Abstract

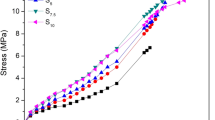

The addition of monodisperse size crosslinked polystyrene (PS) particles, synthesized by emulsifier-free emulsion polymerization, to polysulfide matrix enhanced mechanical properties of the cured rubbery composites. The modulus, fracture strength, and elongation at break increased with increasing filler volume fraction up to 30 wt % PS particles. The strength and elongation at break decreased with increasing particle diameter from 0.315 to 1.25 μm. The strength at break increased, but the extension decreased, as the particle crosslink density increased from 0 to 5 mol % DVB. Interparticle interactions are dominant and lead to the formation of clusters which form a network structure in PS particle filled composites. Since the number density, as well as the total surface area, of particles increase with decreasing particle diameter, interparticle attractions are enhanced, the tendency for cluster formation increased with decreasing particle size from 1.25 to 0.315 μm. As particle crosslink density was reduced, the porosity and surface roughness of particles increased. Then, the dispersion of particles in the matrix was enhanced and particle agglomeration reduced but more polymer matrix was adsorbed on the particles. These particles or clusters act as physical crosslinks, resulting in an increased total effective crosslink density in the filled composites.

Similar content being viewed by others

References

D. C. Edwards, J. Mater. Sci. 25 (1990) 4175.

E. Schmidt, Ind. Eng. Chem. 43 (1951) 679.

P. Delfosse, Rubber Plastics Age 38 (1957) 257.

M. P. Wagner, Rubber Chem. Technol. 49 (1976) 703.

S. W. Shang, J. W. Williams and K. J. M. Soderholm, J. Mater. Sci. 27 (1992) 4949.

K. J. M. Soderholm and S. W. Shang, J. Dent. Res. 72 (1993) 1050.

R. S. Chahal and L. E. St. pierre, Macromolecules 1 (1968) 152.

Idem., Ibid. 1 (1969) 193.

P. H. T. Vollenberg and D. Heikens, in "Composite Interface," edited by H. Ishida and J. L. Koenig (Elsevier Scientific, New York, 1986) p. 171.

D. M. Bigg, Polym. Composite 8 (1987) 115.

S. Mitsuishi, S. Kodama and H. Kawasaki, ibid. 9 (1988) 112.

A. Voet, J. Polym. Sci. 15 (1980) 327.

L. E. Nielsen, "Mechanical Properties of Polymer and Composites" (Marcel Dekker, New York, 1974) p. 411.

M. Sumita, T. Okuma, K. Miyasaka and K. Ishikawa, J. Appl. Polym. Sci. 27 (1982) 3059.

G. Landon, G. Lewis and G. F. Boden, J. Mater. Sci. 12 (1977) 1605.

G. Kraus, "Reinforcement of Elastomers" (JohnWiley & Sons, New York, 1965) p. 129.

Q. Li, PhD dissertation, University of Southern California, 1996.

D. Zou et al., J. Polym. Sci.: Part A: Polym. Chem. 28 (1990) 1909.

D. Zou, S. Ma, R. Guan, M. Park, L. Sun, J. J. Aklonis and R. Salovey, Ibid. 30 (1992) 137.

Z. Y. Ding, S. Ma, D. Kriz, J. J. Aklonis and R. Salovey, J. Polym. Sci.: Part B: Polym. Phys. 30 (1992) 1189.

D. Zou, L. Sun, J. J. Aklonis and R. Salovey, J. Polym. Sci.: Part A: Polym Chem. 30 (1992) 1463.

J. Lee and M. Senna, Colloid Polym. Sci. 273 (1995) 76.

M. Okubo and T. Nakagawa, Ibid. 272 (1994) 530.

L. Sun, PhD dissertation, University of Southern California, 1992.

A. N. Gent, in "Science and Technology of Rubber," edited by F. R. Eirich (Academic Press, New York, 1978) p. 424.

A. M. Bueche, J. Polym. Sci. 25 (1957) 139.

F. R. Eirich, "Science and Technology of Rubber" (Academic Press, New York, 1978).

J. F. Cai and R. Salovey, Polym. Eng. Sci. (1998), submitted.

E. Guth and O. Gold, Phys. Rev. 53 (1938) 322.

S. Ahmed and F. R. Jones, J. Mater. Sci. 25 (1990) 4933.

J. Furukawa and E. Yamada, J. Appl. Polym. Sci. 52 (1994) 1587.

D. S. Ogunniyi, Elastomerics 9 (1986) 24.

J. N. Goodier, J. Appl. Mech. Trans. AME A3 (1988) 55.

A. Oberth, Rubber Chem. Technol. 40 (1967) 1337.

F. R. Eirich, Engineering Fracture Mechanics 5 (1973) 555.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Cai, J.J., Salovey, R. Model filled rubber IV: Dependence of stress-strain relationship on filler particle morphology. Journal of Materials Science 34, 4719–4726 (1999). https://doi.org/10.1023/A:1004666517500

Issue Date:

DOI: https://doi.org/10.1023/A:1004666517500