Abstract

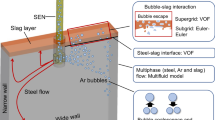

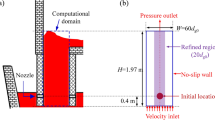

Based on the Eulerian–Lagrangian approach, a mathematical model was established to describe the gas–liquid flow behavior in the Ruhrstahl–Heraeus (RH) degasser. The momentum source and the turbulent kinetic energy source due to the motion of gas bubbles were considered for the liquid flow. The effect of the expansion of gas bubbles on the liquid velocity, recirculation rate, and mixing time was quantitatively evaluated. After the fluid flow reached the steady state, the melting and mixing processes of aluminum alloys in the RH degasser were also investigated. The results indicate that the expansion of gas bubbles has a significant influence on the recirculation rate and the mixing time in the RH process. Increasing the superheat of liquid steel and decreasing the initial diameter of alloy particles are beneficial to promote the melting and mixing of alloy particles. Due to the existence of solidified steel shells, the maximum diameter of the alloy particle is about 1.5 times its initial diameter.

Similar content being viewed by others

References

T. Kuwabara, K. Umezawa, K. Mori, H. Watanabe, Trans. ISIJ 28 (1988) 305–314.

Y. Kato, H. Nakato, T. Fujii, S. Ohmiya, S. Takatori, ISIJ Int. 33 (1993) 1088–1094.

M. Takahashi, H. Matsumoto, T. Saito, ISIJ Int. 35 (1995) 1452–1458.

J.M. Zhang, L. Liu, X.Y. Zhao, S.W. Lei, Q.P. Dong, ISIJ Int. 54 (2014) 1560–1569.

Y.G. Park, W.C. Doo, K.W. Yi, S.B. An, ISIJ Int. 40 (2000) 749–755.

Y.G. Park, K.W. Yi, S.B. Ahn, ISIJ Int. 41 (2001) 403–409.

J.H. Wei, H.T. Hu, Steel Res. Int. 77 (2006) 32–36.

P.A. Kishan, S.K. Dash, ISIJ Int. 49 (2009) 495–504.

H.P. Liu, Z.Y. Qi, M.G. Xu, Steel Res. Int. 82 (2011) 440–458.

H.T. Ling, F. Li, L.F. Zhang, A.N. Conejo, Metall. Mater. Trans. B 47 (2016) 1950–1961.

Y.G. Park, K.W. Yi, ISIJ Int. 43 (2003) 1403–1409.

H.T. Ling, L.F. Zhang, Metall. Mater. Trans. B 49 (2018) 2709–2721.

K. Shirabe, J. Szekely, Trans. ISIJ 23 (1983) 465–474.

Y. Miki, Y. Shimada, B.G. Thomas, A. Denissov, Iron Steelmak. 24 (1997) 31–38.

D.Q. Geng, J.X. Zheng, K. Wang, P. Wang, R.Q. Liang, H.T. Liu, H. Lei, J.C. He, Metall. Mater. Trans. B 46 (2015) 1484–1493.

G.J. Chen, S.P. He, Y.G. Li, Metall. Mater. Trans. B 48 (2017) 2176–2186.

J.J.M. Peixoto, W.V. Gabriel, T.A.S. de Oliveira, C.A. da Silva, I.A. da Silva, V. Seshadri, Metall. Mater. Trans. B 49 (2018) 2421–2434.

L.Y. Zhang, F. Oeters, Steel Res. 70 (1999) 128–134.

H.J. Duan, L.F. Zhang, B.G. Thomas, A.N. Conejo, Metall. Mater. Trans. B 49 (2018) 2722–2743.

B.E. Launder, D.B. Spalding, Lectures in mathematical models of turbulence, Academic Press, England, UK, 1972.

S.A. Morsi, A.J. Alexander, J. Fluid Mech. 55 (1972) 193–208.

M. Sano, K. Mori, Y. Fujita, Tetsu-to-Hagané 65 (1979) 1140–1148.

H. Anglart, O. Nylund, N. Kurul, M.Z. Podowski, Nucl. Eng. Des. 177 (1997) 215–228.

D.A. Drew, R.T. Lahey, Int. J. Multiphas. Flow 13 (1987) 113–121.

H.T. Ling, L.F. Zhang, Metall. Mater. Trans. B 50 (2019) 2017–2028.

S. Whitaker, AIChE J. 18 (1972) 361–371.

L.Y. Zhang, Steel Res. 67 (1996) 466–474.

Acknowledgements

The authors are grateful for support from the Open Fund of Anhui Province Key Laboratory of Metallurgical Engineering & Resources Recycling (Anhui University of Technology) (SKF21-05), the Open Fund of State Key Laboratory of New technology of Iron and Steel Metallurgy (KF21-03), and the National Natural Science Foundation of China (Grant Nos. 51704005 and 51804003).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Hj., Xu, R., Ling, Ht. et al. Numerical simulation of fluid flow and alloy melting in RH process for electrical steels. J. Iron Steel Res. Int. 29, 1423–1433 (2022). https://doi.org/10.1007/s42243-022-00752-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-022-00752-0