Abstract

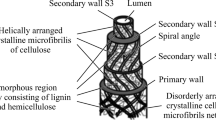

Flax is one of the popular natural fibers used as a reinforcing agent for polymer composite. The raw flax fiber is hydrophilic in nature, and the chemical constituent of flax is mainly cellulose, hemicellulose, lignin, etc. To improve the interfacial adhesion between flax fiber and polymer matrix, the surface treatment is given to the fiber. The polymer matrix used for reinforcement is thermoplastic, thermosets, and polymers derived from natural resources. The composites can be made by various processing techniques such as extrusion, compression, hand lay-up, etc. The flax fiber improves the biodegradability and recyclability of the composite, and it shows better mechanical performance as compared to plain polymers. The reinforcement of flax fiber in polymer matrix improves its tensile properties, flexural properties, impact resistance, hardness, etc. The hybridization of fibers is another approach that combines two or more fibers in a polymer matrix and has a synergistic effect through more than one fiber. The flax fiber composite is more eco-friendly than corresponding petroleum-based fiber composites.

Graphical abstract

Similar content being viewed by others

References

Ramesh M, Nijanthan S, Palanikumar K (2015) Processing and mechanical property evaluation of kenaf-glass fiber reinforced polymer composites. Appl Mech Mater 766:187–192

Rezghi Maleki H, Hamedi M, Kubouchi M, Arao Y (2019) Experimental investigation on drilling of natural flax fiber-reinforced composites. Mater Manuf Process 34(3):283–292

Li X, Tabil LG, Panigrahi S, Crerar WJ (2005) Processing flax fiber-reinforced polymer composites by injection molding. In: Proceedings of the CSAE/SCGR 2005 Meeting Winnipeg, Manitoba-June; p. 26–29

Scaffaro R, Maio A, Gulino EF, Megna B (2019) Structure-property relationship of PLA-Opuntia Ficus Indica biocomposites. Compos B 167:199–206

Scaffaro R, Maio A, Gulino EF, Pitarresi G (2020) Lignocellulosic fillers and graphene nanoplatelets as hybrid reinforcement for polylactic acid: effect on mechanical properties and degradability. Compos Sci Technol 190:108008

Scaffaro R, Maio A, Lopresti F (2018) Physical properties of green composites based on poly-lactic acid or Mater-Bi® filled with Posidonia Oceanica leaves. Compos Part A Appl Sci Manuf 112:315–327

Romhany G, Karger-Kocsis J, Czigany T (2003) Tensile fracture and failure behavior of technical flax fibers. J Appl Polym Sci 90(13):3638–3645

Zimniewska M, Myalski J, Koziol M, Mankowski J, Bogacz E (2012) Natural fiber textile structures suitable for composite materials. J Nat Fibers 9(4):229–239

Bledzki AK, Fink HP, Specht K (2004) Unidirectional hemp and flax EP-and PP-composites: influence of defined fiber treatments. J Appl Polym Sci 93(5):2150–2156

Wang B, Tabil L, Panigrahi S (2008) Effects of chemical treatments on mechanical and physical properties of flax fiber-reinforced composites. Sci Eng Compos Mater 15(1):43–58

Holbery J, Houston D (2006) Natural-fiber-reinforced polymer composites in automotive applications. Jom 58(11):80–86

Yan L, Chouw N, Jayaraman K (2014) Flax fibre and its composites—a review. Compos B Eng 56:296–317

Cao X, Chen Y, Chang PR, Muir AD, Falk G (2008) Starch-based nanocomposites reinforced with flax cellulose nanocrystals. Express Polym Lett 2(7):502–510

Karine C, Jean-Paul J, Moussa G, Baley C, Laurent B, Joël B (2007) Morphology and mechanical behavior of a natural composite: the flax fiber. 16th International Conference on Composite Materials. Kyoto, Japan, pp 1–8

Charlet K, Eve S, Jernot JP, Gomina M, Breard J (2009) Tensile deformation of a flax fiber. Procedia Eng 1(1):233–236

Ahmed S, Ulven CA (2018) Dynamic in-situ observation on the failure mechanism of flax fiber through scanning electron microscopy. Fibers 6(1):17–35

Sparnins E (2009) Mechanical properties of flax fibers and their composites (Doctoral dissertation, Luleå tekniska universitet)

Li X, Panigrahi SA, Tabil LG, Crerar WJ (2004) Flax fiber-reinforced composites and the effect of chemical treatments on their properties. In: North central ASAE/CSAE Conference

Stelescu MD, Airinei A, Manaila E, Craciun G, Fifere N, Varganici C (2017) Property correlations for composites based on ethylene propylene diene rubber reinforced with flax fibers. Polym Test 59:75–83

Siaotong BAC (2006) Effects of fiber content and extrusion parameters on the properties of flax fiber-polyethylene composites (Doctoral dissertation)

Ramesh M, Bhoopathi R, Deepa C, Sasikala G (2018) Experimental investigation on morphological, physical and shear properties of hybrid composite laminates reinforced with flax and carbon fibers. Journal of the Chinese Advanced Materials Society 6(4):640–654

Panigrahy BS, Rana A, Panigrahi S, Chang P (2006) Overview of flax fiber reinforced thermoplastic composites. In 2006 ASAE Annual Meeting. American Society of Agricultural and Biological Engineers

Regazzi A, Léger R, Corn S, Ienny P (2016) Modeling of hydrothermal aging of short flax fiber reinforced composites. Compos Part A Appl Sci Manuf 90:559–566

Bliss RM (2005) Flax fiber offers cotton cool comfort. Agric Res 53(11):12

Wang Y, Zhu W, Wan B, Meng Z, Han B (2021) Hygrothermal ageing behavior and mechanism of carbon nanofibers modified flax fiber-reinforced epoxy laminates. Compos Part A Appl Sci Manuf 140:106142

