Abstract

Nanocomposite fibers are fibrous materials with specific properties and functionalities, which are prepared by introducing nanomaterials or nanostructures in the fibers. Polymeric nanocomposite fibers exhibit multiple functionalities, showing great application potential in healthcare, aerospace, mechanical engineering, and energy storage. Here, six functionalities of polymer nanocomposite fibers are reviewed: mechanical reinforcement, resistance to electromagnetic interference and flame, thermal and electrical conduction, generation of far-infrared ray, negative ion and electricity, energy storage, and sensing. For each functionality, the fiber component selection and preparation methods are summarized. The commonly used polymers comprise natural and synthetic polymers, and typical nanomaterials include carbon-based, polymer-based, metal-based, and metal oxide-based ones. Various compounding strategies and spinning approaches, such as wet-spinning, melt-spinning, and electrospinning, are introduced. Moreover, the functional properties of fibers fabricated from different constituents and by different strategies are compared, providing a reference for performance optimization. Finally, the prospective directions of research and application are discussed, and possible approaches are suggested to facilitate the development of advanced nanocomposite fibers.

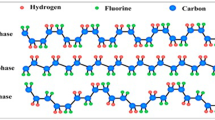

Graphical Abstract

Similar content being viewed by others

Data availability

The data are available from the corresponding author upon request.

References

Shaarawy S. A Review on the development of innovative capabilities in the textile finishing of natural fibers. Egypt J Chem. 2020;63:857.

Hussain T, Masood R, Umar M. Development and characterization of alginate-chitosan-hyaluronic acid (ACH) composite fibers for nedical applications. Fiber Polym. 2016;17(11):1749.

Holbery J, Houston D. natural-fiber-reinforced polymer composites applications in automotive. JOM. 2006;58(11):80.

Williams G, Trask R, Bond I. A self-healing carbon fibre reinforced polymer for aerospace applications. Compos Part A-Appl S. 2007;38(6):1525.

Yu DS, Goh K, Wang H. Scalable synthesis of hierarchically structured carbon nanotube-graphene fibres for capacitive energy storage. Nature Nanotech. 2014;9(7):555.

Habib D, Locke DC, Cannone LJ. Synthetic fibers as indicators of municipal sewage sludge, sludge products, and sewage treatment plant effluents. Water Air Soil Poll. 1998;103(1–4):1.

Weng W, Yang J, Zhang Y, et al. A route toward smart system integration: from fiber design to device construction. Adv Mater. 2020;32(5):1902301.

Kamide K. First commercialization, dead rock, and quick decay after temporary prosperity of cellulose nitrate rayon industry as predecessor of chemical fiber industry. Nara Sangyo Univ J Ind Econ. 2003;18(3):313.

Roger B. Filamentary graphite and method for producing the same. U.S. Patent 2957756. 1960.

Gao C, Han Y, Chen C. Graphene/nylon 6 fabric with permanent far-infrared health care function and its preparation method. Chinese Patent CN201710134838.3. 2018.

Zeng SN, Pian SJ, Su MY, et al. Hierarchical-morphology metafabric for scalable passive daytime radiative cooling. Science. 2021;373:692.

Zhu MF. Nanocomposite fiber materials. Science Press; 2014.

Nagarajan S, Pochat-Bohatier C, Teyssier C. Design of graphene oxide/gelatin electrospun nanocomposite fibers for tissue engineering applications. RSC Adv. 2016;6: 109150.

Zhang CM, Salick MR, Cordie TM. Incorporation of poly(ethylene glycol) grafted cellulose nanocrystals in poly(lactic acid) electrospun nanocomposite fibers as potential scaffolds for bone tissue engineering. Mat Sc Eng C-Mater. 2015;49:463.

Spinks GM, Mottaghitalab V, Bahrami-Samani M. Carbon-nanotube-reinforced polyaniline fibers for high-strength artificial muscles. Adv Mater. 2006;18:637.

Tong HW, Wang M, Li ZY. Electrospinning, characterization and in vitro biological evaluation of nanocomposite fibers containing carbonated hydroxyapatite nanoparticles. Biomed Mater. 2010;5: 054111.

Sharifzadeh G, Soheilmoghaddam M, Adelnia H. Biocompatible regenerated cellulose/halloysite nanocomposite fibers. Polym Eng Sci. 2020;60:1169.

Talebian S, Mehrali M, Raad R. Electrically conducting hydrogel graphene nanocomposite biofibers for biomedical applications. Front Chem. 2020;8:88.

Hu XJ, Li JG, Bai YX. Fabrication of high strength graphene/regenerated silk fibroin composite fibers by wet-spinning. Mater Lett. 2017;194:224.

Huang SW, Zhou L, Li MC. Preparation and properties of electrospun poly (vinyl pyrrolidone)/cellulose nanocrystal/silver nanoparticle composite fibers. Materials. 2016;9:523.

Zhang XY, Chen XG. Preparation of polyamide 6/CeO2 composite nanofibers through electrospinning for biomedical applications. Int J Poly Sci. 2019;2019:2494586.

Ma Y, Bai DC, Hu XJ. Robust and antibacterial polymer/mechanically exfoliated graphene nanocomposite fibers for biomedical applications. ACS Appl Mater Interfaces. 2018;10:3002.

Awasthi GP, Maharjan B. Synthesis, characterizations, and biocompatibility evaluation of polycaprolactone-MXene electrospun fibers. Colloid Surface A. 2020;586: 124282.

Suryavanshi A, Khanna K, Sindhu KR. Magnesium oxide nanoparticle-loaded polycaprolactone composite electrospun fiber scaffolds for bone–soft tissue engineering applications: in-vitro and in-vivo evaluation. Biomed Mater. 2017;12: 055011.

