Abstract

High production rates and wide areas of application of water-soluble polymers indicate their potential occurrence in wastewater. Poly(N-vinylcaprolactam) (PNVCL) is such a water-soluble and poorly biodegradable polymer with non-ionic, non-sticky, non-toxic and thermosensitive properties. Its field of applications covers being a constituent in aerosol sprays, pump sprays, and lotions as well as its usage as flocculant in wastewater treatment plants. However, although discharged into sewage treatment plants at high amounts, analytical methods for determining water soluble polymers, in particular PNVCL, in environmental samples are still missing. Therefore, this study aims at developing an efficient analytical method for detecting trace levels of poly(N-vinylcaprolactam) in wastewaters by applying continuous-flow off-line Py-GC/MS for the first time. The approach was based on the identification of specific off-line pyrolysis products (ε-caprolactam, N-vinylcaprolactam) that haven been used in the following for a calibration process that allowed a quantitative determination. An evaluation including specificity, linearity, sensitivity and reproducibility characterized this approach as very suitable for detection of this polymer in complex environmental matrices such as wastewaters. Finally, the transferability has been checked by analyzing a real wastewater from a sewage treatment plant effluent. Here limitations especially due to matrix effects are lowering the sensitivity of the pyrolysis-based method. Nevertheless, a contamination with approx. 70 µg/L of poly(N-vinylcaprolactam) was determined pointing to a huge emission of PNVCL into the aquatic environment and a general high environmental relevance of this synthetic polymer. Noteworthy, this is the first report on the occurrence of poly(N-vinylcaprolactam) in environmental samples.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Since the first development of synthetic polymers in the early twentieth century, their production and application areas have increased significantly [1, 2]. Most of them are plastics being insoluble in water. However, significant amounts of water-soluble polymers are also produced and used, either as solids, films, or water-based solutions. Water-soluble synthetic polymers are often biocompatible and non-toxic. They contain hydrophilic functional groups, such as ether, hydroxyl, amide, and pyrrolidone. The most commonly used water-soluble polymers are polyethylene glycol, polyvinyl alcohol, polyacrylamide, poly (N-vinylpyrrolidone), and poly (N-isopropylacrylamide). Traditional applications cover thickening and antifoaming agents, binders, lubricants, electrolyte solvents, dispersants, stabilizers, surfactants, and laxatives in various industries, including food, pharmaceuticals, paints, textiles, paper, adhesives, and coatings production, as well as water treatment [3]. Some water-soluble polymers are less significant in the environment due to their biodegradability, such as polyethylene glycol (PEG). Although PEG is used in a wide range of applications, it has not been detected significantly in the aquatic environment so far as it is easily degraded under aerobic and anaerobic conditions [4, 5]. In contrast to PEG, its oligomers, which represent decomposition products, were detected in river water at elevated concentrations [6]. Noteworthy, other water-soluble polymers, showing a much lower degradation potential than PEG, such as the herein studied poly (N-vinylcaprolactam) (PNVCL), are also discharged to sewage treatment plants. Here, as well high production rates and broad fields of application point to a relevant occurrence in wastewater and corresponding surface water systems. Therefore, there is an urgent need to establish an analytical method for determining such water-soluble polymers in order to follow their envirommental fate from entering the environment via sewage treatment plant effluents towards possible accumulation points in the aquatic environment [7].

Poly (N-vinylcaprolactam) is a non-ionic, water-soluble, non-sticky, non-toxic, thermosensitive, biocompatible, and poorly biodegradable polymer [8, 9]. It has a hydrophilic lactam structure as a side group and a hydrophobic carbon chain as the backbone. Therefore, poly (N-vinylcaprolactam) has good solubility in both polar and non-polar solvents. Poly (N-vinylcaprolactam) dissolves in water, but only in the temperature range from 0 to about 33 °C and in organic solvents such as alcohols or aromatic hydrocarbons [10, 11]. At temperatures above approximately 33 °C, the polymer precipitates from an aqueous solution, while it can be redissolved by cooling. The dissolution and precipitation in water make this polymer applicable in biochemistry and medicine [8]. Poly(N-vinylcaprolactam) is suitable for applications such as aerosol sprays, pump sprays, and lotions. Furthermore, poly(N-vinylcaprolactam) is a biocompatible polymer due to its stability against hydrolysis and is suitable as an environmental friendly flocculant. Noteworthy, the field of application of poly(N-vinylcaprolactam) covers also binding of toxic substances such as phenols in wastewater treatment plants [8]. And its ability to bind water is used to dewatering sewage sludge for more convenient disposal [12, 13]. Other areas of application are related to the metal industry, paper, pulp production, oil industry or as constituent in drug delivery systems [14,15,16].

