Abstract

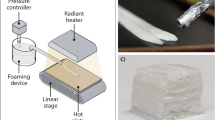

A new self-repairing membrane for inflatable light weight structures such as rubber boats or Tensairity® constructions is presented. Inspired by rapid self-sealing processes in plants, a thin soft cellular polyurethane foam coating is applied on the inside of a fabric substrate, which closes the fissure if the membrane is punctured with a spike. Experimental tests are carried out with a purpose built setup by measuring the air mass flow through a leak in a damaged membrane sample. It is shown that the weight per unit area of the self-repairing foam as well as the curing of the two component PU-foam under an overpressure influence the repair efficiency. Curing the foam under overpressure affects the relative density as well as the microstructure of the foam coatings. Maximal median repair efficiencies of 0.999 have been obtained with 0.16 g·cm−2 foam cured at 1 bar overpressure. These results suggest that the bio-inspired technique has the potential to extend the functional integrity of injured inflatable structures dramatically.

Similar content being viewed by others

References

Brown E N, Sottos N R, White S R. Fracture testing of a self-healing polymer composite. Experimental Mechanics, 2001, 42, 372–379.

Pang I W C, Bond I P. ‘Bleeding composites’ — Damage detection and self-repair using a biomimetic approach. Composites Part A: Applied Science and Manufacturing, 2004, 36, 183–188.

Bhushan B. Biomimetics: Lessons from nature — an overview. Philosophical Transactions of the Royal Society A, 2009, 367, 1445–1486.

Trask R, Bond I. Biomimetic self-healing of advanced composite structures using hollow glass fibres. Smart Materials and Structures, 2006, 15, 704–710.

Trask R, Williams H, Bond I. Self-healing polymer composites: Mimicking nature to enhance performance. Bioinspiration & Biomimetics, 2007, 2, 1–12.

Toohey K S, Sottos N R, Lewis J A, Moore J S, White S R. Self-healing materials with microvsacular networks. Nature Materials, 2007, 6, 581–585.

Trask R S, Bond I P. Bioinspired engineering study of Plantae vascules for self-healing composite structures. Journal of the Royal Society Interface, 2010, 7, 921–931.

Kessler M. Self-healing: A new paradigm in materials design. Proceedings of the IMechE Part G: Journal of Aerospace Engineering, 2007, 221, 479–495.

Motuku M, Vaida U K, Janowski G M. Parametric studies on self-repairing approaches for resin infused composites subjected to low velocity impact. Smart Materials and Structures, 1999, 8, 623–638.

White S R, Sottos N R, Geubelle P H, Moore J S, Kessler M R, Sriram S R, Brown E N, Viswanathan S. Autonomic healing of polymer composites. Nature, 2001, 409, 794–797.

Brown E N, Kessler M R, Sottos N R, White S R. In situ poly(urea-formaldehyde) microencapsulation of decyclopentadiene. Journal of Microencapsulation, 2003, 20, 719–730.

Brown E N, White S R, Sottos N R. Microcapsule induced toughening in a self-healing polymer composite. Journal of Materials Science, 2004, 39, 1703–1710.

Brown E N, White S R, Sottos N R. Retardation and repair of fatigue cracks in a microcapsule toughened epoxy composite — Part I: Manual infiltration. Composites Science and Technology, 2005, 65, 2466–2473.

Brown E N, White S R, Sottos N R. Retardation and repair of fatigue cracks in a microcapsule toughened epoxy composite — Part II: In situ self-healing. Composites Science and Technology, 2005, 65, 2474–2480.

Dry C. Procedures developed for self-repair of polymer matrix composite materials. Composite Structures, 1996, 35, 263–269.

Zako M, Takano N. Intelligent material systems using epoxy particles to repair microcracks and delamination damage in GFRP. Journal of Intelligent Material Systems and Structures, 1999, 10, 836–841.

Kalista S J, Ward T C, Oyetunji Z. Self healing of poly(ethylene-co-methacrylic acid) copolymers following projectile puncture. Mechanics of Advance Materials and Structures, 2007, 14, 391–397.

Yamagiwa T, Nakayama K, Kiyota S, Tanaka A, Makisaka N. Development of puncture resistance of tire tube. Preprint of Society of Automotive Engineers of Japan, 1997, 279–282.

Nagaya K, Ikai S, Chiba M, Chao X. Tire with self-repairing mechanism. JSME International Journal, 2006, 49, 379–384.

Spiegel Online Auto, [2011-01-18], http://www.spiegel.de

Luchsinger R, Pedretti A, Steingruber P, Pedretti M. The new structural concept Tensairity: Basic principles. Progress in Structural Engineering, Mechanics and Computations, London, UK, 2004.

Pedretti M, Luscher R. Tensairity-patent — eine pneumatische tenso-struktur. Stahlbau, 2007, 76, 314–319. (in German)

Luchsinger R, Pedretti M, Reinhard A. Pressure induced stability: From pneumatic structures to Tensairity. Journal of Bionics Engineering, 2004, 1, 141–148.

Speck T, Rowe N P, Civeyrel L, Classen-Bockhoff R, Neinhuis C, Spatz H C. The potential of plant biomechanics in functional biology and systematics. In: Stuessey T, Hörandl F, Mayer V (eds.). Deep Morphology: Toward a Renaissance of Morphology in Plant Systematics, Koeltz, Königstein, Germany, 2004, 241–271.

Speck T, Luchsinger R, Busch S, Rüggeberg M, Speck O. Self-healing processes in nature and engineering: Self-repairing biomimetic membranes for pneumatic structures. In: Brebbia C A (eds.). Design and Nature III, WIT Press, Southampton, UK, 2006, 105–114.

Speck O, Luchsinger R, Busch S, Rüggeberg M, Speck T. Self-repairing membranes for pneumatic structures: Transferring nature’s solutions into technical applications. Proceedings of the 5th International Plant Biomechanics Conference, 2006, 1, 115–120.

Busch S, Seidel R, Speck O, Speck T. Morphological aspects of self-repair of lesions caused by internal growth stresses in stems of Aristolochia macrophylla and Aristolochia ringens. Proceedings of the Royal Society B, 2010, 277, 2113–2120.

Busch S, Schmitt K, Erhardt C, Speck T. Analysis of self-repair mechanisms of Phasaeolus vulgaris var. saxa using near-infrared surface enhanced Raman spectroscopy (SERS). Journal of Raman Spectroscopy, 2010, 41, 490–497.

Masselter T, Speck T. Quantitative and qualitative changes in primary and secondary stem organization of Aristolochia macrophylla during ontogeny: Growth analysis and experiments. Journal of Experimental Botany, 2008, 59, 2955–2967.

Bohl W. Technische Strömungslehre, 12th ed, Vogel, Würzburg, Germany, 2002. (in German)

Gibson L, Ashby M. Cellular Solids, Cambridge University Press, Cambridge, UK, 1997.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rampf, M., Speck, O., Speck, T. et al. Self-repairing membranes for inflatable structures inspired by a rapid wound sealing process of climbing plants. J Bionic Eng 8, 242–250 (2011). https://doi.org/10.1016/S1672-6529(11)60028-0

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1672-6529(11)60028-0