Apalangya VA, Rangari VK, Tiimob BJ. Eggshell based nano-engineered hydroxyapatite and poly(lactic) acid electrospun fibers as potential tissue scaffold. Int J Biomater. 2019;2019: 6762575.

Li JQ, Wen YY, Xiao ZH, et al. Holey reduced graphene oxide scaffolded heterocyclic aramid fibers with enhanced mechanical performance. Adv Funct Mater. 2022;32:2200937.

Luo JJ, Wen YY, Jia XZ, et al. Fabricating strong and tough aramid fibers by small addition of carbon nanotubes. Nat Commun. 2023;14:3019.

Arias-Monje PJ, Davijani AAB, Lu MX. Engineering the interphase of single wall carbon nanotubes/polyacrylonitrile nanocomposite fibers with poly(methyl methacrylate) and its effect on filler dispersion, filler-matrix interactions, and tensile properties. ACS Appl Nano Mater. 2020;3:4178.

Dalton AB, Collins S, Muñoz E. Super-tough carbon-nanotube fibres: these extraordinary composite fibres can be woven into electronic textiles. Nature. 2003;423:703.

Hu XJ, Ren N, Chao YZI. Highly aligned graphene oxide/poly(vinyl alcohol) nanocomposite fibers with high-strength, antiultraviolet and antibacterial properties. Compos Part A. 2017;102:297.

Morimune-Moriya S, Ariyoshi M, Goto T. Ultradrawing of poly (vinyl alcohol)/graphene oxide nanocomposite fibers toward high mechanical performances. Compos Sci Tech. 2017;152:159.

Kearns JC, Shambaugh RL. Polypropylene fibers reinforced with carbon nanotubes. J Appl Polym Sci. 2002;86:2079.

Luo LB, Wu H, Liu Y. Synergistic “anchor” effect of carbon nanotubes and silica: a facile and efficient double-nanocomposite system to reinforce high performance polyimide fibers. Ind Eng Chem Res. 2019;58:16620.

Ryu S, Lee YH, Hwang JW. High-strength carbon nanotube fibers fabricated by infiltration and curing of mussel-inspired catecholamine polymer. Adv Mater. 2011;23:1971.

Novoselov KS, Geim AK, Morozov SV. Electric field effect in atomically thin carbon films. Science. 2004;306:666.

Lee C, Wei X, Kysar JW. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science. 2008;321:385.

Zhu Y, James DK, Tour JM. New routes to graphene, graphene oxide and their related applications. Adv Mater. 2012;24:4924.

Lu JP. Elastic properties of single and multilayered nanotubes. J Phys Chem Solids. 1997;58:1649.

Ausman KD, Piner R, Lourie O. Organic solvent dispersions of single-walled carbon nanotubes: toward solutions of pristine nanotubes. J Phys Chem B. 2000;104:8911.

Xu WH, Ravichandran D, Jambhulkar S. Hierarchically structured composite fibers for real nanoscale manipulation of carbon nanotubes. Adv Funct Mater. 2021;31:2009311.

Chen Y, Zhang H, Yang Y. High-performance epoxy nanocomposites reinforced with three-dimensional carbon nanotube sponge for electromagnetic interference shielding. Adv Funct Mater. 2016;26:447.

Li XL, Yin XW, Han MK, et al. Ti3C2 MXenes modified with in situ grown carbon nanotubes for enhanced electromagnetic wave absorption properties. J Mater Chem C. 2017;5:4068.

Yim YJ, Lee JJ, Tugirumubano A. Electromagnetic interference shielding behavior of magnetic carbon fibers prepared by electroless FeCoNi-plating. Materials. 2021;14:3774.

González M, Pozuelo J, Baselga J. Electromagnetic shielding materials in GHz range. Chem Rec. 2018;18:1000.

Wang W, Li WY, Gao CC. A novel preparation of silver-plated polyacrylonitrile fibers functionalized with antibacterial and electromagnetic shielding properties. Appl Surf Sci. 2015;342:120.

Im JS, Kim JG, Bae TS. Effect of heat treatment on ZrO2-embedded electrospun carbon fibers used for efficient electromagnetic interference shielding. J Phys Chem Solids. 2011;72:1175.

Yim YJ, Baek YM, Park SJ. Influence of nickel layer on electromagnetic interference shielding effectiveness of CuS-polyacrylonitrile fibers. Bull Korean Chem Soc. 2018;39:1406.

Liu LX, Chen W, Zhang HB. Tough and electrically conductive Ti3C2Tx MXene-based core-shell fibers for high-performance electromagnetic interference shielding and heating application. Chem Eng J. 2022;430: 133074.

Wei HW, Zheng WH, Jiang ZX. CNT coatings grown on the outer and inner surfaces of magnetic hollow carbon fibers with enhanced electromagnetic interference shielding performance. J Mater Chem C. 2019;7:14375.

Latko-Durałek P, Bertasius P, Macutkevic J. Fibers of thermoplastic copolyamides with carbon nanotubes for electromagnetic shielding applications. Materials. 2021;14:5699.

Ima JS, Kima JG, Lee SH. Effective electromagnetic interference shielding by electrospun carbon fibers involving Fe2O3/BaTiO3/MWCNT additives. Mater Chem Phys. 2010;124:434.

Gupta S, Tai NH. Carbon materials and their composites for electromagnetic interference shielding effectiveness in X-band. Carbon. 2019;152:159.

Manna R, Srivastava SK. Reduced graphene oxide/Fe3O4/polyaniline ternary composites as a superior microwave absorber in the shielding of electromagnetic pollution. ACS Omega. 2021;6:9164.

Cao HF, Zhang Q, Wu Z. Progress of electromagnetic shielding property of graphene-based material. New Chem Mater. 2016;44(2):1.

