Abstract

The impact of roads on the socioeconomic development and progress of any country cannot be quantified. A geotechnical investigation of subsoils along Isinbode–Ara road, stretching in southeastern to northwestern direction of 7 km distance within Ekiti State, Southwestern Nigeria, was carried out. This investigation follows the British Standard Institution, such as moisture content, particle size distribution, specific gravity, Atterberg limit, compaction, consolidation and California bearing ratio. Results of investigation showed that the moisture content, specific gravity, liquid limit, plastic limits and plasticity index ranged from 7.2–25.9%; 2.64–2.77; 24.0–61.1%; 19.2–26.2% to 4.35–38.90%, respectively. Grain size distribution showed the fine and coarser fractions range from 13.0–66.5% to 32.6–84.8%, respectively. The maximum dry density and its optimum moisture content ranged from 1.48–2.07 g/cm3 to 11.3–30.3%, respectively. Soaked CBR results ranged from 3 to 44%. Two classes of subsoils, namely A-2-4 and A-2-6 (granular materials) and A-6 and A-7-6 (clayey soils), were identified and rendered suitable and unsuitable road construction materials, respectively. This investigation revealed that the subsoils are poor road construction materials due to its fine fractions and plasticities, which should be put into consideration during its foundation design and construction stages.

Similar content being viewed by others

1 Introduction

Road network plays a vital role in the socioeconomic development and progress of many nations; this aids the linkage of all enterprises/markets and leads to employment creation, driving trades and equal wealth distribution. Road transport generally dictates the distribution of economic practices across the world. Records showing loss of several lives and properties abound resulting from road accidents [1, 2]. Foundation soils and highway pavements are inseparable duo toward the development of any country [3]. Several road failure features are noticeable within a short period of time after its commissioning.

Roads are actually constructed on geological materials (rocks or soils), and these materials’ properties influence their performances as transport medium. Subgrade, subbase, base course and riding surfaces are the major components of several typical flexible highway pavements from the base to the top [4, 5]. Most often loss of lives and properties has been associated to the ill-design and weak construction activities relative to non-compliance with relevant standard measures and recommendations. However, road failures are usually preceded by the following destructive signs such as cracking, rutting, potholes, differential heave, deformation and peeling [6,7,8,9,10]. Many causative factors attributed to the increasingly recorded road failures include geological, geomorphological and geotechnical factors, road usage, design and construction inadequacies, and maintenances [11,12,13,14,15,16,17,18]. Climatic factors particularly temperature fluctuations and acid rain attacks have been adjudged to reduce the strength of the road base materials. Gidigasu [19] and Graham and Shields [20] identified inadequate width and composition of the road shoulders as other causative factors that lead to road failures. Notably, widespread pavement failures in the Niger Delta region, Southern region of Nigeria, have been attributed to geological and hydrogeological conditions associated with swampy, poor drainage measures and textural properties of the subsoils [14, 21,22,23,24]. Frequencies of pavement failures have also been related to the engineering indices of the subgrade materials and the underlying geology. The engineering behavior of the underlying geology has been reported to have been influenced by their mineral compositions [25, 26]. Poor geotechnical properties of the soils such as low MDD, poor bearing capacity, high compressibility, and high liquid limit, plasticity index OMC and California bearing ratio (CBR) are usually responsible for road failures [25, 27]. These conditions usually lead to pavement failures in the form of surface deformation and cracked pavements. However, the suitability of soils as base course or subbase course and subgrade are in strong relation to the transfer and bearing of axle load which determine the durability, strength and life of roads [28, 29]. Geotechnical investigation of subsoils helps in the understanding of soil’s behavior that can cause significant damage to road construction and also proffers solutions in solving problems associated with both expansive or unexpansive soils [11, 14,15,16,17, 22, 23, 27, 28, 30,31,32,33,34,35,36,37,38,39,40,41,42,43]. Studies have also reiterated the contribution of solely geophysical studies and integration of geophysical and geotechnical studies in the investigation of causative factors for incessant failures of highways in parts of southwestern Nigeria [5, 33, 44,45,46,47,48,49]. In order to avoid the reoccurrence of premature road failure of Isinbode–Ara road, geotechnical parameters of the residual subsoils which include the natural moisture content, grain size analysis, Atterberg limits, California bearing ratio, consolidation and permeability tests have been investigated to determine their behavior when subjected to loads. Recommendation of suitable materials in in situ or otherwise, deduction of swelling and shrinkage potential of the subsoils and comparison of results with standards were also undertaken.

