Abstract

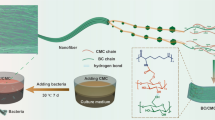

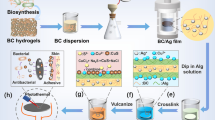

The formulation of an antibiotic-free antibacterial approach is imperative in circumventing escalating bacterial drug resistance. Electrical stimulation presents a viable therapeutic modality for such an approach. Nonetheless, obstacles persist in achieving efficacious sterilization with biosafe low-voltage electrical fields (EFs) and enduring antibacterial capabilities. In this study, we have devised a novel capacitive antibacterial dressing comprising polypyrrole-wrapped carbon cloth (PPy-CC) electrodes and a bacterial cellulose (BC) hydrogel separator. Subjected to 1 V electrical stimulation for 10 min, the dressing attains high bactericidal efficiency (up to 99.97%) and enhanced activity against multidrug-resistant (MDR) bacteria (up to 99.99%). Its considerable electric capacity and rechargeability allow for repeated charging to achieve sustained sterilization. In vivo results demonstrate significant inhibition of wound infection and facilitated wound recovery in infected full-thickness defects in mouse models. This represents an antibiotic-free, physically-stimulated treatment modality for infected wounds with considerable potential for clinical application.

TOC

A capacitive antibacterial dressing consists of polypyrrole-wrapped carbon cloth as electrode layer and bacterial cellulose hydrogel as separator with efficiently accelerated infected-wound healing. The resultant hydrogel dressing exhibits excellent high capacitance characteristics, good biocompatibility, efficient and sustained antibacterial ability after low voltage charging. It is an antibiotic-free, physical stimulation-based strategy for infected wounds.

Similar content being viewed by others

Availability of data and materials

All data and materials supporting the finding of this study are available within the paper and its supplementary information.

References

Zhou L, Zheng H, Liu Z, Wang S, Liu Z, Chen F, Zhang H, Kong J, Zhou F, Zhang Q (2021) ACS Nano 15:2468. https://doi.org/10.1021/acsnano.0c06287

He J, Shi M, Liang Y, Guo B (2020) Chem Eng J 394. https://doi.org/10.1016/j.cej.2020.124888

Liang Y, He J, Guo B (2021) ACS Nano 15:12687. https://doi.org/10.1021/acsnano.1c04206

Li Y, Fu R, Duan Z, Zhu C, Fan D (2022) Bioactive Materials 9:461. https://doi.org/10.1016/j.bioactmat.2021.07.023

Theuretzbacher U, Outterson K, Engel A, Karlén A (2020) Nat Rev Microbiol 18:275. https://doi.org/10.1038/s41579-019-0288-0

Hutchings MI, Truman AW, Wilkinson B (2019) Curr Opin Microbiol 51:72. https://doi.org/10.1016/j.mib.2019.10.008

Zhao Y, Guo Q, Dai X, Wei X, Yu Y, Chen X, Li C, Cao Z, Zhang X (2019) Adv Mater 31:1806024. https://doi.org/10.1002/adma.201806024

Chu J, Vila-Farres X, Inoyama D, Gallardo-Macias R, Jankowski M, Satish S, Freundlich JS, Brady SF (2018) Acs Infectious Diseases 4:33. https://doi.org/10.1021/acsinfecdis.7b00056

Chan BK, Sistrom M, Wertz JE, Kortright KE, Narayan D, Turner PE (2016) Sci Rep 6. https://doi.org/10.1038/srep26717

Shi R, Zhang J, Tian J, Zhao C, Li Z, Zhang Y, Li Y, Wu C, Tian W, Li Z (2020) Nano Energy 77:105201. https://doi.org/10.1016/j.nanoen.2020.105201

Tao Y, Ju E, Ren J, Qu X (2015) Adv Mater 27:1097. https://doi.org/10.1002/adma.201405105

Tang S, Zheng J (2018) Adv Healthc Mater 7. https://doi.org/10.1002/adhm.201701503

Principi N, Silvestri E, Esposito S (2019) Front Pharmacol 10. https://doi.org/10.3389/fphar.2019.00513