Yuksek M. Electromagnetic wave shielding and mechanical properties of vapor-grown carbon nanofiber/polyvinylidene fluoride composite fibers. J Eng Fiber Fabr. 2020;15:1.

Aoyama S, Park YT, Ougizawa T. Melt crystallization of poly (ethylene terephthalate): comparing addition of graphene vs carbon nanotubes. Polymer. 2014;55:2077.

Gilman JW. Flammability and thermal stability studies of polymer layered-silicate (clay) nanocomposite. Appl Clay Sci. 1999;15:31.

Dogan M, Bayramli E. Effect of boron phosphate on the mechanical, thermal and fire retardant properties of polypropylene and polyamide-6 pibers. Fiber Polym. 2013;14(10):1595.

Hribernik S, Smole MS, Kleinschek KS. Flame retardant activity of SiO2-coated regenerated cellulose fibres. Polym Degrad Stabil. 2007;92:1957.

Wang X, Li QS, Di YB. Preparation and properties of flame-retardant viscose fiber containing phosphazene derivative. Fiber Polym. 2012;13(6):718.

Zhai GX, Zhou JL, Xiang HX. Combustion forming hollow nanospheres as a ceramic fortress for flame-retardant fiber. Prog Nat Sci: Mater. 2021;31:239.

Cai YB, Wu N, Wei QF. Structure, surface morphology, thermal and flammability characterizations of polyamide6/organic-modified Fe-montmorillonite nanocomposite fibers functionalized by sputter coating of silicon. Surf Coat Tech. 2008;203:264.

Qiu MH, Wang D, Zhang LP. Simultaneously electrochemical exfoliation and functionalization of graphene nanosheets: Multifunctional reinforcements in thermal, flame-retardant, and mechanical properties of polyacrylonitrile composite fibers. Polym Compos. 2020;41:1561.

Yu SL, Xiang HX, Zhou JL. Preparation and characterization of fire resistant PLA fibers with phosphorus flame retardant. Fiber Polym. 2017;18(6):1098.

Xue BX, Song YH, Peng Y. Enhancing the flame retardant of polyethylene terephthalate (PET) fiber via incorporation of multi-walled carbon nanotubes based phosphorylated chitosan. J Text I. 2018;109(7):871.

Horrocks R, Sitpalan A, Zhou C. Flame retardant polyamide fibres: the challenge of minimising flame retardant additive contents with added nanoclays. Polymers. 2016;8:288.

Kim JS, Song JE, Lim DY. Flame-retardant mechanism and mechanical properties of wet-ppun poly(acrylonitrile-co-vinylidene chloride) pibers with antimony trioxide and zinc hydroxystannate. Polymers. 2020;12:2442.

Dogan M, Erdogan S, Bayramlı E. Mechanical, thermal, and fire retardant properties of poly(ethylene terephthalate) fiber containing zinc phosphinate and organo-modified clay. J Therm Anal Calorim. 2013;112:871.

Lee SH, Yi GR, Lim DY. Study on the flame retardant and mechanical properties of wet-spun poly(acrylonitrile-co-vinylchloride) fibers with antimony trioxide and zinc hydroxystannate. Fiber Polym. 2019;20(4):779.

Jz MA, Wang D, Fu SH. Preparation and properties of flame-retardant viscose fiber/dithiopyrophosphate incorporated with graphene oxide. Text Res J. 2020;41(3):15.

Matsuhisa N, Inoue D, Zalar P, et al. Printable elastic conductors by in situ formation of silver nanoparticles from silver flake. Nat Mater. 2017;16:834.

Hu J, Huang Y, Yao Y, et al. Polymer composite with improved thermal conductivity by constructing a hierarchically ordered three-dimensional interconnected network of BN. ACS Appl Mater Interf. 2017;9:13544.

Hamadneh NN, Khan WS, Khan WA. Prediction of thermal conductivities of polyacrylonitrile electrospun nanocomposite fibers using artificial neural network and prey predator algorithm. J King Saud Univ Sci. 2019;31:618.

Zhang XG, Wu BG, Chen G. Preparation and characterization of flexible smart glycol/polyvinylpyrrolidone/nano-Al2O3 phase change fibers. Energ Fuel. 2021;35:877.

Tian MW, Zhang XS. Enhanced mechanical and thermal properties of regenerated cellulose/graphene composite fibers. Carbohyd Polym. 2014;111:456.

Che HS, Chen QQ, Zhong Q. The effects of nanoparticles on morphology and thermal properties of erythritol/polyvinyl alcohol phase change composite fibers. E-Polymers. 2018;18(4):321.

Khan WS, Hamadneh NN, Khan WA. Prediction of thermal conductivity of polyvinylpyrrolidone (PVP) electrospun nanocomposite fibers using artificial neural network and prey-predator algorithm. PLoS ONE. 2017;12(9): 0183920.

Xin GQ, Yao TK, Sun HT. Highly thermally conductive and mechanically strong graphene fibers. Science. 2015;349:1083.

Khan WS, Asmatulu R, Ahmed I. Thermal conductivities of electrospun PAN and PVP nanocomposite fibers incorporated with MWCNTs and NiZn ferrite nanoparticles. Int J Therm Sci. 2013;71:74.

Qiu L, Zou HY, Zhu N. Iodine nanoparticle-enhancing electrical and thermal transport for carbon nanotube fibers. Appl Therm Eng. 2018;141:913.

Meng WS, Nie MY, Liu ZY, et al. Buckled fiber conductors with resistance stability under strain. Adv Fiber Mater. 2021;3:149.

Zhao S, Li J, Cao D, et al. Recent advancements in flexible and stretchable electrodes for electromechanical sensors: strategies, materials, and features. ACS Appl Mater Interfaces. 2017;9(14):12147.

