Abstract

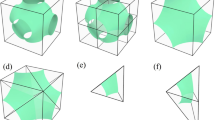

To improve the mechanical properties of Trabecular Beetle Elytron Plates (TBEPs, a type of biomimetic sandwich structure inspired by the beetle elytron) under transverse loads, three-point bending tests are performed to investigate the influence of the trabecular and chamfer radii of the core structure on the mechanical performance of TBEPs manufactured by 3D printing technology. The results show that the three-point bending performance of TBEPs can be improved by setting reasonable trabecular and chamfer radii; however, excessive increases in these radii can cause a decline in the mechanical performance. For the reason, these two structural parameters can enhance the deformation stiffness of the whole structure and the connection property between the core and skin, which is also the mechanical reason why Prosopocoilus inclinatus beetle elytra have thick, short trabeculae with a large chamfer radius. However, when these radii increase to a certain extent, the cracks are ultimately controlled between two adjacent trabeculae, and the failure of the plate is determined by the skin rather than the core structure. Therefore, this study suggests a reasonable range for trabecular and chamfer radii, and indicates that TBEPs are better suited for engineering applications that have high compression requirements and general bending requirements.

Similar content being viewed by others

References

Galehdari S A, Kadkhodayan M, Hadidi-Moud S. Low velocity impact and quasi-static in-plane loading on a graded honeycomb structure; experimental, analytical and numerical study. Aerospace Science and Technology, 2015, 47, 425–433.

Zhao C Q, Ma J, Du S C. The mechanical behaviour of new long-span hollow-core roofs based on aluminum alloy honeycomb panels. Materials and Technology, 2019, 53, 311–318.

Bagaric M, Pecur I B, Milovanovic B. Hygrothermal performance of ventilated prefabricated sandwich wall panel from recycled construction and demolition waste — A case study. Energy and Buildings, 2020, 206, 109573.

Palomba G, Epasto G, Crupi V, Guglielmino E. Single and double-layer honeycomb sandwich panels under impact loading. International Journal of Impact Engineering, 2018, 121, 77–90.

Petrone G, D’Alessandro V, Franco F, De Rosa S. Numerical and experimental investigations on the acoustic power radiated by aluminium foam sandwich panels. Composite Structures, 2014, 118, 170–177.

Yaseer Omar M, Xiang C, Gupta N, Strbik O M, Cho K. Syntactic foam core metal matrix sandwich composite: Compressive properties and strain rate effects. Materials Science and Engineering: A, 2015, 643, 156–168.

Chakravarthy S V, Bilal M. Aluminum foam sandwich with density-graded open-cell core: Compressive and flexural response. Materials Science and Engineering: A, 2018, 731, 220–230.

Sun G Y, Wang E, Wang H X, Xiao Z, Li Q. Low-velocity impact behaviour of sandwich panels with homogeneous and stepwise graded foam cores. Materials & Design, 2018, 160, 1117–1136.

Arunkumar M P, Pitchaimani J, Gangadharan K V. Bending and free vibration analysis of foam-filled truss core sandwich panel. Journal of Sandwich Structures & Materials, 2018, 20, 617–638.

Xu J, Wu Y B, Wang L B, Li J N, Yang Y W, Tian Y L, Gong Z Z, Zhang P L, Nutt S, Yin S. Compressive properties of hollow lattice truss reinforced honeycombs (Honeytubes) by additive manufacturing: Patterning and tube alignment effects. Materials & Design, 2018, 156, 446–457.

Zamanifar H, Sarrami-Foroushani S, Azhari M. Static and dynamic analysis of corrugated-core sandwich plates using finite strip method. Engineering Structures, 2019, 183, 30–51.

Li G, Li Z K, Hao P, Wang Y T, Fang Y C. Failure behavior of hierarchical corrugated sandwich structures with second-order core based on Mindlin plate theory. Journal of Sandwich Structures & Materials, 2019, 21, 552–579.

Ha N S, Lu G X. A review of recent research on bio-inspired structures and materials for energy absorption applications. Composites Part B — Engineering, 2020, 181, 107406.

