Abstract

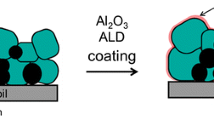

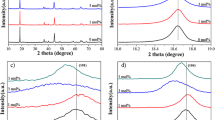

Atomic layer deposition (ALD) technology has been adopted to obtain the ultrathin coating layer on the surface of LiNixCoyMnzO2 (NCM) cathode materials. However, the as-reported coating materials usually form dense film layers and present low electronic conductivity, leading to poor electrochemical kinetics. Herein, the ultrafine Pd nanoparticles (~ 5 nm) with superior electronic conductivity are successfully deposited on the surface of LiNi0.8Co0.1Mn0.1O2 (NCM811) particles by ALD technology. Benefiting from its high electrical conductivity, intrinsic electrochemical inertia to Li+ and HF, unique point coating, and the interfacial Pd–O bond, the coating of ultrafine Pd nanoparticles significantly weakens the electrochemical polarization and enhances the rate capability of NCM811 cathode. The capacity retention ratio at 1 C after 100 cycles reaches 84.6%, and the capacity of 153.5 mA·h·g−1 is realized at 5 C. Further research finds that the battery with the coating layer of 5 deposition cycles has a better electrochemical performance than the batteries with 2 and 8 deposition cycles. This work enriches the application of ALD technology in the surface modification of electrode materials and broadens the mind of electrochemical performance enhancement.

Similar content being viewed by others

References

Ding Y, Cano ZP, Yu A, Lu J, Chen Z. Automotive Li-ion batteries: current status and future perspectives. Electrochem Energy Rev. 2019;2(1):1.

Biasi LD, Schwarz B, Brezesinski T, Hartmann P, Janek J, Ehrenberg H. Chemical, structural, electronic aspects of formation and degradation behavior on different length scales of Ni-rich NCM and Li-rich HE-NCM cathode materials in Li-ion batteries. Adv Mater. 2019;31(26):1900985.

Liu W, Oh P, Liu X, Lee MJ, Cho W, Chae S, Kim Y, Cho J. Nickel-rich layered lithium transition-metal oxide for high-energy lithium-ion batteries. Angew Chem Int Ed Engl. 2015;54(15):4440.

Myung ST, Maglia F, Park KJ, Yoon CS, Lamp P, Kim SJ, Sun YK. Nickel-rich layered cathode materials for automotive lithium-Ion batteries: achievements and perspectives. ACS Energy Lett. 2016;2(1):196.

Sari HMK, Li X. Controllable cathode-electrolyte interface of Li[Ni0.8Co0.1Mn0.1]O2 for lithium ion batteries: a review. Adv Energy Mater. 2019;39(9):1901597.

Bai X, Ban L, Zhuang W. Research progress on coating and doping modification of nickel rich ternary cathode materials. J Inorg Mater. 2020;35(9):972.

Lv Y, Cheng X, Qiang W, Huang B. Improved electrochemical performances of Ni-rich LiNi0.83Co0.12Mn0.05O2 by Mg-doping. J Power Sourc. 2020;450:227718.

Si Z, Shi B, Huang J, Yu Y, Han Y, Zhang J, Li W. Titanium and fluorine synergetic modification improves the electrochemical performance of Li(Ni0.8Co0.1Mn0.1)O2. J Mater Chem A. 2021;9(14):9354.

Zhang X, Qiu Y, Cheng F, Wei P, Li Y, Liu Y, Sun S, Xu Y, Li Q, Fang C, Han J, Huang Y. Realization of a high-voltage and high-rate nickel-rich NCM cathode material for LIBs by Co and Ti dual modification. ACS Appl Mater Interfaces. 2021;13(15):17707.

Binder JO, Culver SP, Pinedo R, Weber DA, Friedrich MS, Gries KI, Volz K, Zeier WG, Janek J. Investigation of fluorine and nitrogen as anionic dopants in nickel-rich cathode materials for lithium-ion batteries. ACS Appl Mater Interfaces. 2018;10(51):44452.

Li J, Wu J, Li S, Liu G, Cui Y, Dong Z, Liu H, Sun X. Stabilizing LiNi0.8Co0.15Mn0.05O2 cathode by doping sulfate for lithium-ion batteries. Chemsuschem. 2021;14(13):2721.

Becker D, Börner M, Nölle R, Diehl M, Klein S, Rodehorst U, Schmuch R, Winter M, Placke T. Surface modification of Ni-rich LiNi0.8Co0.1Mn0.1O2 cathode material by tungsten oxide coating for improved electrochemical performance in lithium-ion batteries. ACS Appl Mater Interfaces. 2019;11(20):18404.

Guo S, Yuan B, Zhao H, Hua D, Shen Y, Sun C, Chen T, Sun W, Wu J, Zheng B, Zhang W, Li S, Huo F. Dual-component LixTiO2@silica functional coating in one layer for performance enhanced LiNi0.6Co0.2Mn0.2O2 cathode. Nano Energy. 2019;58:673.

Zheng J, Xu P, Gu M, Xiao J, Browning ND, Yan P, Wang C, Zhang J-G. Structural and chemical evolution of Li- and Mn-Rich layered cathode material. Chem Mater. 2015;27(4):1381.

