Abstract

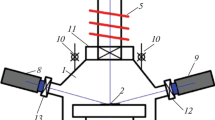

A complex experimental set-up was built to study the impact of liquid alumina droplets on different substrates (stainless steel 304L, sintered alumina, carbon–carbon) kept at temperatures up to 2100 K. The impact behavior: rebound, deposition, splashing, spattering was systematically studied as well as the resulting splat shapes. The set-up consists in a controlled atmosphere chamber where molten alumina particles with diameters between 10 and 90 μm, are produced by a d.c. plasma torch, substrates being heated by a second d.c. plasma torch. In such conditions, it was possible to achieve particle temperatures between 2300 and 4200 K with velocities in the range 50 to 300 m/s. The particle behavior at impact was characterized by the Sommerfeld parameter K (K=We1/2 Re1/4 We and Re being respectively the Weber and Reynolds numbers of impacting particles). It was possible to vary K between 3 and 1300. Low K values were obtained by tilting the substrate up to 60°. The parameters of a single particle at impact were measured: its velocity vp and diameter dp by Phase Doppler Anemometry (Δvp=5%, Δdp=10%) and its temperature Tp by fast (100 ns) two color pyrometry (ΔTp=15%). The particle impact was visualized by a fast camera coupled to a microscope (exposure delay time 50 ns . . .100 ms) with complex synchronization and light intensity problems. To solve the latter, the impacting particle had to be illuminated with a 2 W c.w. Ar+ laser at 488 nm. Unfortunately, the controlled atmosphere chamber did not allow to change the substrate after each particle impact. Starting from a smooth surface for the first impact, due to the successively deposited splats, rapidly droplets impacted on a rough surface (Ra∼5 μm).

• For splats collected on a hot alumina substrate (2100 K), where flattening is completed before solidification starts (case similar to that of ethanol droplets on cold copper) deposition occurs for K between 4 and 90 while splashing occurs for K as low as 30. These results are slightly different from those related to the ethanol droplet for which deposition occurs for 3<K<57.7 and splashing for K>57.7. This could be due to the precision of measured values and the rough surface.

• For splats collected in spraying conditions splashing is always the rule K values up to 1400) especially on rough surfaces. However the particle impact velocity and temperature, the substrate temperature and tilting plays an important role on the resulting splat diameters, distortion and elongation rates. The question which is still pending is which quantity of splashed material is incorporated within the constructing coating and how does it affect its thermophysical properties.

Similar content being viewed by others

REFERENCES

S. E. Hinckle, Appl. Eng. Agric. 5, 386–391 (1979).

J. L. Zable, J. Res. Develop. 21, 315–320 (1997).

L. H. Wachters and N. A. J. Westerling, Chem. Ing. Sci. 21, 1047–1056 (1966).

O. Engel, J. Appl. Phys. 38, 3935–3940 (1967).

L. Bianchi, F. Blein, P. Lucchese, M. Vardelle, A. Vardelle, and P. Fauchais, in Thermal Spray Industrial Applications (C. C. Berndt and S. Sampath, eds.), ASM International, Materials Park, Ohio, USA, 1995, pp. 569–574.

L. Bianchi, P. Lucchese, A. Denoirjean, and P. Fauchais, in Advances in Thermal Spray Science and Technology (C. C. Berndt and S. Sampath, eds.), ASM International, Ohio, 1995, pp. 261–266.

L. Bianchi, A. Grimaud, F. Blein, P. Lucchese, and P. Fauchais, J. Thermal Spray Technol. 4, 59–66 (1995).

A. C. Leger, M. Vardelle, A. Vardelle, P. Fauchais, S. Sampath, C. C. Berndt, and H. Herman, in Thermal Spray: Practical Solutions for Engineering Problems (C. C. Berndt, ed.), ASM International, Ohio, 1996, pp. 623–628.

S. Sampath, J. Matejicek, C. C. Berndt, H. Herman, A. C. Leger, M. Vardelle, A. Vardelle, and P. Fauchais, in Thermal Spray: Practical Solutions for Engineering Problems (C. C. Berndt, ed.), ASM International, Ohio, 1996, pp. 629–636.