Smardzewski J, Kramski D. Modelling stiffness of furniture manufactured from honeycomb panels depending on changing climate conditions. Thin-Walled Structures, 2019, 137, 295–302.

Imbalzano G, Tran P, Ngo T D, Lee P V S. Three-dimensional modelling of auxetic sandwich panels for localised impact resistance. Journal of Sandwich Structures & Materials, 2017, 19, 291–316.

Dutra J R, Ribeiro S L M, Christoforo A L, Panzera TH, Scarpa F. Investigations on sustainable honeycomb sandwich panels containing eucalyptus sawdust, Piassava and cement particles. Thin-Walled Structures, 2019, 143, 106191.

Ha N S, Lu G X, Xiang X M. Energy absorption of a bio-inspired honeycomb sandwich panel. Journal of Materials Science, 2019, 54, 6286–6300.

Fratzl P, Weinkamer R. Nature’s hierarchical materials. Progress in Materials Science, 2007, 52, 1263–1334.

Tsang H H, Tse K M, Chan K Y, Lu G X, Lau A K T. Energy absorption of muscle-inspired hierarchical structure: Experimental investigation. Composite Structures, 2019, 226, 111250.

Tao Y, Li W G, Wei Kai, Duan S Y, Wen W B, Chen L M, Pei Y M, Fang D N. Mechanical properties and energy absorption of 3d printed square hierarchical honeycombs under in-plane axial compression. Composites Part B: Engineering, 2019, 176, 107219.

Tsang H H, Raza S. Impact energy absorption of bio-inspired tubular sections with structural hierarchy. Composite Structures, 2018, 195, 199–210.

Bru J, Leite M, Ribeiro A R, Reis L, Deus A M, Vaz M F. Bioinspired structures for core sandwich composites produced by fused deposition modelling. Proceedings of the Institution of Mechanical Engineers Part L-Journal of Materials-Design and Applications, 2020, 234, 379–393.

Matsuka M, Ono M, Kitano H, Gokan N, Matsumoto T. Insects biology. Tamagawa University, Tokyo, Japan, 1992.

Noh M Y, Muthukrishnan S, Kramer K J, Arakane Y. Development and ultrastructure of the rigid dorsal and flexible ventral cuticles of the elytron of the red flour beetle, Tribolium castaneum. Insect Biochemistry and Molecular Biology, 2017, 91, 21–33.

Ren L Q. Initial exploring for mechanism of decreasing resistance and reducing adhesion of the bionic bulldozing plate. Transactions of the Chinese Society of Agricultural Engineering, 1990, 6, 13–20.

Sun J Y, Liu C, Bhushan B. A review of beetle hindwings: Structure, mechanical properties, mechanism and bioinspiration. Journal of the Mechanical Behavior of Biomedical Materials, 2019, 94, 63–73.

Roux-Pertus C, Oliviero E, Véronique R, Frédéric F, Cleymand F. Multiscale characterization of the hierarchical structure of dynastes hercules elytra. Micron, 2017, 101, 16–24.

Le V T, Ha N S, Goo N S. Thermal protective properties of the allomyrina dichotoma beetle forewing for thermal protection systems. Heat Transfer Engineering, 2018, 16, 1–30.

Sun J Y, Wu W, Liu C, Jin T. Investigating the nanomechanical properties and reversible color change properties of the beetle. Dynastes tityus. Journal of Materials Science, 2017, 52, 6150–6160.

Zhang Z, Wu W, Tong J, Sun J Y. Relationship of hydration and nanomechanical characteristics of beetle cuticle. Bioinspired, Biomimetic and Nanobiomaterials, 2017, 6, 1–25.

Dai Z D, Yang Z X. Macro-/micro-structures of elytra, mechanical properties of the biomaterial and the coupling strength between elytra in beetles. Journal of Bionic Engineering, 2010, 7, 6–12.

