five regions, i.e., the unmelted, melted, vaporized, escaped, and rebounded, which represent the various states of the particles at impact on the substrate. The X and Y axes of the chart are particle entry conditions, i.e., diameter (ranging from 20 to 100 μm) and injection velocity (between 10 to 50 m/s), respectively. The regions indicate the fate of the particle on impact. A grid-array of (14×11) entry conditions is simulated in developing the chart. The proposed chart is aimed at providing a general guideline for plasma spraying process in achieving a thoroughly melted particle on arrival at the substrate to be coated.

Similar content being viewed by others

REFERENCES

Y. C. Lee, Y. P. Chyou, and E. Pfender, “Particle Dynamics and Particle Heat and Mass Transfer, Part I, Thermal Plasma. Part II: Particle Heat and Mass Transfer in Thermal Plasmas,” Plasma Chem. Plasma Process. 5, 391 (1985).

J. R. Fincke, W. D. Swank, and D. C. Haggard, “Plasma Spraying of Alumina: Plasma and Particle Flow Fields,” Plasma Chem. Plasma Process. 13, 579 (1993).

M. Rahmane, G. Soucy, M. I. Boulus, and R. Henne, “Fluid Dynamic Study of Direct Current Plasma Jets for Plasma Spraying Applications,” J. Thermal Spray Technol. 7, 356 (1998).

K. G. Shaw and R. M. German, “Particle Classification Effects During Plasma Spraying,” Proc. 7th Nat. Thermal Spray Conf. June 20–24, 1994, Boston, Massachusetts.

E. Pfender and Y. C. Lee, “Particle Dynamics and Particle Heat and Mass Transfer in Thermal Plasmas. Part I: The Motion of a Single Particle without Thermal Effect,” Plasma Chem. Plasma Process. 5, 211 (1985).

M. I. Boulos, P. Fauchais, A. Vardelle, and E. Pfender, in Fundamental of Plasma Particle Momentum and Heat Transfer, Plasma Spraying: Theory and Application, R. Suryanarayanan (ed.), World Scientific Publ., Singapore (1993), p. 3.

M. Dadi, M. Stanislas, O. Rodriguez, and A. Dyment, “A Study by Holographic Velocity of the Behaviour of Free Small Particle in a Flow,” Exp. Fluids 10, 285 (1991).

S. Elghobashi and G. C. Truesdell, “Direct Simulation of Particle Dispersion in a Decaying Isotropic Turbulence,” J. Fluid Mech. 242, 655 (1992).

S. A. Mori and A. J. Alexander, “An Investigation of Particle Temperature in Two-Phase Flow System,” J. Fluid Mech. 55(2), 193 (1972).

FLUENT V4.3, User's Guide, Fluent Inc, Lebanon, New Hampshire (1994).

Seungho Paik, Hoa D. Nguyen, and Jacob N. Chung, “A study of argon thermal plasma flow over a solid sphere,” J. Fluid Mech. 252, 543 (1993).

M. I. Boulos, P. Fauchais, and E. Pfender, Thermal Plasma: Fundamentals and Applications, Vol. 1. Plenum Press, New York (1994).

PreBFC V4.3, User's Guide, Fluent Inc, Lebanon, New Hampshire (1994).

Y. C. Lee and E. Pfender, “Particle Dynamics and Particle Heat and Mass Transfer in Thermal Plasmas. Part III: Thermal Jet Reactors and Multiparticle Injection,” Plasma Chem. Plasma Process. 7, 1 (1987).

W. Rodi, Turbulence Models and Their Applications in Hydraulics, Technology University Delft, The Netherlands, IARH (1984).

M. Vardelle, A. Vardelle, and P. Fauchais, “Spraying Parameters and Particle Relationships During Plasma Spraying,” J. Thermal Spray Technol. 2, 79 (1993).

E. Ryshkewitch and D. W. Richerson, Oxide Ceramic: Physical Chemistry and Technology, 2nd edn. Academic Press, Orlando, Florida (1985).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Ang, C.B., Ng, H.W., Yu, S.C.M. et al. A Proposed Process Control Chart for DC Plasma Spraying Process. Plasma Chemistry and Plasma Processing 20, 325–342 (2000). https://doi.org/10.1023/A:1007040227158

Issue Date:

DOI: https://doi.org/10.1023/A:1007040227158