Pyrolysis–gas chromatography/mass spectrometry (Py-GC/MS) is a common technique used in polymer science to analyze the chemical composition of polymers. In recent works, Py-GC/MS has been also applied to environmental samples and used to analyze microplastic particles in the environment [17,18,19]. However, the identification and quantification of water-soluble polymers has been rarely reported [20]. A pyrolysis-based method that allows the quantification of water-soluble polymers used as drilling fluids in oil exploration and production was presented, but no environmental concentrations have been measured [21]. The only study presenting environmental data on a water-soluble polymer, poly(vinylpyrrolidone) (PVP), in an aqueous medium was performed by Antic et al. [22]. In this report, the advantages of off-line pyrolysis over on-line pyrolysis-GC/MS are clearly stated comprising in particular an enhanced sample size on gram level, possibility to use surrogate or inetrnal standards and improved purification of raw pyrolyzates. These analytical features enhancing sensitivity and accuracy are not applicable in conventional on-line pyrolysis systems.

Poly (N-vinylcaprolactam) has been analysed in various studies, mainly focusing on specific application areas arising from its thermo-sensitive properties [10, 23, 24]. In pyrolysis studies the monomer, N-vinylcaprolactam (NVCL), has been described as one of the main pyrolytic products [25]. Thermogravimetric analysis of poly (N-vinylcaprolactam) showed that above 380 °C the weight decreased sharply and reached zero percent, indicating a depolymerization mechanism, with the maximum weight loss rate temperature of about 430 °C [16]. However, the polymer's general thermal degradation pathway was not investigated in depth and, in particular, the pyrolysis-based detection of poly(N-vinylcaprolactam) in environmental samples has not been performed so far.

Consequently, this study aimed at developing an efficient analytical method for detecting trace levels of poly(N-vinylcaprolactam) in wastewaters by applying continuous-flow off-line Py-GC/MS.

2 Material and methods

2.1 Sample material

Poly(N-vinylcaprolactam) (PNVCL, Mw = 5000, purity 98%) was purchased from BASF AG under the commercial name Luviskol® Plus. Tetramethylammonium hydroxide (TMAH; 0.1 M in methanol; CS Chromatographie Service GmbH, Langerwehe, GER) was used for in situ derivatization during PNVCL pyrolysis.

One wastewater sample was taken from the effluent wastewater treatment plant (WWTP) in Aachen, Germany, in May 2014. Until the water sample was processed in the laboratory, it was stored frozen at − 16 °C in precleaned aluminum bottles.

2.2 Wastewater sample treatment

The wastewater sample was analysed in duplicate. The sample was preextracted five times, three times with 50 mL of hexane and twice with 50 mL of diethyl ether. Thereafter, the preextracted water sample was evaporated to dryness using a rotary evaporator. The jellylike residue was redissolved in 50 mL of methanol by ultrasonic assistance. This methanolic solution was separated from undissolved residues and evaporated to a final volume of 400 µL and was completely subjected to the off-line pyrolysis.

2.3 On-line pyrolysis GC/MS

On-line pyrolysis was performed using a Curie-Point-Pyrolizer 1040 PSC (Fischer GSG, Bruchsal, Germany) directly coupled to a gas chromatograph GC 8000 series (Fisons Instruments, Glasgow, UK) and a Finnigan Trace MS. The capillary GC column was a Zebron ZB-1 (30 m × 0.35 mm ID × 0.25 µm film). Helium was used as a carrier gas (purity: 5.0) with a flow of ca. 1.5 mL/min. The injector temperature was set to 270 °C and a splitless time was 60 s. Different sample amounts (50 µg–1.96 mg) were weighed into a metal tube and pyrolyzed at temperatures between 458 and 764 °C with 10 s pyrolysis time. On-line Py-GC/MS method was used as a rapid method for the identification of specific pyrolysis products of PNVCL.

