Abstract

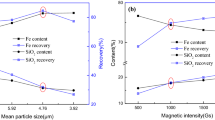

The ever-increasing demand for steel and the subsequent depletion of high-grade ores requires the massive utilization of low-grade iron ores. In the present study, an iron ore slime sample containing 56.1% Fe was investigated using physical beneficiation, carbothermal reduction, and a microwave-assisted process; however, physical beneficiation and microwave exposure were found to be inefficient as they yielded lower iron recovery. Using coconut shell as an alternative reductant was found to be promising and does not lead to the formation of higher iron oxides, such as fayalite and wustite phases. The microwave-assisted carbothermal reduction was found at par with conventional reduction, saving time and heating. The optimum magnetic concentrate obtained in both carbothermal reduction routes (microwave and muffle furnace: Fe grade, Fe recovery, and yield of 64.3, 97, and 84%, and 67, 99, and 83%, respectively) are suitable for alternative iron-making or blast furnace units.

Similar content being viewed by others

References

IBM, Indian Bureau of Mines, Indian Minerals Yearbook 2017 (Part- III: Mineral Reviews) 56th edition IRON ORE

Rajshekar Y, Alex TC, Sahoo DP, Babu GA, Balakrishnan V, Venugopalan T, Kumar S (2016) Iron ore slime as an alternate coolant in steelmaking: performance evaluation at commercial scale. J Clean Prod 139:886–893

Srivastava MP, Pan SK, Prasad N, Mishra BK (2001) Characterization and processing of iron ore fines of Kiriburu deposit of India. Int J Miner Process 61:93–107

Dixit P, Tiwari R, Mukherjee AK, Banerjee PK (2015) Aplication of response surface methodology for modeling and optimization of the spiral separator for processing of iron ore slime. Powder Technol 275:105–112

Singh S, Sahoo H, Rath SS, Sahu AK, Das B (2015) Recovery of iron minerals from Indian iron ore slimes using a colloidal magnetic coating. Powder Technol 269:38–45

Rath SS, Rao DS, Tripathy A, Biswal SK (2018) Biomass briquette as an alternative reductant for low-grade iron ore resources. Biomass Bioenergy 108:447–454

Yu J, Han Y, Li Y, Gao P (2017) Beneficiation of an iron ore fine by magnetization roasting and magnetic separation. Int J Miner Process 68:102–108

Kumar R, Mandre NR (2017) Recovery of iron from iron ore slimes by selective flocculation. J South Afr Inst Min Metall 117:397–400

Jain V, Tammishetti V, Joshi K, Kumar D, Rai B (2017) Guar gum as a selective flocculant for the beneficiation of alumina-rich iron ore slimes: density functional theory and experimental studies. Miner Eng 109:144–152

Pattanaik A, Rayasam V (2018) Analysis of reverse cationic iron ore fines flotation using RSM-D-optimal design–an approach towards sustainability. Adv Powder Technol. https://doi.org/10.1016/j.apt.2018.09.021

Rath SS, Dhawan N, Rao DS, Das B, Mishra BK (2016) Beneficiation studies of a difficult to treat iron ore using conventional and microwave roasting. Powder Technol 301:1016–1024

Rath SS, Rao DS (2017) Dolochar as a reductant in the reduction roasting of iron ore slimes. Int J Miner Metall Mater 24(12):1341–1351

Yu J, Han Y, Li Y, Gao P (2017) Beneficiation of an iron ore fine by magnetization roasting and magnetic separation. Int J Miner Process 168:102–108

Rath SS, Rao DS, Mishra BK (2016) A novel approach for reduction roasting of iron ore slime using cow dung. Int J Miner Process 157:216–226

Rayapudi V, Agrawal S, Dhawan N (2019) Optimization of microwave carbothermal reduction for processing of banded hematite jasper ore. Miner Eng 138(9):204–214

Rayapudi V, Agrawal S, Dhawan N (2019) Investigation of microwave exposure on beneficiation of low grade banded iron ore. Miner Metall Proc 36(2):327–334

Hu M, Wei R, Hu M, Wen L, Ying F (2018) Non-isothermal Carbothermal reduction kinetics of titanium-bearing blast furnace slag. JOM 70:1443–1448

Acknowledgments

The authors would like to thank and acknowledge the funding agency Science Engineering Research Board (SERB) for providing early career research (ECR) funds.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sunil, S.R., Rayapudi, V. & Dhawan, N. Recovery of Iron Values from Discarded Iron Ore Slimes. Mining, Metallurgy & Exploration 37, 287–295 (2020). https://doi.org/10.1007/s42461-019-00119-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42461-019-00119-2