2 Location, geomorphology and geology of the study area

The study area (Fig. 1) lies within latitude 7°40′54.8328″ and 7°43′3.7092″ North of the Equator and Longitude 5°35′33.2988″ and 5°37′39.3672″ East of Greenwich Meridian. The area enjoys tropical climate with high rainfall of up to 1600 mm, temperature ranges (21–28 °C), and mean monthly relative humidity is less than 70% with thick rain forest vegetation. It is characterized by two distinct seasons [the rainy season (April–October) and dry season (November–March)]. The road site is a 7-km-long stretch in a southeastern to northwestern direction, from Isinbode Garage to the North of Ikole Ekiti. The site is undulating with an uneven topography and daily accessed by motorcycles and cars conveying commuters as well as farm produces. The study area is also underlain by the Precambrian rocks (undifferentiated migmatitic rocks) of the Basement Complex of Southwestern Nigeria [50] (Fig. 1). The Basement rocks are concealed in places with the development of residual soils (engineering soils) of variable thickness on these basement rocks. The migmatitic derived soils are generally lateritic silty clayey sand [5].

Geological map of Ekiti State showing Isinbode–Ara road alignment [51]

3 Materials and methods

The methodology adopted for this study includes reconnaissance survey, site works (disturbed and undisturbed soil samples collection), laboratory tests and interpretation of results. The reconnaissance survey involved a detailed geological field mapping in order to ascertain the local geology of the area, as well as identify failed and stable sections of the road under study. During this survey, observation and description of rock and soil in the area were undertaken. A total of eighteen (18) bulk samples from the subgrade soils were collected from sixteen trial pits and two borrow pits. Disturbed soil samples were collected along the road alignment at 450 m intervals. This was achieved by excavation of trial pits up to depth of 1.0 m. The undisturbed soil samples were collected at 1.75 m interval along the road alignment with the aid of a core cutter, through excavation of trial pits to 1 m depth. Soil samples were also collected off the road alignment at two nearby borrow pits. The collected soil samples were subjected to two classes of laboratory tests, which include: soil classification tests (moisture content, Atterberg limits, specific gravity and particle size distribution) and soil strength tests (standard proctor compaction tests, California bearing ratio (CBR), consolidation, permeability and in situ density). These analyses were carried out in accordance with [52, 53].

4 Results and discussion

4.1 Index properties

The results of index tests on the soil samples are summarized in Table 1. The natural moisture content of the analyzed soil samples varied from 7.2 to 25.9% (Table 1). All the soils have high natural moisture content, because these values are higher than the average range (5–15%) specified by FMWH [54] for engineering construction. This indicates high water adsorption capability of the soil materials. Values in this range have been showed to result in decrease in the shear strength of these road construction materials [27]. Hence, they are not suitable as subgrade, subbase and base materials. High variation in the moisture content causes large volume changes in the clayey soils [49]. The moisture content ranges from favorable, marginal favorable to unfavorable road construction materials in relation to the work of [55]. The specific gravity of the soils ranged from 2.64 to 2.77 (Table 1). These values conformed to those generally obtained for residual soils within the basement complex of Nigeria [34]. The soils have been classified as inorganic soils [56].

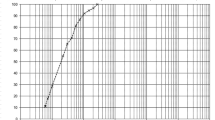

Grain analysis determines the particle distribution of the studied soils. The fine fraction ranged from 13.0 to 66.5%, and the coarse fraction ranged from 32.6 to 84.8% (Table 1 and Fig. 2). Standard specification by Federal Ministry of Works and Housing [54] requires subgrade soils to possess less than 35% amount of fines. A comparison of the obtained results with FMWH [54] specification indicates that thirteen soil samples did not conform to the specification. This suggest that the soils are prone to repeated shrinkage and swelling abilities during alternate dry and wet seasons typified of the climatic conditions of the study area. High amount of the fine grains had been related to abundance of clay content which makes them mechanically unstable. Therefore, they are unsuitable for subgrade, subbase and base road construction materials [27].