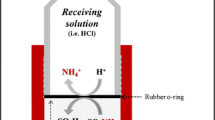

2.4 Continuous flow off-line pyrolysis

Continuous-flow off-line pyrolysis was carried out with a Carbolite tube furnace, model MTF 10/15/130 equipped with a glass tube (length of 150 mm and 15 mm diameter). The following pyrolysis conditions were applied: a heating rate of 100 °C/min up to 550 °C. The final temperature was held for 30 min. Pyrolysis was performed under an inert gas atmosphere with nitrogen flow of 15 mL/min. Dissolved sample material with volumes of 10–100 μL were situated in a porcelain vessel which was filled with a small amount of sea sand and the vessel was transferred into the furnace in the middle of the glass tube. This glass tube was put into the furnace and connected to a nitrogen supply on one end and a recipient trap on the other end. The pyrolysate was collected in a solvent trap filled with 4 mL of acetone cooled with mixture of ethanol and dry ice.

After pyrolysis, the glass tube and the glass adapters were rinsed with acetone and the organic solutions (rinsing solution and pyrolysate) were combined and evaporated to a volume 0.5 mL. This raw pyrolysate was dried over anhydrous sodium sulfate and finally evaporated to a volume of ca. 0.5 mL. Thereafter, 50 mL of a surrogate standard (SS) containing fluoracetophenone (5.8 ng/µL), d20-benzophenone (6.3 ng/µL), d34-hexadecane (6.0 ng/µL) was added. Directly prior to GC/MS analyses the pyrolysates were reduced to a final volume of approx. 20 µL.

The described pyrolysis procedure was applied to solutions of pure polymer and pretreated wastewater samples. A blank procedure was applied comprising all steps of pyrolysate treatment to check for interfering laboratory contamination.

2.5 Gas chromatography–mass spectrometry (GC/MS)

Qualitative and quantitative GC/MS analysis of all pyrolysates was performed on a Finnigan Trace MS single quadrupole mass spectrometer (ThermoElectron, Egelsbach, Germany) connected to a HRGC 5160 gas chromatograph (Carlo Erba, Milano, Italy), equipped with a ZB-5 (Phenomenex, Aschaffenburg, Germany) capillary column (30 mm × 0.25 mm ID × 0.25 µm film). Chromatographic conditions were: 1 µL splitless injection (injector temperature 270 °C) at 80 °C, isothermal time 3 min and heating up to 310 °C with a ramp of 4 °C/min. Helium carrier gas flow was set to 1.5 mL/min. The mass spectrometer operated in electron impact ionization mode (EI+, 70 eV) with a source temperature of 200 °C, an interface temperature of 270 °C and scanned from 35 to 500 m/z in full scan mode with 0.67 scans per second.

2.6 Identification and quantification

Detection of pyrolytic products was based on comparison of mass spectra and retention time with those of reference material and with assistance of mass spectral data bases (NIST 14 and Wiley 7th Ed) as well as by comparison with published data. Quantification was performed by integration of specific ion chromatograms for each individual specific pyrolysis product.

3 Results and discussion

The main focus of this study was to develope and to evaluate an analytical pyrolysis-based approach for identification and quantification of poly(vinylcaprolactam) in sewage water and polluted river water. This approach consisted: (i) of identification of specific pyrolysis products allowing an unambigueous identification of the original synthetic polymer, (ii) of a quantification based on GC/MS analysis of the pyrolysis products at low concetrations reflecting the expected natural pollution levels and, finally, (iii) of testing the applicability by analysing real waste water samples.

3.1 Specific pyrolytic products

The main clue of the approach consists of the identification of specific pyrolysis products that exhibit molecular properties closely linked to the polymer structure. This does not allow only an unambiguous identification but also quantification of the original polymer amount based on the analysis of the pyrolysis products.

