Abstract

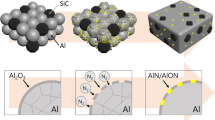

This paper is centred on a study of the interface reaction mechanisms which participate in the fabrication of an aluminium-SiC composite by a casting route, when reinforcements (particles, in this case) have been previously coated by oxidation with a SiO2 layer. The studies, which were carried out using transmission electron microscopy and differential scanning calorimetry, made it possible to propose a model of action of the SiO2 barrier in relation to the coating thickness and the reaction time. The first reaction that occurred in this SiC-SiO2-molten Al system was the formation of an Al-Si-O glassy phase which progressively consumed the SiO2 barrier, reducing the matrix-particle interface energy and favouring wetting of the SiC surfaces. When the oxidation coating was completely consumed, the SiC was preferentially dissolved by the glassy phase, inside which the formation of amorphous carbon was detected. These studies also show that carbon enrichment of the reaction layer activated the precipitation of metallic impurities (such as Fe or Cu) in the reaction. Longer reaction times (8 h) could also favour crystallization of the glassy phase to form mullite and the formation of microcrystalline alumina at the reaction interface.

Similar content being viewed by others

References

P. MOGILEVSKY, A. WERNER and H. J. DUDEK, Mater. Sci. Eng. A 242 (1998) 235.

V. LAURENT, D. CHATAIN and N. EUSTATHOPOLOUS, ibid., 135 (1991) 89.

Z. FAN, Z. X. GUO and B. CANTOR, Composites Part A: Applied Science and Manufacturing 28 (1997) 131.

L. C. KWANG and B. DERBY, in Proceedings of Topical Symposium III Advanced Fiber Composites of the 8th CIMTEC-World Ceramics Congress and Forum on New Materials. 28 June-4 July 1994; Florence, Italy, p. 179.

S. Q. GUO, Y. KAGAWA, Y. TANAKA and C. MASUDA, Acta Materialia, 46 (1998) 4941.

S. M. JENG, J. M. YANG and J. A. GRAVES, J. Mater. Res. 8 (1993) 905.

T. D. MCGARRY, M. J. PINDERA and F. E. WAWNER, Composites Engineering 5 (1995) 951.

B. S. MAJUMDAR, Materials Science and Engineering 259 (1999) 171.

A. UREÑA, J. M. GÓMEZ DE SALAZAR, L. GIL, M. D. ESCALERA and J. L. BALDOMERO, Journal of Microscopy 196 (1999) 124.

A. UREÑA, P. RODRIGO, L. GIL, M. D. ESCALERA and J. L. BALDONEDO, J. Mater. Sci. 36 (2001) 419.

Idem., ibid. 36 (2001) 429.

J. P. ROCHER, J. M. QUENISSET and R. NASLAIN, ibid. 24 (1989) 2697.

Y. L. LIU and B. KINDL, Scripta Metallurgica et Materialia, 27 (1992) 1367.

B. KINDL, Y. H. TENG and Y. L. LIU, Composites 25 (1994) 671.

M. SUERY, G. L'ESPERANCE, B. D. HONG, L. NGUYEN-THANH and F. BORDEAUX, J. Mater. Eng. and Perform. 2 (1993).

P. TRESPAILLE-BARRAU and M. SUERY, Materials Science and Technology 10 (1994) 497.

J. C. LEE, J. I. LEE and H. I. LEE, J. Mater. Sci. Lett. 15 (1996) 1539.

K. T. KIM, M. W. KO and C. H. LEE, Journal of the Korean Institute of Metals and Materials 31 (1993) 1487.

R. ASTHANA and P. K. ROHATGI, J. Mater. Sci. Lett. 12 (1993) 442.

W. S. CHUNG, S. Y. CHANG and S. J. LIN, Plating & Surface Finishing 83 (1996) 68.

A. MANZANO, E. NAVA and C. VAZQUEZ, Scripta Metallurgica et Materialia 29 (1993) 1241.

R. ASTHANA and P. K. ROHATGI, Key Engineering Materials 79/80 (1993) 47.

A. UREÑA, E. E. MARTÍNEZ, E. CRIADO and L. GIL, Mater. Sci. Tech., in press.

A. E. HUGHES, M. M. HEDGES and B. A. SEXTON, J. Mater. Sci. 25 (1990) 4856.

J. WEISS, H. L. LUKAS, J. LORENZ, G. PETZOW and H. KRIEG, CALPHAD: Comput. Coupling Phase Diagrams Thermochem. 5 (1981) 125.

I. M. LOW and R. MCPHERSON, J. Mater. Sci. 24 (1989).

A. MORTESEN and Y. JIN, Int. Mat. Reviews. 37 (1992) 101.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Ureña, A., Escalera, M.D. & Gil, L. Oxidation barriers on SiC particles for use in aluminium matrix composites manufactured by casting route: Mechanisms of interfacial protection. Journal of Materials Science 37, 4633–4643 (2002). https://doi.org/10.1023/A:1020612819045

Issue Date:

DOI: https://doi.org/10.1023/A:1020612819045