Seyedin S, Zhang P, Naebe M, et al. Textile strain sensors: a review of the fabrication technologies, performance evaluation and applications. Mater Horiz. 2019;6:219.

Ajmal CM, Bae S, Baik S. A superior method for constructing electrical percolation network of nanocomposite fibers: in situ thermally reduced silver nanoparticles. Small. 2019;15:1803255.

Han JT, Choi S, Jang JI. Rearrangement of 1D conducting nanomaterials towards highly electrically conducting nanocomposite fibres for electronic textiles. Sci Rep-UK. 2015;5:9300.

Nilsson E, Oxfall H, Wandelt W. Melt spinning of conductive textile fibers with hybridized graphite nanoplatelets and carbon black filler. J Appl Polym Sci. 2013;130:2579.

Kim SW, Kwon SN, et al. Stretchable and electrically conductive polyurethane- silver/graphene composite fibers prepared by wet-spinning process. Compos Part B. 2019;167:573.

Zhang X, Wang A, Zhou XY. Fabrication of aramid nanofiber-wrapped graphene fibers by coaxial spinning. Carbon. 2020;165:340.

Han ZP, Wang JQ, Liu SP, et al. Electrospinning of neat graphene nanofbers. Adv Fiber Mater. 2022;4:268.

Wang K, Liu MQ, Song CY. Surface-conductive UHMWPE fibres via in situ reduction and deposition of graphene oxide. Mater Des. 2018;148:167.

Ma T, Gao HL, Cong HP. A bioinspired interface design for improving the strength and electrical conductivity of graphene-based fibers. Adv Mater. 2018;30:1706435.

Xu Z, Liu Z, Sun HY, Gao C. Highly electrically conductive Ag-doped graphene fibers as stretchable conductors. Adv Mater. 2013;25:3249.

Vaia RA, Lee JW, Wang CS. Hierarchical control of nanoparticle deposition: high-performance electrically conductive nanocomposite fibers via infiltration. Chem Mater. 1998;10:2030.

Bae S, Ajmal CM, Lee Y. Significantly enhanced mechanical strength by the hollow structure of conductive stretchable silver nanoflower polyurethane fibers. Adv Eng Mater. 2020;22:2000674.

Lee YJ, Bae S, Hwang B. Considerably improved water and oil washability of highly conductive stretchable fibers by chemical functionalization with fluorinated silane. J Mater Chem C. 2019;7:12297.

Zhang XX. Study and development of the far-infrared fibers and fabrics. Text Res J. 1994;15(11):530.

Bajirova M. Miraculous effects of negative ions on urogenital infections. Int J Gynecol Obstet. 2018;9:00297.

Larciprete MC, Paoloni S, Orazi N. Infrared emissivity characterization of carbon nanotubes dispersed poly (ethylene terephthalate) fibers. Int J Therm Sci. 2019;146: 106109.

Zhang KJ, Li QS, Luo JQ. Preperation and characterization of anion functional polyester fiber. J Funct Mater. 2017;9(48):09184.

Chen Z, Sun C, Zhu YN, et al. PET/Germanium fibrous composite fabricated by melt-spinning technique: negative air ions emission and antibacterial properties. Mater Rev. 2008;32(4):1333.

Wang X, Yan QL, Gao X, et al. Infrared and fluorescence properties of reduced graphene oxide/regenerated cellulose composite fibers. BioResources. 2020;15(2):4434.

Li N, Li JW, Lv LH, et al. Preparation and properties of nano-graphene/PLA far infrared fibers. China Text Aux. 2018;35(11):33.

Zhang YC, Hu JL. Robust effects of graphene oxide on polyurethane/tourmaline nanocomposite fiber. Polymers. 2021;13:16.

Hu YM, An WF, Zhang DD, et al. Synthesis of tourmaline-containing functional copolymer and its fibre. J Funct Mater. 2021;2(52):02034.

Li CL, Yan J, Jia SJ, et al. Preparation and properties study of germanium cellulose fiber. China Knitting Ind. 2020;11:18.

Hu XW, Xu RP, Wang SC, et al. Preparation and properties of graphene anion modified polymer fibers. Synth Fiber China. 2018;47(4):30.

Jiao J, Li QS, Lu ZZ, et al. Structure and properties of bamboo carbon modified polyester staple fiber. China Synth Fiber Ind. 2011;34(3):31.

Shindell D, Smith CJ. Climate and air-quality benefits of a realistic phase-out of fossil fuels. Nature. 2019;573:408.

Shi Q, Dong B, He T, et al. Progress in wearable electronics/photonics-Moving toward the era of artificial intelligence and internet of things. InfoMat. 2020;2:1131.

Bai P, Zhu G, Lin ZH, et al. Integrated multilayered triboelectric nanogenerator for harvesting biomechanical energy from human motions. ACS Nano. 2013;7:3713.

Yin J, Zhang Z, Li X, et al. Waving potential in graphene. Nat Commun. 2014;5:3582.

Lan XQ, Wang TZ, Liu CC, et al. A high performance all-organic thermoelectric fiber generator towards promising wearable electron. Compos Sci Tech. 2019;182: 107767.

Li XH, Lin ZH, Cheng G, et al. 3D Fiber-based hybrid nanogenerator for energy harvesting and as a self-powered pressure sensor. ACS Nano. 2014;8(10):10674.

Yu XH, Pan J, Zhang J, et al. A coaxial triboelectric nanogenerator fiber for energy harvesting and sensing under deformation. J Mater Chem A. 2017;5:6032.

He X, Zi YL, Guo HY, et al. A highly stretchable fiber-based triboelectric nanogenerator for self-powered wearable electronics. Adv Funct Mater. 2017;27:1604378.