The GC/MS analysis of pyrolysates obtained after both on-line and off-line pyrolysis revealed two characteristic pyrolytic products of poly (N-vinylcaprolactam), namely ε-caprolactam (CL) and N-vinylcaprolactam (NVCL) (Fig. 1).

On-line pyrolysis of PNVCL. a Main degradation products of poly(N-vinylcaprolactam). b Total ion chromatogram (TIC) of the main pyrolytic products and their mass spectra: I ε-caprolactam (molecular ion (M+) with m/z = 113 for identification) and II N-vinylcaprolactam (M+ with m/z = 139 for identification)

The unambiguous identification was based on comparison of mass spectra and retention times with those of reference material. The pyrolytic formation of both pyrolysis products can be explained by an elimination mechanism of the cyclic side group [26]. The preservation of the specific caprolactam ring allows a clear attribution of the pyrolysis products to the original polymer. However, to avoid misinterpretation a simultaneous detection of both products is mandatory. Noteworthy, both types of pyrolysis (on-line and off-line) generated the same products with a highly similar relative composition. Further on, procedural blank analyses indicated no noticeable impurities and, consequently, no cross contamination was evident.

As illustrated in Fig. 2, the two products exhibit different gas chromatographic characteristics and differ in particular in peak shape. ε-Caprolactam tend to produce an intensively fronting peak compared to N-vinylcaprolactam. This fronting may be induced by the interaction of the unsubstituted amide nitrogen prevents a satisfactory quantitation due to a resulting low quality in peak integration. Unfortunately, the better integrable peak of N-vinylcaprolactam exhibit a smaller peak area leading to lower sensitivity in quantitation.

An attempt to improve the gas chromatographic properties of ε-caprolactam by derivatization with a methylating substance failed. The addition of tetramethylammonium hydroxide (TMAH) or tetramethylaniline hydroxide as in-situ methylation agent during the pyrolysis, an already reported approach in analytical pyrolysis [21, 27], did not produce a N-methylated derivative. Also a systematic pyrolysis optimization approach by evaluating the duration of pyrolysis, heating rate, different nitrogen flow and different pyrolysis temperatures revelaed no significantly affect on the content of ε-caprolactam but just increased the formation of N-vinylcaprolactam. Hence, all attempts to improve the relative pyrolysis yields as well as to optimize chromatographic properties failed.

3.2 Quality assessment of quantitation

However, these specific pyrolysis products have been used for quantitation of poly (N-vinylcaprolactam). The quantitation is based on an external calibration using a linear correlation between the initial amount of polymer and the detected peak areas of the product obtained after pyrolysis. For evaluating this analytical approach, the linearity, sensitivity and reproducibility have been investigated as described in the following.

3.2.1 Linearity and calibration

Reference material of poly (N-vinylcaprolactam) was pyrolyzed at different concentration levels (5–500 μg) for generation of calibration curves. Triplicates were carried out for each concentration level. Representative GC chromatograms of pyrolysis products for different initial amounts of poly (N-vinylcaprolactam) are shown in Fig. 3, while the calibration curve is presented in Fig. 4. Notably, for correction of inaccuracies in particular of volumes (e.g., injection volume or pyrolsate solvent volume) and to enhance the precision, the external calibration was normalized to a surrogate standard.

For all different initial amounts of poly(N-vinylcaprolactam) a good reproducibility was achieved with relative standard deviations (RSD) varying from 13 to 68% for ε-caprolactam and from 54 to 68% for N-vinylcaprolactam (Table 1) pointing to a moderate but constant deviation. The generally higher RSD values for N-vinylcaprolactam can be explained by the lower peak areas of this second pyrolysis product (see Fig. 3). A more extensive replication was applied for the lowest and highest amounts to evaluate better the reproducibility of the pyolysis approach. Considering the pyrolysis process as a complex process as well as the very low amounts or corresponding concentrations in water samples, these values of reproducibility are acceptable for environmental analyses.

Notably, the peak shape of ε-caprolactam changed systematically from a fronting to a tailing with decreasing amounts.