Atterberg limits estimates the strength and settlement characteristics of soils for road construction [57, 58]. The liquid limit, plastic limit and plasticity index results of the soils ranged from 24.0–61.1%, 19.2–26.2% to 4.35–38.90%, respectively. All these soils possess the ability to cause significant deformation under load due to their plastic natures. However, only nine soil samples are within [54] specified maximum liquid limit of 50% making them suitable for subgrade, sub-base and base road materials and maximum plasticity index of 20% for highway subgrade materials, while other soil samples are above the maximum standard limit rendering them unsuitable for subgrade materials.

The Casagrande’s plasticity chart (Fig. 3) containing the A-line plays a major role in the classification [59]. The studied soil samples are then classified into CL, CI and CH based on the following three soil characteristics: particle size distribution, liquid limit and plasticity index. Four samples fall within the low plasticity (CL), ten falls within the medium plasticity (CI), and three falls within the high plasticity (CH) categories in the Casagrande’s chart.

Clay “activity” of soil is obtained by combining Atterberg limits and clay content into a single parameter [60]. The results of plasticity index and percentage clay sized fraction were used to calculate the activity in order to determine the measure of the degree of likelihood of exhibiting colloidal behavior (Table 1). This relates the mineralogy and geologic history of clays present in the soils. The properties of clay soils are determined fundamentally by the physicochemical characteristics of the various constituent minerals and by the relative proportions in which the minerals are present. Activity less than 1 corresponds to kaolinite, while activity between 1 and 2 corresponds to illite and greater than 2 corresponds to montmorillonite, and activity values less than 0.75 represent the mineral is inactive, 0.75–1.25 is normal, and greater than 1.25 is active [60]. The clay activity of the soils under investigation ranged from 0.41 to 0.63 (Figs. 4, 5). This indicates that the predominant clay mineral present in the soils is kaolinite, which is inactive and has low moisture affinity and inter-layer spacing of 7A′.

The linear shrinkage of the soils varied from 7.7 to 14.4% (Table 1). Almost all the soil samples except for three (3) soils (Ch0+900, Ch0+600 and Ch0+850) have values greater than [15, 61] recommendation, which require 8% maximum to be suitable as sub grade materials. This consideration suggests that the soils would be subjected to swelling and shrinkage during alternate dry and wet seasons typical of tropical climatic condition of the study area. The linear shrinkage result correlates with results obtained from grain size analysis; hence, the soil samples are not suitable for both highway subbase and subgrade material. Only two soils satisfy the specification as subsoil materials that are suitable for road construction. The soils that are susceptible to swelling and shrinkage can be modified by stabilization processes to establish desire properties for road construction.

AASHTO [62] classification system is based on the plasticity index, particle sizes and liquid limit. According to the classification, soils with less than 35% pass through the No. 200 sieve are classified under groups A-1 to A-3, typically clayey soils. While soils with more than 35% pass through the No. 200 sieve are classified under groups A-4 to A-7, typically granular soils. Group index is the parameter that gives an indication of the load carrying capacity within AASHTO soil group. Resulting increase in the group index will cause decrease in the load carrying capacity. Based on the obtained results, the soils are classified as A-2-4 (0–4), A-2-6 and A-6, A-7-6 (6.5–24.5) (Table 1). The clayey soils are classified as fair to poor road materials, while the granular materials are classified as excellent or good road construction materials.

4.2 Soil strength properties

The strength properties of subsoils for road construction are controlled or dictated by the soil’s resistance to distress under load application as determined by compaction, CBR and consolidation tests, and their results are summarized in Tables 2 and 3.

The in situ density for the soils ranged from 17.14 to 18.27 (Table 3) with Ch0+5250 and Ch0+7000; Ch0+1750 and Ch0+3000 falling under fair and poor suitability categories, respectively, as road construction materials.