Jin Y, Xu Y, Sun X, Xiong L, Mao S. Electrochemically active MnO2 coated Li1.2Ni0.18Co0.04Mn0.58O2 cathode with highly improved initial coulombic efficiency. Appl Surf Sci. 2016;384:125.

Song J, Wang Y, Feng Z, Zhang X, Wang K, Gu H, Xie J. Investigation on the electrochemical properties and stabilized surface/interface of nano-AlPO4-coated Li1.15Ni0.17Co0.11Mn0.57O2 as the cathode for lithium-ion batteries. ACS Appl Mater Interfaces. 2018;10(32):27326.

Ku L, Cai Y, Ma Y, Zheng H, Liu P, Qiao Z, Xie Q, Wang L, Peng DL. Enhanced electrochemical performances of layered-spinel heterostructured lithium-rich Li1.2Ni0.13Co0.13Mn0.54O2 cathode materials. Chem Eng J. 2019;370:499.

Shobana MK. Metal oxide coated cathode materials for Li ion batteries-a review. J Alloy Compd. 2019;802:477.

Hu S, Pillai AS, Liang G, Pang WK, Wang H, Li Q, Guo Z. Li-rich layered oxides and their practical challenges: recent progress and perspectives. Electrochem Energy Rev. 2019;2(2):277.

Berdova M, Wiemer C, Lamperti A, Tallarida G, Cianci E, Lamagna L, Losa S, Rossini S, Somaschini R, Gioveni S, Fanciulli M, Franssila S. Protective coatings of hafnium dioxide by atomic layer deposition for microelectromechanical systems applications. Appl Surf Sci. 2016;368:470.

Zhao Y, Zheng K, Sun X. Addressing interfacial issues in liquid-based and solid-state batteries by atomic and molecular layer deposition. Joule. 2018;2(12):2583.

Zhang X, Belharouak I, Li L, Lei Y, Elam JW, Nie A, Chen X, Yassar RS, Axelbaum RL. Structural and electrochemical study of Al2O3 and TiO2 coated Li1.2Ni0.13Mn0.54Co0.13O2 cathode material using ALD. Adv Energy Mater. 2013;3(10):1299.

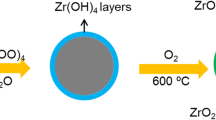

Zhao J, Wang Y. Atomic layer deposition of epitaxial ZrO2 coating on LiMn2O4 nanoparticles for high-rate lithium ion batteries at elevated temperature. Nano Energy. 2013;2(5):882.

Deng S, Xiao B, Wang B, Li X, Kaliyappan K, Zhao Y, Lushington A, Li R, Sham TK, Wang H, Sun X. New insight into atomic-scale engineering of electrode surface for long-life and safe high voltage lithium ion cathodes. Nano Energy. 2017;38:19.

Zhou Y, Lee Y, Sun H, Wallas JM, George SM, Xie M. Coating solution for high-voltage cathode: AlF3 atomic layer deposition for freestanding LiCoO2 electrodes with high energy density and excellent flexibility. ACS Appl Mater Interfaces. 2017;9(11):9614.

Nanthagopal M, Santhoshkumar P, Shaji N, Praveen S, Kang HS, Senthil C, Lee CW. Nitrogen-doped carbon-coated Li[Ni0.8Co0.1Mn0.1]O2 cathode material for enhanced lithium-ion storage. Appl Surf Sci. 2019;492:871.

Kong JZ, Ren C, Tai GA, Zhang X, Li AD, Wu D, Li H, Zhou F. Ultrathin ZnO coating for improved electrochemical performance of LiNi0.5Co0.2Mn0.3O2 cathode material. J Power Sources. 2014;266:433.

Wu K, Li W, Qin J, Hao Y, Sari HMK, Feng H, Li X. Controllable atomic layer deposition coatings to boost the performance of LiMnxCoyNi1−x−yO2 in lithium-ion batteries: a review. J Mater Res. 2020;35(7):762.

Xu Q, Li X, Sari HMK, Li W, Liu W, Hao Y, Qin J, Cao B, Xiao W, Xu Y, Wei Y, Kou L, Tian Z, Shao L, Zhang C, Sun X. Surface engineering of towards boosting lithium storage: bimetallic oxides versus monometallic oxides. Nano Energy. 2020;77:105034.

Wang J, Zhang Z, Han J, Wang X, Chen L, Li H, Wu F. Interfacial and cycle stability of sulfide all-solid-state batteries with Ni-rich layered oxide cathodes. Nano Energy. 2022;100: 107528.

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant No. 5210130199 and 52072298), China Postdoctoral Science Foundation (Grant No. 2021M692596), Innovation Ability Strengthening Foundation Plan of Xi’an (Grant No. 21XJZZ0043), Young Talent Fund of University Association for Science and Technology in Shaanxi of China (Grant No. 20200418), Open Foundation of Key Laboratory of Green Preparation and Functionalization for Inorganic Materials (Grant No. 202002), the Local Special Service Program Funded by Education Department of Shaanxi Provincial Government (Grant No. 19JC031), and Natural Science Foundation of Shaanxi (Grant No. 2020JC-41 and 2021TD-15).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, WB., Wu, K., Feng, H. et al. Atomic layer deposition of ultrafine Pd nanoparticles for enhancing the rate capability of LiNi0.8Co0.1Mn0.1O2 cathode. Tungsten 4, 346–355 (2022). https://doi.org/10.1007/s42864-022-00178-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42864-022-00178-x