Abstract

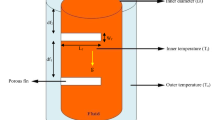

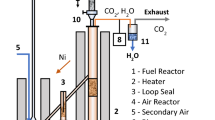

The chemical-looping combustion of methane in a three-dimensional cylindrical fuel reactor is numerically studied using the developed multiphase particle-in-cell reactive model, featuring the multi-phase flow, heat transfer, reduction of oxygen carriers, and particle shrinkage. After model validation, the general flow patterns, and the thermophysical properties of oxygen carriers (e.g., temperature, heat transfer coefficient) and gas phase (e.g., temperature, density, thermal conductivity, specific heat capacity, and viscosity) are comprehensively studied with the discussion on several crucial operating parameters. The results show that bubble dynamics (e.g., generation, rising, coalescence, and eruption) induce the segregation of small- and large-mass particles. CH4 is thoroughly converted in a very short distance above the bottom distributor while CO and H2 increase above the bottom distributor and then decrease axially. The temperature of particles ranges from 1275 to 1295 K, leading to a 20 K temperature difference in the bed. The heat transfer coefficient (HTC) of particles is in the range of 50–150 W/(m2·K). Increasing the investigated operating parameters (i.e., superficial gas velocity, methane ratio, and wall temperature) enlarges the particle properties (i.e., temperature, HTC) and most of the gas properties (i.e., temperature, thermal conductivity, specific capacity, and viscosity), but decreases the gas density. The findings shed light on the reactor design and process control of the chemical-looping combustion systems.

Similar content being viewed by others

Abbreviations

- A :

-

Particle acceleration (m/s2)

- D g,k :

-

Turbulent mass diffusion coefficient (m2/s)

- D s :

-

Drag coefficient of the solid phase (1/s)

- f D :

-

Particle distribution function obtained by collapsing the velocity dependence

- f s :

-

Particle distribution function

- F gs :

-

Inter-phase momentum exchanging rate per volume (kg/(m3·s))

- h g :

-

Enthalpy of gas mixture (J/kg)

- h s :

-

Enthalpy of solid phase (J/kg)

- ΔH rg :

-

Heat of chemical reactions (W/m3)

- ΔH rs :

-

Heat of chemical reactions (W/m3)

- k s :

-

Kinetic constant evaluated

- m s :

-

Particle mass (kg)

- Nu s :

-

Nusselt number

- N k :

-

Total number of gas species

- p g :

-

Gas pressure (Pa)

- Pr :

-

Turbulent Prandtl number

- q :

-

Heat flux (W/m2)

- \({{\dot Q}_{\rm{D}}}\) :

-

Enthalpy diffusion (W/m3)

- Q radi :

-

Radiative heat transfer (W)

- Q sg :

-

Convective heat transfer (W)

- R 0,ilm :

-

Oxygen transport capacity of oxygen carriers

- S gs :

-

Gas–solid energy exchanging rate (W/m3)

- S gw :

-

Gas–wall convective heat transfer (W/m3)

- t :

-

Time instant (s)

- T 0 :

-

Reference temperature (K)

- T b,local :

-

Environmental temperature (K)

- T g :

-

Gas temperature (K)

- T P :

-

Particle temperature (K)

- T s :

-

Solid temperature (K)

- u g :

-

Gas velocity (m/s)

- u s :

-

Solid velocity (m/s)

- Y g,k :

-

Mass fraction of gas species i

- \(\delta {{\dot m}_{\rm{s}}}\) :

-

Mass source term of solid phase (kg/(m3·s))

- \(\delta {{\dot m}_{k,{\rm{react}}}}\) :

-

Mass transfer between the gas species (kg)

- θ g :

-

Gas volume fraction

- θ s :

-

Solid volume fraction

- ε s :

-

Emissivity coefficient

- λ g :

-

Gas thermal conductivity (J/(m·s·K))

- λ t :

-

Turbulent component (J/(m·s·K))

- μ t :

-

Gas turbulent viscosity (kg/(m·s))

- π g :

-

Gas density (kg/m3)

- π s :

-

Solid phase density (kg/m3)

- σ :

-

Stefan–Boltzmann constant (W/(m2·K4))

- τ g :

-

Gas stress tensor (Pa)

- τ D :

-

Particle collision damping time (s)

- τ s :

-

Particle normal stress (Pa)

- g:

-

Gas phase

- s:

-

Solid (particle) phase

- x, y, z :

-

Coordinate index

- 3D:

-

Three-dimensional

- AR:

-

Air reactor

- BFB:

-

Bubbling fluidized bed

- CCS:

-

CO2 capture and storage

- CFB:

-

Circulating fluidized bed

- CFD-DEM:

-

Computational fluid dynamics-discrete element method

- CLC:

-

Chemical-looping combustion

- EMMS:

-

Energy-minimization multi-scale

- FR:

-

Fuel reactor

- FVM:

-

Finite volume method

- HTC:

-

Heat transfer coefficient

- IGCC:

-

Integrated gasification combined-cycle

- LES:

-

Large-eddy simulation

- MP-PIC:

-

Multi-phase particle-in-cell

- PISO:

-

Pressure implicit with splitting of operator

- RANS:

-

Reynolds-averaged Navier–Stokes

- SIMPLE:

-

Semi-implicit method for pressure-linked equations

- TFM:

-

Two-fluid model

References

Abad, A., Adánez, J., García-Labiano, F., de Diego, L. F., Gayán, P., Celaya J. 2007. Mapping of the range of operational conditions for Cu-, Fe-, and Ni-based oxygen carriers in chemical-looping combustion. Chemical Engineering Science, 62: 533–549.

Adánez, J., Abad, A. 2019. Chemical-looping combustion: Status and research needs. Proceedings of the Combustion Institute, 37: 4303–4317.

Adánez, J., Dueso, C., de Diego, L. F., García-Labiano, F., Gayán, P., Abad, A. 2009. Methane combustion in a 500 Wth chemical-looping combustion system using an impregnated Ni-based oxygen carrier. Energy & Fuels, 23: 130–142.

Adánez, J., García-Labiano, F., de Diego, L. F., Gayán, P., Celaya, J., Abad, A. 2006. Nickel-copper oxygen carriers to reach zero CO and H2 emissions in chemical-looping combustion. Industrial & Engineering Chemistry Research, 45: 2617–2625.

Chavda, A., Mehta, P., Harichandan, A. 2022. Numerical analysis of multiphase flow in chemical looping reforming process for hydrogen production and CO2 capture. Experimental and Computational Multiphase Flow, 4: 360–376.

Chen, C., Zhao, L., Wu, X., Wang, J. 2019a. Numerical and experimental study on oxy-fuel coal and biomass co-firing in a bubbling fluidized bed. Energy & Fuels, 33: 5829–5839.

Chen, X., Ma, J., Tian, X., Wan, J., Zhao, H. 2019b. CPFD simulation and optimization of a 50 kWth dual circulating fluidized bed reactor for chemical looping combustion of coal. International Journal of Greenhouse Gas Control, 90: 102800.

Chen, Y.-Y., Guo, M., Kim, M., Liu, Y., Qin, L., Hsieh, T.-L., Fan, L.-S. 2021. Predictive screening and validation on chemical looping oxygen carrier activation by tuning electronic structures via transition metal dopants. Chemical Engineering Journal, 406: 126729.

Durmaz, M., Dilmaç, N., Dilmaç, Ö. F. 2020. Evaluation of performance of copper converter slag as oxygen carrier in chemical-looping combustion (CLC). Energy, 196: 117055.

Gidaspow, D. 1994. Multiphase Flow and Fluidization: Continuum and Kinetic Theory Descriptions. Cambridge, Massachusetts, USA: Academic Press.

Gu, J., Shao, Y., Liu, X., Zhong, W., Yu, A. 2018. Modelling of particle flow in a dual circulation fluidized bed by a Eulerian-Lagrangian approach. Chemical Engineering Science, 192: 619–633.

Hoteit, A., Chandel, M. K., Delebarre, A. 2009. Nickel- and copper-based oxygen carriers for chemical looping combustion. Chemical Engineering & Technology, 32: 443–449.

Khalifa, O., Alkhatib, I. I. I., Bahamon, D., Alhajaj, A., Abu-Zahra, M. R. M., Vega, L. F. 2022. Modifying absorption process configurations to improve their performance for post-combustion CO2 capture—What have we learned and what is still missing? Chemical Engineering Journal, 430: 133096.

Kraft, S., Kirnbauer, F., Hofbauer, H. 2017. CPFD simulations of an industrial-sized dual fluidized bed steam gasification system of biomass with 8 MW fuel input. Applied Energy, 190: 408–420.

