Abstract

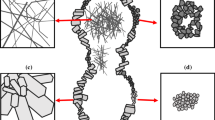

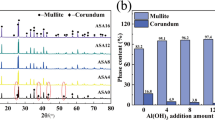

An electrically conductive mullite-bonded porous SiC-based Mn3O4–Ni system was designed, which provided low-temperature sintering and excellent extrudability into complex shapes. Each designed composition contained kaolin (30 wt%) and Mn3O4 (10 wt%) as sintering aids. The combination of Ni (0–20 wt%) and sintering temperature (1100–1300 °C) regulated the electrical resistivity (5.5 × 107–3.4 × 10–1 Ω cm) and flexural strength (33 ± 2–59 ± 3 MPa) of the sintered samples. Interface reactions formed secondary phases [e.g. nickel silicide (Ni2Si) and manganese silicate (MnSiO3)], which decreased the electrical resistivity. The in situ formation of mullite and an increased amount of Ni collectively improved the flexural strength. The sample with 15 wt% Ni sintered at 1200 °C in argon flow had a low electrical resistivity of 5.6 × 10–1 Ω cm and a good flexural strength of 51 ± 4 MPa. The same composition was extruded to form a square honeycomb structure to verify the large-scale viability of the developed composition.

Similar content being viewed by others

References

W.W. Chen, Y. Miyamoto, Fabrication of porous silicon carbide ceramics with high porosity and high strength. J. Eur. Ceram. Soc. 34, 837–840 (2014). https://doi.org/10.1016/j.jeurceramsoc.2013.10.008

J.H. She, Z.Y. Deng, J. Daniel-doni, T. Ohji, Oxidation bonding of porous silicon carbide ceramics. J. Mater. Sci. 37, 3615–3622 (2002). https://doi.org/10.1023/A:1016596805717

J.J. Liu, B. Ren, Y.D. Rong, Y.J. Lu, Y. Zhao, L. Wang, X.Q. Xi, J.L. Yang, Y. Huang, Ultralight and mechanically robust SiC foams with interconnected cellular architecture. Ceram. Int. 46, 17962–17968 (2020). https://doi.org/10.1016/j.ceramint.2020.04.108

Y. Li, L. Chen, L. Hong, K. Ran, Y.H. Zhan, Q. Chen, Fabrication of porous silicon carbide ceramics at low temperature using aluminum dihydrogen phosphate as binder. J. Alloys Compd. 785, 838–845 (2019). https://doi.org/10.1016/j.jallcom.2019.01.114

J.W. Seo, K. Choi, Application of CFD simulation to silicon carbide deposition for nozzles with funnel. J. Korean Ceram. Soc. 58, 184–191 (2021). https://doi.org/10.1007/s43207-020-00082-5

S. Schaafhausen, E. Yazhenskikh, S. Heidenreich, M. Muller, Corrosion of silicon carbide hot gas filter candles in gasification environment. J. Eur. Ceram. Soc. 34, 575–588 (2014). https://doi.org/10.1016/j.jeurceramsoc.2013.10.011

S.Z.A. Bukhari, J.H. Ha, J. Lee, I.H. Song, Fabrication and optimization of a clay-bonded SiC flat tubular membrane support for microfiltration applications. Ceram. Int. 43, 7736–7742 (2017). https://doi.org/10.1016/j.ceramint.2017.03.079

J.H. Eom, Y.W. Kim, I.H. Song, Effects of the initial α-SiC content on the microstructure, mechanical properties, and permeability of macroporous silicon carbide ceramics. J. Eur. Ceram. Soc. 32, 1283–1290 (2012). https://doi.org/10.1016/j.jeurceramsoc.2011.11.040

Y.W. Kim, Y.H. Kim, K.J. Kim, Electrical properties of liquid-phase sintered silicon carbide ceramics: a review. Crit. Rev. Solid State. 45, 66–84 (2020). https://doi.org/10.1080/10408436.2018.1532394

J. Ihle, H.P. Martin, M. Herrmann, P. Obenaus, J. Adler, W. Hermel, A. Michaelis, The influence of porosity on the electrical properties of liquid-phase sintered silicon carbide. Int. J. Mater. Res. 97, 649–656 (2006). https://doi.org/10.3139/146.101285

