Abstract

This paper studies the internal relationship between peridynamics (PD) models, which address to the Poisson's ratio limitation in original bond-based PD theory by considering tangential bond force or tangential stiffness. Firstly, a non-ordinary state-based PD model is formulated based on a micro-potential considering a more general three-body interaction potential, which can also remove the constraint on values of Poisson’s ratio. Then, a special three-body interaction potential, called novel three-body interaction potential, is adopted in the proposed PD model stated above; it can be found that the resulting PD model can be equivalent to that considering bond stretch and rotation published earlier under assumption of small deformation conditions. This discovery in turn reveals the macroscopic mechanical mechanism of the novel three-body interaction potential in resisting shear deformation. Moreover, the result not only provides a physical explanation for the latter to some extent, but also is helpful to reveal the internal relationships between those PD models considering tangential bond force directly. In addition, another special example of PD model considering distribution of the intensity of long range forces is also given within the proposed PD modeling framework. Its performance is computationally demonstrated by a dynamic fracture problem. These results show that formulating PD models within state-based PD framework by assuming reasonable micro-potential can be proper and flexible in practical engineering problems.

Similar content being viewed by others

Availability of Data and Materials

The datasets supporting the conclusions of this article are included within the article and its additional files.

References

Silling SA (2000) Reformulation of elasticity theory for discontinuities and long-range forces. J Mech Phys Solids 48(1):175–209

Gerstle W, Sau N, Silling SA (2007) Peridynamic modeling of concrete structures. Nucl Eng Des 237:1250–1258

Silling SA, Bobaru F (2005) Peridynamic modeling of membranes and fibers. Int J Non-Linear Mech 40:395–409

Hu YL, De Carvalho NV, Madenci E (2015) Peridynamic modeling of delamination growth in composite laminates. Compos Struct 132:610–620

Hu YL, Madenci E (2016) Bond-based peridynamic modeling of composite laminates with arbitrary fiber orientation and stacking sequence. Compos Struct 153:139–175

Madenci E, Barut A, Phan N (2018) Peridynamic unit cell homogenization for thermoelastic properties of heterogenous microstructures with defects. Compos Struct 188:104–115

Chen Z, Niazi S, Bobaru F (2019) A peridynamic model for brittle damage and fracture in porous materials. Int J Rock Mech Min Sci 122:104059

Oterkus S, Madenci E, Agwai A (2014) Peridynamic thermal diffusion. J Comput Phys 265:71–96

Madenci E, Oterkus S (2016) Oridnary state-based peridynamics for plastic deformation according to von Mises yield criteria with isotropic hardening. J Mech Phys Solids 86:192–219

Zhang Y, Madenci E (2021) A coupled peridynamic and finite element approach in ANSYS framework for fatigue life prediction based on the kinetic theory of fracture. J Peridyn Nonlocal Model 4:51–87

Bang DJ, Ince A, Oterkus E, Oterkus S (2021) Crack growth modeling and simulation of a peridynamic fatigue model based on numerical and analytical solution approaches. Theor Appl Fract Mech 114:103026

Hu YL, Madenci E (2017) Peridynamics for fatigue life and residual strength prediction of composite laminates. Compos Struct 160:169–184

Madenci E, Barut A, Yaghoobi A, Phan N, Fertig RS (2021) Combined peridynamics and kinetic theory of fracture for fatigue failure of composites under constant and variable amplitude loading. Theor Appl Fract Mech 112:102824

Jafarzadeh S, Chen Z, Bobaru F (2018) Peridynamic modeling of intergranular corrosion damage. J Electrochem Soc 165(7):362–374

Kulkarni SS, Tabarraei A (2020) An ordinary state based peridynamic correspondence model for metal creep. Eng Fract Mech 233:107042

Deng X, Wang B (2020) Peridynamic modeling of dynamic damage of polymer bonded explosive. Comput Mater Sci 173:109405

Madenci E, Dorduncu M, Barut A, Futch M (2017) Numerical solution of linear and nonlinear partial differential equations using the peridynamic differential operator. Numer Methods Partial Differ Equ 33:1726–1753

Silling SA, Askari E (2005) A meshfree method based on the peridynamic model of solid mechanics. Comput Struct 83(17):1526–1535

Silling SA, Epton M, Weckner O, Xu J, Askari E (2007) Peridynamic states and constitutive modeling. J Elast 88(2):151–184

Silling SA (2017) Stability of peridynamic correspondence material models and their particle discretizations. Comput Methods Appl Mech Eng 322:42–57

Li P, Hao Z, Zhen W (2018) A stabilized non-ordinary state-based peridynamic model. Comput Methods Appl Mech Eng 339:262–280

Breitzman T, Dayal K (2018) Bond-level deformation gradients and energy averaging in peridynamics. J Mech Phys Solids 110:192–204

Le Q, Chan WK, Schwartz J (2014) A two-dimensional ordinary, state-based peridynamic model for linearly elastic solids. Int J Numer Meth Eng 98(8):547–561

Madenci E, Oterkus E (2014) Peridynamic Theory and Its Application. Springer, New York, pp 53–74

Tupek MR, Radovitzky R (2014) An extended constitutive correspondence formulation of peridynamics based on nonlinear bond-strain measures. J Mech Phys Solids 65:82–92

Chen H (2018) Bond-associated deformation gradients for peridynamic correspondence model. Mech Res Commun 90:34–41

Chen H, Spencer BW (2019) Peridynamic bond-associated correspondence model: Stability and convergence properties. Int J Numer Meth Eng 117:713–727