Zhang J, Wang H, Ou R, Wang Q (2018) The properties of flax fiber reinforced wood flour/high density polyethylene composites. J For Res 29(2):533–540

Zhang D, Milanovic NR, Zhang Y, Su F, Miao M (2014) Effects of humidity conditions at fabrication on the interfacial shear strength of flax/unsaturated polyester composites. Compos B Eng 60:186–192

Ausias G, Bourmaud A, Coroller G, Baley C (2013) Study of the fibre morphology stability in polypropylene-flax composites. Polym Degrad Stabil 98(6):1216–1224

Czigany T (2004) An acoustic emission study of flax fiber-reinforced polypropylene composites. J Compos Mater 38(9):769–778

El Jaouhari A, Jadi SB, El Guerraf A, Bouabdallaoui M, Aouzal Z, Bazzaoui EA, Martins JI, Bazzaoui M (2018) Synthesis and spectroscopic characterization of polypyrrole PPy coating on flax fibers and its behaviour toward trimethylamine vapor. Synth Met 245:237–244

McCracken A, Sadeghian P (2018) Corrugated cardboard core sandwich beams with bio-based flax fiber composite skins. J Build Eng 20:114–122

Moudood A, Rahman A, Öchsner A, Islam M, Francucci G (2019) Flax fiber and its composites: an overview of water and moisture absorption impact on their performance. J Reinf Plast Compos 38(7):323–339

Hagstrand PO, Oksman K (2001) Mechanical properties and morphology of flax fiber reinforced melamine-formaldehyde composites. Polym Compos 22(4):568–578

Rodriguez E, Alvarez VA, Moran J, Moreno S, Petrucci R, Kenny JM, Vazquez A (2006) Mechanical properties evaluation of a recycled flax fiber-reinforced vinyl ester. J Compos Mater 40(3):245–256

Arbelaiz A, Fernandez B, Ramos JA, Retegi A, Llano-Ponte R, Mondragon I (2005) Mechanical properties of short flax fibre bundle/polypropylene composites: influence of matrix/fibre modification, fibre content, water uptake and recycling. Compos Sci Technol 65(10):1582–1592

Foulk JA, Chao WY, Akin DE, Dodd RB, Layton PA (2006) Analysis of flax and cotton fiber fabric blends and recycled polyethylene composites. J Polym Environ 14(1):15–25

Mehmood S, Madsen B (2012) Properties and performance of flax yarn/thermoplastic polyester composites. J Reinf Plast Compos 31(24):1746–1757

Niu H, Jiao X, Wang R, Zhou H (2010) Direct manufacturing of flax fibers reinforced low melting point PET composites from nonwoven mats. Fiber Polym 11(2):218–222

Habibi M, Laperrière L, Mahi Hassanabadi H (2019) Replacing stitching and weaving in natural fiber reinforcement manufacturing, part 1: mechanical behavior of unidirectional flax fiber composites. J Nat Fibers 16(7):1064–1076

Chegdani F, Mezghani S, El Mansori M (2016) On the multiscale tribological signatures of the tool helix angle in profile milling of woven flax fiber composites. Tribol Int 100:132–140

Andersons J, Modniks J, Spārniņš E (2015) Modeling the nonlinear deformation of flax-fiber-reinforced polymer matrix laminates in active loading. J Reinf Plast Compos 34(3):248–256

Daoud H, Rebiere JL, Makni A, Taktak M, El Mahi A, Haddar M (2016) Numerical and experimental characterization of the dynamic properties of flax fiber reinforced composites. Int J Appl Mech 8(05):1650068–1650084

Sathish S, Kumaresan K, Prabhu L, Vigneshkumar N (2017) Experimental investigation on volume fraction of mechanical and physical properties of flax and bamboo fibers reinforced hybrid epoxy composites. Polym Polym Compos 25(3):229–236

Prakash RV, Maharana M (2017) Damage detection using infrared thermography in a carbon-flax fiber hybrid composite. Procedia Struct Integrity 7:283–290

Prasad V, Hunize CM, Abhiraj RI, Jospeh MA, Sekar K, Ali, M (2019) Mechanical properties of flax fiber reinforced composites manufactured using hand layup and compression molding—a comparison. In: Advances in Industrial and Production Engineering. pp. 781–789

Romhány G, Karger-Kocsis J, Czigány T (2003) Tensile fracture and failure behavior of thermoplastic starch with unidirectional and cross-ply flax fiber reinforcements. Macromol Mater Eng 288(9):699–707

Li Y, Li Q, Ma H (2015) The voids formation mechanisms and their effects on the mechanical properties of flax fiber reinforced epoxy composites. Compos Part A Appl Sci Manuf 72:40–48

Fages E, Gironés S, Sánchez-Nacher L, García-Sanoguera D, Balart R (2012) Use of wet-laid techniques to form flax-polypropylene nonwovens as base substrates for eco-friendly composites by using hot-press molding. Polym Compos 33(2):253–261

Alimuzzaman S, Gong RH, Akonda M (2014) Biodegradability of nonwoven flax fiber reinforced polylactic acid biocomposites. Polym Compos 35(11):2094–2102

Habibi M, Lebrun G, Laperrière L (2017) Experimental characterization of short flax fiber mat composites: tensile and flexural properties and damage analysis using acoustic emission. J Mater Sci 52(11):6567–6580

Kong C, Park H, Lee J (2014) Study on structural design and analysis of flax natural fiber composite tank manufactured by vacuum assisted resin transfer molding. Mater Lett 130:21–25

Flynn J, Amiri A, Ulven C (2016) Hybridized carbon and flax fiber composites for tailored performance. Mater Design 102:21–29

Charlet K, Jernot JP, Gomina M, Bizet L, Bréard J (2010) Mechanical properties of flax fibers and of the derived unidirectional composites. J Compos Mater 44(24):2887–2896

