Abstract

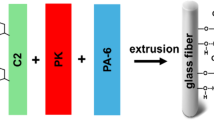

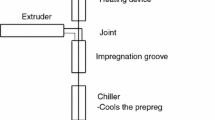

Ethylene–methacrylate–glycidyl (EMG) copolymer is employed to strengthen polyethylene terephthalate (PET)/glass fiber (GF) blends. This paper starts from investigating the effects of various EMG contents on mechanical properties, thermal properties and fractured surface morphology of PET/GF blends. All of the above-mentioned properties own extreme limits of EMG concentration. The crystallization ability of the blends increases with an increment in EMG content, whereas the crystallinity keeps stable at a relatively high level of 0–20 wt.% EMG loading. The tension, bending and impact properties of PET blends are enhanced with the addition of a self-made three-dimensional hierarchical porous carbon sponge (3DC) based on an optimal additive amount. Results indicate that EMG possesses the capabilities of increasing the toughness of PET/GF blends remarkably and transforming the blends from brittle fracture to tough fracture. According to the results, the blends exhibit the best overall properties as the content of EMG reaches 10–15 wt.%.

Similar content being viewed by others

References

Fei, Y.E., Tian, W., Feng, Z., et al.: Preparation and properties of GF/PET hybrid woven thermoplastic composite. J. Text. Res. 32(11), 28–457 (2011)

Amash, A., Zugenmaier, P.: Thermal and dynamic mechanical investigations on fiber-reinforced polypropylene composites. J. Appl. Polym. Sci. 63(9), 1143–1154 (2015)

Bergeret, A., Ferry, L., Ienny, P.: Influence of the fibre/matrix interface on ageing mechanisms of glass fibre reinforced thermoplastic composites (PA-6, 6, PET, PBT) in a hygrothermal environment. Polym. Degrad. Stab. 94(9), 1315–1324 (2009)

Schäfer, J., Foest, R., Sigeneger, F., et al.: Sgl-mrc:successful startup of precursor production in japan for bmw i3. Plast. Manuf. 52(10), 872–880 (2011)

Huq, T., Khan, A., Noor, N., et al.: Comparative studies on the mechanical, degradation and interfacial properties between jute and e-glass fiber-reinforced pet composites. Polym. Plast. Technol. Eng. 49(11), 1128–1135 (2010)

Wang, J., Liang, X., Sun, D., et al.: Study on properties of glass fiber reinforced PBT/PET blends. Eng. Plast. Appl. 6, 95–98 (2015)

Yan, W., Han, K.Q., Qin, L.L., et al.: Study on long fiber—reinforced thermoplastic composites prepared by in situ solid-state polycondensation. J. Appl. Polym. Sci. 91(6), 3959–3965 (2010)

Ji, L.N.: Study on preparation process and properties of polyethylene terephthalate (PET). Appl. Mech. Mater. 312, 406–410 (2013)

Xanthos, M.: Functional Fillers for Plastics. Wiley-VCH, Germany (2005)

Yanfang, L.I., Wang, Y., et al.: Flame retardant and flame retardant glass fiber reinforced pet. Plastics 1, 5–18 (2017)

Yu, Z.Z., Yang, M.S., Dai, S.C., et al.: Toughening of recycled poly(ethylene terephthalate) with a maleic anhydride grafted SEBS triblock copolymer. J. Appl. Polym. Sci. 93(3), 1462–1472 (2010)

Kunimune, N., Yamada, K., Leong, Y.W., et al.: Influence of the reactive processing of recycled poly(ethylene terephthalate)/poly(ethylene- co -glycidyl methacrylate) blends. J. Appl. Polym. Sci. 120(1), 50–55 (2011)

Sheng, P.H., Ding, Y., Luo, X., et al.: Structure and properties of PET/TPEE melt blend samples. Plastics 38(6), 37–38 (2009)

Tan, Z.Y., Liu, S.C., Cui, X.L., et al.: Toughening of poly(ethylene terephthalate) and optimizing of the compatibilization between PET and EPDM by functionalized EPDM. Polym. Plast. Technol. Eng. 53(2), 141–149 (2014)

Cheng, H.Y., Tian, M., Zhang, L.Q., et al.: Preparation and properties of poly(ethylene terephthalate)/gf toughened by different modifiers. Plastics 36(6), 17–20 (2007)

Zhu, Y.F.: Effect of ax8900 on the properties of pc/pbt blends. China Plast. Ind. 37(s1), 51–53 (2009)

Tong, L.I., Dong, C.L., Huo, Y., et al.: Morphology and properties of PP/PET fiber/GF composites at different molding temperatures. China Plast. Ind. 43(4), 83–86 (2015)

Pracella, M., Chionna, D., Pawlak, A., et al.: Reactive mixing of PET and PET/PP blends with glycidyl methacrylate–modified styrene-b-(ethylene-co-olefin) block copolymers. J. Appl. Polym. Sci. 98(5), 2201–2211 (2010)

Mondadori, N., Nunes, R., Canto, L.B., et al.: Composites of recycled PET reinforced with short glass fiber. J. Thermoplast. Compos. Mater. 25(6), 747–764 (2012)

Cheng, H., Tian, M., Zhang, L., et al.: Toughening of recycled poly (ethylene terephthalate)/glass fiber blends with ethylene-butyl acrylate-glycidyl methacrylate copolymer and maleic anhydride grafted polyethylene-octene rubber. J. Appl. Polym. Sci. 109(5), 2795–2801 (2010)

Acknowledgements

This work was also supported by the Special Support Plan for High-Level Talents of Guangdong Province (No. 2017TQ04N840) and Science and Technology Planning Project of Guangdong Province (No. 2017A030313081). In addition, the authors are very grateful to the editors and all the anonymous reviewers for their constructive comments, which contributed greatly to improving our work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shen, Q., Li, X., Zhao, Y. et al. Experimental and Performance Analyses on Elastomer-Strengthened Polyethylene Terephthalate/Glass Fiber Blends. Automot. Innov. 2, 71–78 (2019). https://doi.org/10.1007/s42154-019-00047-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42154-019-00047-3