Abstract

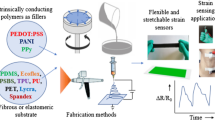

This article presents recent advancements in the development of flexible piezoresistive strain sensors based on carbon nanotubes (CNTs)–polymer composites, with particular attention to their electromechanical properties. Various fabrication approaches and material preparation of CNTs–polymer composites with improved piezoresistive performance are introduced. Moreover, the article presents the working principle of the piezoresistive sensors in terms of the tunneling effect and disconnection-reconnection mechanism. The sensing performances of recently reported applications are studied. This work also reveals that the CNTs–polymer composites have great potential for flexible, skin-mountable, and wearable electronics applications. Finally, possible challenges for the future developments of CNTs–polymer composites are discussed.

Similar content being viewed by others

References

Gao L et al (2019) All paper-based flexible and wearable piezoresistive pressure sensor. ACS Appl Mater Interfaces 11(28):25034–25042

Sencadas V, Tawk C, Alici G (2020) Environmentally Friendly and Biodegradable Ultrasensitive Piezoresistive Sensors for Wearable Electronics Applications. ACS Appl Mater Interfaces 12(7):8761–8772

Chen Q et al (2018) Facile fabrication and performance of robust polymer/carbon nanotube coated spandex fibers for strain sensing. Compos A Appl Sci Manuf 112:186–196

Yi Y, Wang B, Bermak A (2019) A low-cost strain gauge displacement sensor fabricated via shadow mask printing. Sensors 19(21):4713

Zhang X et al (2021) High-performance flexible strain sensors based on biaxially stretched conductive polymer composites with carbon nanotubes immobilized on reduced graphene oxide. Compos Part A: Appl Sci Manuf 151:106665

Yi Y, Chiao M, Wang B (2021) An electrochemically actuated drug delivery device with in-situ dosage sensing. Smart Mater Struct 30(5):055003

Iijima S (1991) Helical microtubules of graphitic carbon. Nature 354(6348):56–58

Iijima S, Ichihashi T (1993) Single-shell carbon nanotubes of 1-nm diameter. Nature 363(6430):603–605

Bethune D et al (1993) Cobalt-catalysed growth of carbon nanotubes with single-atomic-layer walls. Nature 363(6430):605–607

Eshkalak SK et al (2017) A review on inkjet printing of CNT composites for smart applications. Appl Mater Today 9:372–386

Amjadi M et al (2016) Stretchable, skin-mountable, and wearable strain sensors and their potential applications: a review. Adv Funct Mater 26(11):1678–1698

Berber S, Kwon Y-K, Tománek D (2000) Unusually high thermal conductivity of carbon nanotubes. Phys Rev Lett 84(20):4613

Troiani H et al (2003) Direct observation of the mechanical properties of single-walled carbon nanotubes and their junctions at the atomic level. Nano Lett 3(6):751–755

Balandin AA (2011) Thermal properties of graphene and nanostructured carbon materials. Nat Mater 10(8):569–581

Lee C et al (2008) Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 321(5887):385–388

Klemens P, Pedraza D (1994) Thermal conductivity of graphite in the basal plane. Carbon 32(4):735–741

Zhang Y et al (2011) Enhanced thermal conductivity in copper matrix composites reinforced with titanium-coated diamond particles. Script Mater 65(12):1097–1100

Powell R, Ho CY, Liley PE (1966) Thermal conductivity of selected materials. Vol. 8. 1966: US Department of Commerce, National Bureau of Standards Washington, DC

Gau C, Ko H, Chen H (2009) Piezoresistive characteristics of MWNT nanocomposites and fabrication as a polymer pressure sensor. Nanotechnology 20(18):185503

Kang JH et al (2009) Piezoresistive characteristics of single wall carbon nanotube/polyimide nanocomposites. J Polym Sci, Part B: Polym Phys 47(10):994–1003

Hu N et al (2011) Piezoresistive strain sensors made from carbon nanotubes based polymer nanocomposites. Sensors 11(11):10691–10723

Obitayo W, Liu T (2012) A review: carbon nanotube-based piezoresistive strain sensors. J Sens

Hu N et al (2008) Tunneling effect in a polymer/carbon nanotube nanocomposite strain sensor. Acta Mater 56(13):2929–2936

Wang L, Li Y (2012) A review for conductive polymer piezoresistive composites and a development of a compliant pressure transducer. IEEE Trans Instrum Meas 62(2):495–502

Sun X et al (2018) A highly-sensitive flexible tactile sensor array utilizing piezoresistive carbon nanotube–polydimethylsiloxane composite. J Micromech Microeng 28(10):105011

