Abstract

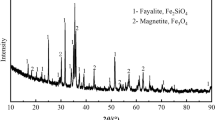

The change of iron composition as well as the removal of copper from iron was investigated in the reduction process, and a new way to deal with copper slag was proposed. The iron in copper slag exists mainly in the form of fayalite, and the copper sulfide content accounts for just about 50%. Therefore, the magnetic separation as well as grinding floatation method is not suitable, and a pyrogenic treatment on copper slag is necessary. The carburization and desulfurization process is restricted to a degree within the carbon composite pellets, and copper matte phase precipitates from copper slag in the reduction process, which is immiscible with molten iron and slag. The copper content decreases to 0.4% as the carbon content in molten iron reaches 3.84%, and the removal ratio of copper from molten iron approaches to 80%. The reduction and sulfurization process can be completed in one step, and the copper is separated from iron based on the ternary system of iron-matte-slag.

Similar content being viewed by others

References

B. Li, H. Wang, J. H. Hu, L. Li, Mining and Metallurgy 18 (2009) No. 1, 44–48.

J. H. Hu, H. Wang, H. L. Liu, L. Li, Journal of Hunan University of Science and Technology, Natural Science Edition 26 (2011) No. 2, 97–100.

L. N. Zhang, L. Zhang, M. Y. Wang, Z. D. Sui, Nonferrous Metals 57 (2005) No. 3, 44–47.

H. Q. Chen, P. X. Li, S. G. Liu, Z. J. Zhang, Hu Nan Nonferrous Metals 22 (2006) No. 3, 16–18.

R. G. Reddy, V. L. Prabhu, D. Mantha, Miner. Metall. Process. 23 (2006) 97–103.

S. Vaisburd, D. G. Brandon, S. Kozhakhmetov, E. Kenzhaliyev, Metall. Mater. Trans. B 33 (2002) 561–564.

A. Sarrafi, B. Rahmati, H. R. Hassani, H. H. A. Shirazi, Miner. Eng. 17 (2004) 457–459.

W. J. Bruckard, M. Somerville, F. Hao, Miner. Eng. 17 (2004) 495–504.

R. Jin, J. S. Wang, Q. R. Long, Jiangxi Nonferrous Metals 23 (2009) No. 1, 12–14.

M. A. Wei, Mining and Metallurgy 13 (2004) No. 1, 38–41.

J. A. Chen, E. M. Gong, X. B. Li, J. Liu, Journal of Jiangxi University of Science and Technology 31 (2010) No. 3, 19–21.

X. J. Hu, P. G. Jiang, Z. Yan, L. Q. Zhu, K. C. Chou, H. Matsuura, F. Tsukihashi, ISIJ Int. 53 (2013) 541–543.

X. J. Hu, Z. Yan, P. G. Jiang, L. Q. Zhu, K. Chou, H. Matsuura, F. Tsukihashi, ISIJ Int. 53 (2013) 920–922.

C. Wang, J. Hirama, T. Nagasaka, S. Ban-ya, ISIJ Int. 31 (1991) 1292–1299.

C. Wang, T. Nagasaka, M. Hino, S. Ban-ya, ISIJ Int. 31 (1991) 1300–1308.

C. Wang, T. Nagasaka, M. Hino, S. Ban-ya, ISIJ Int. 31 (1991) 1309–1315.

T. V. Long, J. Palacios, M. Sanches, T. Miki, Y. Sasaki, M. Hino, ISIJ Int. 52 (2012) 1211–1216.

K. Yamaguchi, H. Ono, ISIJ Int. 52 (2012) 18–25.

J. Zhang, Y. H. Qi, D. L. Yan, X. L. Cheng, P. He, J. Iron Steel Res. Int. 22 (2015) 121–127.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by National Natural Science Foundation of China (51404075)

Rights and permissions

About this article

Cite this article

Zhang, J., Qi, Yh., Yan, Dl. et al. A new technology for copper slag reduction to get molten iron and copper matte. J. Iron Steel Res. Int. 22, 396–401 (2015). https://doi.org/10.1016/S1006-706X(15)30018-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(15)30018-2