Cheng Y, Lu X, Chan KH, et al. A stretchable fiber nanogenerator for versatile mechanical energy harvesting and self-powered full-range personal healthcare monitoring. Nano Energy. 2017;41:511.

Yang YJ, Xu BG, Gao YY, et al. Conductive composite fiber with customizable functionalities for energy harvesting and electronic textiles. ACS Appl Mater Interfaces. 2021;13:49927.

Liu JM, Cui NY, Du T, et al. Coaxial double helix structured fiber-based triboelectric nanogenerator for effectively harvesting mechanical energy. Nanoscale Adv. 2020;2:4482.

Sim HJ, Choi CS, Shi HK, et al. Stretchable triboelectric fiber for self-powered kinematic sensing textile. Sci Rep. 2020;6:35153.

Zhang M, Gao T, Wang JS. A hybrid fibers based wearable fabric piezoelectric nanogenerator for energy harvesting application. Nano Energy. 2015;13:298.

Bairagi S, Ali SW. A unique piezoelectric nanogenerator composed of melt-spun PVDF/KNN nanorod-based nanocomposite fibre. Eur Polym J. 2019;116:554.

Parandeh S, Kharaziha M, Karimzadeh F. An eco-friendly triboelectric hybrid nanogenerators based on graphene oxide incorporated polycaprolactone fibers and cellulose paper. Nano Energy. 2019;59:412.

Fuh YK, Kuo CC, Huang ZM. A Transparent and flexible graphene-piezoelectric fiber generator. Small. 2016;12(14):1875.

Liu CL, Zhang WG, Sun JB, et al. Piezoelectric nanogenerator based on a flexible carbon-fiber/ZnO-ZnSe bilayer structure wire. Appl Surf Sci. 2014;322:95.

Zhao TC, Hu YJ, Zhuang W, et al. A fiber fluidic nanogenerator made from aligned carbon nanotubes composited with transition metal oxide. ACS Mater Lett. 2021;3:1448.

Ghosha SK, Mandal D. Synergistically enhanced piezoelectric output in highly aligned 1D polymer nanofibers integrated all-fiber nanogenerator for wearable nano-tactile sensor. Nano Energy. 2018;53:245.

Parandeh S, Kharaziha M, Karimzadeh F, et al. Triboelectric nanogenerators based on graphene oxide coated nanocomposite fibers for biomedical applications. Nanotechnology. 2020;31: 385402.

Miller JR, Simon P. Electrochemical capacitors for energy management. Science. 2008;321:651.

Yang QY, Xu Z, Gao C. Graphene fiber based supercapacitors: strategies and perspective toward high performances. J Energy Chem. 2018;27:6.

Lyu W, Zhang WY, Liu H, et al. Conjugated microporous polymer network grafted carbon nanotube fibers with tunable redox activity for efficient flexible wearable energy storage. Chem Mater. 2020;32:8276.

Ke QQ, Wang J. Graphene-based materials for supercapacitor electrodes—a review. J Materiomics. 2016;2:37.

Lu Z, Foroughi J, Wang CY, et al. Superelastic hybrid CNT/graphene fibers for wearable energy storage. Adv Energy Mater. 2018;8:1702047.

Cai SY, Huang TQ, Chen H, et al. Wet-spinning of ternary synergistic coaxial fibers for high performance yarn supercapacitors. J Mater Chem A. 2017;5:22489.

Liu JL, Wang DS, Li JM, et al. Facile fabrication of hierarchically porous graphene/poly(1,5-diaminoanthraquinone) nanocomposite fibers as flexible and robust free-standing electrodes for solid-state supercapacitors. J Taiwan Inst Chem E. 2021;126:154.

Kou L, Huang TQ, Zheng BN, et al. Coaxial wet-spun yarn supercapacitors for high-energy density and safe wearable electronics. Nat Commun. 2014;5:3754.

Zhao XL, Zheng BN, Huang TQ, et al. Graphene-based single fiber supercapacitor with a coaxial structure. Nanoscale. 2015;7:9399.

Chen XL, Qiu LB, Ren J, et al. Novel electric double-layer capacitor with a coaxial fiber structure. Adv Mater. 2013;25:6436.

Pan ZH, Zhong J, Zhang QC, et al. Ultrafast all-solid-state coaxial asymmetric fiber supercapacitors with a high volumetric energy density. Adv Energy Mater. 2018;8:1702946.

Yang ZP, Zhao W, Niu YT, et al. Direct spinning of high-performance graphene fiber supercapacitor with a three-ply core-sheath structure. Carbon. 2018;132:241.

Pan ZH, Yang J, Zhang QC, et al. All-solid-state fiber supercapacitors with ultrahigh volumetric energy density and outstanding flexibility. Adv Energy Mater. 2019;9:1802753.

Lim L, Liu YS, Liu WW, et al. All-in-one graphene based composite fiber: Toward wearable supercapacitor. ACS Appl Mater Interfaces. 2017;9:39576.

Adusei PK, Kanakaraj SN, Gbordzoe S, et al. A scalable nano-engineering method to synthesize 3D-graphenecarbon nanotube hybrid fibers for supercapacitor applications. Electrochim Acta. 2019;312:411.

Gopalsamy K, Xu Z, Zheng BN, et al. Bismuth oxide nanotubes–graphene fiber-based flexible supercapacitors. Nanoscale. 2014;10:1039.

Jian XL, Li HB, Li H, et al. Flexible and freestanding MoS2/rGO/CNT hybrid fibers for high capacity all-solid supercapacitors. Carbon. 2021;172:132.

Li XY, Liu D, Yin X, et al. Hydrated ruthenium dioxides @ graphene based fiber supercapacitor for wearable electronics. J Power Sourc. 2019;440: 227143.