Chan WL, Chen H (2021) Peridynamic bond-associated correspondence model: Wave dispersion property. Int J Numer Meth Eng 122(18):4848–4863

Zheng G, Shen G, Xia Y, Hu P (2020) A bond-based peridynamic model considering effects of particle rotation and shear influence coefficient. Int J Numer Meth Eng 121:93–109

Hu YL, Madenci E (2016) Bond-based peridynamics with an arbitrary Poisson’s ratio. In: American Institute of Aeronautics and Astronautics 57th AIAA/ASCE/AHS/ASC structures, structural dynamics, and materials conference, San Diego, California, USA

Wang Y, Zhou X, Wang Y, Shou Y (2017) A 3-D conjugated bond-pair-based peridynamic formulation for initiation and propagation of cracks in brittle solids. Int J Solids Struct 134:1–27

Huang X, Li S, Jin Y, Yang D, Su G, He X (2019) Analysis on the influence of Poisson’s ratio on brittle fracture by applying uni-bond dual-parameter peridynamic model. Eng Fract Mech 222:106685

Li S, Lu H, Jin Y, Sun P, Huang X, Bie Z (2021) An improved unibond dual-parameter peridynamic model for fracture analysis of quasi-brittle materials. Int J Mech Sci 204:106–571

Huang D, Lu G, Qiao P (2015) An improved peridynamic approach for quasi-static elastic deformation and brittle fracture analysis. Int J Mech Sci 94:111–122

Zhu Q, Ni T (2017) Peridynamic formulations enriched with bond rotation effects. Int J Eng Sci 121:118–129

Li W, Zhu Q, Ni T (2020) A local strain-based implementation strategy for the extended peridynamic model with bond rotation. Comput Methods Appl Mech Eng 358:112–625

Madenci E, Barut A, Phan N (2021) Bond-Based Peridynamics with stretch and rotation kinematics for opening and shearing modes of fracture. J Peridyn Nonlocal Model 3:211–254

Mayo SL, Olafson BD, Goddard WA (1990) DREIDING: A generic force field for molecular simulations. J Phys Chem 94(26):8897–8909

Silling SA, Lehoucq RB (2010) Peridynamic theory of solid mechanics. Adv Appl Mech 44(10):73–168

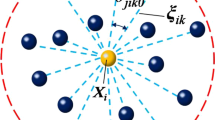

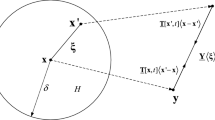

Li X, Huang Z (2020) A non-ordinary state-based peridynamic constitutive model based on three-body interaction potential and its implementation on algorithm. J Peridyn Nonlocal Model 2(12–13):1–26

Gurtin E (1981) An Introduction to Continuum Mechanics. Academic Press

T. Foster J., Silling S.A., Chen, W. (2011) An Energy based failure criterion for use with peridynamic states. J Multiscale Comput Eng 9(6):675–687

Field JE (1992) Hot spot ignition mechanisms for explosives. Acc Chem Res 25:489–496

Ha YD, Bobaru F (2010) Studies of dynamic crack propagation and crack branching with peridynamics. Int J Fract 162:229–244

Belytschko T, Chen H, Xu J, Zi G (2003) Dynamic crack propagation based on loss of hyperbolicity and a new discontinuous enrichment. Int J Numer Meth Eng 58(12):1873–1905

Bobaru F, Zhang G (2015) Why do cracks branch? A peridynamic investigation of dynamic brittle fracture. Int J Fract 196(1–2):59–98

Wang X, Kulkarni SS, Tabarraei A (2019) Concurrent coupling of peridynamics and classical elasticity for elastodynamic problems. Comput Methods Appl Mech Eng 344:251–275

Bowden FP, Brunton JH, Field JE, Heyes Ad (1967) Controlled fracture of brittle solids and interruption of electrical current. Nature 216:38–42

Acknowledgements

We thank Dr. Pan Li of China Academy of Engineering Physics for useful discussions. The supports from China Academy of Engineering Physics Institute of Systems Engineering are gratefully acknowledged. The authors would like to thank the editor and reviewer for valuable comments and suggestions.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing Interests

The authors declare that they have no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A Proof for Eq. (24)

Proof

By using Eq. (17), (19), we arrive at

Then,

with \(s\approx {\varvec{\upchi}}\cdot {\varvec{\upvarepsilon}}\cdot {\varvec{\upchi}}\) under small deformation and \({\varvec{\upchi}}\cdot {\varvec{\upomega}}\cdot {\varvec{\upchi}}\)=0. Therefore, \({s}^{2}=\overline{\mathbf{e} }\cdot \overline{\mathbf{e} }\) in Eq. (24) is satisfied.

Appendix B Proof for Eq. (52)

Proof

By Eq. (23)

under small deformation conditions, note that \(s\approx {\varvec{\upchi}}\cdot {\varvec{\upvarepsilon}}\cdot {\varvec{\upchi}}\), then

which implies \(\mathbf{r}\cdot \mathbf{r}+{s}^{2}=\left({\varvec{\upvarepsilon}}\cdot {\varvec{\upchi}}\right)\cdot \left({\varvec{\upvarepsilon}}\cdot {\varvec{\upchi}}\right)\), i.e., Eq. (52) holds.

Rights and permissions

About this article

Cite this article

Li, X., Hao, Z. Thoughts on the Non-ordinary Peridynamics Model Based on Three-body Potential. J Peridyn Nonlocal Model 4, 398–419 (2022). https://doi.org/10.1007/s42102-022-00084-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42102-022-00084-3