M.S. Anwar, S.Z.A. Bukhari, J.H. Ha, J. Lee, I.H. Song, Y.W. Kim, Controlling the electrical resistivity of porous silicon carbide ceramics and their applications: a review. Int J Appl Ceram Tec. (2022). https://doi.org/10.1111/ijac.14034

C. Duong-Viet, H. Ba, Z. El-Berrichi, J.M. Nhut, M.J. Ledoux, Y.F. Liu, C. Pham-Huu, Silicon carbide foam as a porous support platform for catalytic applications. New J. Chem. 40, 4285–4299 (2016). https://doi.org/10.1039/c5nj02847g

Y.W. Kim, J.H. Eom, S. Raju, Processing and properties of macroporous silicon carbide ceramics: a review. J. Asian Ceram. Soc. 1, 220–242 (2013). https://doi.org/10.1016/j.jascer.2013.07.003

G.D. Kim, Y.W. Kim, I.H. Song, K.J. Kim, Effects of carbon and silicon on electrical, thermal, and mechanical properties of porous silicon carbide ceramics. Ceram. Int. 46, 15594–15603 (2020). https://doi.org/10.1016/j.ceramint.2020.03.106

S. Kultayeva, J.H. Ha, R. Malik, Y.W. Kim, K.J. Kim, Effects of porosity on electrical and thermal conductivities of porous SiC ceramics. J. Eur. Ceram. Soc. 40, 996–1004 (2020). https://doi.org/10.1016/j.jeurceramsoc.2019.11.045

Y. Taki, M. Kitiwan, H. Katsui, T. Goto, Electrical conductivity of C-SiC and Si-SiC prepared by spark plasma sintering. Mater. Today 4, 11441–11444 (2017). https://doi.org/10.1016/j.matpr.2017.09.024

Y. Taki, M. Kitiwan, H. Katsui, T. Goto, Electrical and thermal properties of off-stoichiometric SiC prepared by spark plasma sintering. J Asian Ceram Soc. 6, 95–101 (2018). https://doi.org/10.1080/21870764.2018.1446490

K. Konig, V. Boffa, B. Buchbjerg, A. Farsi, M.L. Christensen, G. Magnacca, Y.Z. Yue, One-step deposition of ultrafiltration SiC membranes on macroporous SiC supports. J Membr. Sci. 472, 232–240 (2014). https://doi.org/10.1016/j.memsci.2014.08.058

B.L. Yuan, H.X. Wang, G. Yu, J.B. Ma, W.K. Liu, L.F. Liu, Y.S.Z.J. Shen, Preparation and properties of porous silicon carbide based ceramic filter. J. Alloys Compd. 684, 613–615 (2016). https://doi.org/10.1016/j.jallcom.2016.05.216

B. Wang, H. Zhang, H.T. Phuong, F. Jin, J.F. Yang, K. Ishizaki, Gas permeability and adsorbability of the glass-bonded porous silicon carbide ceramics with controlled pore size. Ceram. Int. 41, 2279–2285 (2015). https://doi.org/10.1016/j.ceramint.2014.10.032

A. Une, P. Kunyoo, M. Mochida, K. Yoshitomi, S. Matsui, A new vacuum pin chuck for ArF laser lithography. Microelectron. Eng. 61–2, 113–121 (2002). https://doi.org/10.1016/S0167-9317(02)00457-4

C.C. Agrafiotis, I. Mavroidis, A.G. Konstandopoulos, B. Hoffschmidt, P. Stobbe, M. Romero, V. Fernandez-Quero, Evaluation of porous silicon carbide monolithic honeycombs as volumetric receivers/collectors of concentrated solar radiation. Sol. Energy Mater. Sol. Cells. 91, 474–488 (2007). https://doi.org/10.1016/j.solmat.2006.10.021

Y.W. Kim, Y.K. Seo, T. Nishimura, W.S. Seo, High thermal conductivity of spark plasma sintered silicon carbide ceramics with yttria and scandia. J. Am. Ceram. Soc. 100, 1290–1294 (2017). https://doi.org/10.1111/jace.14748

