Abstract

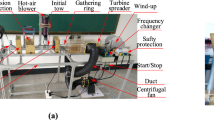

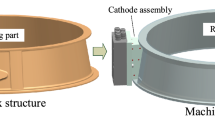

Carbon fibers are commonly used in many specialized, high-performance applications such as race cars and aircraft due to their lightweight and high durability. The most important stage in the production of carbon fibers is the carbonization process. During this process, carbon fibers are subjected to high temperatures in the absence of oxygen to prevent fibers from burning. Labyrinth seals are attached to a carbonization furnace to prevent airflow into the furnace and to assist in the elimination of off-gases. This study investigated flow characteristics inside a carbonization furnace and the effects of different geometric parameters of labyrinth seals such as labyrinth tooth shape, number of teeth, and tooth clearance. Varying carbonization furnace operating conditions were also studied in regard to flow behavior, including fiber movement and outlet vacuum pressure. A high working gas flow rate at the furnace inlet resulted in recirculation zones. Properly regulated gas flow from the main and labyrinth inlets enabled uniform flow around the fibers’ inlet and outlet which prevented air from being trapped in the reactor. Flow behavior was minimally effected by changes to labyrinth seal geometry such as tooth length, tooth clearance, and outlet pressure. However, the movement of fibers had a clear effect on flow characteristics in the furnace.

Similar content being viewed by others

References

Bhatt P, Goel A (2017) Carbon fibres: production, properties and potential use. Mater Sci Res India 14(1):52–57

Huang X (2009) Fabrication and properties of carbon fibers. Materials 2:2369–2403

Zhang MY, Niu HQ, Qi SL, Tian GF, Wang XD, Wu DZ (2014) Structure evolutions involved in the carbonization of polyimide fibers with different chemical constitution. Mater Today Commun 1:1–8

Liu Y, Kumar S (2012) Recent progress in fabrication, structure, and properties of carbon fibers. Polym Rev 52:234–258

Witten E, Kraus T, Kuhnel M (2014) Composites market report 2016, market developments, trends, challenges and opportunities. AVK Carbon Compos, 25–36

Haider S, Lie JA, Lindbråthen A, Hägg MB (2018) Pilot-scale production of carbon hollow fiber membranes from regenerated cellulose precursor—part II: carbonization procedure. Membranes 8(97):1–13. https://doi.org/10.3390/membranes8040097

Pham H, Lim Y, Cho C-H, Bang Y-H (2017) Hydrodynamics of low temperature carbonization furnace for production of polyacrylonitrile (PAN)-based carbon fiber. Chem Eng Res Des 128:192–204

Rajalingam P, Radhakrishxan G (1991) Polyacrylonitrile precursor for carbon fibers. J Macromol Sci 31(2):301–310

Rahaman MSA, Ismail AF, Mustafa A (2007) A review of heat treatment on polyacrylonitrile fiber. Polym Degrad Stability 92(8):1421–1432

Lee T-S, Witting P (2016), Computaional fluid dynamics (CFD) analysis for off-gas mixing and ventilation inside carbonization furnace during PAN-based carbon fiber manufacturing. Harper International White paper, 1–11

Funding

This paper was supported by research funds of Jeonbuk National University in 2020.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there are no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Abdelmotalib, H.M., Ko, D.G., Lee, G.W. et al. Computational study of flow characteristics in a carbon fiber carbonization reactor. Carbon Lett. 32, 1297–1305 (2022). https://doi.org/10.1007/s42823-022-00360-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42823-022-00360-8