Qi X, Huang Y, You S, Xiang Y, Cai E, Mao R, Pan W, Tong X, Dong W, Ye F, Shen J (2022) Adv Sci 9. https://doi.org/10.1002/advs.202106015

Tian J, Feng H, Yan L, Yu M, Ouyang H, Li H, Jiang W, Jin Y, Zhu G, Li Z, Wang ZL (2017) Nano Energy 36:241. https://doi.org/10.1016/j.nanoen.2017.04.030

Wang G, Feng H, Hu L, Jin W, Hao Q, Gao A, Peng X, Li W, Wong K-Y, Wang H, Li Z, Chu PK (2018) Nat Commun 9:2055. https://doi.org/10.1038/s41467-018-04317-2

Li C, Li Z, Zeng Y, Cao X, Zhao H, Yang YY, Yuan P, Lu X, Ding X (2022) Adv Healthcare Mater 11:2102044. https://doi.org/10.1002/adhm.202102044

Duncan B, Li X, Landis RF, Kim ST, Gupta A, Wang L-S, Ramanathan R, Tang R, Boerth JA, Rotello VM (2015) ACS Nano 9:7775. https://doi.org/10.1021/acsnano.5b01696

Balint R, Cassidy NJ, Cartmell SH (2014) Acta Biomater 10:2341. https://doi.org/10.1016/j.actbio.2014.02.015

Thakur AV, Pathan HM, Lokh BJ, e. e. (2022) ES Energy Environ 18:75. https://doi.org/10.30919/esee8c751

Liang Y, Wei Z, Zhang X, Wang R (2022) ES Energy Environ 18:101. https://doi.org/10.30919/esee8c783

Wang J, Tavakoli J, Tang Y (2019) Carbohyd Polym 219:63. https://doi.org/10.1016/j.carbpol.2019.05.008

Boni BOO, Lamboni L, Bakadia BM, Hussein SA, Yang G (2020) Eng Sci 10:68. https://doi.org/10.30919/es8d906

Boni BOO, Lamboni L, Mao L, Bakadia BM, Shi Z, Yang G (2022) Eng Sci 19:175. https://doi.org/10.30919/es8d700

Lin W-C, Lien C-C, Yeh H-J, Yu C-M, Hsu S-H (2013) Carbohyd Polym 94:603. https://doi.org/10.1016/j.carbpol.2013.01.076

Xie Y-Y, Hu X-H, Zhang Y-W, Wahid F, Chu L-Q, Jia S-R, Zhong C (2020) Carbohydr Polym 229. https://doi.org/10.1016/j.carbpol.2019.115456

Nautiyal A, Qiao M, Cook JE, Zhang X, Huang T-S (2018) Appl Surf Sci 427:922. https://doi.org/10.1016/j.apsusc.2017.08.093

Jasim A, Ullah MW, Shi Z, Lin X, Yang G (2017) Carbohyd Polym 163:62. https://doi.org/10.1016/j.carbpol.2017.01.056

Zheng R-Z, Shi Z-J, Yang G (2020) Acta Polymerica Sinica 51:942. https://doi.org/10.11777/j.issn1000-3304.2020.20110

Malinauskas A (2001) Polymer 42:3957. https://doi.org/10.1016/s0032-3861(00)00800-4

Snook GA, Kao P, Best AS (2011) J Power Sources 196:1. https://doi.org/10.1016/j.jpowsour.2010.06.084

Chen X, Yuan F, Zhang H, Huang Y, Yang J, Sun D (2016) J Mater Sci 51:5573. https://doi.org/10.1007/s10853-016-9899-2

Bedre MD, Basavaraja S, Deshpande R, Balaji DS, Venkataraman A (2010) International Journal of Polymeric Materials and Polymeric. Biomaterials 59:531. https://doi.org/10.1080/00914031003760642

Ge H, Qi G, Kang E-T, Neoh KG (1994) Polymer 35:504. https://doi.org/10.1016/0032-3861(94)90503-7

Lu K-H, Sheen Y-J, Huang T-P, Kao S-H, Cheng C-L, Hwang C-A, Sheen S, Huang L, Sheen L-Y (2020) Food Microbiol 89:103374. https://doi.org/10.1016/j.fm.2019.103374

