Abstract

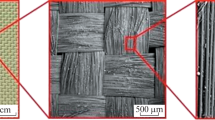

This is a part of a series of studies on the influence of thermal processing on microstructures and mechanical properties of thermoplastic composites. In this paper, the effect of cooling rate during thermal moulding processes on the mechanical properties of bulk unidirectional commingled yarn GF/PA6 composites (Iosipescu shear strength, transverse flexural tensile strength and elastic modulus) has been investigated. Cooling rate from fast to slow, −60°C/min, −3°C/min and −1°C/min, were achieved at 1.5 MPa pressure. Scanning electron microscopy (SEM) was used to analyse the damaging mechanisms of the fracture surfaces of the tested samples. The different dynamic responses of the samples were observed by polarised optical microscopy (POM) during the mechanical tests. The results indicated that when the cooling rate was varied from fast to slow, the interfacial tensile and shear strength were improved associated with enhanced elastic modulus. These results may be attributed to the slow cooling achieved a high transcrystallinity between the glass fibres and PA6 matrix, and high crystallinity of α phase in the PA6 matrix.

Similar content being viewed by others

References

J. Seferis, C. Ahlstrom and S. H. Dillman, “Cooling Rate and Annealing as Processing Parameters for Semicrystalline Thermoplastic Based Composites,” ANTEC, 1987, pp. 1467–1471.

S. Siello, J. Kenny and Nicolais, J. Mater. Sci. 25 (1990) 3493–3496.

P. Curtis, P. Davies, I. K. Patridge and J. P. Sainty, in Proceeding of ICCM6-ECCM2 (Elsevier Applied Science, London, 1987) pp. 4.401–4.412.

T. Kwei, H. Schonhorn and H. L. Frisch, J. Appl. Phys. 38 (1967) 2512.

S. Matsuaka, J. H. Daane, H. E. Bair and T. K. Kwei, J. Polym. Sci. Polym. Lett. Ed. 6 (1968) 87.

M. Kantz and R. D. Corneliussen, ibid. 11 (1973) 279.

D. Campbell and M. M. Qayyum, J. Mater. Sci. 12 (1977) 2427.

B. Haiso and E. J. Chen, in “Controlled Interphases in Composite,” edited by H. Ishida (Elsevier Science, New York, 1990) pp. 613–622.

J. Denault, Composite Interfaces 2(4) (1994) 275–289.

F. Cogswell, in Proceedings of the 28th National SAMPE Symposium, 1983, pp. 528–534.

Y. Lee and R. S. Porter, Polym Eng Sci 26 (1986) p. 633.

M. Huson and W. J. Mcgill, J. Polym. Sci. Polym. Chem. Ed. 22 (1984) 3571.

H. Cartledge and C. A. Baillie, J. Mater. Sci. 34 (1999) 5099.

J. Russell and D. B. Curliss, in 23rd International SAMPE Technical Conference, October 1991, pp. 91–103.

D. B. Curliss in 23rd International SAMPE Technical Conference, October 1991, Journal of Thermoplastic Composite Materials 5 (1992) 238–255.

M. Folkes, G. Kalay and A. Ankara, Composites Science and Technology 46 (1993) 77–83.

G. Shonaike and M. Masaou, in International Symposium of Advance Materials, Japan, 1993, pp. 221–225.

A. Tregub, H. Harel and G. Marom, Composites Science and Technology 48 (1993) 185–190.

N. Iosipescu, Studii si Cercetari de Mecanica Aplicata 13(3) (1962).

N. Iosipescu, Journal of Materials 2(3) (1967) 537–566.

T. Place, Private Communication, Aeronutronic Division, Ford Aerospace and Communications Corporation, Newport Beach, CA, 1974.

F. Matthews and R. D. Rawlings, “Composite Materials: Engineering and Science, Imperial College of Science, Technology and Medicine,” (Chapman and Hall, London, 1994).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Cartledge, H.C.Y., Baillie, C.A. Studies of microstructural and mechanical properties of Nylon/Glass composite Part II The effect of microstructures on mechanical and interfacial properties. Journal of Materials Science 34, 5113–5126 (1999). https://doi.org/10.1023/A:1004765201803

Issue Date:

DOI: https://doi.org/10.1023/A:1004765201803