With respect to the four-point calibration curves, the corresponding linear correlation between the amount of PNVCL and the response levels of ε-caprolactam and N-vinylcaprolactam exhibited very high correlation coefficients (R2 = 0.9983 for ε-caprolactam and R2 = 0.9942 for N-vinylcaprolactam) This high accuracy of the linear correlation pointing to a high potential for performing a reliable quantification based on this calibration approach (Fig. 4).

3.2.2 Limit of detection and limit of quantification

The calculations of the limits of detection (LOD) and quantification (LOQ) were based on the lowest calibration point (5 μg) and the measured signal-to-noise ratios (S/N). The LOQ was determined by extrapolation of these values to a concentration at which the signal-to-noise ratios would reach approx. 10:1. LOQ values vary for both pyrolysis products used for quantitation but are in the range of 0.5 and 5 µg absolute amount of PNVCL subjected to pyrolysis, respectively. Lower LOQ were obtained by using ε-caprolactame as the result of higher peak areas as discussed in Sect. 3.1 (Table 2).

3.2.3 Pyrolysis yield

To determine the relative pyrolysis yield of ε-caprolactam, an external calibration based on the reference compound ε-caprolactam (concentrations varied from 5 to 25 ng) corrected by the surrogate standard was used. The calibration exhibited a very high correlation coefficient (R2 = 0.976) and was used to directly quantify the yield of ε-caprolactam produced by pyrolysis (Fig. 5a). The results are presented in Table 3.

Pyrolysis yield values for ɛ-caprolactam varied between 1.5 and 2.3%. For calculating a correct yield, pyrolysis yield of ε-caprolactamwas multiplied by a correction factor of 1.23 which represents (= 139/113, the molar mass ratio of ε-caprolactam to N-vinylcaprolactam). However, this overall yield is lower as reported for poly(vinylpyrrolidone) by Antic et al. [19]. However, the pyrolysis yield remains constant by decreasing amounts of pyrolyzed poly(N-vinycaprolactam). This is also reflected by a very high correlation between initial amount of pyrolyzed poly(N-vinycaprolactam) and the pyrolysis product ɛ-caprolactam (Fig. 5b). These results revealed a very high stability of pyrolysis yields independent from amounts and is a base for accurate pyrolysis-based quantitation.

3.2.4 Reproducibility of the pyrolysis procedure

Reproducibility as basic parameter for quantification procedures has been determined by multiple measurements including all analytical steps. Five replications (pyrolysis) were performed with a minimum and maximum amount of polymers of 5 μg and 500 μg. The relative standard deviation (RSD) was determined for individual specific pyrolysis products, as summarized in Table 4. The values of RSD varied between 50 and 70% pointing to a moderate but constant deviation. Considering the pyrolysis process as a complex process as well as the very low amounts or corresponding concentrations in water samples, these values of reproducibility are acceptable for environmental analyses.

3.3 Real samples

Finally, the analytical approach has been tested by quantifying poly(N-vinylcaprolactam) in real wastewater samples from Aachen, Germany. The analyses have been performed in duplicate. As illustrated in Fig. 6, the specific pyrolytic products have been clearly identified in the waste water sample. Quantitation based on the described approach revealed a concentration of around 70 µg/L. In more detail, for both samples the ion chromatograms of both pyrolysis products have been used for quantitation revealing in total four different values, 87 and 92 µg/L for N-vinylcaprolactam as well as 53 and 51 µg/L for ɛ-caprolactam. This slight difference based on the different calibration curves for both pyrolysis products. Nevertheless, the relatively good correspondence for both specific products provides clear evidence for the presence of poly(N-vinylcaprolactam) in the waste water.

4 Conclusion

In summary, this work provided a methodological approach for the quantitative determination of poly (N-vinylcaprolactam) in wastewater samples by continuous-flow off-line pyrolysis-GC/MS for the first time. The analytical method was proved for analytical quality by investigating the specificity of the pyrolysis products, the linearity, sensitivity and reproducibility. This evaluation characterized this approach as very suitable for detection of this polymer in complex environmental matrices such as wastewaters. Finally, the transferability has been checked by analyzing a real waste water from a sewage treatment plant effluent.