D.H.A. Besisa, E.M.M. Ewais, E.A.M. Shalaby, A. Usenko, D.V. Kuznetsov, Thermoelectric properties and thermal stress simulation of pressureless sintered SiC/AlN ceramic composites at high temperatures. Sol. Energy Mater. Sol. Cell. 182, 302–313 (2018). https://doi.org/10.1016/j.solmat.2018.03.032

M. Fujisawa, T. Hata, H. Kitagawa, P. Bronsveld, Y. Suzuki, K. Hasezaki, Y. Noda, Y. Imamura, Thermoelectric properties of porous SiC/C composites. Renew. Energy 33, 309–313 (2008). https://doi.org/10.1016/j.renene.2007.07.010

X. Liu, H. Xu, G. Liu, W. Duand, Y. Zhang, X. Fan, R. Riedel, Electromagnetic shielding performance of SiC/graphitic carbon-SiCN porous ceramic nanocomposites derived from catalyst assisted single-source-precursors. J. Eur. Ceram. Soc. 41, 4806–4814 (2021). https://doi.org/10.1016/j.jeurceramsoc.2021.03.026

B.Y. Nan, Y.S. Liu, Q.W. You, J.X. Li, F. Ye, L.F. Cheng, Electromagnetic interference shielding performance of alternatively-deposited multilayer SiC/PyC porous ceramics. Ceram. Int. 45, 21483–21490 (2019). https://doi.org/10.1016/j.ceramint.2019.07.139

S.Z.A. Bukhari, M.S. Anwar, D. Naseer, J.H. Ha, J. Lee, I.H. Song, Effect of graphite and Mn3O4 on clay-bonded SiC ceramics for the production of electrically conductive heatable filter. Ceram. Int. 47, 23045–23052 (2021). https://doi.org/10.1016/j.ceramint.2021.05.019

S. Kultayeva, Y.W. Kim, I.H. Song, Influence of sintering atmosphere and BN additives on microstructure and properties of porous SiC ceramics. J. Eur. Ceram. Soc. (2021). https://doi.org/10.1016/j.jeurceramsoc.2021.07.039

S. Kultayeva, Y.W. Kim, I.H. Song, Effects of dopants on electrical, thermal, and mechanical properties of porous SiC ceramics. J. Eur. Ceram. Soc. 41, 4006–4015 (2021). https://doi.org/10.1016/j.jeurceramsoc.2021.01.049

S. Rajpoot, J.H. Ha, Y.W. Kim, Effects of initial particle size on mechanical, thermal, and electrical properties of porous SiC ceramics. Ceram. Int. 47, 8668–8676 (2020). https://doi.org/10.1016/j.ceramint.2020.11.238

R. Malik, Y.W. Kim, Effects of initial α-phase content on properties of pressureless solid-state sintered SiC ceramics. Int. J. Appl. Ceram. Tec. 19, 703–712 (2021). https://doi.org/10.1111/ijac.13892

K.J. Kim, K.Y. Lim, Y.W. Kim, M.J. Lee, W.S. Seo, Electrical resistivity of alpha-SiC ceramics sintered with Al2O3 or AlN additives. J. Eur. Ceram. Soc. 34, 1695–1701 (2014). https://doi.org/10.1016/j.jeurceramsoc.2014.01.004

K.J. Kim, K.Y. Lim, Y.W. Kim, Electrical and thermal properties of SiC ceramics sintered with yttria and nitrides. J. Am. Ceram. Soc. 97, 2943–2949 (2014). https://doi.org/10.1111/jace.13031

K.Y. Lim, Y.W. Kim, K.J. Kim, Mechanical properties of electrically conductive silicon carbide ceramics. Ceram. Int. 40, 10577–10582 (2014). https://doi.org/10.1016/j.ceramint.2014.03.036

H.Q. Liang, X.M. Yao, H. Deng, H. Zhang, X.J. Liu, Z.R. Huang, High electrical resistivity of spark plasma sintered SiC ceramics with Al2O3 and Er2O3 as sintering additives. J. Eur. Ceram. Soc. 35, 399–403 (2015). https://doi.org/10.1016/j.jeurceramsoc.2014.08.025

D.H. Yoon, I.E. Reimanis, A review on the joining of SiC for high-temperature applications. J. Korean Ceram. Soc. 57, 246–270 (2020). https://doi.org/10.1007/s43207-020-00021-4