The coefficient of permeability for the soils ranged from 1.58 × 10−3 to 9.89 × 10−7, and it can be classified into practically impermeable, medium permeable to low permeability which make the soils suitable as road materials for construction purposes [63]. However, when these soils come in contact with water, the soils will retain water and lead to the rapid weakened due to poor drainage and exposure to the surface [5].

Compaction of soils for road construction required the attainment of a high degree of densification in order to prevent detrimental consolidation that will arise from traffic load. The typical compaction curve of the maximum dry density and optimum moisture content of the lateritic soils at the West African level of compaction are shown in Table 2 and Fig. 6, respectively. The maximum dry density (MDD) of the soils in the study area ranged from 1480 to 2070 kg/cm3 at optimum moisture content (OMC) of 11.3–30.3% (Table 3). Nine samples have MDD values above the maximum 1700 kg/cm3 as specified by [64]. Therefore, the residual soils have low bearing capacities and cannot ultimately serve as construction barriers except if well compacted and stabilized to reduce voids, to increase the strength and reduce its permeability. This trend totally agrees with the in situ density determined which ranged from poor to fair. These values show that, the soils respond gradually to compaction. However, the best soil for foundation is the soil with highest maximum dry density (MDD) at lowest optimum moisture content (OMC) [15]. The compaction suggests that the foundation of pavement structures must always be compacted above the MDD and OMC values to yield the maximum strength, prevent ingress of water and distribute wheel loads uniformly into the pavement structures.

California bearing ratio is a test often employed in the evaluation of soil strength in subgrade, subbase and base course materials for footpath, road and airfield pavement design [5, 36, 65]. The results of soaked CBR of the soils ranged from 3 to 44% (Table 2, Fig. 7a, b). Only five of the analyzed soil samples have the required 30% soaked CBR value recommended for highway subbase, subgrade soils and base materials by [54, 66]. The CBR values of the study area are generally low, requiring that the soils should be subjected to soil improvement strategies in order to acquire the necessary strength for road construction materials. Samples with the following chainages (Ch0+000, Ch0+450, Ch0+900, Ch1+350, Ch2+250, Ch3+150, Ch3+600, Ch4+950, Ch5+400, Ch5+850 and borrow pits) with CBR values less than 10% are posed to be of excellent subgrade materials, while locations with the following chainages (Ch0+000, Ch0+450, Ch0+900, Ch1+350, Ch2+250, Ch3+150, Ch3+600, Ch4+050, Ch4+950, Ch5+400, Ch5+850 and the burrow pits) are posed to be good subbase materials, while all the soil samples can serve as base materials because their CBR values fall lower 80% (Fig. 8).

The consolidation analysis reveals that Ch0+5250 and Ch0+7000 have coefficient of volume compressibility falling within medium degree of compressibility category according to [67]. The other subsoils fall within high degree of compressibility. Only Ch0+5250 has settlement value lower than 1, while Ch0+1750, Ch0+3500 and Ch0+7000 have settlement values greater than 1 indication potential to settle. Soils with settlement rates greater than 1 mm/year show that high settlement has no relation to shallow water table. The water table is at deep depth and can therefore not contribute to any settlement of the subsoil. The cause of the high settlement values is possibly related to the deep weathering of locally enriched zones of feldspars in the original parent rocks, which has also been shown elsewhere with related geology [68].

5 Conclusion and recommendations

The subsoil investigation of Isinbode–Ara road has been undertaken. The result revealed that the soil samples are essentially granular and clayey soils, incompressible, easily compacted with good drainage. The soil samples indicate a general cohesive nature with variable high moisture content due to hydrological and climatic conditions of the study area. This geotechnical investigation also revealed that the subsoils are poor road construction materials, but its strength can be improved when subjected to stabilization measures as indicated from the strength tests (compaction, California bearing ratios and consolidation tests). This should be put into consideration during the Isinbode–Ara road foundation design and construction.