Noteworthy, this is the first report on the occurrence of poly(N-vinylcaprolactam) in environmental samples. The relatively high concentration of approx. 70 µg/L in the wastewater treatment plant effluent point to a general high environmental relevance of this synthetic polymer for the aquatic environment.

Data availability

All data generated or analysed during this study are included in this published article.

References

Geyer R, Jambeck JR, Law KL. Production, use, and fate of all plastics ever made. Sci Adv. 2017;3(7): e1700782. https://doi.org/10.1126/sciadv.1700782.

Thompson RC, Olsen Y, Mitchell RP, Davis A, Rowland SJ, John AW, McGonigle D, Russell AE. Lost at sea: where is all the plastic? Science. 2004;304(5672):838. https://doi.org/10.1126/science.1094559.

Kadajji VG, Betageri GV. Water soluble polymers for pharmaceutical applications. Polymers. 2011;3:1972–2009. https://doi.org/10.3390/polym3041972.

Bernhard M, Eubeler JP, Zok S, Knepper TP. Aerobic biodegradation of polyethylene glycols of different molecular weights in waste water and seawater. Water Res. 2008;42(19):4791–801. https://doi.org/10.1016/j.watres.2008.08.028.

Kawai F. Biodegradation of polyethers (polyethylene glycol, polypropylene glycol, polytetramethylene glycol, and others). In: Steinbüchel A, editor. Biopolymers online. Hoboken: Wiley; 2005. https://doi.org/10.1002/3527600035.bpol9012.

Jonkers N, de Voogt P, Barcelo D. Analysis and fate of surfactants in the aquatic environment, Wilson & Wilson’s comprehensive analytical chemistry, vol. XI. Amsterdam: Elsevier; 2003. p. 719–47.

Huppertsberg S, Zahn D, Pauelsen F, Reemtsma T, Knepper TP. Making waves: Water-soluble polymers in the aquatic environment: an overlooked class of synthetic polymers? Water Res. 2020;181: 115931. https://doi.org/10.1016/j.watres.2020.115931.

Lau ACW, Wu C. Thermally sensitive and biocompatible poly(N-vinylcaprolactam): synthesis and characterization of high molar mass linear chains. Macromolecules. 1999;32:581–4.

Vihola H, Laukkanen A, Valtola L, Tenhun H, Hirvonen J. Cytotoxicity of thermosensitive polymers poly(N-isopropylacrylamide), poly(N-vinylcaprolactam) and amphiphilically modified poly(N-vinylcaprolactam). Biomaterials. 2005;26(16):3055–64. https://doi.org/10.1016/j.biomaterials.2004.09.008.

Cortez-Lemus NA, Licea-Claverie A. Poly (N-vinylcaprolactam), a comprehensive review on a thermoresponsive polymer becoming popular. Prog Polym Sci. 2016;53:1–51. https://doi.org/10.1016/j.progpolymsci.2015.08.001.

Liu J, Debuigne A, Detrembleur C, Jérôme C. Poly(N-vinylcaprolactam): a thermoresponsive macromolecule with promising future in biomedical field. Adv Healthcare Mater. 2014;3(12):1941–68. https://doi.org/10.1002/adhm.201400371.

Qiu Q, Pethica BA, Somasundaran P. Reversible flocculation of silica across the phase boundary of poly(vinyl caprolactam) in aqueous solution. Langmuir. 2005;21(26):12096–9. https://doi.org/10.1021/la0517235.

Schwarz S, Ponce-Vargas SM, Licea-Claverie A, Steinbach C. Chitosan and mixtures with aqueous biocompatible temperature sensitive polymer as flocculants. Colloids Surf A. 2012;413:7–12. https://doi.org/10.1016/j.colsurfa.2012.03.048.

Peng S, Wu C. Poly(N-vinylcaprolactam) microgels and its related composites. Macromol Symp. 2000;159(1):179–86. https://doi.org/10.1002/1521-3900(200010)159:1%3c179::AID-MASY179%3e3.0.CO;2-8.

Wang Y, Nie J, Chang B, Sun Y, Yang W. Poly(vinylcaprolactam)-based biodegradable multiresponsive microgels for drug delivery. Biomacromolecules. 2013;14(9):3034–46. https://doi.org/10.1021/bm401131w.

