Abstract

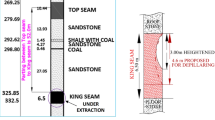

The study aims to evaluate the pillar behavior during the depillaring operation by continuous miner (CM) technology. A panel with five headings developed as per the coal mine regulation of Indian coal mines [2] has been selected for the study. The depillaring operation has been carried out using CM technology after widening and heightening the original entries. An extensive field investigation has been carried out throughout the depillaring operation to access the mining conditions. Depillaring operation has been performed smoothly up to the middle of the panel (fourth row out of eight rows of four pillars each). Advanced blinking of the auto warning tell-tale (AWTT) has also been observed on some of the instruments during the splitting of pillar no. 18. The panel shows extremely difficult mining conditions at this stage. The case has been numerically simulated using three-dimensional numerical techniques. The simulation result has indicated the high stress and yield condition on the working and the barrier pillar (surrounding goaf from both sides) after the extraction of pillar no. 18. The analysis has also indicated the marginal stability of the 2nd barrier pillar (namely “pillar B”). The failure of the barrier pillar could be the responsible for global instability of the panel as observed in the field. Understanding the importance of the barrier pillars, panel design has been modified by incorporating an additional row of barrier pillars. The stability of the modified panel has been evaluated. Both working and barrier pillars have been observed stable in the modified panel. This could be an alternative layout considering safety at the working face.

Similar content being viewed by others

Abbreviations

- B & P :

-

Bord and pillar

- CM :

-

Continuous miner

- FO S :

-

Factor of safety

- SDL :

-

Side discharge loader

- LHD :

-

Load haul dumper

- SECL :

-

South Eastern Coalfields Limited

- ECL :

-

Eastern Coalfields Limited

- WCL :

-

Western Coalfields Limited

- SCCL :

-

Singareni Collieries Company Limited

- CMR :

-

Coal Mines Regulations, India

- DGMS :

-

Directorate General of Mines Safety, India

- CIMFR :

-

Central Institute of Mining and Fuel Research, India

- RQD :

-

Rock quality designation

- NEW :

-

Noneffective width

- AWTT :

-

Auto-warning tell-tale

- RTT :

-

Rotary tell-tale

- DHTT :

-

Dual height tell-tale

- VW :

-

Vibrating wire

- UCS :

-

Uniaxial compressive strength

- LTD :

-

Load transfer distance

- FLAC 3D :

-

Fast Lagrangian analysis of continua in 3 dimensions

References

Kumar Ashok et al (2021) Development of empirical model for strength estimation of irregular-shaped-heightened-rib/snook for mechanised depillaring. Int J Rock Mech Min Sci 148:104969

CMR India (2017) Coal mines regulations 2017. Retrieved 9 December 2017 from: http://www.dgms.net/Coal%20Mines%20Regulation%202017.pdf

Van der Merwe JN (2006) Beyond Coalbrook: what did we really learn? J S Afr Inst Min Metall 106(12):857–868

Gates RA, Gauna M, Morley TA, O’Donnell JR, Smith GE, Watkins TR, Weaver CA, Zelanko JC (2008) Report of the investiga-tion, fatal underground coal burst accidents, August 6 and 16, 2007, Crandall Canyon Mine. Available from http://www.msha.gov/Fatals/2007/CrandallCanyon/FTL07CrandallCanyon.pdf

http://ismenvis.nic.in/Database/West_Chirimiri_Colliery_1141968_9322.aspx; 2020. Accessed July 14, 2020

Beauchamp C (2014) Disaster at the Australian Agricultural Company’s mine, Hamilton NSW, 1889. J Australas Min Hist 12:193

DGMS (2015) (coal) Statistics of mines in India, Vol I, India: Directorate General of Mines Safety. Retrieved 26 February 2018 from: http://dgms.gov.in/writereaddata/UploadFile/Coal_2015.pdf

Kumar A, Kumar D, Verma AK, Singh AK, Ram S, Kumar R (2018) Influence of overlying roof strata on rib design in mechanised depillaring. J Geol Soc India 91(3):341–347

Singh AK, Kumar A, Kumar D et al (2020) Coal pillar extraction under weak roof. Mining Metall Explor 37(5):1451–1459

Singh AK, Kumar A, Kumar D et al (2021) Field and simulation studies for mechanised depillaring below weak and laminated geology in Indian coalmines. J Geol Soc India 97(4):405–415

Mishra AK, Mishra AK, Rout M (2013) Blast induced caving from surface over continuous miner panel at a 110 m cover in an Indian Mine. Arabian J Sci Eng 38(7):1861–1870