References

Ajaero C (2009) “Roads to Hell” in Sunday Newswatch, 20th December 2009, p 10

Ebuzoeme OD (2015) Evaluating the significance of poor road design as a factor of road failure: a study of Onitsha–Enugu Expressway, Southeastern Nigeria. Civ Environ Res 7(2):180–195

Meshida EA (2006) Highway failure over talc–tremolite schist terrain: a case study of the Ife to Ilesha Highway, Southwestern Nigeria. Bull Eng Geol Environ 65:457–461. https://doi.org/10.1007/s10064-005-0037-7

Gupta BL, Gupta A (2003) Roads, railways, bridges, tunnel and harbor dock engineering, 5th edn. Standard Publishers Distributors, Nai Sarak, New Delhi

Adeyemi GO (2013) Engineering geology: the Big Heart for structures and their environment. An Inaugural Lecture 2012/2013 University of Ibadan 21 February, 2013. Ibadan University Press, Publishing House University of Ibadan, Ibadan, p 91

Gidigasu MD (1976) Laterite soil engineering. Elsevier, Amsterdam, p 554

Alexander WS, Maxwell J (1996) Controlling shrinkage cracking from expansive clay sub-grade. In: Francken LB, Molenaar AA (eds) Reflective cracking in pavements, 2nd edn. E&FN Spon, London, pp 64–71

Jain SS, Kumar P (1998) Report on causes of cracks occurrence in Ramghat–Aligarh road in UP. Report submitted to PWD, Aligarh

Abam TKS, Osadebe CC, Omange GN (2005) Influence of geology on pavement performance: a case study of Shagamu–Benin road. Glob J Geol Sci 3(1):17–24

Adlinge SS, Gupta AK (2010) Pavement deterioration and its cause. J Mech Civ Eng 2(4):9–15

Adegoke–Anthony WC, Agada OA (1980) Geotechnical characteristics of some residual soils and their implications on road design in Nigeria. Technical Lecture. Lagos, Nigeria pp 1–16

Mesida EA (1981) Laterite on the highways—understanding soil behaviour. West Afr Tech Rev 112–118

Ajayi LA (1987) Thought on road failures in Nigeria. Niger Eng 22(1):10–17

Arumalu SO, Akpokodje EG (1987) Soil properties and pavement performances in the Niger Delta. Q J Eng Geol 20(4):287–296

Jegede OG (2004) Highway pavement failure induced by poor geotechnical properties at a section along the F209 Okitipupa-Igbokoda highway, Southwest Nigeria. Ife J Sci 6(1):41–44

Osadebe CC, Omange GN (2005) Soil properties and pavement performance in the Nigerian rainforest; a case study of Shagamu–Benin road, Southwestern Nigeria. Ife J Sci 7(1):119–122

Oke SA, Amadi AN, Abalaka AE, Nwosu JE, Ajibade SA (2009) Index and compaction properties of laterite deposits for road construction in Minna Area, Nigeria. Niger J Constr Tech Man 10(1–2):28–35

Nwankwoala HO, Amadi AN, Ushie FA, Warmate T (2014) Determination of subsurface geotechnical properties for foundation design and construction in Akenfa Community, Bayelsa, Nigeria. Am J Civ Eng Archit 2(4):130–135

Gidigasu MD (1983) Development of acceptance specifications for tropical gravel paving materials. Eng Geol 19:213–240

Graham J, Shields DH (1984) Influence of geology and geological processes on the geotechnical properties of a plastic clay. J Eng Geol 22(2):109–126

James AN, Edworthy KJ (1985) The effect of water interaction on engineering structures. Hydrol Sci J 30(3):395–406

Akpokodje EG (1986) The geotechnical properties of lateritic and non-lateritic soils of southeastern Nigeria and their evaluation for road construction. Bull Eng Geol Environ 33(1):115–121

Jegede G (1997) Highway pavement failure induced by soil properties along the F209 highway at Omuoke, southwestern Nigeria. Niger J, Sci

Abam TKS, Ofoegbu CO, Osadebe CC, Gobo AE (2000) Impact of hydrology on the PortHarcourt–Patani-Warri road. J Environ Geol 40(1–2):153–162

Akpan O (2005) Relationship between road pavement failures, engineering indices and underlying geology in a tropical environment. Glob J Geol Sci 3(2):99–108

Amadi AN, Eze CJ, Igwe CO, Okunlola IA, Okoye NO (2012) Architect’s and Geologist’s view on the causes of building failures in Nigeria. Mod Appl Sci 6(6):31–38

