Abstract

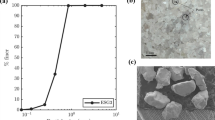

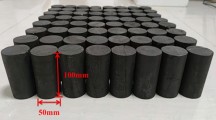

The use of a woven wire-mesh screen as part of a flooded-bed dust-scrubbing system is very popular in the underground coal mining industry. It is used in combination with a demister (mist eliminator) to remove dust from the dust-laden air. A study was conducted to measure the pressure drop across a flooded-bed wire-mesh screen at different airflow rates in one-phase (dry) and two-phase (wet) conditions. Two empirical relationships between pressure drop and air velocity were developed for dry and wet conditions, respectively. In both cases, the form of the empirical relationships was found to be similar to relationships given by Sabri Ergun for high velocity non-Darcy single and multi-phase flow through porous media. The experiments were repeated on a reduced-scale model of the wire-mesh screen, and the pressure-velocity relationships obtained from the full-scale prototype experiments were tested. The test results show validation of the full-scale empirical formulas on the small-scale model with an insignificant variation. This paper presents the empirical equations for pressure drop across the wire-mesh screen in dry and wet conditions. Researchers can use these equations as a tool to predict total pressure drops for wire-mesh screens of different scale sizes.

Similar content being viewed by others

Abbreviations

- ∇p :

-

Pressure gradient (Pa)

- μ :

-

Dynamic viscosity (Pa s)

- v :

-

Superficial velocity (m/s)

- ρ :

-

Air density (kg/m3)

- K :

-

Intrinsic permeability (m2)

- k :

-

Relative permeability (m2)

- η :

-

Intrinsic passability (m)

- Y :

-

Inertial factor

- α :

-

Scale factor

- l :

-

Characteristic length (m)

- g :

-

Acceleration of gravity (m/s2)

- F i :

-

Inertia force of air (N)

- F g :

-

Gravitational force on airflow (N)

- C c :

-

Orifice coefficient

- d :

-

Hydraulic dia. reduced scale (m)

- D :

-

Hydraulic dia. prototype (m)

- A 1 :

-

Area of wind tunnel (m2)

- A 2 :

-

Area of wire mesh (m2)

- X :

-

Shock loss (Pa)

References

Colinet JF, Reed W, Potts JD (2013) Impact on respirable dust levels when operating a flooded-bed scrubber in 20-foot cuts. National Institute of Environmental Health Safety (NIOSH)

Wedding WC, Novak T, Arya S, Kumar A (2015) CFD modeling of a flooded-bed scrubber concept for a longwall shearer operating in a U.S. coal seam. In: Proceedings of 15th US mine Ventilation Symposium. pp 385–390

Colinet JF, Reed WR, Potts JD (2014) Continuous mining dust levels in 20-foot cuts with and without a scrubber operating. In: Proceedings of Society for Mining, Metallurgy & Exploration. Salt Lake City, UT, p Preprint 14–033

Arya S, Sottile J, Novak T (2018) Development of a flooded-bed scrubber for removing coal dust at a longwall mining section. Saf Sci 110:204–213. https://doi.org/10.1016/j.ssci.2018.08.003

Arya S, Sottile J, Rider JP, Colinet JF, Novak T, Wedding C (2018) Design and experimental evaluation of a flooded-bed dust scrubber integrated into a longwall shearer. Powder Technol 339:487–496. https://doi.org/10.1016/j.powtec.2018.07.072

Organiscak JA, Beck TW (2013) Examination of redirected continuous miner scrubber discharge configurations for exhaust face ventilation systems. Trans Soc Mining, Metall Explor Inc 334:435–443

Campbell JAL, Moynihan DJ, Roper WD, Willis C (1983) Dust Control System and Method of Operation

Colinet JF, Rider JP, Listak JM, Organiscak JA, Anita LW (2010) Best practices for dust control in coal mining. IC 9517 Inf Circ Best Pract Dust Control Coal Min 01:17–36

McPherson MJ (1993) Subsurface ventilation engineering. Mine Ventilation Services

Anonymous (2002) Exposure to silica dust on continuous mining operations using flooded-bed scrubbers. Appl Occup Environ Hyg 17:322–323

Colinet JF, Jankowski RA (2000) Silica collection concerns when using flooded-bed scrubbers. Min Eng 4:49–54