Hua L, Ma ZY, Shi PP, et al. Ultrathin and large-sized vanadium oxide nanosheets mildly prepared at room temperature for high performance fiber-based supercapacitors. J Mater Chem A. 2017;5:2483.

Guo ZJ, Lu Z, Li Y, et al. Highly performed fiber-based supercapacitor in a conjugation of mesoporous MXene. Adv Mater Interf. 2022;9: 2101977.

Xu T, Yang DZ, Fan ZJ, et al. Reduced graphene oxide/carbon nanotube hybrid fibers with narrowly distributed mesopores for flexible supercapacitors with high volumetric capacitances and satisfactory durability. Carbon. 2019;152:134.

Seyedin SY, Yanza ERS, Razal JM. Knittable energy storing fiber with high volumetric performance made from predominantly MXene nanosheets. J Mater Chem A. 2017;5: 24076.

Yang QY, Xu Z, Fang B, et al. MXene/graphene hybrid fibers for high performance flexible supercapacitors. J Mater Chem A. 2017;5: 22113.

Gao LB, Song J, Surjadi JU, et al. Graphene-bridged multifunctional flexible fiber supercapacitor with high energy density. ACS Appl Mater Interfaces. 2018;10:28597.

Guo ZJ, Li Y, Lu Z, et al. High-performance MnO2@MXene/carbon nanotube fiber electrodes with internal and external construction for supercapacitors. J Mater Sci. 2022;57:3613.

Zhang ZF, Zhang DS, Lin H, et al. Flexible fiber-shaped supercapacitors with high energy density based on self-twisted graphene fibers. J Power Sourc. 2019;433: 226711.

Zhang ZY, Xiao F, Xiao J, et al. Functionalized carbonaceous fibers for high performance flexible all-solid-state asymmetric supercapacitors. J Mater Chem A. 2015;3: 11817.

Deng J, Zhang Y, Zhao Y, et al. A shape-memory supercapacitor fiber. Angew Chem Intl Ed. 2015;54: 15419.

Yuan H, Wang G, Zhao YX, et al. A stretchable, asymmetric, coaxial fiber-shaped supercapacitor for wearable electronics. Nano Res. 2020;13(6):1686.

Sun J, Zhang QC, Wang XN, et al. Constructing hierarchical dandelion-like molybdenum–nickel–cobalt ternary oxide nanowire arrays on carbon nanotube fiber for high performance wearable fiber-shaped asymmetric supercapacitors. J Mater Chem A. 2017;5: 21153.

Cai ZB, Li L, Ren J, et al. Flexible, weavable and efficient microsupercapacitor wires based on polyaniline composite fibers incorporated with aligned carbon nanotubes. J Mater Chem A. 2013;1:258.

Wang CJ, Zhai SL, Yuan ZW, et al. A core-sheath holey graphene/graphite composite fiber intercalated with MoS2 nanosheets for high-performance fiber supercapacitors. Electrochim Acta. 2019;305:493.

Li MY, Zu M, Yu JS, et al. Stretchable Fiber supercapacitors with high volumetric performance based on buckled MnO2/oxidized carbon nanotube fiber electrodes. Small. 2017;13: 1602994.

Gopalsamy K, Yang QY, Cai SY, et al. Wet-spun poly(ionic liquid)-graphene hybrid fibers for high performance all-solid-state flexible supercapacitors. J Energy Chem. 2019;34:104.

Ma Y, Liu N, Li L, et al. A highly flexible and sensitive piezoresistive sensor based on MXene with greatly changed interlayer distances. Nat Commun. 2017;8:1.

Zhang T, Han SS, Guo WL, et al. Continuous carbon nanotube composite fibers for flexible aqueous lithium-ion batteries. Sustain Mater Techno. 2019;17: e00096.

Guo W, Liu C, Zhao F, et al. A novel electromechanical actuation mechanism of a carbon nanotube fiber. Adv Mater. 2012;24:5379.

Zhou JW, Li XL, Yang C, et al. A quasi-solid-state flexible fiber-shaped Li-CO2 battery with low overpotential and high energy efficiency. Adv Mater. 2019;31: 1804439.

Zeng YX, Meng Y, Lai ZZ, et al. An ultrastable and high-performance flexible fiber-shaped Ni-Zn battery based on a Ni-NiO heterostructured nanosheet cathode. Adv Mater. 2017;29: 1702698.

Xiao X, Xiao X, Zhou YH, et al. An ultrathin rechargeable solid-state zinc ion fiber battery for electronic textiles. Sci Adv. 2021;7(49): abl3742.

Li M, Meng JS, Li Q, et al. Finely crafted 3D electrodes for dendrite-free and high-performance flexible fiber-shaped Zn-Co batteries. Adv Funct Mater. 2018;28: 1802016.

Xu YF, Zhao Y, Ren J, et al. An all-solid-state fiber-shaped aluminum-air battery with flexibility, stretchability, and high electrochemical performance. Angew Chem Int E. 2016;55:7979.

Li M, Li ZQ, Ye XR, et al. Tendril-inspired 900% ultrastretching fiber-based Zn-ion batteries for wearable energy textiles. ACS Appl Mater Interfaces. 2021;13: 17110.

Weng W, Sun Q, Zhang Y, et al. Winding aligned carbon nanotube composite yarns into coaxial fiber full batteries with high performances. Nano Lett. 2014;14:3432.

Zhang QC, Li CW, Li QL, et al. Flexible and high-voltage coaxial-fiber aqueous rechargeable zinc-ion battery. Nano Lett. 2019;19:4035.

Zhang Y, Wang YH, Wang L, et al. A fiber-shaped aqueous lithium ion battery with high power density. J Materi Chem A. 2016;4:9002.