Kim SH, Park CH (2017) Direct impregnation of thermoplastic melt into flax textile reinforcement for semi-structural composite parts. Ind Crops Prod 95:651–663

Arias A, Heuzey MC, Huneault MA (2013) Thermomechanical and crystallization behavior of polylactide-based flax fiber biocomposites. Cellulose 20(1):439–452

Andersons J, Spārniņš E, Joffe R (2006) Stiffness and strength of flax fiber/polymer matrix composites. Polym Compos 27(2):221–229

Mihai M, Chapleau N, Denault J (2015) Processing–formulation–performance relationships of polypropylene/short flax fiber composites. J Appl Polym Sci 132(9):41528–41543

Pilla S, Kramschuster A, Lee J, Auer GK, Gong S, Turng LS (2009) Microcellular and solid polylactide–flax fiber composites. Compos Interfaces 16(7–9):869–890

Barkoula NM, Garkhail SK, Peijs T (2010) Biodegradable composites based on flax/polyhydroxybutyrate and its copolymer with hydroxyvalerate. Ind Crops Prod 31(1):34–42

Angelov I, Wiedmer S, Evstatiev M, Friedrich K, Mennig G (2007) Pultrusion of a flax/polypropylene yarn. Compos Part A Appl Sci Manuf 38(5):1431–1438

Aranberri-Askargorta I, Lampke T, Bismarck A (2003) Wetting behavior of flax fibers as reinforcement for polypropylene. J Colloid Interface Sci 263(2):580–589

Zafeiropoulos NE, Baillie CA, Matthews FL (2001) A study of transcrystallinity and its effect on the interface in flax fibre reinforced composite materials. Compos Part A Appl Sci Manuf 32(3–4):525–543

Dissanayake NP, Summerscales J, Grove SM, Singh MM (2009) Energy use in the production of flax fiber for the reinforcement of composites. J Nat Fibers 6(4):331–346

Lefeuvre A, Bourmaud A, Lebrun L, Morvan C, Baley CA (2013) study of the yearly reproducibility of flax fiber tensile properties. Ind Crops Prod 50:400–407

Foulk JA, Akin DE, Dodd RB, McAlister III DD (2002) Flax fiber: potential for a new crop in the Southeast. Trends in new crops and new uses, 361

De Prez J, Van Vuure AW, Ivens J, Aerts G, Van de Voorde I (2019) Effect of enzymatic treatment of flax on fineness of fibers and mechanical performance of composites. Compos Part A Appl Sci Manuf 123:190–199

Evans JD, Akin DE, Foulk JA (2002) Flax-retting by polygalacturonase-containing enzyme mixtures and effects on fiber properties. J Biotechnol 97(3):223–231

Kessler RW, Becker U, Kohler R, Goth B (1998) Steam explosion of flax—a superior technique for upgrading fibre value. Biomass Bioenerg 14(3):237–249

Van den Oever MJA, Bos HL, Van Kemenade MJJM (2000) Influence of the physical structure of flax fibres on the mechanical properties of flax fibre reinforced polypropylene composites. Appl Compos Mater 7(5–6):387–402

Martin N, Mouret N, Davies P, Baley C (2013) Influence of the degree of retting of flax fibers on the tensile properties of single fibers and short fiber/polypropylene composites. Ind Crops Prod 49:755–767

Soleimani M, Tabil L, Panigrahi S, Opoku A (2008) The effect of fiber pretreatment and compatibilizer on mechanical and physical properties of flax fiber-polypropylene composites. J Polym Environ 16(1):74–82

Wang B, Panigrahi S, Tabil L, Crerar W, Sokansanj S, Braun L (2003) Modification of flax fibers by chemical treatment. Csae/Scgr. 6–9

Baiardo M, Zini E, Scandola M (2004) Flax fibre–polyester composites. Compos Part A Appl Sci Manuf 35(6):703–710

Wong S, Shanks R, Hodzic A (2004) Interfacial improvements in poly (3-hydroxybutyrate)-flax fibre composites with hydrogen bonding additives. Compos Sci Technol 64(9):1321–1330

Wang X, Petrů M, Yu H (2019) The effect of surface treatment on the creep behavior of flax fiber reinforced composites under hygrothermal aging conditions. Constr Build Mater 208:220–227

Aydın M, Tozlu H, Kemaloglu S, Aytac A, Ozkoc G (2011) Effects of alkali treatment on the properties of short flax fiber–poly (lactic acid) eco-composites. J Polym Environ 19(1):11–17

Gassan J, Mildner I, Bledzki AK (1999) Influence of fiber structure modification on the mechanical properties of flax fiber-epoxy composites. Mech Compos Mater 35(5):435–440

Xia X, Liu W, Zhou L, Hua Z, Liu H, He S (2016) Modification of flax fiber surface and its compatibilization in polylactic acid/flax composites. Iran Polym J 25(1):25–35

Cherif ZE, Poilâne C, Falher T, Vivet A, Ouail N, Doudou BB, Chen J (2013) Influence of textile treatment on mechanical and sorption properties of flax/epoxy composites. Polym Compos 34(10):1761–1773

Abdel-Halim ES, El-Rafie MH, Kohler R (2007) Surface characterization of differently pretreated flax fibers and their application in fiber-reinforced composites. Polym-Plast Technol 47(1):58–65

Huner U (2018) Effect of chemical surface treatment on flax-reinforced epoxy composite. J Nat Fibers 15(6):808–821

Karsli NG, Aytac A (2014) Properties of alkali treated short flax fiber reinforced poly (lactic acid)/polycarbonate composites. Fiber Polym 15(12):2607–2612