Jambhekar VA (2011) Forchheimer porous-media flow models-numerical investigation and comparison with experimental data. Universität Stuttgart-Institut für Wasserund Umweltsystemmodellierung

Zeng Z, Grigg R (2006) A criterion for non-Darcy flow in porous media. Transp Porous Media 63:57–69

Chen Z, Ewing RE, Shi Z-C (2000) Numerical treatment of multiphase flows in porous media: proceedings of the international workshop held at Beijing, China, 2–6 August 1999. Springer Science & Business Media

Hellström G, Lundström S (2006) Flow through porous media at moderate Reynolds number. In: Proceedings of international scientific colloquium modelling for material processing. pp 129–134

Nield DA, Bejan A (2013) Convection in porous media, 4th edn. Springer New York, New York, NY

Wu Y-S, Lai B, Miskimins JL, Fakcharoenphol P, di Y (2011) Analysis of multiphase non-Darcy flow in porous media. Transp Porous Media 88:205–223. https://doi.org/10.1007/s11242-011-9735-8

Wu Y-S, Lai B, Miskimins JL (2011) Simulation of non-Darcy porous media flow according to the Barree and Conway model. J Comput Multiph Flows 3:107–122

Bear J (1972) Dynamics of fluids in porous media. Courier Corporation

Veyskarami M, Hassani AH, Ghazanfari MH (2016) Modeling of non-Darcy flow through anisotropic porous media: role of pore space profiles. Chem Eng Sci 151:93–104. https://doi.org/10.1016/j.ces.2016.05.020

Lai B, Miskimins JL, Wu Y-S (2012) Non-Darcy porous-media flow according to the Barree and Conway model: laboratory and numerical-modeling studies. SPE J 17:70–79

Ewing RE, Lazarov RD, Lyons SL et al (1998) Numerical well model for non-Darcy flow through isotropic porous media. Comput Geosci 11

Ergun S (1952) Fluid flow through packed columns. Chem Eng Prog 48:89–94

Chikhi N, Clavier R, Laurent J-P, Fichot F, Quintard M (2016) Pressure drop and average void fraction measurements for two-phase flow through highly permeable porous media. Ann Nucl Energy 94:422–432. https://doi.org/10.1016/j.anucene.2016.04.007

Schmidt W (2004) Influence of multidimensionality and interfacial friction on the coolability of fragmented corium. Institut für Kernenergetik und Energiesysteme (IKE)

Schäfer P, Lohnert G (2006) Boiling experiments for the validation of dryout models used in reactor safety. Nucl Eng Des 236:1511–1519. https://doi.org/10.1016/j.nucengdes.2006.03.046

Subramanian S, Chander S, Ityokumbul MT (1996) Two-phase flow in a flooded-bed filter. Appl Occup Environ Hyg 11:845–848. https://doi.org/10.1080/1047322X.1996.10389979

Miguel AF (1998) Airflow through porous screens: from theory to practical considerations. Energy Build 28:63–69. https://doi.org/10.1016/S0378-7788(97)00065-0

Teitel M, Dvorkin D, Haim Y, Tanny J, Seginer I (2009) Comparison of measured and simulated flow through screens: effects of screen inclination and porosity. Biosyst Eng 104:404–416. https://doi.org/10.1016/j.biosystemseng.2009.07.006

Teitel M (2010) Using computational fluid dynamics simulations to determine pressure drops on woven screens. Biosyst Eng 105:172–179. https://doi.org/10.1016/j.biosystemseng.2009.10.005

Teitel M (2011) On the applicability of the Forchheimer equation in simulating flow through woven screens. Biosyst Eng 109:130–139. https://doi.org/10.1016/j.biosystemseng.2011.02.009

Arya S, Wedding WC, Novak T, et al (2017) Pressure drop measurement across flooded-bed scrubber screen and demister in a laboratory setup for its use in a longwall shearer. In: Proceedings of 16h US mine Ventilation Symposium. Golden, CO, pp 15–1

TSI Airflow Instruments Ltd (2014) Traversing a duct to determine average air velocity or volume (Application note AF-106-A4)

Emori RI, Schuring DJ (1977) Scale models in engineering: fundamentals and applications. Pergamon Press, Oxford

Penmetsa SS (2004) Scale modeling of aluminum melting furnace. University of Kentucky, Lexington

