Abstract

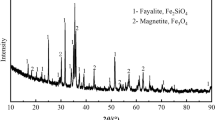

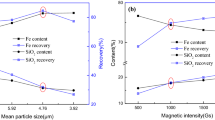

Chromium slag (CS) has become one of the most hazardous solid waste containing chromium and iron. Based on its characteristics, the technology of reduction roasting and magnetic separation was employed to treat CS. The major impurity element of CS is magnesium and it exists in magnesium ferrite phase, which is hard to recover iron in the absence of additives. During reduction roasting, additives (Al2O3 and CaF2) could destroy the structure of magnesium ferrite and improve the iron grade and recovery. The final product, i. e. chromium-iron powder, contains 72.54% Fe and 13.56% Cr, with the iron recovery of 80.34% and chromium recovery of 80.70%.

Similar content being viewed by others

References

Y. M. Shi, X. H. Du, Q. J. Meng, S. W. Song, Z. T. Sui, J. Iron Steel Res. Int. 14 (2007) No. 1, 12–15.

V. Achal, X. Pan, D. J. Lee, D. Kumari, D. Zhang, Chemosphere 93 (2013) 1352–1358.

Y. Wang, Z. Yang, L. Chai, K. Zhao, J. Hazard. Mater. 169 (2009) 1173–1178.

C. Wu, H. Zhang, P. He, L. Shao, J. Environ. Sci. 22 (2010) 1110–1115.

L. Y. Chai, D W. He, X. Yu, H. Liu, X. B. Min, W. L. Chen, Trans. Nonferrous Met. Soc. China 12 (2002) 514–518.

L. L. Jiang, R. W. Li, Y. Q. Mao, M. Zhou, Environ. Sci. Technol. 36 (2013) No. 6L, 480–483.

L. S. Zheng, S. L. Wang, J. X. Li, Modern Chemical Industry 19 (1999) No. 3, 31–33.

M. Y. A. Mollah, Y. N. Tsai, T. R. Hess, D. L. Cocke, J. Hazard. Mater. 30 (1992) 273–283.

A. Kindness, A. Macias, F. P. Glasser, Waste Manage. 14 (1994) 3–11.

L. Y. Chai, Y. Y. Wang, Z. H. Yang, Q. W. Wang, H. Y. Wang, Trans. Nonferrous Met Soc. China 20 (2010) 1500–1504.

L. Y. Chai, S. H. Huang, Z. H. Yang, B. Peng, Y. Huang, Y. H. Chen, J. Hazard. Mater. 167 (2009) 516–522.

T. J. Chun, D. Q. Zhu, J. Pan, Z. He, Can. Met. Quart. 53 (2014) 183–189.

D. Q. Zhu, T. J. Chun, J. Pan, Z. He, J. Iron Steel Res. Int. 19 (2012) No. 8, 1–5.

J. Smit, H. P. J. Wijn, Ferrites, Z. Z.Wang, Trans., National Defence Industry Press, Beijing, 1966.

X. G. Huang, Principle of Ferrous Metallurgy, 3rd ed, Metallurgical Indudstry Press, Beijing, 2008.

X. Ge, Y. Wang, J. Y. Shen, H. L. Zhang, Chinese Journal of Inorganic Chemistry 16 (2000) 79–83.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Foundation Item: Item Sponsored by National Natural Science Foundation of China (50904001, U1260101); Program for Innovative Research Team in Anhui University of Technology (TDZ00909)

Rights and permissions

About this article

Cite this article

Long, Hm., Meng, Qm., Wang, P. et al. Preparation of Chromium-iron Metal Powder from Chromium Slag by Reduction Roasting and Magnetic Separation. J. Iron Steel Res. Int. 22, 771–776 (2015). https://doi.org/10.1016/S1006-706X(15)30070-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(15)30070-4