S.Q. Ding, S.M. Zhu, Y.P. Zeng, D.L. Jiang, Fabrication of mullite-bonded porous silicon carbide ceramics by in situ reaction bonding. J. Eur. Ceram. Soc. 27, 2095–2102 (2007). https://doi.org/10.1016/j.jeurceramsoc.2006.06.003

S.P. Chaudhuri, S.K. Patra, A.K. Chakraborty, Electrical resistivity of transition metal ion doped mullite. J. Eur. Ceram. Soc. 19, 2941–2950 (1999). https://doi.org/10.1016/S0955-2219(99)00058-8

J. Kim, J.H. Ha, J. Lee, I.H. Song, Optimization for permeability and electrical resistance of porous alumina-based ceramics. J. Korean Ceram. Soc. 53, 548–556 (2016). https://doi.org/10.4191/kcers.2016.53.5.548

J. Kim, J.-H. Ha, J. Lee, I.H. Song, The effect of MnO2 content on the permeability and electrical resistance of porous alumina-based ceramics. J. Korean Ceram. Soc. 54, 331–339 (2017). https://doi.org/10.4191/kcers.2017.54.4.07

S. Rajpoot, J.H. Ha, Y.W. Kim, K.J. Kim, Electrical, thermal, and mechanical properties of porous SiC-nitride composites. J. Eur. Ceram. Soc. 40, 3851–3862 (2020). https://doi.org/10.1016/j.jeurceramsoc.2020.04.018

B.R. Manso, F.M. Figueiredo, B. Achiaga, R. Barea, D.P. Coll, A.M. Gomez, M. Terrones, M.I. Osendi, M. Belmonte, P. Miranzo, Electrically functional 3D-architectured graphene/SiC composites. Carbon 100, 318–328 (2016). https://doi.org/10.1016/j.carbon.2015.12.103

K.F. Cai, J.P. Liu, C.W. Nan, X.M. Min, Effect of porosity on the thermal-electric properties of Al-doped SiC ceramics. J. Mater. Sci. Lett. (1997). https://doi.org/10.1023/A:1018557827330

Y. Takeda, K. Nakamura, K. Maeda, Y. Matsushi, Effects of elemental additives on electrical resistivity of silicon carbide ceramics. J. Am. Cermn. Soc. 70, 266–267 (1987). https://doi.org/10.1111/j.1151-2916.1987.tb04895.x

M.S. Anwar, S.Z.A. Bukhari, J.H. Ha, J. Lee, I.H. Song, Effect of Ni content and its particle size on electrical resistivity and flexural strength of porous SiC ceramic sintered at low-temperature using clay additive. Ceram. Int. 47, 31536–31547 (2021). https://doi.org/10.1016/j.ceramint.2021.08.032

P. Bazhin, A. Chizhikov, A. Stolin, M. Antipov, A. Konstantinov, Long-sized rods of Al2O3–SiC–TiB2 ceramic composite material obtained by SHS-extrusion: microstructure. X-ray analysis and properties. Ceram. Int. 47, 28444–28448 (2021). https://doi.org/10.1016/j.ceramint.2021.06.262

S.L. Byoungkwan Kim, Review on characteristics of metakaolin-based geopolymer and fast setting. J. Korean Ceram. Soc. 57, 368–377 (2020). https://doi.org/10.1007/s43207-020-00043-y

S. Lee, Y.J. Kim, H.S. Moon, Phase transformation sequence from kaolinite to mullite investigated by an energy-filtering transmission electron microscope. J. Am. Ceram. Soc. 82, 2841–2848 (1999). https://doi.org/10.1111/j.1151-2916.1999.tb02165.x

T. Kusunose, T. Sekino, Increasing resistivity of electrically conductive ceramics by insulating grain boundary phase. Acs Appl. Mater. Int. 6, 2759–2763 (2014). https://doi.org/10.1021/am4052766

O. Carvalho, S. Madeira, M. Buciumeanu, D. Soares, F.S. Silva, G. Miranda, Pressure and sintering temperature influence on the interface reaction of SiCp/410L stainless steel composites. J. Compos. Mater. 50, 2005–2015 (2016). https://doi.org/10.1177/0021998315598851