Wu J, Zheng Y, Song W, Luan J, Wen X, Wu Z, Chen X, Wang Q, Guo S (2014) Carbohyd Polym 102:762. https://doi.org/10.1016/j.carbpol.2013.10.093

Wu C, Shen L, Lu Y, Hu C, Liang Z, Long L, Ning N, Chen J, Guo Y, Yang Z, Hu X, Zhang J, Wang Y (2021) ACS Appl Mater Interfaces 13:52308. https://doi.org/10.1021/acsami.1c14088

Lin T-Y, Weibel DB (2016) Appl Microbiol Biotechnol 100:4255. https://doi.org/10.1007/s00253-016-7468-x

Ashrafi M, Baguneid M, Alonso-Rasgado T, Rautemaa-Richardson R, Bayat A (2017) Future Microbiol 12:337. https://doi.org/10.2217/fmb-2016-0204

Lai S, Wang Y, Wan Y, Ma H, Fang L, Su J (2022) ACS Appl Mater Interfaces 14:20139. https://doi.org/10.1021/acsami.2c04359

Bainbridge P (2013) J Wound Care 22:407. https://doi.org/10.12968/jowc.2013.22.8.407

Talikowska M, Fu X, Lisak G (2019) Biosens Bioelectron 135:50. https://doi.org/10.1016/j.bios.2019.04.001

Khaw JS, Xue R, Cassidy NJ, Cartmell SH (2022) Acta Biomaterialia 139:204. https://doi.org/10.1016/j.actbio.2021.08.010

Mao L, Hu S, Gao Y, Wang L, Zhao W, Fu L, Cheng H, Xia L, Xie S, Ye W, Shi Z, Yang G (2020) Adv Healthc Mater 9

Wang L, Mao L, Qi F, Li X, Ullah MW, Zhao M, Shi Z, Yang G (2021) Chem Eng J 424

Luo R, Dai J, Zhang J, Li Z (2021) Adv Healthc Mater 10. https://doi.org/10.1002/adhm.202100557

Versey Z, da Cruz Nizer WS, Russell E, Zigic S, DeZeeuw KG, Marek JE, Overhage J, Cassol E (2021) Front Immunol 12. https://doi.org/10.3389/fimmu.2021.648554

Atamas SP (2002) Life Sci 72:631. https://doi.org/10.1016/s0024-3205(02)02299-3

Abedin-Do A, Zhang Z, Douville Y, Methot M, Bernatchez J, Rouabhia M (2022) J Tissue Eng Regen Med 16:643. https://doi.org/10.1002/term.3305

Veith AP, Henderson K, Spencer A, Sligar AD, Baker AB (2019) Adv Drug Deliv Rev 146:97. https://doi.org/10.1016/j.addr.2018.09.010

Li C, Zhang S, Yao Y, Wang Y, Xiao C, Yang B, Huang J, Li W, Ning C, Zhai J, Yu P, Wang Y (2023) Adv Healthc Mater. https://doi.org/10.1002/adhm.202300064

Acknowledgements

The author also was grateful for the Analytical and Testing Centre of Huazhong University of Science and Technology (HUST) and the test platform of Life Sciences College at HUST for characterization of samples.

Funding

This work was supported by the National Natural Science Foundation of China (Grant No.51973076).

Author information

Authors and Affiliations

Contributions

Hao Wang, Zhijun Shi, Guang Yang conceived this research and designed experiments. Hao Wang, Ruizhu Zheng, Pengyu He and Xiaoming Li performed experiments, analysis, and interpretation of the data. All authors participated in the interpretation of the data. Hao Wang and Zhijun Shi wrote the paper and participated in the revision of it. All authors read, revised, and approved the final manuscript.

Corresponding authors

Ethics declarations

Conflicts of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, H., Zheng, R., He, P. et al. A capacitive polypyrrole-wrapped carbon cloth/bacterial cellulose antibacterial dressing with electrical stimulation for infected wound healing. Adv Compos Hybrid Mater 7, 10 (2024). https://doi.org/10.1007/s42114-023-00814-1

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42114-023-00814-1