Kozanoǧlu S, Özdemir T, Usanmaz A. Polymerization of N-vinylcaprolactam and characterization of poly(N-Vinylcaprolactam). J Macromol Sci Part A. 2011;48(6):467–77. https://doi.org/10.1080/10601325.2011.573350.

Kruge MA. Analytical pyrolysis principles and applications to environmental science. In: Barbooti M, editor. Part 15. Environmental applications of instrumental chemical analysis. Boca Raton: CRC Press; 2015. p. 533–69. https://doi.org/10.1201/b18376-18.

Lara-Gonzalo A, Kruge MA, Lores I, Gutiérrez B, Gallego JLR. Pyrolysis-GC-MS for the rapid environmental forensic screening of contaminated brownfield soil. Org Geochem. 2015;87:9–20. https://doi.org/10.1016/j.orggeochem.2015.06.012.

Kruge MA, Lara-Gonzalo A, Gallego JLR. Environmental forensics of complexly contaminated sites: a complimentary fingerprinting approach. Environ Pollut. 2020;263B: 114645. https://doi.org/10.1016/j.envpol.2020.114645.

Fries E, Dekiffab HJ, Willmeyera J, Nuelleab MT, Ebertc M, Remy D. Identification of polymer types and additives in marine microplastic particles using pyrolysis-GC/MS and scanning electron microscopy. Environ Sci Process Impacts. 2013;15(10):1949–56. https://doi.org/10.1039/c3em00214d.

Al Sandouk-Linke N, Schwarzbauer J, Antic V, Antic M, Caase J, Grünelt S, Reßing K. Off-line-pyrolysis–gas chromatography–mass spectrometry analyses of drilling fluids and drill cuttings—Identification of potential environmental marker substances. Org Geochem. 2015;88:17–28. https://doi.org/10.1016/j.orggeochem.2015.08.001.

Antic V, Antic M, Kronimus A, Oing K, Schwarzbauer J. Quantitative determination of poly(vinylpyrrolidone) by continuous-flow off-line pyrolysis-GC/MS. J Anal Appl Pyrol. 2011;90(2):93–9. https://doi.org/10.1016/j.jaap.2010.10.011.

Polat Ö. Polymerization and polymer characterization of N-vinylcaprolactam. Master Thesis. Polymer Science and Technology Department, Middle East Technical University, Ankara, Turkey. 2005.

Thomassin JM, Mathieu K, Kermagoret A, Fustin CA, Jérôme C, Debuigne A. Double thermo-responsive hydrogels from poly(vinylcaprolactam) containing diblock and triblock copolymers. Polym Chem. 2015;6(10):1856–64. https://doi.org/10.1039/C4PY01606H.

Meussen F, Nies E, Berghmans H, Verbrugghe S, Goethals E, Du Prez F. Phase behaviour of poly(N-vinyl caprolactam) in water. Polymer. 2000;41:8597–602. https://doi.org/10.1016/S0032-3861(00)00255-X.

Pielichowski K, Njuguna J. Thermal degradation of polymeric materials. 1st ed. Shrewsbury: Rapra Technology; 2005.

Kronimus A, Schwarzbauer J. Analysis of structurally modified polyacrylamides by on-line thermochemolysis-GC–MS. J Anal Appl Pyrol. 2007;80:471–6. https://doi.org/10.1016/j.jaap.2007.06.004.

Acknowledgements

This research was financially supported by DFG (Grant No. SCHW750-25).

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Contributions

NV: performing of analysis and experimental work, writing, preparing graphics, data evaluation L-MK: performing of analysis and experimental work. IJ: performing of analysis and experimental work, data evaluation. VA: supervision, data interpretation. JS: project leading, editing, data interpretation. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Vidovic, N., Krauskopf, LM., Jovancicevic, I. et al. Determination of the water-soluble polymer poly(N-vinylcaprolactam) in wastewater effluents by continuous-flow off-line pyrolysis-GC/MS. Discov Water 2, 3 (2022). https://doi.org/10.1007/s43832-022-00010-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43832-022-00010-0