Can-Ortiz A, Abot J, Avilés F (2019) Electrical characterization of carbon-based fibers and their application for sensing relaxation-induced piezoresistivity in polymer composites. Carbon 145:119–130

Kingston C et al (2014) Release characteristics of selected carbon nanotube polymer composites. Carbon 68:33–57

Arash B, Wang Q, Varadan V (2014) Mechanical properties of carbon nanotube/polymer composites. Sci Rep 4:6479

Benson J et al (2013) Multifunctional CNT–polymer composites for ultra-tough structural supercapacitors and desalination devices. Adv Mater 25(45):6625–6632

Dalmas F et al (2005) Multiwalled carbon nanotube/polymer nanocomposites: processing and properties. J Polym Sci Part B: Polym Phys 43(10):1186–1197

Dufresne A et al (2002) Processing and characterization of carbon nanotube/poly (styrene-co-butyl acrylate) nanocomposites. J Mater Sci 37(18):3915–3923

Xiang D et al (2021) 3D-printed flexible piezoresistive sensors for stretching and out-of-plane forces. Macromol Mater Eng 2021:2100437

Thostenson ET, Chou T-W (2002) Aligned multi-walled carbon nanotube-reinforced composites: processing and mechanical characterization. J Phys D Appl Phys 35(16):L77

Meincke O et al (2004) Mechanical properties and electrical conductivity of carbon-nanotube filled polyamide-6 and its blends with acrylonitrile/butadiene/styrene. Polymer 45(3):739–748

Sandler J et al (2004) A comparative study of melt spun polyamide-12 fibres reinforced with carbon nanotubes and nanofibres. Polymer 45(6):2001–2015

Andrews R et al (2002) Multiwall carbon nanotubes: synthesis and application. Acc Chem Res 35(12):1008–1017

Velasco-Santos C et al (2003) Improvement of thermal and mechanical properties of carbon nanotube composites through chemical functionalization. Chem Mater 15(23):4470–4475

Zhao C et al (2005) Synthesis and characterization of multi-walled carbon nanotubes reinforced polyamide 6 via in situ polymerization. Polymer 46(14):5125–5132

Putz KW et al (2004) Elastic modulus of single-walled carbon nanotube/poly (methyl methacrylate) nanocomposites. J Polym Sci, Part B: Polym Phys 42(12):2286–2293

Byrne MT, Gun’ko YK (2010) Recent advances in research on carbon nanotube–polymer composites. Adv Mater 22(15):1672–1688

Coleman JN et al (2006) Small but strong: a review of the mechanical properties of carbon nanotube–polymer composites. Carbon 44(9):1624–1652

Coleman JN, Khan U, Gun’ko YK (2006) Mechanical reinforcement of polymers using carbon nanotubes. Adv Mater 18(6):689–706

Mamedov AA et al (2002) Molecular design of strong single-wall carbon nanotube/polyelectrolyte multilayer composites. Nat Mater 1(3):190–194

Olek M et al (2004) Layer-by-layer assembled composites from multiwall carbon nanotubes with different morphologies. Nano Lett 4(10):1889–1895

O’Connor I et al (2009) High-strength, high-toughness composite fibers by swelling Kevlar in nanotube suspensions. Small 5(4):466–469

O’Connor I et al (2009) Development of transparent, conducting composites by surface infiltration of nanotubes into commercial polymer films. Carbon 47(8):1983–1988

Endo M et al (2005) ‘Buckypaper’from coaxial nanotubes. Nature 433(7025):476–476

Wang D et al (2008) Highly oriented carbon nanotube papers made of aligned carbon nanotubes. Nanotechnology 19(7):075609

Zhou Y, Hu L, Grüner G (2006) A method of printing carbon nanotube thin films. Appl Phys Lett 88(12):123109

Berhan L et al (2004) Mechanical properties of nanotube sheets: Alterations in joint morphology and achievable moduli in manufacturable materials. J Appl Phys 95(8):4335–4345

Chae HG et al (2005) A comparison of reinforcement efficiency of various types of carbon nanotubes in polyacrylonitrile fiber. Polymer 46(24):10925–10935

Mai F et al (2010) Superior reinforcement in melt-spun polyethylene/multiwalled carbon nanotube fiber through formation of a shish-kebab structure. J Phys Chem B 114(33):10693–10702

Mercader C et al (2012) Scalable process for the spinning of PVA–carbon nanotube composite fibers. J Appl Polym Sci 125(S1):E191–E196

Miaudet P et al (2007) Thermo-electrical properties of PVA–nanotube composite fibers. Polymer 48(14):4068–4074