Kuo, P.-C., Chen, J.-R., Wu, W., Chang, J.-S. 2018. Hydrogen production from biomass using iron-based chemical looping technology: Validation, optimization, and efficiency. Chemical Engineering Journal, 337: 405–415.

Latifi, M. S., Colangelo, G., Starace, G. 2020. A CFD study on the effect of size of fuel sphere on PBR core. Experimental and Computational Multiphase Flow, 2: 109–114.

Li, T., Rogers, W. A., Syamlal, M., Dietiker, J.-F., Musser, J., Shahnam, M., Rabha S. 2017. The NETL MFiX suite of multiphase flow models: A brief review and recent applications of MFiX-TFM to fossil energy technologies. Chemical Engineering Science, 169: 259–272.

Lin, J., Luo, K., Sun, L., Wang, S., Hu, C., Fan, J. 2019. Numerical investigation of nickel-copper oxygen carriers in chemical-looping combustion process with zero emission of CO and H2. Energy & Fuels, 33: 12096–12105.

Liu, W., Teng, L., Rohani, S., Qin, Z., Zhao, B., Xu, C. C., Ren, S., Liu, Q., Liang, B. 2021. CO2 mineral carbonation using industrial solid wastes: A review of recent developments. Chemical Engineering Journal, 416: 129093.

Liu, Z., Li, Z., Zhang, Y., Zhang, Y., Zhao, B. 2022. Thermodynamic analysis of using chemical-looping combustion in Allam-Z cycle instead of common combustion. Energy Conversion and Management, 254: 115229.

Luo, C., Peng, Z., Doroodchi, E., Moghtaderi, B. 2018. A three-dimensional hot flow model for simulating the alumina encapsulated NI-NIO methane-air CLC system based on the computational fluid dynamics-discrete element method. Fuel, 224: 388–400.

Lyngfelt, A., Pallarès, D., Linderholm, C., Lind, F., Thunman, H., Leckner, B. 2022. Achieving adequate circulation in chemical looping combustion—Design proposal for a 200 MWth chemical looping combustion circulating fluidized bed boiler. Energy & Fuels, 36: 9588–9615.

Ma, Y., Luo, Y., Xu, H., Du, R., Wang, Y. 2021. Review on air and water thermal energy storage of buildings with phase change materials. Experimental and Computational Multiphase Flow, 3: 77–99.

Mattisson, T., Johansson, M., Jerndal, E., Lyngfelt, A. 2008. The reaction of NiO/NiAl2O4 particles with alternating methane and oxygen. The Canadian Journal of Chemical Engineering, 86: 756–767.

Mei, D., Soleimanisalim, A. H., Lyngfelt, A., Leion, H., Linderholm, C., Mattisson, T. 2022. Modelling of gas conversion with an analytical reactor model for biomass chemical looping combustion (bio-CLC) of solid fuels. Chemical Engineering Journal, 433: 133563.

Parker, J. M. 2014. CFD model for the simulation of chemical looping combustion. Powder Technology, 265: 47–53.

Reinking, Z., Shim, H.-S., Whitty, K. J., Lighty, J. S. 2019. Computational simulation of a 100 kW dual circulating fluidized bed reactor processing coal by chemical looping with oxygen uncoupling. International Journal of Greenhouse Gas Control, 90: 102795.

Shao, Y., Agarwal, R. K., Wang, X., Jin, B. 2021. Review of computational fluid dynamics studies on chemical looping combustion. Journal of Energy Resources Technology, 143: 8.

Sheth, M., Roy, A., Harichandan, A. 2018. Performance of fuel reactor in a chemical looping combustion system with different oxygen carriers. Thermal Science and Engineering Progress, 5: 303–308.

Smagorinsky, J. 1963. General circulation experiments with the primitive equations: I. The basic experiment. Monthly Weather Review, 91: 99–164.

Snider, D. M. 2001. An incompressible three-dimensional multiphase particle-in-cell model for dense particle flows. Journal of Computational Physics, 170: 523–549.

Snider, D. M., Clark, S. M., O’Rourke, P. J. 2011. Eulerian-Lagrangian method for three-dimensional thermal reacting flow with application to coal gasifiers. Chemical Engineering Science, 66: 1285–1295.

Sorgenfrei, M., Tsatsaronis, G. 2014. Design and evaluation of an IGCC power plant using iron-based syngas chemical-looping (SCL) combustion. Applied Energy, 113: 1958–1964.

