Abstract

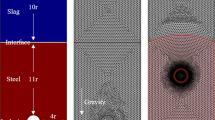

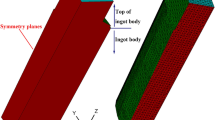

A boundary layer model was developed to predict the capture of inclusions by steel–slag interface in a turbulent fluid flow, which is based on the detailed analysis of inclusion trajectories. The effective boundary layer for inclusion removal was proposed by a statistical method. It is noticed that the capture of inclusions by steel–slag interface is not only dependent on the diameter of inclusions but also related to the local turbulent conditions. In high turbulent flow fields, the transport of inclusions is mainly dominated by the turbulent flow, and thus, the effective boundary layer thickness is mainly affected by the level of turbulent kinetic energy and is almost independent of the inclusion diameter. The inertia of inclusions gradually takes over the stochastic effect of turbulent flow, and the effect of inclusion diameter on effective boundary layer thickness becomes more noticeable with the decrease in the level of turbulent kinetic energy. Besides, the effective boundary layer thickness is more susceptible to the inclusion diameter for larger inclusions due to its greater inertia under the same turbulent condition while it principally depends on the level of turbulent kinetic energy for smaller inclusions. As the characteristic velocity increases, the time for inclusions transport and interaction with steel–slag interface decreases, and thus, the effective boundary layer thickness decreases. Moreover, the graphical user interface was developed by using the cubic spline interpolation for ease of coupling the current boundary layer model with the macro-scale model of the a turbulent fluid flow in the metallurgical vessel.

Similar content being viewed by others

References

L. Zhang, B.G. Thomas, ISIJ Int. 43 (2003) 271–291.

L. Zhang, B.G. Thomas, Metall. Mater. Trans. B 37 (2006) 733–761.

E.A. Chichkarev, Metallurgist 54 (2010) 236–243.

L. Zhang, JOM 65 (2013) 1138–1144.

W. Lou, M. Zhu, ISIJ Int. 54 (2014) 9–18.

G.J. Chen, S. He, Y. Li, Q. Wang, Ind. Eng. Chem. Res. 55 (2016) 7030–7042.

Q. Cao, L. Nastac, Ironmak. Steelmak. 45 (2018) 984–991.

H. Duan, Y. Ren, L. Zhang, JOM 70 (2018) 2128–2138.

H. Duan, L. Zhang, B.G. Thomas, A.N. Conejo, Metall. Mater. Trans. B 49 (2018) 2722–2743.

G. Chen, S. He, JOM 71 (2019) 4206–4214.

H. Duan, Y. Ren, B.G. Thomas, L. Zhang, Metall. Mater. Trans. B 50 (2019) 36–41.

H. Duan, Y. Ren, L. Zhang, Metall. Mater. Trans. B 50 (2019) 16–21.

H. Duan, Y. Ren, L. Zhang, Chem. Eng. Sci. 196 (2019) 14–24.

H. Duan, P.R. Scheller, Y. Ren, L. Zhang, JOM 71 (2019) 69–77.

L. Zhang, Q. Ren, H. Duan, Y. Ren, W. Chen, G. Cheng, W. Yang, S. Sridhar, Miner. Process. Extr. Metall. 129 (2020) 184–206.

J. Wang, L. Zhang, Y. Zhang, Q. Ren, H. Duan, Metall. Mater. Trans. B 52 (2021) 2831–2836.

Z. Hu, H. Duan, L. Zhang, Metall. Mater. Trans. B 53 (2022) 1339–1343.

L. Zhang, S. Taniguchi, K. Cai, Metall. Mater. Trans. B 31 (2000) 253–266.

M. Söder, P. Jönsson, L. Jonsson, Steel Res. Int. 75 (2004) 128–138.

H. Ling, F. Li, L. Zhang, A.N. Conejo, Metall. Mater. Trans. B 47 (2016) 1950–1961.

D.Y. Sheng, M. Söder, P. Jönsson, L. Jonsson, Scand. J. Metall. 31 (2002) 134–147.

L.T. Wang, Q.Y. Zhang, S.H. Peng, Z.B. Li, ISIJ Int. 45 (2005) 331–337.

Y. Kwon, J. Zhang, H. Lee, ISIJ Int. 48 (2008) 891–900.

V. De Felice, I.L.A. Daoud, B. Dussoubs, A. Jardy, J.P. Bellot, ISIJ Int. 52 (2012) 1273–1280.

J.P. Bellot, V. Descotes, A. Jardy, JOM 65 (2013) 1164–1172.

W. Lou, M. Zhu, Metall. Mater. Trans. B 44 (2013) 762–782.

J.P. Bellot, V. De Felice, B. Dussoubs, A. Jardy, S. Hans, Metall. Mater. Trans. B 45 (2014) 13–21.

J. Strandh, K. Nakajima, R. Eriksson, P. Jönsson, ISIJ Int. 45 (2005) 1597–1606.

J. Strandh, K. Nakajima, R. Eriksson, P. Jönsson, ISIJ Int. 45 (2005) 1838–1847.

M. Valdez, K. Prapakorn, A.W. Cramb, S. Seetharaman, Steel Res. 72 (2001) 291–297.

M. Valdez, K. Prapakorn, A.W. Cramb, S. Sridhar, Ironmak. Steelmak. 29 (2002) 47–52.

M. Valdez, G.S. Shannon, S. Sridhar, ISIJ Int. 46 (2006) 450–457.

S. Yang, J. Li, C. Liu, L. Sun, H. Yang, Metall. Mater. Trans. B 45 (2014) 2453–2463.

C. Liu, S. Yang, J. Li, L. Zhu, X. Li, Metall. Mater. Trans. B 47 (2016) 1882–1892.

D. Bouris, G. Bergeles, Metall. Mater. Trans. B 29 (1998) 641–649.

G. Shannon, L. White, S. Sridhar, Mater. Sci. Eng. A 495 (2008) 310–315.

Y. Chung, A.W. Cramb, Metall. Mater. Trans. B 31 (2000) 957–971.

J.C. Cao, Y. Li, W. Lin, J. Che, F. Zhou, Y. Tan, D. Li, J. Dang, C. Chen, Crystals 13 (2023) 202.

C. Chen, P. Ni, L.T.I. Jonsson, A. Tilliander, G. Cheng, P.G. Jönsson, Metall. Mater. Trans. B 47 (2016) 1916–1932.

Acknowledgements

The authors are grateful for support from the National Natural Science Foundation of China (Grant Nos. 51904025 and U22A20171), the Fundamental Research Funds for the Central Universities (Grant No. FRF-IDRY-20-011), National Postdoctoral Program for Innovative Talents (Grant No. BX20190030), and the High Steel Center (HSC) at North China University of Technology and University of Science and Technology Beijing, China.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors have no competing interests to declare that are relevant to the content of this article.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sun, Yp., Duan, Hj. & Zhang, Lf. A boundary layer model for capture of inclusions by steel–slag interface in a turbulent flow. J. Iron Steel Res. Int. 30, 1101–1108 (2023). https://doi.org/10.1007/s42243-023-00957-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-023-00957-x