Scaffaro R, Maio A, Tito A (2012) High performance PA6/CNTs nanohybrid fibers prepared in the melt. Compos Sci Technol 72(15):1918–1923

Zeng J et al (2004) Processing and properties of poly (methyl methacrylate)/carbon nanofiber composites. Compos B Eng 35(3):245–249

Anand KA et al (2010) PET-SWNT nanocomposite fibers through melt spinning. Int J Polym Mater 59(6):438–449

Kim J-W et al (2007) Characteristics of pitch-based carbon fibers containing multi-wall carbon nanotubes. J Ind Eng Chem 13(5):757–763

Andrews R et al (1999) Nanotube composite carbon fibers. Appl Phys Lett 75(9):1329–1331

Mottaghitalab V, Spinks GM, Wallace GG (2005) The influence of carbon nanotubes on mechanical and electrical properties of polyaniline fibers. Synth Met 152(1–3):77–80

Jose MV et al (2007) Polypropylene/carbon nanotube nanocomposite fibers: process–morphology–property relationships. J Appl Polym Sci 103(6):3844–3850

Teng N-Y, Dallmeyer I, Kadla JF (2013) Incorporation of multiwalled carbon nanotubes into electrospun softwood Kraft lignin-based fibers. J Wood Chem Technol 33(4):299–316

Jain R et al (2010) Processing, structure and properties of poly (ether ketone) grafted few wall carbon nanotube composite fibers. Polymer 51(17):3940–3947

Muñoz E et al (2005) Highly conducting carbon nanotube/polyethyleneimine composite fibers. Adv Mater 17(8):1064–1067

Khan WS, Asmatulu R, Eltabey MM (2013) Electrical and thermal characterization of electrospun PVP nanocomposite fibers. J Nanomater

Siochi EJ et al (2004) Melt processing of SWCNT-polyimide nanocomposite fibers. Compos B Eng 35(5):439–446

Saligheh O et al (2013) The effect of multi-walled carbon nanotubes on morphology, crystallinity and mechanical properties of PBT/MWCNT composite nanofibers. J Polym Res 20(2):1–6

Soroudi A, Skrifvars M (2010) Melt blending of carbon nanotubes/polyaniline/polypropylene compounds and their melt spinning to conductive fibres. Synth Met 160(11–12):1143–1147

Hooshmand S, Soroudi A, Skrifvars M (2011) Electro-conductive composite fibers by melt spinning of polypropylene/polyamide/carbon nanotubes. Synth Met 161(15–16):1731–1737

Xiang D et al (2020) Synergistic effects of hybrid conductive nanofillers on the performance of 3D printed highly elastic strain sensors. Compos Part A: Appl Sci Manuf 129:105730

Cheng H et al (2019) Synergetic effect of Fe3O4 nanoparticles and carbon on flexible poly (vinylidence fluoride) based films with higher heat dissipation to improve electromagnetic shielding. Compos A Appl Sci Manuf 121:139–148

Sohn K-S et al (2016) A mechanoluminescent ZnS: Cu/rhodamine/SiO2/PDMS and piezoresistive CNT/PDMS hybrid sensor: red-light emission and a standardized strain quantification. ACS Appl Mater Interfaces 8(50):34777–34783

Yoon SG, Chang ST (2017) Microfluidic capacitive sensors with ionic liquid electrodes and CNT/PDMS nanocomposites for simultaneous sensing of pressure and temperature. J Mater Chem C 5(8):1910–1919

Lai Y-T, Chen Y-M, Yang Y-JJ (2011) A novel CNT-PDMS-based tactile sensing array with resistivity retaining and recovering by using dielectrophoresis effect. J Microelectromech Syst 21(1):217–223

Wu L et al (2019) Screen-printed flexible temperature sensor based on FG/CNT/PDMS composite with constant TCR. J Mater Sci: Mater Electron 30(10):9593–9601

Du J et al (2020) Optimized CNT-PDMS flexible composite for attachable health-care device. Sensors 20(16):4523

Le H et al (2014) The role of linked phospholipids in the rubber-filler interaction in carbon nanotube (CNT) filled natural rubber (NR) composites. Polymer 55(18):4738–4747

Thomas PS et al (2012) Electrical properties of natural rubber nanocomposites: effect of 1-octadecanol functionalization of carbon nanotubes. J Mater Sci 47(7):3344–3349

Le H et al (2012) Kinetics of filler wetting and dispersion in carbon nanotube/rubber composites. Carbon 50(12):4543–4556

Jung S et al (2014) Reverse-micelle-induced porous pressure-sensitive rubber for wearable human–machine interfaces. Adv Mater 26(28):4825–4830