Saito K (2008) Progress in scale modeling: summary of the first International Symposium on Scale Modeling (ISSM I in 1988) and selected papers from subsequent Symposia (ISSM II in 1997 through ISSM V in 2006). Springer Netherlands

Saito K, Ito A, Nakamura Y, Kuwana K (2014) Progress in scale modeling, volume II: selections from the International Symposia on Scale Modeling, ISSM VI (2009) and ISSM VII (2013). Springer International Publishing

Aitken R, Vincent J, Mark D, Botham R (1988) Investigations of the feasibility of using aerodynamic models for studying the local build – up of methane gas and risk of frictional ignition in mines. Final report on CEC Contract 7258 – 03/107/08. Edinburgh

Jones A, Lowrie S (1993) Applications of aerodynamic scale model simulations to predicting the accumulation of methane gas and airborne pollutants in modern coal mines. Final report on CEC research contract 7262/32/229/08. Edinburgh

Jones A, Lowrie S (1995) Construction and validation of models for a study of the circulation of gas in the waste of French longwall retreat coalfaces. Edinburgh

Wala AM, Stoltz JR, Jacob Lexington, Kentucky (USA). Department of Mining Engineering] JD [University of K (2001) Numerical and experimental study of a mine face ventilation system for CFD code validation. EMAG, Research and Development Center for Electrical Engineering and Automation in Mining, Katowice (Poland), Poland

Gangrade V, Harteis SP, Addis JD (2017) Development and applications of a scaled aerodynamic model for simulations of airflows in a longwall panel. In: Brune JF (ed) 16th North American Mine Ventilation Symposium. Golden, CO, pp 6/17–6/24

Gangrade V, Schatzel SJ, Harteis SP, Addis JD (2019) Investigating the impact of caving on longwall mine ventilation using scaled physical modeling. Mining, Metall Explor. https://doi.org/10.1007/s42461-019-0065-7

Kumar AR, Arya S, Wedding WC, Novak T (2017) Examination of capture efficacies of a shearer mounted flooded-bed dust scrubber using experiments and computational fluid dynamics (CFD) modeling on a reduced scaled model. In: Brune JF (ed) 16th North American Mine Ventilation Symposium. Golden, CO, pp 20/1–20/8

Ajitha SS, Bhargava R, Pan Y, et al (2019) A preliminary experimental investigation of the airflow resistance of an evolving cave in a block/panel cave mine BT - Proceedings of the 11th International Mine Ventilation Congress. In: Chang X (ed) Springer Singapore, Singapore, pp 70–81

Pan Y, Bhargava R, Jha A, et al (2019) An investigation of the effects of particle size, porosity, and cave size on the airflow resistance of a block/panel cave BT - Proceedings of the 11th International Mine Ventilation Congress. In: Chang X (ed) Springer Singapore, Singapore, pp 82–91

Fig MK, Bogin GE, Brune JF, Grubb JW (2016) Experimental and numerical investigation of methane ignition and flame propagation in cylindrical tubes ranging from 5 to 71 cm – part I: effects of scaling from laboratory to large-scale field studies. J Loss Prev Process Ind 41:241–251. https://doi.org/10.1016/j.jlp.2016.03.018

Juganda A, Brune J, Bogin G (2019) Incorporating ventilation network simulation into CFD modeling to analyze airflow distribution around longwall panels BT - Proceedings of the 11th International Mine Ventilation Congress. In: Chang X (ed) Springer Singapore, Singapore, pp 863–875

Gad-el-Hak M, Bandyopadhyay PR (1994) Reynolds number effects in wall-bounded turbulent flows. Appl Mech Rev 47:307–365

Acknowledgments

We want to thank personnel from Joy Global, Inc., and the Tunnel Ridge Longwall Mine (Alliance Coal, LLC) for their guidance.

Funding

Funding for this research was provided by the Alpha Foundation for the Improvement of Mine Safety and Health, Inc. (grant number AFC113-10).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that there is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Arya, S., Novak, T., Saito, K. et al. Empirical Formulae for Determining Pressure Drop Across a 20-Layer Flooded-Bed Scrubber Screen. Mining, Metallurgy & Exploration 36, 1169–1177 (2019). https://doi.org/10.1007/s42461-019-0091-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42461-019-0091-5