Chen J X, Ni Q Q. Three dimensional composite structures in the fore-wing of beetles. Acta Materiae Compositae Sinica, 2003, 20, 61–66.

Chen J X, Xu M Y, Okabe Y, Guo Z S, Yu X D. Structural characteristics of the core layer and biomimetic model of the ladybug forewing. Micron, 2017, 101, 156–161.

Chen J X, Ni Q Q, Ken K, Lwamoto M. Failure type of trabecular root and its model analysis in a beetle fore-wing. Transactions of the Japan Society of Mechanical Engineers Series A, 2001, 68, 364–369.

Chen J X, Zu Q, Wu G, Xie J, Tuo W Y. Review of beetle forewing structures and their biomimetic applications in China: (II) On the three-dimensional structure, modeling and imitation. Materials Science and Engineering: C, 2015, 55, 620–633.

Chen J X, Zhang X M, Okabe Y, Saito K, Guo Z S, Pan L C. The deformation mode and strengthening mechanism of compression in the beetle elytron plate. Materials & Design, 2017, 131, 481–486.

Chen J X, Zhang X M, Okabe Y, Xie J. Beetle elytron plate and the synergistic mechanism of a trabecular-honeycomb core structure. Science China Technological Sciences, 2019, 62, 87–93.

Zhang X M, Chen J X, Okabe Y, Xie J, Zhang Z Z. Compression properties of metal beetle elytron plates and the elementary unit of the trabecular-honeycomb core structure. Journal of Sandwich Structures & Materials, 2019, 21, 2031–2041.

Zhang X M, Yu X D, Chen J X, Pan L C, Hu L P. Vibration properties and transverse shear characteristics of multibody molded beetle elytron plates. Science China-Technological Sciences, 2020, 63, 2584–2592.

Xiang J W, Du J X. Energy absorption characteristics of bio-inspired honeycomb structure under axial impact loading. Materials Science & Engineering A, 2017, 696, 283–289.

Du J X, Hao P, Liu M B, Scarpa F. Multi-cell energy absorbing structures with hollow columns inspired by the beetle elytra. Journal of Materials Science, 2020, 55, 4279–4291.

Xu M Y, Pan L C, Chen J X, Zhang X M, Yu X D. The flexural properties of end-trabecular beetle elytron plates and their flexural failure mechanism. Journal of Materials Science, 2019, 54, 8414–8425.

Yu X D, Zhang X M, Chen J X, Zhao C Q, Zhao T D, Fu Y Q. The flexural property and its synergistic mechanism of multibody molded beetle elytron plates. Science China Technological Sciences, 2020, 63, 768–776.

Sahu S K, Badgayan N D, Samanta S, Sahu D, Sreekanth P S R. Influence of cell size on out of plane stiffness and in-plane compliance character of the sandwich beam made with tunable PCTPE nylon honeycomb core and hybrid polymer nanocomposite skin. International Journal of Mechanical Sciences, 2018, 148, 284–292.

Azzouz L, Chen Y, Zarrelli M, Pearce J M, Mitchell L, Ren G G, Grasso M. Mechanical properties of 3-D printed truss-like lattice biopolymer non-stochastic structures for sandwich panels with natural fibre composite skins. Composite Structures, 2019, 213, 220–230.

Gibson L, Ashby M F. Cellular Solids: Structure and Properties, 2nd ed, Cambridge University Press, Cambridge, UK, 1997.

Chen J X, Tuo W Y, Zhang X M, He C L, Xie J, Liu C. Compressive failure modes and parameter optimization of the trabecular structure of biomimetic fully integrated honeycomb plates. Materials Science and Engineering: C, 2016, 69, 255–261.

Acknowledgment

The work was financially supported by the National Key R&D Program of China under project 2017YFC0703700.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, X., Yu, X., Chen, J. et al. Influence Mechanism of the Trabecular and Chamfer Radii on the Three-point Bending Properties of Trabecular Beetle Elytron Plates. J Bionic Eng 18, 409–418 (2021). https://doi.org/10.1007/s42235-021-0025-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42235-021-0025-z