Ademilua O (2018) Geotechnical characterization of subgrade soils in Southwestern Part of Nigeria. In: Proceedings of first and second international conferences of the Nigerian Association of Engineering Geology and the Environment, Lagos, Nigeria, vol 1, pp 42–48

Jegede OG, Olaleye BM (2013) Evaluation of engineering geologic and geotechnical properties of subgrade soils along re-alligned Igbara-Ikogosi Highway, South-west Nigeria. Int J Eng Sci 2(5):18–21

Nwankwoala HO, Amadi AN (2013) Geotechnical investigation of sub-soil and rock characteristics in parts of Shiroro–Muya–Chanchaga Area of Niger State, Nigeria. Int J Earth Sci Eng 6(1):8–17

Adeyemi GO (1992) Highway geotechnical properties of laterised residual soils in the Ajebo–Ishara geological transition zone of southwestern Nigeria. Unpublished Ph.D. thesis, Obafemi Awolowo University, Ile Ife Nigeria

Adeyemi GO (1994) Clay mineralogy, major elements geochemistry and strength characteristics of three highway subgrade soils in southwestern Nigeria. Bull Eng Geol Environ 50:5–8

Adeyemi GO, Owoyemi F (1998) Geotechnical basis for failure of sections of the Lagos–Ibadan Expressway, Southwestern Nigeria. Bull Eng Geol Environ 39:39–45

Olayinka AI, Oyedele AA (2001) Geoelectric survey in site investigation of locations along the proposed Ibadan–Ilorin dual carriage way. J Min Geol 37:165–175

Jegede G (1998) Effects of some engineering and geological factors on highway failures in parts of Southwestern Nigeria. Unpublished Ph.D. thesis, Federal University of Technology, Akure, p 251

Adeyemi GO, Abolurin SB (2000) Strength characteristics of a chemically stabilized lateritic soil from Kilometer 4, Ile-Ife/Sekona road, southwestern Nigeria. J Min Geol 36(1):113–119

Adeyemi GO (2002) Geotechnical properties of lateritic soil developed over quartz schist in Ishara Area Southwestern Nigeria. J Min Geol 38(1):65–69

Abubakar JB (2006) Geotechnical study of lateritic soil in Tipper garage, Katampe Area, Abuja Federal Capital Territory, pp 4–34

Oke SA, Amadi AN (2008) An assessment of the geotechnical properties of the subsoil of parts of Federal University of Technology, Minna, Gidan Kwano Campus, for foundation design and construction. J Sci Educ Technol 1(2):87–102

Aghamelu OP, Okogbue CO (2011) Geotechnical assessment of road failures in Abakaliki area, South-East Nigeria. Int J Civ Environ Eng 11(2):22–24

Osadebe CO, Salami BM, Obrike SE, Ajala MO (2011) The Kano-Kazaure highway, north central Nigeria: the significance of the engineering geology in construction. Bull Eng Geol Enivron 70:33–40

Amadi AN, Akande WG, Okunlola IA, Jimoh MO, Francis-Deborah G (2015) Assessment of the geotechnical properties of lateritic soils in Minna, North Central Nigeria for road design and construction. Am J Min Metall 3(1):15–20. https://doi.org/10.1269/ajmm-3-1-3

Daramola SO, Malomo S, Asiwaju-Bello YA (2015) Engineering geology of failed sections of Isua–Idoani road Southwestern Nigeria. J Environ Earth Sci 5(19):38–45

Owoyemi OO, Adeyemi GO (2017) Variability in the highway geotechnical properties of two residual lateritic soils from Central Nigeria. J Geol Geophys 6:290. https://doi.org/10.4172/2381-8719.1000290

Loke MH (1999) Electrical imaging surveys for environmental and engineering studies. Minden Heights, 11700 Penang, Malaysia, p 57

Momoh LO, Akintorinwa O, Olorunfemi MO (2008) Geophysical Investigation of highway failure—a case study from the basement complex terrain of Southwestern Nigeria. J Appl Sci Res 4(6):637–648