Urdiales Montesino, Á., Jiménez Álvaro, Á., Rodríguez Martín, J., Nieto Carlier, R. 2016. Exergy analysis of a syngas-fueled combined cycle with chemical-looping combustion and CO2 sequestration. Entropy, 18: 314.

Vin, N., Bakoc, K., Lambert, A., Pelletant, W., Bertholin, S. 2022. Chemical looping combustion of petcoke using two natural ores in a 10 kWth continuous pilot plant: A performance comparison. Energy & Fuels, 36: 9485–9501.

Wan, Z., Yang, S., Wang, H. 2021. MP-PIC investigation of the multi-scale gas–solid flow in the bubbling fluidized bed. Experimental and Computational Multiphase Flow, 3: 289–302.

Wang, S., Lu, H., Li, D., Tang, Y. 2013. Simulation of the chemical looping reforming process in the fuel reactor with a bubble-based energy minimization multiscale model. Energy & Fuels, 27: 5008–5015.

Wang, S., Luo, K., Hu, C., Sun, L., Fan, J. 2018. Impact of operating parameters on biomass gasification in a fluidized bed reactor: An Eulerian-Lagrangian approach. Powder Technology, 333: 304–316.

Wu, H., Gui, N., Yang, X., Tu, J., Jiang, S. 2021. Parameter analysis and wall effect of radiative heat transfer for CFD-DEM simulation in nuclear packed pebble bed. Experimental and Computational Multiphase Flow, 3: 250–257.

Xie, J., Zhong, W., Jin, B., Shao, Y., Huang, Y. 2013. Eulerian-Lagrangian method for three-dimensional simulation of fluidized bed coal gasification. Advanced Powder Technology, 24: 382–392.

Yang, S., Wan, Z., Wang, S., Wang, H. 2021a. Reactive MP-PIC investigation of heat and mass transfer behaviors during the biomass pyrolysis in a fluidized bed reactor. Journal of Environmental Chemical Engineering, 9: 105047.

Yang, S., Wang, S., Wang, H. 2021b. Particle-scale evaluation of the pyrolysis process of biomass material in a reactive gas–solid spouted reactor. Chemical Engineering Journal, 421: 127787.

Yang, S., Zhou, T., Wei, Y., Hu, J., Wang, H. 2019. Influence of size-induced segregation on the biomass gasification in bubbling fluidized bed with continuous lognormal particle size distribution. Energy Conversion and Management, 198: 111848.

Zeng, J., Li, H., Zhang, D. 2019. Numerical simulation of proppant transport in propagating fractures with the multi-phase particle-in-cell method. Fuel, 245: 316–335.

Zhang, Y., Langørgen, Ø., Saanum, I., Chao, Z., Jakobsen, H. A. 2017. Modeling and simulation of chemical looping combustion using a copper-based oxygen carrier in a double-loop circulating fluidized bed reactor system. Industrial & Engineering Chemistry Research, 56: 14754–14765.

Zhang, Z., Liu, D., Zhuang, Y., Meng, Q., Chen, X. 2014. CFD-DEM modeling of CO2 capture using alkali metal-based sorbents in a bubbling fluidized bed. International Journal of Chemical Reactor Engineering, 12: 441–449.

Zhao, Y., Li, Y., Jin, B., Liang, Z. 2022. Layered double hydroxide derived bifunctional Ca–Fe–Mg material for integrated CO2 capture and utilization via chemical looping strategy. Chemical Engineering Journal, 431: 133826.

Zylka, A., Krzywanski, J., Czakiert, T., Idziak, K., Sosnowski, M., Grabowska, K., Prauzner, T., Nowak, W. 2019. The 4th generation of CeSFaMB in numerical simulations for CuO-based oxygen carrier in CLC system. Fuel, 255: 115776.

Acknowledgements

The authors thank the financial support from the Applied Basic Research Project of Yunnan Province, China (Grant No. 202101AT070135).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors have no competing interests to declare that are relevant to the content of this article.

Supporting Information

Rights and permissions

About this article

Cite this article

Zhang, K., Liang, J., Liu, H. et al. Modeling of chemical-looping combustion process of methane with nickel-based oxygen carrier. Exp. Comput. Multiph. Flow 6, 180–194 (2024). https://doi.org/10.1007/s42757-023-0161-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42757-023-0161-2