Balkema AA (1993) Modelling of barrier pillars in bord and pillar workings. Int J Rock Mech Min Sci Geomech Abstr 30(4):A261. https://doi.org/10.1016/0148-9062(93)92160-R

Mohammadi S, Ataei M, Kakaie R, Mirzaghorbanali A (2019) A New roof strata cavability index (RS Ci) for longwall mining incorporating new rating system. Geotech Geol Eng 37:3619–3636

Wang J, Ning J, Jiang L, Jiang JQ, Bu T (2018) Structural characteristics of strata overlying of a fully mechanized longwall face: a case study. J South Afr Inst Min Metall 118:1195–1204

Singh GSP (2015) Conventional approaches for assessment of caving behaviour and support requirement with regard to strata control experiences in longwall workings. J Rock Mech Geotech Eng 7:291–297

Sheorey PR (1984) Use of rock caving span classification to estimate in oblong workings. Int J Min Eng 2:133–140

Sarkar SK (1998) Mechanized longwall mining - The Indian experiences. Oxford and IBH Publishing Company Private Limited, New Delhi

Singh R, Singh AK, Coggan J, Ram S (2016) Rib/snook design in mechanized depillaring of rectangular/square pillars. Int J Rock Mech Min Sci 84:119–129

Peng SS, Chiang HS (1984) Longwall mining. John Wiley and Sons Inc, New York

Jaiswal A, Sharma S, Shrivastva BK (2004) Numerical modeling study of asymmetry in the induced stresses over coal mine pillars with advancement of the goaf line. Int J Rock Mech Min Sci 41(5):859–864

Jena SK, Lokhande RD, Pradhan M, Kumar N (2019) Development of a model to estimate strata behavior during bord and pillar extraction in underground coal mining. Arab J Geosci 12:242

Singh AK, Singh R, Maiti J, Kumar R, Mandal PK (2011) Assessment of mining induced stress development over coal pillars during depillaring. Int J Rock Mech Min Sci 48:805–818

Holland CT (1964) The strength of coal in mine pillars. In Proceedings of the 6th Symposium on Rock Mechanics. Univ. of Missouri, Rolla, 450–66

Salamon MDG, Munro AH (1967) A study of the strength of coal pillars. J South Afr Inst Min Metall 68:55–67

Obert L, Duvall WI (1967) Rock mechanics and the design of structures in rock. Wiley, New York

Bieniawski ZK (1968) The effect of specimen size on compressive strength of coal. Int J Rock Mech Min Sci Geomech Abstr 5:325–326

Sheorey PR, Das MN, Barat D, Prasad RK, Singh B (1987) Coal pillar strength estimation from failed and stable cases. Int J Rock Mech Min Sci Geomech Abstr. 24(6):347–355 (Pergamon)

Murali MG, Sheorey PR, Kushwaha A (2001) Numerical estimation of pillar strength in coal mines. Int J Rock Mech Min Sci 38:1185–1192

Jaiswal A, Shrivastva BK (2009) Numerical simulation of coal pillar strength. Int J Rock Mech Min Sci 46:779–788

Kumar A, Kumar R, Singh AK, Ram S, Singh PK, Singh R (2017) Numerical modelling-based pillar strength estimation for an increased height of extraction. Arab J Geosci 10:411

Chawla S, Jaiswal A, Shrivastva BK (2017) Design of snook in the depillaring panel using continuous miner. J Inst Eng (India) Ser D 99(1):39–49

Medhurst TP, Brown ET (1998) A study of the mechanical behaviour of coal for pillar design. Int J Rock Mech Min Sci Geomech Abstr 35:1087–1105

Larson M, Whyatt J (2012) Load transfer distance calibration of a coal panel scale model: a case study. In proceedings 31st International Conference on Ground Control, Morgantown, W. Va. 195–205

Sheorey PR (1994) A theory for in situ stresses in isotropic and transversely isotropic rock. Int J Rock Mech Min Sci Geo-mech Abstr 31:23–34

Acknowledgements

The authors are thankful to the head of the Department of Mining Engineering, IIT (BHU), Varanasi, for providing laboratory facility. The authors are also thankful to the mine management for their cooperation and encouragement for this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chawla, S., Jaiswal, A. & Shrivastva, B.K. Numerical Study of Pillars Behavior in Continuous Miner Depillaring Panel: A Case Study. Mining, Metallurgy & Exploration 39, 1537–1552 (2022). https://doi.org/10.1007/s42461-022-00601-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42461-022-00601-4