Abstract

Purpose

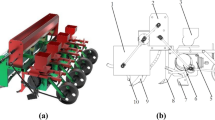

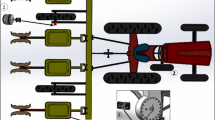

The seed-metering device is an essential component of the precision seeding process since it ensures accurate metering and placement of the seeds. In this study, the performance of a new slotted roller seed-metering device, used in Balanian and Karparvarfard’s (Balanian and Karparvarfard, Iranian Journal of Biosystems Engineering 51:305–317, 2020) study, was simulated in EDEM software to predict the performance and mass flow rate of the optimized condition and compare the results with the experimental data.

Methods

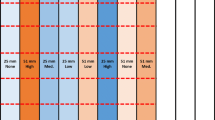

To achieve this, EDEM simulation results were compared with those obtained from the laboratory tests and the limitations of the simulation were found and discussed. The number of slots (N), angle of the mouth, and rotational velocity (n) were used in Design Expert to develop an optimized model with a high desirability rating.

Results

The study suggests that the metering device position in simulations may have been over-predicted due to the use of divided time steps, potentially leading to higher miss index values. Additionally, the experiments showed that the variation in grain dimensions resulted in increased multiple index values. The predicted optimized model was similar to the model obtained from the experiments which confirm EDEM was successful in predicting the device’s performance and demonstrates the utility of simulation tools in predicting and optimizing the device’s design.

Conclusion

This approach can significantly reduce costs and save time in the development of an optimized slotted roller seed-metering device for maize planting.

Similar content being viewed by others

Data Availability

Data associated with this research is available upon request from the corresponding authors.

References

Balanian, H., & Karparvarfard, S. H. (2020). Design, development and laboratory evaluation of grooved roller metering device for corn planting. Iranian Journal of Biosystems Engineering, 51(2), 305–317. https://doi.org/10.22059/ijbse.2020.292725.665243

Balanian, H., Karparvarfard, S. H., Khaneghah, A. M., Raoufat, M. H., & Azimi-Nejadian, H. (2021). Prediction of seed flow rate of a multi-slot rotor feeding device of a corn planter. Journal of Agricultural Machinery, 11(1), 17–27. https://doi.org/10.22067/jam.v11i1.79992

Coşkun, M. B., Yalçin, I., & Özarslan, C. (2006). Physical properties of sweet corn seed (Zea mays saccharata Sturt.). Journal of Food Engineering, 74(4), 523–528. https://doi.org/10.1016/j.jfoodeng.2005.03.039

Cundall, P. A., & Strack, O. D. L. (1979). A discrete numerical model for granular assemblies. Geotechnique, 29, 47–65. https://doi.org/10.1680/geot.1979.29.1.47

Dolati, M., & Karparvarfard, S. H. (2006). Design, development & evaluation of a penumatic punch planter for corn planting. Iranian Journal of Agriculture Science, 37(2), 193–204. (In Farsi).

Favier, J., Abbaspour-Fard, M., Kremmer, M., & Raji, A. O. (1999). Shape representation of axi-symmetrical, non-spherical particles in discrete element simulation using multi-element model particles. Engineering Computations, 16, 467–480. https://doi.org/10.1108/02644409910271894

González-Montellano, C., Fuentes, J. M., Ayuga-Téllez, E., & Ayuga, F. (2012). Determination of the mechanical properties of maize grains and olives required for use in DEM simulations. Journal of Food Engineering, 111(4), 553–562. https://doi.org/10.1016/j.jfoodeng.2012.03.017

Horabik, J., & Molenda, M. (2016). Parameters and contact models for DEM simulations of agricultural granular materials: A review. Biosystems Engineering, 147, 206–225. https://doi.org/10.1016/J.BIOSYSTEMSENG.2016.02.017

Iacomi, C., & Popescu, O. (2015). A new concept for seed precision planting. Agriculture and Agricultural Science Procedia, 6, 38–43. https://doi.org/10.1016/j.aaspro.2015.08.035

Im, D., Lee, H.-S., Kim, J.-H., Moon, D.-J., Moon, T.-I., Yu, S.-H., & Park, Y.-J. (2023). Bucket size optimization for metering device in garlic planter using discrete element method. Agriculture, 13, 1199. https://doi.org/10.3390/agriculture13061199

