Abstract

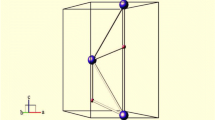

Piezoelectric zinc oxide films are used in microelectromechanical systems (MEMS) applications, where they can be used in sensors to detect, e.g., pressure or acceleration. Beside sensors, ZnO films are applied in activation devices, where force is needed. Conductive-doped zinc oxide (most often with aluminum) is also used in optoelectronics. Piezoelectric films including AlN and ZnO are more difficult to produce than the corresponding conductive materials. In order to achieve good piezoelectricity in ZnO films, they have to possess high purity, a (0 0 1) orientation (ZnO has hexagonal crystal structure), high resistivity, and fine columnar microstructure perpendicular to the substrate. We have used r.f. magnetron (13.56 MHz) sputtering from a ZnO target in an oxygen atmosphere to achieve the piezoelectric ZnO. The aim of this work has been to develop an r.f. sputtering process for ZnO to achieve highly piezoelectric thin films. As a test vehicle to measure the piezoelectricity of the ZnO films we have fabricated resonators and passband filters in the 1–2 GHz range using standard microelectronics photolithography, deposition, and etching techniques on 100-mm diameter Corning glass or silicon wafers. The influence of the sputtering-process parameters on the film properties has been studied by X-ray diffraction, scanning electron microscopy, atomic force microscopy, and electrical measurements. In this study, the effects of the process parameters on the final material properties of the ZnO film are discussed in detail.

Similar content being viewed by others

References

J. Kaitila, M. Ylilammi, J. Molarius, J. EllÄ and T. Makkonen, IEEE Ultrason. Sympo. (2001) 223.

K. Lakin, G. Kline and K. Mcgarron, IEEE Trans. Microw. Theory 43 (1995) 2933.

I. Safi, Surf. Coat. Technol. 127 (2000) 203.

W.-J. Jeong and G.-C. Park, Sol. Energy Mater. Cells 65 (2001) 37.

C. R. Aita, IEEE Ultrason. Symp. (1980) 483.

F. S. Hickernell, ibid. (1980), 785.

JCPDS-ICDD (the Joint Committee on Powder Diffraction Standards-International Centre for Diffraction Data) file no. 36–1451.

A. C. Anderson and D. E. Oates, IEEE Ultrason. Symp. (1982) 329.

P. Sharma, A. Mansigh, K. Sreenivas, Appl. Phys. Lett. 80 (2002) 553.

IEEE Standard on Piezoelectricity, ANSI/IEEE Std 176–1987.

H. Jaffe and D. A. Berlincourt, Proc. IEEE 53 (1965) 1372.

C. W. Seabury, J. T. Cheung, P. H. Kobrin, R. Addison and D. P. Havens, IEEE Trans. Ultrason., Ferroelect., Freq. Control 42 (1995) 339.

Y. Igasaki, T. Naito, K. Murakami and W. Tomoda, Appl. Surf. Sci. 169–170 (2001) 512.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Molarius, J., Kaitila, J., Pensala, T. et al. Piezoelectric ZnO films by r.f. sputtering. Journal of Materials Science: Materials in Electronics 14, 431–435 (2003). https://doi.org/10.1023/A:1023929524641

Issue Date:

DOI: https://doi.org/10.1023/A:1023929524641