Sarikanat M, Seki Y, Sever K, Bozaci E, Demir A, Ozdogan E (2016) The effect of argon and air plasma treatment of flax fiber on mechanical properties of reinforced polyester composite. J Ind Text 45(6):1252–1267

Bledzki AK, Mamun AA, Lucka-Gabor M, Gutowski VS (2008) The effects of acetylation on properties of flax fibre and its polypropylene composites. Express Polym Lett 2(6):413–422

Fiore V, Scalici T, Valenza A (2018) Effect of sodium bicarbonate treatment on mechanical properties of flax-reinforced epoxy composite materials. J Compos Mater 52(8):1061–1072

Gassan J, Dietz T, Bledzki AK (2000) Effect of silicone interphase on the mechanical properties of flax-polyurethane composites. Compos Interfaces 7(2):103–115

Joffe R, Andersons J, Wallström L (2003) Strength and adhesion characteristics of elementary flax fibres with different surface treatments. Compos Part A Appl Sci Manuf 34(7):603–612

Van de Velde K, Kiekens P (2001) Influence of fiber surface characteristics on the flax/polypropylene interface. J Thermoplast Compos Mater 14(3):244–260

Georgiopoulos P, Kontou E, Georgousis G (2018) Effect of silane treatment loading on the flexural properties of PLA/flax unidirectional composites. Compos Commun 10:6–10

Arbelaiz, A, Fernández B, Cantero G, Llano-Ponte R, Valea A, Mondragon I (2005) Mechanical properties of flax fibre/polypropylene composites. Influence of fibre/matrix modification and glass fibre hybridization. Compos. Part A Appl Sci Manuf 36(12):1637–44

Wu CM, Lai WY, Wang CY (2016) Effects of surface modification on the mechanical properties of flax/β-polypropylene composites. Materials 9(5):314–325

Puch F, Hopmann C (2015) Experimental investigation of the influence of the compounding process and the composite composition on the mechanical properties of a short flax fiber–reinforced polypropylene composite. Polym Compos 36(12):2282–2290

Van de Velde K, Kiekens P (2002) Development of a flax/polypropylene composite with optimal mechanical characteristics by fiber and matrix modification. J Thermoplast Compos Mater 15(4):281–300

Wang H, Xian G, Li H (2015) Grafting of nano-TiO2 onto flax fibers and the enhancement of the mechanical properties of the flax fiber and flax fiber/epoxy composite. Compos Part A Appl Sci Manuf 76:172–180

Amiri A, Ulven CA, Huo S (2015) Effect of chemical treatment of flax fiber and resin manipulation on service life of their composites using time-temperature superposition. Polymers 7(10):1965–1978

Tayfun U, Dogan M, Bayramli E (2017) Investigations of the flax fiber/thermoplastic polyurethane eco-composites: influence of isocyanate modification of flax fiber surface. Polym Compos 38(12):2874–2880

Kaith BS, Kalia S (2007) Grafting of flax fiber (Linum usitatissimum) with vinyl monomers for enhancement of properties of flax-phenolic composites. Polym J 39(12):1319–1327

Fathi B, Harirforoush M, Foruzanmehr M, Elkoun S, Robert M (2017) Effect of TEMPO oxidation of flax fibers on the grafting efficiency of silane coupling agents. J Mater Sci 52(17):10624–10636

Fathi B, Foruzanmehr M, Elkoun S, Robert M (2019) Novel approach for silane treatment of flax fiber to improve the interfacial adhesion in flax/bio epoxy composites. J Compos Mater 53(16):2229–2238

Stuart T, Liu Q, Hughes M, McCall RD, Sharma HSS, Norton A (2006) Structural biocomposites from flax—part I: effect of bio-technical fibre modification on composite properties. Compos Part A Appl Sci Manuf 37(3):393–404

Li X, Panigrahi S, Tabil LG (2009) A study on flax fiber-reinforced polyethylene biocomposites. Appl Eng Agric 25(4):525–531

Wang A, Xia D, Xian G, Li H (2019) Effect of nanoclay grafting onto flax fibers on the interfacial shear strength and mechanical properties of flax/epoxy composites. Polym Compos 40(9):3482–3492

Javanshour F, Ramakrishnan KR, Layek RK, Laurikainen P, Prapavesis A, Kanerva M, Sarlin E (2021) Effect of graphene oxide surface treatment on the interfacial adhesion and the tensile performance of flax epoxy composites. Compos Part A Appl Sci Manuf 142:106270

Bayart M, Adjallé K, Diop A, Ovlaque P, Barnabé S, Robert M, Elkoun S (2020) PLA/flax fiber bio-composites: effect of polyphenol-based surface treatment on interfacial adhesion and durability. Compos Interfaces 1–22

Whitacre R, Amiri A, Ulven C (2015) The effects of corn zein protein coupling agent on mechanical properties of flax fiber reinforced composites. Ind Crops Prod 77:232–238

Zhang L, Li Z, Pan YT, Yáñez AP, Hu S, Zhang XQ, Wang R, Wang DY (2018) Polydopamine induced natural fiber surface functionalization: a way towards flame retardancy of flax/poly (lactic acid) biocomposites. Compos B Eng 154:56–63

Jia Y, Fiedler B (2018) Influence of furfuryl alcohol fiber pre-treatment on the moisture absorption and mechanical properties of flax fiber composites. Fibers 6(3):59–73

Doineau E, Coqueugniot G, Pucci MF, Caro AS, Cathala B, Bénézet JC, Le Moigne N (2021) Hierarchical thermoplastic biocomposites reinforced with flax fibres modified by xyloglucan and cellulose nanocrystals. Carbohydr Polym 254:117403

Fiore V, Badagliacco D, Sanfilippo C, Miranda R, Valenza A (2021) An innovative treatment based on sodium citrate for improving the mechanical performances of flax fiber reinforced composites. Polymers 13(4):559