Xu M et al (2021) Breathable, degradable piezoresistive skin sensor based on a sandwich structure for high-performance pressure detection. Adv Electron Mater 7(10):2100368

Ellingford C et al (2019) Electrical dual-percolation in MWCNTs/SBS/PVDF based thermoplastic elastomer (TPE) composites and the effect of mechanical stretching. Eur Polymer J 112:504–514

Wang S et al (2021) In situ and intraoperative detection of the ureter injury using a highly sensitive piezoresistive sensor with a tunable porous structure. ACS Appl Mater Interfaces 13(18):21669–21679

Wang L et al (2020) Highly electrically conductive polymer composite with a novel fiber-based segregated structure. J Mater Sci 55(25):11727–11738

Zhang X et al (2020) Flexible and high-performance piezoresistive strain sensors based on carbon nanoparticles@ polyurethane sponges. Compos Sci Technol 200:108437

Chen X et al (2022) 3D printed high-performance spider web-like flexible strain sensors with directional strain recognition based on conductive polymer composites. Mater Lett 306:130935

Chen S et al (2021) Flexible Piezoresistive Three-Dimensional Force Sensor Based on Interlocked Structures. Sens Actuat A: Phys 2021:112857

Tran AV, Zhang X, Zhu B (2018) Mechanical structural design of a piezoresistive pressure sensor for low-pressure measurement: a computational analysis by increases in the sensor sensitivity. Sensors 18(7):2023

Zhang P et al (2019) Flexible piezoresistive sensor with the microarray structure based on self-assembly of multi-walled carbon nanotubes. Sensors 19(22):4985

Yang Q et al (2020) Performance evaluation of bitumen with a homogeneous dispersion of carbon nanotubes. Carbon 158:465–471

Simmons JG (1963) Low-voltage current-voltage relationship of tunnel junctions. J Appl Phys 34(1):238–239

Fisher J, Giaever I (1961) Tunneling through thin insulating layers. J Appl Phys 32(2):172–177

Wang L, Wang X, Li Y (2012) Relation between repeated uniaxial compressive pressure and electrical resistance of carbon nanotube filled silicone rubber composite. Compos A Appl Sci Manuf 43(2):268–274

Wang Z, Ye X (2014) An investigation on piezoresistive behavior of carbon nanotube/polymer composites: II. Positive piezoresistive effect. Nanotechnology 25(28):285502

Luheng W, Tianhuai D, Peng W (2009) Influence of carbon black concentration on piezoresistivity for carbon-black-filled silicone rubber composite. Carbon 47(14):3151–3157

Yi Y, Samara A, Wang B (2020) A new approach for an ultra-thin piezoresistive sensor based on solidified carbon ink fil m. J Mater Sci 2020:1–8

Shindo Y et al (2012) Electrical resistance change and crack behavior in carbon nanotube/polymer composites under tensile loading. Compos B Eng 43(1):39–43

Sekitani T, Someya T (2010) Stretchable, large-area organic electronics. Adv Mater 22(20):2228–2246

Wang X et al (2014) Silk-molded flexible, ultrasensitive, and highly stable electronic skin for monitoring human physiological signals. Adv Mater 26(9):1336–1342

Yi Y, Chen J, Takahata K (2019) Wirelessly powered resonant-heating stent system: design, prototyping, and optimization. IEEE Trans Antennas Propag 68(1):482–490

Yi Y et al (2019) Wireless hyperthermia stent system for restenosis treatment and testing with swine model. IEEE Trans Biomed Eng 67(4):1097–1104

Yi Y et al (2019) Wirelessly Heating Stents via Radiofrequency Resonance toward Enabling Endovascular Hyperthermia. Adv Healthcare Mater 8(22):1900708

Loh KJ et al (2007) Multifunctional layer-by-layer carbon nanotube–polyelectrolyte thin films for strain and corrosion sensing. Smart Mater Struct 16(2):429

Kang I et al (2006) A carbon nanotube strain sensor for structural health monitoring. Smart Mater Struct 15(3):737

Funding

This research received no external funding.

Author information

Authors and Affiliations

Contributions

YY organized, modified, optimized, revised, and prepared the manuscript, BW summarized the Table 2, and XL drew Fig. 1 and summarized the Table 1. CL provided the content about the working principle in the section "Strain-Responsive Principle". All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yi, Y., Wang, B., Liu, X. et al. Flexible piezoresistive strain sensor based on CNTs–polymer composites: a brief review. Carbon Lett. 32, 713–726 (2022). https://doi.org/10.1007/s42823-022-00320-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42823-022-00320-2