Kim JC, Kim DW. Electrospun Cu/Sn/C nanocomposite fiber anodes with superior usable lifetime for lithium- and sodium-ion batteries. Chem Asian J. 2014;9:3313.

Zhu YJ, Han XG, Xu YH, et al. Electrospun Sb/C fibers for a stable and fast sodium-ion battery anode. ACS Nano. 2013;7(7):6378.

Qin XY, Zhang HR, Wu JX, et al. Fe3O4 nanoparticles encapsulated in electrospun porous carbon fibers with a compact shell as high-performance anode for lithium ion batteries. Carbon. 2015;87:347.

Zhang CL, Lu BR, Cao FH, et al. Hierarchically structured Co3O4@carbon porous fibers derived from electrospun ZIF-67/PAN nanofibers as anodes for lithium ion batteries. J Mater Chem A. 2018;6: 12962.

Chen X, Hu P, Xiang JW, et al. Confining silicon nanoparticles within freestanding multichannel carbon fibers for high-performance Li-ion batteries. ACS Appl Energy Mater. 2019;2:5214.

Hwang TH, Lee YM, Kong BS, et al. Electrospun core-shell fibers for robust silicon nanoparticle-based lithium ion battery anodes. Nano Lett. 2012;12:802.

Hoshide T, Zheng YC, Hou JY, et al. Flexible lithium-ion fiber battery by the regular stacking of two dimensional titanium oxide nanosheets hybridized with reduced graphene oxide. Nano Lett. 2017;17:3543.

Chen Q, Sun S, Zhai T, et al. Yolk-shell NiS2 nanoparticle-embedded carbon fibers for flexible fiber-shaped sodium battery. Adv Energy Mater. 2018;8: 1800054.

Li H, Shao F, Wen XZ, et al. Graphene/MXene fibers-enveloped sulfur cathodes for high-performance Li-S batteries. Electrochim Acta. 2021;371: 137838.

Kim JC, Kim DW, et al. Synthesis of multiphase SnSb nanoparticles-on-SnO2/Sn/C nanofibers for use in Li and Na ion battery electrodes. Electrochem Commun. 2014;46:124.

Yan B, Chen L, Wang T, et al. Preparation and characterization of Li3V2(PO4)3 grown on carbon nanofiber as cathode material for lithium-ion batteries. Electrochim Acta. 2015;176:1358.

Zhu YJ, Fan XL, Suo LM, et al. Electrospun FeS2@carbon fiber electrode as a high energy density cathode for rechargeable lithium batteries. ACS Nano. 2016;10:1529.

Qu GL, Geng HB, Ge DH, et al. Graphene-coating mesoporous Co3O4 fibers as an efficient anode material for Li-ion batteries. RSC Adv. 2016;6(75):71006.

Gu MS, Ko SH, Yoo SM, et al. Double locked silver-coated silicon nanoparticle/graphene core/shell fiber for high-performance lithium-ion battery anodes. J Power Sourc. 2015;300:351.

Lee JG, Kwon YB, Ju JY, et al. Fiber electrode by one-pot wet-spinning of graphene and manganese oxide nanowires for wearable lithium-ion batteries. J Appl Electrochem. 2017;47:865.

Cheng X, Na R, Wang XX, et al. Si nanoparticles embedded in 3D carbon framework constructed by sulfur-doped carbon fibers and graphene for anode in lithium-ion battery. Inorg Chem Front. 2019;6:1996.

Zhou YY, Jiang K, Zhao ZG, et al. Giant two-dimensional titania sheets for constructing a flexible fiber sodium-ion battery with long-term cycling stability. Energy Storage Mater. 2020;24:504.

Lin HJ, Weng W, Ren J, et al. Twisted aligned carbon nanotube/silicon composite fiber anode for flexible wire-shaped lithium-ion battery. Adv Mater. 2014;26:1217.

Sanchez JS, Xu J, Xia ZY, et al. Electrophoretic coating of LiFePO4/Graphene oxide on carbon fibers as cathode electrodes for structural lithium ion batteries. Compos Sci Technol. 2021;208: 108768.

Zou YH, Yang XF, Lv CX, et al. Multishelled Ni-rich Li(NixCoyMnz)O2 hollow fibers with low cation mixing as high-performance cathode materials for Li-ion batteries. Adv Sci. 2017;4:1600262.

Pandey N, Tiwari K, Roy A. ZnO-TiO2 nanocomposite: Characterization and moisture sensing studies. B Mater Sci. 2012;35:347.

Khan AQ, Yu KQ, Li JT, et al. Spider silk supercontraction-inspired cotton-hydrogel self-adapting textiles. Adv Fiber Mater. 2022;4:1572.

Farahani H, Wagiran R, Hamidon MN. Humidity sensors principle, mechanism, and fabrication technologies: a comprehensive review. Sensors. 2014;14:7881.

Horzum N, Tascıoglu D, Okur S, et al. Humidity sensing properties of ZnO-based fibers by electrospinning. Talanta. 2011;85:1105.

Parangusan H, Bhadra J, Ahmad Z, et al. Humidity sensor based on poly(lactic acid)/PANI-ZnO composite electrospun fibers. RSC Adv. 2021;11:28735.

Wang XF, Ding B, Yu JY, et al. Highly sensitive humidity sensors based on electro-spinning/netting a polyamide 6 nano-fiber/net modified by polyethyleneimine. J Mater Chem. 2011;21:16231.

Lv SJ, Shuai LYZ, Ding WF, et al. Flexible humidity sensitive fiber with swellable metal-organic frameworks. Adv Fiber Mater. 2021;3:107.

Du B, Yang DX, She XY, et al. MoS2-based all-fiber humidity sensor for monitoring human breath with fast response and recovery. Sens Actuat B-Chem. 2017;251:180.