Adiat KAN, Adelusi AO, Ayuk MA (2009) Relevance of geophysics in road failures investigation in a typical basement complex of South Western Nigeria. Pac J Sci Technol 5(1):528–539

Salami BM, Falebita DE, Fatoba OJ, Ajala MO (2012) Integrated geophysical and geotechnical investigation of a bridge site—a case study of swamp/creek environment in SE Lagos, Nigeria. Ife J Sci 14(1):75–82

Akinlalu AA (2017) Integrated geophysical investigation for pavement failure along a dual carriageway, Southwestern Nigeria a case study. Kuwait J Sci 44(4):135–149

Daramola SO, Malomo S, Asiwaju-Bello YA (2018) Premature failure of a major highway in Southwestern Nigeria. The case of Ipele–Isua highway. Int J Geo-Eng 9:1–12

Rahaman MA (1988) Recent advances in the study of the basement complex of Nigeria. In: Precambrian geology of Nigeria. Geological Survey of Nigeria Publication, Kaduna, pp 11–43

Nigerian Geologic Survey Agency (NGSA) (2006) Geological map of Nigeria. www.ngsa.gov.ng/GeoMaps

British Standard (BS) 1377 (1990) Methods of testing soils for civil engineering purposes. British Standards Institution, London

British Standard Institute (BSI) 5930 (1990) Code of practice for site investigation. London, p 148

Federal Ministry of Works and Housing (FMWH) (2010) General specification of roads and bridges 2:137–275

Underwood LB (1967) Classification and identification of shales. J Soil Mech Found 93(11):97–116

Ramamurthy TN, Sitharam TG (2005) Geotechnical engineering. S. Chand, New Delhi, p 28

Sowers GM, Sowers GE (1970) Introductory soil mechanics and foundations. Macmillan, New York, p 556

Adeyemi GO (1995) The influence of parent rock factor on some engineering index properties of three residual lateritic soils in southwestern Nigeria. Bull Eng Geol Environ 52:3–8

Casagrande A (1947) Classification and identification of soils. American Society of Engineers, Reston, pp 783–811

Skempton AW (1953) The colloidal “activity” of clays. In: Proceedings of 3rd international conference of soil mechanics, Zurich, pp 57–61

Madedor AO (1983) Pavement design guidelines and practice for different geological areas in Nigeria. In: Ola SA (ed) Tropical soils of Nigeria in engineering practices. Balkena Publishers, Rotterdam, pp 291–298

AASHTO (1993) Standard specification for transportation materials and methods of sampling and testing, 14th edn. American Association of State Highway and Transportation Officials, Washington, DC

Lambe TW (1951) Soil testing for engineers. Wiley, New York, p 165

Federal Ministry of Works and Housing (FMWH) (1997) General specification for roads and bridges, vol II. Federal Highway Department Lagos, Abuja, p 317

Wignall A, Kendrick PS, Ancil R, Capson M (1999) Roadwork; theory and practice, 4th edn. Butterworth-Heinemann, Oxford, p 309

Ashworth GB, Overgaard RT (1996) Highway planning methods. In: Thagesan B (ed) Highway and Traffic engineering in developing countries. Chapman and Hall, London, 593 p

Bell FG (2007) Engineering geology, 2nd edn. Butterworth-Heinemann Publishers, Oxford, p 581

Asiwaju-Bello YA, Odeyemi IB, Akintorinwa OJ, Oladeji J, Imolore M, Alabi S, Olabode OF, Ojo JB (2015) Unpublished report on Geotechnical and Geophysical investigations of proposed new School of Agriculture and Agricultural Technology Building site, Federal University of Technology, Akure Campus, p 168

Acknowledgements

The authors would like to appreciate the staff of Tripple O Geotechnical Consults for the collection of the soil samples and Mr. Samuel Alabi of Engineering Geological Laboratory of the Applied Geology Department with the carrying out of the geotechnical tests in the laboratory.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Olofinyo, O.O., Olabode, O.F. & Fatoyinbo, I.O. Engineering properties of residual soils in part of Southwestern Nigeria: implication for road foundation. SN Appl. Sci. 1, 507 (2019). https://doi.org/10.1007/s42452-019-0515-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-019-0515-3