L. Bianchi, A. C. Leger, M. Vardelle, A. Vardelle, and P. Fauchais, Thin Solid Films 305, 35–47 (1997).

L. Bianchi, A. Denoirjean, and P. Fauchais, Thin Solid Films 299, 125–135 (1997).

C. J. Li, J. L. Li, W. B. Wang, A. Ohmori, and K. Tani, in Thermal Spray: Meeting the Challenges of the 21st Century (C. Coddet, ed.) ASM International, Ohio, 1998, pp. 481–487.

S. Sampath, X. Y. Jiang, J. Matejicek, A. C. Leger, and A. Vardelle, Materials Sci. Engng. A272, 181–188 (1999).

A. Vardelle, C. Moreau, and P. Fauchais, MRS Bulletin, July, 32–37 (2000).

N. Cesco, Study and modeling of a two phase flow inside a powder booster (in French), PhD, Ecole Nationale Supérieure de l'Aéronautique et de l'Escape, Toulouse, Nov. 1997.

F. Kappei, B. Platet, A. C. Tournayre, and G. Lavergne, Contribution to the study of impact of droplets on a wall or a liquid film (in French), Technical Report No. RT1/5400.29, Toulouse, 1999.

C. Mundo, M. Sommerfeld, and C. Tropea, Experimental studies of deposition and splashing of small liquid droplets impinging on a flat surface, ICLASS-94, Ruoen, Paper I-18, 1994.

C. Mundo, M. Sommerfeld, and C. Tropea, Int. J. Multiphase Flow 21, 151–173 (1995).

G. Lavergne and B. Platet, Study of the impact of droplets on a heated wall (in French), Final Report, Nbl/2401/CERT/DERMES, 1991.

P. Fauchais, A. Vardelle, and B. Dussoubs, J. Thermal Spray Technol. 10, 44–66 (2001).

P. Fauchais, A. Vardelle, M. Vardelle, A. Denoirjean, B. Pateyron, and M. El Ganaoui, in Thermal Spray 2001: New Surface for a New Millennium (C. C. Berndt, K. A. Khor, and E. F. Lugsheider, eds.) ASM International, Ohio, 2001, pp. 865–874.

M. Fukumoto, S. Katoh, and I. Okane, in Thermal Spraying: Current Status and Future Trends (A. Ohmori, ed.), Society of High Temp. of Japan, 1995, pp. 353–358.

M. Fukumoto, Y. Huang, and M. Ohwatari, in Thermal Spray: Meeting the Challenges of the 21st Century (C. Coddet, ed.), ASM International, Ohio, 1998, pp. 401–406.

M. Pasandideh-Fard and J. Mostaghimi, in Thermal Spray: Practical Solutions for Engineering Problems (C. C. Berndt, ed.), ASM International, Ohio, 1996, pp. 637–646.

M. Pasandideh-Fard, J. Mostaghimi, and S. Chandra, in Thermal Spray: Surface Engineering via Applied Research (C. C. Berndt, ed.), ASM International, Ohio, 2000, pp. 125–134.

M. Bussmann, J. Mostaghimi, and S. Chandra, Physics of Fluids 11, 1406–1417 (1999).

V. Pershin, I. Thomson, S. Chandra, and J. Mostaghimi, in Thermal Spray: Surface Engineering via Applied Research (C. C. Berndt, ed.), ASM International, Ohio, 2000, pp. 813–820.

V. Pershin, I. M. Pasandideh-Fard, J. Mostaghimi, and S. Chandra, in Thermal Spray 2001: New Surface for a New Millennium (C. C. Berndt, K. A. Khor, and E. F. Lugsheider, eds.), ASM International, Ohio, 2001, pp. 813–820.

R. Ghafouri-Azar, J. Motaghimi, and S. Chandra, in Thermal Spray 2001: New Surface for a New Millennium, (C. C. Berndt, K. A. Khor, and E. F. Lugsheider, eds.), ASM International, Ohio, 2001, pp. 951–958.