J.L. Hongming Zhou, D. Yi, L. Xiao, Effect of manganese oxide on the sintered properties of 8ysz. Phys. Proc. 22, 14–19 (2011). https://doi.org/10.1016/j.phpro.2011.11.005

J.B.P. Casey, J.G. Lozano, P.D. Nellist, G. Hughes, Chemical and structural investigation of the role of both Mn and Mn oxide in the formation of manganese silicate barrier layers on SiO2. J. Appl. Phys. (2011). https://doi.org/10.1063/1.3630123

I.H. Jung, Y.B. Kang, S.A. Decterov, A.D. Pelton, Thermodynamic evaluation and optimization of the MnO-Al2O3 and MnO-Al2O3-SiO2 systems and applications to inclusion engineering. Metall. Mater. Trans. B. 35, 259–268 (2004). https://doi.org/10.1007/s11663-004-0027-3

R.B. Snow, Equilibrium relationships on the liquidus surface in part of the MnO-Al2O3-SiO2 system. J. Am. Ceram. Soc. 26, 11–20 (1943). https://doi.org/10.1111/j.1151-2916.1943.tb15177.x

C. Byrne, B. Brennan, A.P. McCoy, J. Bogan, A. Brady, G. Hughes, In situ xps chemical analysis of MnSiO3 copper diffusion barrier layer formation and simultaneous fabrication of metal oxide semiconductor electrical test mos structures. Acs Appl Mater Inter. 8, 2470–2477 (2016). https://doi.org/10.1021/acsami.5b08044

D. Dotlimord, Differential thermal analysis and therrnogravimetric analysis studies at salford on metal oxy-salts, coals and polymers. Proc. Soc. Anal. Chem. 2, 167–172 (1965). https://doi.org/10.1039/SA9650200167

C. Soto, C.G. Rosales, J. Echeberria, E. Platacis, A. Shisko, F. Muktepavela, T. Hernandez, M.M. Huertac, Development, characterization, and testing of a SiC-based material for flow channel inserts in high-temperature DCLL blankets. Ieee T Plasma Sci. 46, 1561–1569 (2018). https://doi.org/10.1109/Tps.2018.2809571

N. Ordas, A. Bereciartu, C.G. Rosales, A. Morono, M. Malo, E.R. Hodgson, J. Abella, S. Colominas, L. Sedano, Testing of porous SiC with dense coating under relevant conditions for Flow Channel Insert application. Fusion Eng. Des. 89, 1274–1279 (2014). https://doi.org/10.1016/j.fusengdes.2014.03.056

H.P. Martin, J. Adler, Electrical properties, in Cellular ceramics: structure, manufacturing, properties and applications. ed. by D.M. Scheffler, P.I.P. Colombo (Wiley, 2005), pp.289–399. https://doi.org/10.1002/3527606696.ch4d

J.M. Montes, F.G. Cuevas, J. Cintas, F. Ternero, E.S. Caballero, Electrical resistivity of powdered porous compacts, in Electrical and Electronic Properties of Materials. ed. by M.K. Alam (IntechOpen, 2019). https://doi.org/10.5772/intechopen.76159

J.H. Eom, Y.W. Kim, I.H. Song, H.D. Kim, Microstructure and properties of porous silicon carbide ceramics fabricated by carbothermal reduction and subsequent sintering process. Mat. Sci. Eng. A-Struct. 464, 129–134 (2007). https://doi.org/10.1016/j.msea.2007.03.076

Y.F. Chen, M.C. Wang, M.H. Hon, Phase transformation and growth of mullite in kaolin ceramics. J. Eur. Ceram. Soc. 24, 2389–2397 (2004). https://doi.org/10.1016/S0955-2219(03)00631-9

R. Sarkar, M. Mallick, Formation and densification of mullite through solid-oxide reaction technique using commercial-grade raw materials. Bull. Mater. Sci. (2018). https://doi.org/10.1007/s12034-017-1533-7

F.R. Barrientos-Hernandez, M. Perez-Labra, A. Lobo-Guerrero, M. Reyes-Perez, J.C. Juarez-Tapia, J. Hernandez-Avila, E. Cardoso-Legorreta, J.P. Hernandez-Lara, Effect of particle size and sintering temperature on the formation of mullite from kyanite and aluminum mixtures. Adv. Mater. Sci. Eng. (2021). https://doi.org/10.1155/2021/6678297