Gouanvé F, Marais S, Saiter JM, Poncin-Epaillard F, Métayer M, Garda MR (2005) Characterization of composites with flax fibers treated with cold plasma-water permeation and thermal analysis. Mater Res Innov 9(1):15–17

Enciso B, Abenojar J, Paz E, Martínez MA (2018) Influence of low pressure plasma treatment on the durability of thermoplastic composites LDPE-flax/coconut under thermal and humidity conditions. Fiber Polym 19(6):1327–1334

Li X, Tabil LG, Oguocha IN, Panigrahi S (2008) Thermal diffusivity, thermal conductivity, and specific heat of flax fiber–HDPE biocomposites at processing temperatures. Compos Sci Technol 68(7–8):1753–1758

Foulk JA, Chao WY, Akin DE, Dodd RB, Layton PA (2004) Enzyme-retted flax fiber and recycled polyethylene composites. J Polym Environ 12(3):165–171

Kakroodi AR, Bainier J, Rodrigue D (2012) Mechanical and morphological properties of flax fiber reinforced high density polyethylene/recycled rubber composites. Int Polym Proc 27(2):196–204

Powell T, Panigrahi S, Ward J, Tabil LG, Crerar WJ, Sokansanj S (2002) Engineering properties of flax fiber and flax fiber-reinforced thermoplastic in rotational molding. Book Engineering Properties of Flax Fiber and Flax Fiber-Reinforced thermoplastic in Rotational molding

Wang B, Panigrahi S, Crerar W, Tabil L (2003) Application of pre-treated flax fibers in composites. CSAE/SCGR

Zhong Y, Kureemun U, Lee HP (2017) Prediction of the mechanical behavior of flax polypropylene composites based on multi-scale finite element analysis. J Mater Sci 52(9):4957–4967

Mieck KP, Lützkendorf R, Reussmann T (1996) Needle-punched hybrid nonwovens of flax and ppfibers—textile semiproducts for manufacturing of fiber composites. Polym Compos 17(6):873–878

Davis AM, Hanzly LE, DeButts BL, Barone JR (2019) Characterization of dimensional stability in flax fiber reinforced polypropylene composites. Polym Compos 40(1):132–140

Ramnath BV, Elanchezhian C, Nirmal PV, Kumar GP, Kumar VS, Karthick S, Rajesh S, Suresh K (2014) Experimental investigation of mechanical behavior of jute-flax based glass fiber reinforced composite. Fiber Polym 15(6):1251–1262

Arbelaiz A, Cantero G, Fernandez B, Mondragon I, Ganan P, Kenny JM (2005) Flax fiber surface modifications: effects on fiber physico mechanical and flax/polypropylene interface properties. Polym Compos 26(3):324–332

Huang K, Kureemun U, Teo WS, Lee HP (2018) Vibroacoustic behavior and noise control of flax fiber-reinforced polypropylene composites. J. Nat, Fibers

Stamboulis A, Baillie CA, Garkhail SK, Van Melick HGH, Peijs T (2000) Environmental durability of flax fibres and their composites based on polypropylene matrix. Appl Compos Mater 7(5–6):273–294

Helwig M, Paukszta D (2000) Flammability of composites based on polypropylene and flax fibers. Molecular Crystals and Liquid Crystals Science and Technology. Section A. Mol Cryst Liq Cryst 354(1):373–80

Bledzki AK, Mamun AA, Faruk O (2007) Abaca fibre reinforced PP composites and comparison with jute and flax fibre PP composites. Express Polym Lett 1(11):755–762

Stamboulis A, Baillie C, Schulz E (1999) Interfacial characterisation of flax fibre-thermoplastic polymer composites by the pull-out test. Die Angewandte Makromolekulare Chemie 272(1):117–120

López Manchado MA, Arroyo M, Biagiotti J, Kenny JM (2003) Enhancement of mechanical properties and interfacial adhesion of PP/EPDM/flax fiber composites using maleic anhydride as a compatibilizer. J Appl Polym Sci 90(8):2170–2178

Lopez‐Manchado MA, Biagiotti J, Arroyo M, Kenny JM (2003) Ternary composites based on PP‐EPDM blends reinforced with flax fibers. Part I: Processing and thermal behavior. Polym Eng Sci 43(5):1018–30

Biagiotti J, López‐Manchado MA, Arroyo M, Kenny JM (2003) Ternary composites based on PP‐EPDM blends reinforced with flax fibers. Part II: Mechanical properties/morphology relationship. Polym Eng Sci 43(5):1031–43

Bourmaud A, Le Duigou A, Gourier C, Baley C (2016) Influence of processing temperature on mechanical performance of unidirectional polyamide 11–flax fibre composites. Ind Crops Prod 84:151–165

Kaith BS, Singha AS, Kumar S, Kalia S (2008) Mercerization of flax fiber improves the mechanical properties of fiber-reinforced composites. Int J Polym Mater 57(1):54–72

Haggui M, El Mahi A, Jendli Z, Akrout A, Haddar M (2019) Static and fatigue characterization of flax fiber reinforced thermoplastic composites by acoustic emission. Appl Acoust 147:100–110

Zhang M, Bareille O, Salvia M (2019) Cure and damage monitoring of flax fiber-reinforced epoxy composite repairs for civil engineering structures using embedded piezo micro-patches. Constr Build Mater 225:196–203

Xu J, Gao X, Zhang C, Yin S (2017) (2017) Flax fiber-reinforced composite lattice cores: a low-cost and recyclable approach. Mater Design 133:444–454

Shen Y, Zhong J, Cai S, Ma H, Qu Z, Guo Y, Li Y (2019) Effect of temperature and water absorption on low-velocity impact damage of composites with multi-layer structured flax fiber. Materials 12(3):453–463