Choi SJ, Yu HY, Jang JS, et al. Nitrogen-doped single graphene fiber with platinum water dissociation catalyst for wearable humidity sensor. Small. 2018;14:1703934.

Chen ZC, Chang TL, Su KW, et al. Application of self-heating graphene reinforced polyvinyl alcohol nanowires to high-sensitivity humidity detection. Sens Actuat B-Chem. 2021;327: 128934.

Gao R, Lu DF, Cheng J, et al. Humidity sensor based on power leakage at resonance wavelengths of a hollow core fiber coated with reduced graphene oxide. Sens Actuat B-Chem B. 2016;222:618.

Qi HS, Schulz B, Vad T, et al. Novel carbon nanotube/cellulose composite fibers as multifunctional materials. ACS Appl Mater Interfaces. 2015;7:22404.

Jiang M, Wang CC, Zhang XR, et al. A cellular nitric oxide sensor based on porous hollow fiber with flow-through configuration. Biosens Bioelectron. 2021;191: 113442.

Ma JW, Fan HQ, Li ZX, et al. Multi-walled carbon nanotubes/polyaniline on the ethylenediamine modified polyethylene terephthalate fibers for a flexible room temperature ammonia gas sensor with high responses. Sens Actuat B-Chem. 2021;334: 129677.

Wang XP, Li YL, Pionteck J, et al. Flexible poly(styrene-butadiene-styrene)/carbon nanotube fiber based vapor sensors with high sensitivity, wide detection range, and fast response. Sens Actuat B-Chem. 2018;256:896.

Cabrala TS, Sgobbib LF, Delezuk J, et al. Glucose sensing via a green and low-cost platform from electrospun poly (vinyl alcohol)/graphene quantum dots fibers. Mater Today: Proc. 2019;14:694.

Shu Y, Su T, Lu Q, et al. Highly stretchable wearable electrochemical sensor based on Ni-Co MOF nanosheet-decorated Ag/rGO/PU fiber for continuous sweat glucose detection. Anal Chem. 2021;93:16222.

Inderan V, Arafat MM, Hasee ASMA, et al. Electrospun (nickel and palladium) tin(IV) oxide/polyaniline/polyhydroxy-3-butyrate biodegradable nanocomposite fibers for low temperature ethanol gas sensing. Nanotechnology. 2020;31: 425503.

Zhu ZY, Liu CC, Jiang FX, et al. Flexible fiber-shaped hydrogen gas sensor via coupling palladium with conductive polymer gel fiber. J Hazard Mater. 2021;411: 125008.

Eom W, Jang JS, Lee SH, et al. Effect of metal/metal oxide catalysts on graphene fiber for improved NO2 sensing. Sens Actuat B-Chem. 2021;344: 130231.

Shin DH, Choi YS, Park SY, et al. Fast and complete recovery of TMDs-decorated rGO fiber gas sensors at room temperature. Appl Surf Sci. 2022;578: 151832.

Zeng JF, Ding XT, Chen LW, et al. Ultra-small dispersed CuxO nanoparticles on graphene fibers for miniaturized electrochemical sensor applications. RSC Adv. 2019;9:28207.

Ugale AD, Umarji GG, Jung SH, et al. ZnO decorated flexible and strong graphene fibers for sensing NO2 and H2S at room temperature. Sens Actuat B-Chem. 2020;308: 127690.

Lee SH, Eom W, Shin H, et al. Room-temperature, highly durable Ti3C2Tx MXene/graphene hybrid fibers for NH3 gas sensing. ACS Appl Mater Interfaces. 2020;12:10434.

Li WW, Chen RS, Qi WZ, et al. Reduced graphene oxide/mesoporous ZnO NSs hybrid fibers for flexible, stretchable, twisted, and wearable NO2 E-textile gas sensor. ACS Sens. 2019;4:2809.

Chen C, Han Y, Sun HY, et al. Flower-shaped graphene oxide in-situ unfolding polyamide-6 and functional fibers thereof. Text Res J. 2023;44(1):47.

Liang J, Wu JW, Guo J, et al. Radiative cooling for passive thermal management towards sustainable carbon neutrality. Natl Sci Rev. 2023;10: nwac208.

Shi X, Zuo Y, Zhai P, et al. Large-area display textiles integrated with functional systems. Nature. 2021;591:240.

Yan W, Inès R, Güven K, et al. Structured nanoscale metallic glass fibres with extreme aspect ratios. Nat Nanotechnol. 2020;15:875.

Acknowledgements

L. J. Liu and D. Chang have contributed equally to this work. The authors would like to thank Zheng Li in School of Micro-Nano Electronics at ZJU-Hangzhou Global Scientific and Technological Innovation Center for discussion. The authors would also like to thank Lin Ding and Tianfeng Qin in MOE Key Laboratory of Macromolecular Synthesis and Functionalization at Zhejiang University for assistance with modifying graphical abstract and 6.2.2 section. The authors are grateful for the financial support from the National Natural Science Foundation of China (No. 52090030), Shanxi-Zheda Institute of New Materials and Chemical Engineering (2022SZ-TD011, 2022SZ-TD012, 2022SZ-TD014, and 2021SZ-FR004), and the Fundamental Research Funds for the Central Universities (No. 2021FZZX001-17).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

Chao Gao is an Editorial Board Member/Editor-in-Chief for [Advanced Fiber Materials] and was not involved in the editorial review or the decision to publish this article. All authors declare that there are no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, L., Chang, D. & Gao, C. A Review of Multifunctional Nanocomposite Fibers: Design, Preparation and Applications. Adv. Fiber Mater. 6, 68–105 (2024). https://doi.org/10.1007/s42765-023-00340-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42765-023-00340-1