M. Vardelle, A. Vardelle, A. C. Leger, and P. Fauchais, J. Thermal Spray Technol. 4, 50–58 (1995).

H. Fukanuma, in Thermal Spray: Practical Solutions for Engineering Problems (C. C. Berndt, ed.), ASM International, Ohio, 1996, pp. 647–656.

V. Sobolev, in Thermal Spray: Meeting the Challenges of the 21st Century, (C. Coddet, ed.), ASM International, Ohio, 1998, pp. 507–510.

J. Pech, B. Hannoyer, A. Denoirjean, and P. Fauchais, in Thermal Spray: Surface Engineering via Applied Research (C. C. Berndt, ed.), ASM International, Ohio, 2000, pp. 759–765.

M. Fukumoto, E. Nishivka, and T. Nishiyama, in Thermal Spray 2001: New Surface for a New Millennium, (C. C. Berndt, K. A. Khor, and E. F. Lugsheider, eds.), ASM International, Ohio, 2001, pp. 841–848.

O. Engel, J. Applied Phys. 38, 3935–3940 (1967).

B. Platet and G. Lavergne, Characterization of the interaction phenomenon droplet wall (in French), 3rd Symposium Research and Technology, Internal flows in solid propellants 2, 231–242 (1998).

J. F. Coudert, M. P. Planche, and P. Fauchais, Plasma Chem. Plasma Process 15, 47–70 (1996).

M. Vardelle, A. Vardelle, and P. Fauchais, J. Thermal Spray Technol. 2, 79–91 (1993).

M. Vardelle, A. Vardelle, P. Fauchais, and C. Moreau, Meas. Sci. Technol. 5, 205–215 (1994).

B. Glorieux, J. C. Rifflet, C. Pulvin, F. Millot, and J. P. Coutures, Thermodynamic properties of liquid alumina (in French), Technical note NT1-phC-ASSM6 CRPHT/CNRS, May 1997.

P. Fauchais and A. Vardelle, Int. J. Therm. Sci. 39, 852–870 (2000).

G. Mariaux, P. Fauchais, A. Vardelle, and B. Pateyron, J. High Temp. Mater. Process. 5, 61–85 (2001).

A. Vardelle, P. Fauchais, B. Dussoubs, and N. J. Themelis, Plasma Chem. Plasma Process. 18, 551–574 (1998).

M. Boulos, P. Fauchais, and E. M. Pfender, Thermal Plasmas Fundamental and Applications, Vol. 1, Plenum Press, NY, London, 1994.

C. R. Wilkes, J. Chem. Phys. 18, 517–519 (1950).

E. A. Mason and S. C. Sucena, The Physics of Fluids 1, 361–369 (1958).

C. H. Chang and J. D. Ramshaw, Phys. Plasmas 1, 3698, 3708 (1994).

Ph. Roumilhac, J. F. Coudert, and P. Fauchais, in Plasma Process. and Synthesis of Materials (D. Apelian and J. Szekely, eds.), MRS, Pittsburgh 190, 227–238 (1990).

O. Betoule, G. Soucy, M. Vardelle, P. Fauchais, M. Boulos, and M. Ducos, in Thermal Spray: Int. Advances in Coating Technology (C. Berndt, ed.), ASM International, Ohio, 1992, pp. 773–779.

A. B. Murphy, Phys. Rev. E 55, 7473–7494 (1997).

P. Gougeon and C. Moreau, J. of Thermal Spray Technol. 10, 76–82 (2001).

A. Vardelle, M. Vardelle, P. Fauchais, and D. Gobin, NATO Series E: Applied Sciences 282, 95–121 (1995).

M. P. Kanouff, R. A. Neiser, and T. R. Roemer, J. Thermal Spray Technol. 7, 219–228 (1998).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Escure, C., Vardelle, M. & Fauchais, P. Experimental and Theoretical Study of the Impact of Alumina Droplets on Cold and Hot Substrates. Plasma Chemistry and Plasma Processing 23, 185–221 (2003). https://doi.org/10.1023/A:1022976914185

Issue Date:

DOI: https://doi.org/10.1023/A:1022976914185