Habibi M, Laperrière L, Hassanabadi HM (2018) Influence of low-velocity impact on residual tensile properties of nonwoven flax/epoxy composite. Compos Struct 186:175–182

El Sawi I, Fawaz Z, Zitoune R, Bougherara H (2014) An investigation of the damage mechanisms and fatigue life diagrams of flax fiber-reinforced polymer laminates. J Mater Sci 49(5):2338–2346

Di Bella G, Fiore V, Valenza A (2010) Effect of areal weight and chemical treatment on the mechanical properties of bidirectional flax fabrics reinforced composites. Mater Design 31(9):4098–4103

Huner U (2015) Effect of water absorption on the mechanical properties of flax fiber reinforced epoxy composites. Advances in Science and Technology Research Journal 9(26):1–6

Habibi M, Laperriere L, Lebrun G, Toubal L (2017) Combining short flax fiber mats and unidirectional flax yarns for composite applications: effect of short flax fibers on biaxial mechanical properties and damage behaviour. Compos B Eng 123:165–178

Oksman K (2001) High quality flax fibre composites manufactured by the resin transfer moulding process. J Reinf Plast Compos 20(7):621–627

Huang K, Rammohan AV, Kureemun U, Teo WS, Lee HP (2016) Shock wave impact behavior of flax fiber reinforced polymer composites. Compos B Eng 102:78–85

Sathish S, Kumaresan K, Prabhu L, Gokulkumar S (2018) Experimental investigation of mechanical and FTIR analysis of flax fiber/epoxy composites incorporating SiC, Al2O3 and graphite. Rev Rom Mater 48(4):476–482

Meenakshi CM, Krishnamoorthy A (2019) Study on the effect of surface modification on the mechanical and thermal behaviour of flax, sisal and glass fiber-reinforced epoxy hybrid composites. J Renew Mater 7(2):153–169

Xia Y, Xian G, Kafodya I, Li H (2014) Compression behavior of concrete cylinders externally confined by flax fiber reinforced polymer sheets. Adv Struct Eng 17(12):1825–1833

Campana C, Leger R, Sonnier R, Ferry L, Ienny P (2018) Effect of post curing temperature on mechanical properties of a flax fiber reinforced epoxy composite. Compos Part A Appl Sci Manuf 107:171–179

Spārniņš E, Nyström B, Andersons J (2012) Interfacial shear strength of flax fibers in thermoset resins evaluated via tensile tests of UD composites. Int J Adhes Adhes 36:39–43

Szabo JS, Romhány G, Czigány T, Karger-Kocsis J (2003) Interpenetrating vinylester/epoxy resins reinforced by flax fibre mat. Adv Compos Lett 12(3):115–120

Joffe R, Wallström L, Berglund LA (2001) Natural fiber composites based on flax–matrix effects. In International scientific colloquium: modelling for saving resources. Riga

Croccolo D, De Agostinis M, Fini S, Liverani A, Marinelli N, Nisini E, Olmi G (2015) Mechanical characteristics of two environmentally friendly resins reinforced with flax fibers. Strojniški vestnik-Journal of Mechanical Engineering 61(4):227–236

Gao L, Tang Q, Chen Y, Wang Z, Guo W (2018) Investigation of novel lightweight phenolic foam-based composites reinforced with flax fiber mats. Polym Compos 39(6):1809–1817

Kalia S, Kaith BS (2008) Microwave enhanced synthesis of flax-g-poly (MMA) for use in phenolic composites as reinforcement. E-Journal of Chemistry 5(1):163–168

Kalia S, Kaith BS (2009) Synthesis of flax-g-copolymers under pressure for use in phenolic composites as reinforcement. J Chil Chem Soc 54(2):108–112

Shanks RA, Hodzic A, Ridderhof D (2006) Composites of poly (lactic acid) with flax fibers modified by interstitial polymerization. J Appl Polym Sci 99(5):2305–2313

Le Duigou A, Davies P, Baley C (2010) Interfacial bonding of Flax fibre/Poly (l-lactide) bio-composites. Compos Sci Technol 70(2):231–239

Aliotta L, Gigante V, Coltelli MB, Cinelli P, Lazzeri A, Seggiani M (2019) Thermo-mechanical properties of PLA/short flax fiber biocomposites. Appl Sci 9(18):3797–4011

Siengchin S, Dangtungee R (2013) Effect of woven flax structures on morphology and properties of reinforced modified polylactide composites. J Thermoplast Compos Mater 26(10):1424–1440

Xia X, Shi X, Liu W, Zhao H, Li H, Zhang Y (2017) Effect of flax fiber content on polylactic acid (PLA) crystallization in PLA/flax fiber composites. Iran Polym J 26(9):693–702

Arias A, Sojoudiasli H, Heuzey MC, Huneault MA, Wood-Adams P (2017) Rheological study of crystallization behavior of polylactide and its flax fiber composites. J Polym Res 24(3):46–56

Regazzi A, Corn S, Ienny P, Bergeret A (2016) Coupled hydro-mechanical aging of short flax fiber reinforced composites. Polym Degrad Stabil 130:300–306

Kumar R, Yakubu MK, Anandjiwala RD (2010) Biodegradation of flax fiber reinforced poly lactic acid. Express Polym Lett 4(7):423–430

Stepczyńska M, Rytlewski P (2018) Enzymatic degradation of flax-fibers reinforced polylactide. Int Biodeter Biodegr 126:160–166

Kumar R, Yakabu MK, Anandjiwala RD (2010) Effect of montmorillonite clay on flax fabric reinforced poly lactic acid composites with amphiphilic additives. Compos Part A Appl Sci Manuf 41(11):1620–1627

Yuan Y, Guo M, Wang Y (2011) Flax fibers as reinforcement in poly (lactic acid) biodegradable composites. International Conference on Intelligent Computing and Information Science. Springer, Berlin, Heidelberg, pp 547–553