D. Das, N. Kayal, Influence of clay content on microstructure and flexural strength of in situ reaction bonded porous SiC ceramics. Mater. Today Proc. 33, 5150–5155 (2020). https://doi.org/10.1016/j.matpr.2020.02.862

J.F. Li, H. Lin, J.B. Li, Factors that influence the flexural strength of SiC-based porous ceramics used for hot gas filter support. J. Eur. Ceram. Soc. 31, 825–831 (2011). https://doi.org/10.1016/j.jeurceramsoc.2010.11.033

Z.Y. Luo, W. Han, K.Q. Liu, W.Q. Ao, K.K. Si, Influence of bonding phases on properties of in-situ bonded porous SiC membrane supports. Ceram. Int. 46, 8536–8542 (2020). https://doi.org/10.1016/j.ceramint.2019.12.082

W. Wang, W.J. Chen, H.T. Liu, Recycling of waste red mud for fabrication of SiC/mullite composite porous ceramics. Ceram. Int. 45, 9852–9857 (2019). https://doi.org/10.1016/j.ceramint.2019.02.024

S.Z.A. Bukhari, J.H. Ha, J. Lee, I.H. Song, Expansionless oxidation-bonded SiC microfiltration membrane by controlling the oxidation of SiC particle mixtures. J Asian Ceram Soc. (2021). https://doi.org/10.1080/21870764.2021.1937855

A. Septiadi, D.H. Yoon, Fabrication of mullite-bonded porous SiC usingTi3AlC2 max phase. J Korean Ceram Soc. 56, 191–196 (2019). https://doi.org/10.4191/kcers.2019.56.2.11

F. Wang, J. Yin, K. Zuo, Y. Xia, D. Yao, Y. Zeng, Effect of organic additives on mechanical properties of SiC ceramics prepared by a modified gelcasting method. Process. Appl. Ceram. 10, 227–233 (2016). https://doi.org/10.2298/PAC1604227W

M.H. Zare, N. Hajilary, M. Rezakazemi, Microstructural modifications of polyethylene glycol powder binder inthe processing of sintered alpha alumina under different conditions ofpreparation. Mater. Sci. Energy Technol. 2, 89–95 (2019). https://doi.org/10.1016/j.mset.2018.11.003

R.H.C.-E.A. Balam, A. Castillo-Atoche, F. Avile’s, Investigation of directional effects on the electrical conductivity and piezoresistivity of carbon nanotube/polypropylene composites obtained by extrusion. J Mater Sci. 56, 14570–14586 (2021). https://doi.org/10.1007/s10853-021-06223-3

Z. Zhang, Z. Shi, B. Yang, B. Ge, X. Zhang, Y. Guo, Preparation and anisotropic thermophysical properties of SiC honeycomb/Al-Mg-Si composite via spontaneous infiltration. Prog. Nat. Sci-Mater. 29, 177–183 (2019). https://doi.org/10.1016/j.pnsc.2019.02.004

A. Kovalcikova, J. Sedlacek, Z. Lences, R. Bystricky, J. Dusza, P. Sajgalik, Oxidation resistance of SiC ceramics prepared by different proceessing routes. J. Eur. Ceram. Soc. 36, 3783–3793 (2016). https://doi.org/10.1016/j.jeurceramsoc.2016.03.016

R. Malik, Y.H. Kim, Y.W. Kim, Effect of additive content on the mechanical and thermal properties of pressureless liquid-phase sintered SiC. J. Asian Ceram. Soc. 8, 448–459 (2020). https://doi.org/10.1080/21870764.2020.1749376

Acknowledgements

This work was supported by (1) National R&D Program through the National Research Foundation of Korea (NRF) funded by Ministry of Science and ICT [Grant number 2020M3H4A3106359] and (2) the Research Program of the Korea Institute of Materials Science (Republic of Korea) [Grant number PNK 8120].

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Anwar, M.S., Bukhari, S.Z.A., Ha, JH. et al. Mullite-bonded porous SiC-based Mn3O4–Ni system: control of electrical resistivity, flexural strength, and extrusion. J. Korean Ceram. Soc. 59, 835–845 (2022). https://doi.org/10.1007/s43207-022-00238-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s43207-022-00238-5