International Organization for Standardization. (1984). Sowing equipment — Test methods — Part 1: Single seed drills (precision drills) (ISO 7256–1:1984 (en). https://www.iso.org/standard/13910.html

Jun, G., Yue, Y., Memon, M. S., Chuang, T., Linyu, W., & Pei, T. (2022). Design and simulation for seeding performance of high-speed inclined corn metering device based on discrete element method (DEM). Scientific Reports, 12(1). https://doi.org/10.1038/s41598-022-23993-1

Kumar, N., Upadhyay, G., Choudhary, S., Patel, B., Naresh, Chhokar, R. S., & Gill, S. C. (2023). Resource conserving mechanization technologies for dryland agriculture. In Enhancing resilience of dryland agriculture under changing climate: Interdisciplinary and convergence approaches (pp. 657–688). Springer Nature Singapore.

Li, Z., Yu, J., & Fu, H. (2012). Prediction of fluted roll metering device performance using two-dimensional discrete element method. 1329–1332. https://doi.org/10.1109/MACE.2012.347.

Li, Y., Xiantao, H., Tao, C., Dongxing, Z., Song, S., Zhang, R., & Mantao, W. (2015). Development of mechatronic driving system for seed meters equipped on conventional precision corn planter. International Journal of Agricultural and Biological Engineering, 8(4), 1–9.

Markauskas, D., Ramírez-Gómez, Á., Kačianauskas, R., & Zdancevičius, E. (2015). Maize grain shape approaches for DEM modelling. Computers and Electronics in Agriculture, 118, 247–258. https://doi.org/10.1016/j.compag.2015.09.004

Molin, J. P., Bashford, L. L., Von Bargen, K., Leviticus, L. I., & Bashford, L. L. (1998). Design and evaluation of a punch planter for no-till systems.

Mousaviraad, M., Tekeste, M.Z., & Rosentrater, K.A. (2016). Discrete Element Method (DEM) simulation of corn grain flow in commercial screw auger. https://doi.org/10.13031/aim.20162462358

Tang, H., Xu, C., Wang, Z., Wang, Q., & Wang, J. (2022). Optimized design, monitoring system development and experiment for a long-belt finger-clip precision corn seed metering device. Frontiers in Plant Science, 13. https://doi.org/10.3389/fpls.2022.814747

Upadhyay, G., Raheman, H., & Rasool, S. (2017). Three dimensional modelling and stress analysis of a powered single acting disc harrow using FEA. Current Agriculture Research Journal, 5(2). https://doi.org/10.12944/CARJ.5.2.08

Upadhyay, G., Raheman, H., & Dubey, R. (2022). Novel draught resistance sensing elements for measurement of drawbar power of agricultural machinery. Spanish Journal of Agricultural Research, 20(4). https://doi.org/10.5424/sjar/2022204-19171

Yazgi, A., & Degirmencioglu, A. (2014). Measurement of seed spacing uniformity performance of a precision metering unit as function of the number of holes on vacuum plate. Measurement, 56, 128–135. https://doi.org/10.1016/j.measurement.2014.06.026

Zhou, L., Yu, J., Wang, Y., Yan, D., & Yu, Y. (2020). A study on the modelling method of maize-seed particles based on the discrete element method. Powder Technology, 374, 353–376. https://doi.org/10.1016/j.powtec.2020.07.051

Zhou, L., Yu, J., Liang, L., Wang, Y., Yu, Y., Yan, D., Sun, K., & Liang, P. (2021). DEM parameter calibration of maize seeds and the effect of rolling friction. Processes, 9(6). https://doi.org/10.3390/pr9060914

Acknowledgements

The study authors express their gratitude to Shiraz University in Shiraz, Iran for providing technical support for the research.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Baghooee, M., Karparvarfard, S.H., Azimi-Nejadian, H. et al. DEM Simulation for Seeding Performance of a Slotted Roller Seed-Metering Device for Planting Maize in Laboratory Condition. J. Biosyst. Eng. 48, 428–436 (2023). https://doi.org/10.1007/s42853-023-00202-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42853-023-00202-z