Zhang H, Ming R, Yang G, Li Y, Li Q, Shao H (2015) Influence of alkali treatment on flax fiber for use as reinforcements in polylactide stereocomplex composites. Polym Eng Sci 55(11):2553–2558

Kodal M, Topuk ZD, Ozkoc G (2015) Dual effect of chemical modification and polymer precoating of flax fibers on the properties of short flax fiber/poly (lactic acid) composites. J Appl Polym Sci 132(48):42564–42577

Xia X, Liu W, Zhou L, Liu H, He S, Zhu C (2015) Study on flax fiber toughened poly (lactic acid) composites. J Appl Polym Sci 132(38):42573–42583

Rytlewski P, Stepczyńska M, Moraczewski K, Malinowski R, Jagodziński B, Żenkiewicz M (2018) Mechanical properties and biodegradability of flax fiber-reinforced composite of polylactide and polycaprolactone. Polimery 63:603–610

Duc F, Bourban PE, Plummer CJG, Månson JA (2014) Damping of thermoset and thermoplastic flax fibre composites. Compos Part A Appl Sci Manuf 64:115–123

Lee SG, Choi SS, Park WH, Cho D (2003) Characterization of surface modified flax fibers and their biocomposites with PHB. In Macromolecular symposia 197:89–100

Taylor C, Amiri A, Paramarta A, Ulven C, Webster D (2017) Development and weatherability of bio-based composites of structural quality using flax fiber and epoxidized sucrose soyate. Mater Design 113:17–26

Liu Z, Erhan SZ, Akin DE, Barton FE (2006) “Green” composites from renewable resources: preparation of epoxidized soybean oil and flax fiber composites. J Agr Food Chem 54(6):2134–2137

Liu Z, Erhan SZ, Akin DE, Barton FE, Onwulata C, McKeon TA (2008) Modified flax fibers reinforced soy-based composites: mechanical properties and water absorption behavior. Compos Interfaces 15(2–3):207–220

Hosseini N, Javid S, Amiri A, Ulven C, Webster DC, Karami G (2015) Micromechanical viscoelastic analysis of flax fiber reinforced bio-based polyurethane composites. J Renew Mater 3(3):205–215

Hosseini N, Ulven CA, Azarmi F, Webster DC, Nelson TJ (2014) Utilization of flax fibers and glass fibers in a bio-based resin. In : ASME International Mechanical Engineering Congress and Exposition. Am Soc Mech Eng 46637

Amiri A, Yu A, Webster D, Ulven C (2016) Bio-based resin reinforced with flax fiber as thermorheologically complex materials. Polymers 8(4):153

Amiri A, Hosseini N, Ulven C, Webster D (2015) Advanced bio-composites made from methacrylated epoxidized sucrose soyate resin reinforced with flax fibers. In: Proceedings of the 20th International Conference on Composite Materials, Copenhagen, Denmark. p. 9–24

Jiang L, Hinrichsen G (1999) Flax and cotton fiber reinforced biodegradable polyester amide composites, 2. Characterization of biodegradation. Die Angewandte Makromolekulare Chemie 268(1):18–21

Huang X, Netravali A (2007) Characterization of flax fiber reinforced soy protein resin based green composites modified with nano-clay particles. Compos Sci Technol 67(10):2005–2014

Rana A, Evitts RW (2015) Development and characterization of flax fiber reinforced biocomposite using flaxseed oil-based bio-resin. J Appl Polym Sci 132(15):41807–41815

Romhány G, Czigány T, Karger-Kocsis J (2006) Determination of J-R curves of thermoplastic starch composites containing crossed quasi-unidirectional flax fiber reinforcement. Compos Sci Technol 66(16):3179–3187

Soykeabkaew N, Supaphol P, Rujiravanit R (2004) (2004) Preparation and characterization of jute-and flax-reinforced starch-based composite foams. Carbohydr Polym 58(1):53–63

Liber-Kneć A, Kuźniar P, Kuciel S (2015) Accelerated fatigue testing of biodegradable composites with flax fibers. J Polym Environ 23(3):400–406

Toriz G, Arvidsson R, Westin M, Gatenholm P (2003) Novel cellulose ester–poly (furfuryl alcohol)–flax fiber biocomposites. J Appl Polym Sci 88(2):337–345

Loong ML, Cree D (2018) Enhancement of mechanical properties of bio-resin epoxy/flax fiber composites using acetic anhydride. J Polym Environ 26(1):224–234

Malloum A, Mahi AE, Idriss M (2019) The effects of water ageing on the tensile static and fatigue behaviors of greenpoxy–flax fiber composites. J Compos Mater 53(21):2927–2939

Arbelaiz A, Fernández B, Valea A, Mondragon I (2006) Mechanical properties of short flax fibre bundle/poly (ε-caprolactone) composites: Influence of matrix modification and fibre content. Carbohydr Polym 64(2):224–232

Guduri BR, Semosa H, Meng YZ (2009) Green composites from woven flax fiber and bio-copolyester. In: Proceedings of 17th ICCM international conferences on composite materials, Edinburgh 2731

Marrot L, Bourmaud A, Bono P, Baley C (2014) Multi-scale study of the adhesion between flax fibers and biobased thermoset matrices. Mater Design 1980–2015(62):47–56

Tripathi KM, Vincent F, Castro M, Feller JF (2016) Flax fibers–epoxy with embedded nanocomposite sensors to design lightweight smart bio-composites. Nanocomposites 2(3):125–134

Saiah R, Sreekumar PA, Gopalakrishnan P, Leblanc N, Gattin R, Saiter JM (2009) Fabrication and characterization of 100% green composite: thermoplastic based on wheat flour reinforced by flax fibers. Polym Compos 30(11):1595–1600

