Abstract

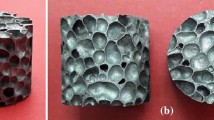

Experiments have been carried out to investigate the mechanical behavior of foamed aluminum with different matrixes and states. It is found that the matrix composition has a significant influence over the deformation, failure and fracture of foamed aluminum. Like other cellular solid materials, Al foam shows a smooth compression stress–strain curve with three regions characteristic of plastic foams: linear elastic, plastic collapse and densification. AlMg10 foam has a serrated plateau and no densification, characteristic of brittle foams. AlMg10 foam has higher compressive and tensile strength but lower ductility than Al foam. The difference in the mechanical properties between Al foam and AlMg10 foam decreases as the relative density decreases, and when it is lower than roughly 0.15, no difference can be discerned. The mechanical properties in compression are clearly higher than those in tension, which can be explained in terms of dislocation theory and stress concentration behavior.

Similar content being viewed by others

References

_ M. Kellomaki, J. Astrom and J. Timonen, Phys.Rev. Lett. 77 (1996) 2730.

V. Shapovalov, MRS Bull., (1994) 24.

H. Fusheng, Z. Zhengang and L. Changsong, Acustica/Acta Acust. to be published in June, 1998.

H. Fusheng, Z. Zhengang and L. Changsong, Scr.Metall. Mater. 37 (1997) 1441.

P. H. Thornton and C. L. Magee, Metall. Trans. A 6 (1975) 1253.

H. Fusheng, Z. Zhengang and L. Changsong, Acta Phys. Sin. (in Chinese) 47 (1998) 372.

M. Fukushima, T. Fuji and K. Kitazawa, Hitachi ShipbuildingTech. Rep. (in Japanese) 49 (1988) 41.

L. J. Gibson, M. F. Ashby, J. Zhang and T. C. Triantafillou, Int. J. Mech. Sci. 31 (1989) 635.

S. K. Maiti, L. J. Gibson and M. F. Ashby, Acta Metall. Mater. 32 (1984) 1963.

M. F. Ashby, Metall. Trans. A 14 (1983) 1755.

I. A. Ibrahim, F. A. Mohamed and E. J. Lavernia,J. Mater. Sci. 26 (1991) 1137.

A. B. Eric, in “Metals Reference Book,” (6th Edn., Butterworth & Co. Ltd., 1983) pp. 11–40.

F. Duan and Q. Dirong, in “Metallurgical Physics,”Vol. 1,Structure and Defects (in Chinese), (Science Press, Beijing, 1987) p. 301.

A. Emelyanov, E. L. Furman, I. P. Conacova and V. A. Beloglazov, Adv. Compos. Mater. 1 (1993) 1.

A. E. Simone and L. J. Gibson, Acta Metall. Mater. 44 (1996), 1437.

L. J. Gibson and M. F. Ashby, Proc. R. Soc. Lond. A 43 (1982) 382.

P. P. Castaheda and M. Zaidman, J. Mech. Phys. Solids. 42 (1994) 1459.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Fusheng, H., Zhengang, Z. The mechanical behavior of foamed aluminum. Journal of Materials Science 34, 291–299 (1999). https://doi.org/10.1023/A:1004401521842

Issue Date:

DOI: https://doi.org/10.1023/A:1004401521842