Dhakal HN, Zhang ZY, Guthrie R, MacMullen J, Bennett N (2013) Development of flax/carbon fibre hybrid composites for enhanced properties. Carbohydr Polym 96(1):1–8

Amiri A, Krosbakken T, Schoen W, Theisen D, Ulven CA (2018) Design and manufacturing of a hybrid flax/carbon fiber composite bicycle frame. Proceedings of the Institution of Mechanical Engineers, Part P: Journal of Sports Engineering and Technology 232(1):28–38

Bagheri ZS, El Sawi I, Schemitsch EH, Zdero R, Bougherara H (2013) Biomechanical properties of an advanced new carbon/flax/epoxy composite material for bone plate applications. J Mech Behav Biomed Mater 20:398–406

Yu H, Zhou C (2018) Sandwich diffusion model for moisture absorption of flax/glass fiber reinforced hybrid composite. Compos Struct 188:1–6

Zhang Y, Li Y, Ma H, Yu T (2013) Tensile and interfacial properties of unidirectional flax/glass fiber reinforced hybrid composites. Compos Sci Technol 88:172–177

Calabrese L, Fiore V, Scalici T, Valenza A (2019) Experimental assessment of the improved properties during aging of flax/glass hybrid composite laminates for marine applications. J Appl Polym Sci 136(14):47203–47215

Ghasemzadeh-Barvarz M, Duchesne C, Rodrigue D (2015) Mechanical, water absorption, and aging properties of polypropylene/flax/glass fiber hybrid composites. J Compos Mater 49(30):3781–3798

Mohan K, Rajmohan T (2018) Effects of MWCNT on mechanical properties of glass-flax fiber reinforced nano composites. Materials Today: Proceedings 5(5):11628–11635

Morye SS, Wool RP (2005) Mechanical properties of glass/flax hybrid composites based on a novel modified soybean oil matrix material. Polym Compos 26(4):407–416

Benevolenski OI, Karger-Kocsis J, Mieck KP, Reubmann T (2000) Instrumented perforation impact response of polypropylene composites with hybrid reinforcement flax/glass and flax/cellulose fibers. J Thermoplast Compos Mater 13(6):481–496

Adekunle K, Cho SW, Patzelt C, Blomfeldt T, Skrifvars M (2011) Impact and flexural properties of flax fabrics and Lyocell fiber-reinforced bio-based thermoset. J Reinf Plast Compos 30(8):685–697

Wang H, Yang L, Wu H (2021) Study on mechanical and thermomechanical properties of flax/glass fiber hybrid-reinforced epoxy composites. Polym Compos 42(2):714–723

Živković I, Fragassa C, Pavlović A, Brugo T (2017) Influence of moisture absorption on the impact properties of flax, basalt and hybrid flax/basalt fiber reinforced green composites. Compos B Eng 111:148–164

Almansour FA, Dhakal HN, Zhang ZY, Ghasemnejad H (2017) Effect of hybridization on the mode II fracture toughness properties of flax/vinyl ester composites. Polym Compos 38(8):1732–1740

Eselini N, Tirkes S, Akar AO, Tayfun U (2020) Production and characterization of poly (lactic acid)-based biocomposites filled with basalt fiber and flax fiber hybrid. J Elastom Plast 52(8):701–716

Chaudhary V, Bajpai PK, Maheshwari S (2018) Studies on mechanical and morphological characterization of developed jute/hemp/flax reinforced hybrid composites for structural applications. J Nat Fibers 15(1):80–97

Chaudhary V, Bajpai PK, Maheshwari S (2018) An investigation on wear and dynamic mechanical behavior of jute/hemp/flax reinforced composites and its hybrids for tribological applications. Fiber Polym 19(2):403–415

Khanlou HM (2018) Degradation of flax PLA biocomposites during and after manufacture. Griffith University, Queensland, Australia

Le Duigou A, Bourmaud A, Davies P, Baley C (2014) Long term immersion in natural seawater of flax/PLA biocomposite. Ocean Eng 90:140–148

Zaki Abdullah, M, Dan-mallam, Y, & Megat Yusoff, PSM (2013) Effect of environmental degradation on mechanical properties of kenaf/polyethylene terephthalate fiber reinforced polyoxymethylene hybrid composite. Adv Mater Sci Eng 2013

Muniyasamy S, Ofosu O, Thulasinathan B, Rajan AST, Ramu SM, Soorangkattan S, Alagarsamy A (2019) Thermal-chemical and biodegradation behaviour of alginic acid treated flax fibres/poly (hydroxybutyrate-co-valerate) PHBV green composites in compost medium. Biocatal Agric Biotechnol 22:101394

La Mantia FP, Morreale M (2011) Green composites: a brief review. Compos Part A Appl Sci Manuf 42(6):579–588

Joshi SV, Drzal LT, Mohanty AK, Arora S (2004) Are natural fiber composites environmentally superior to glass fiber reinforced composites? Compos Part A Appl Sci Manuf 35(3):371–376

Le Duigou A, Davies P, Baley C (2011) Environmental impact analysis of the production of flax fibres to be used as composite material reinforcement. J Biobased Mater Bioenergy 5(1):153–165

Deng Y, Paraskevas D, Tian Y, Van Acker K, Dewulf W, Duflou JR (2016) Life cycle assessment of flax-fibre reinforced epoxidized linseed oil composite with a flame retardant for electronic applications. J Clean Prod 133:427–438

Deng Y, Guo Y, Wu P, Ingarao G (2019) Optimal design of flax fiber reinforced polymer composite as a lightweight component for automobiles from a life cycle assessment perspective. J Ind Ecol 23(4):986–997

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

More, A.P. Flax fiber–based polymer composites: a review. Adv Compos Hybrid Mater 5, 1–20 (2022). https://doi.org/10.1007/s42114-021-00246-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42114-021-00246-9