Abstract

We are currently experiencing a resurgence in the realm of electrochemical organic synthesis, driven by the transformative potential of conducting redox chemistry under mild conditions through the simple use of electrons, thereby circumventing the use of harmful reductants and oxidants. This renaissance is further bolstered by the fusion of electrochemistry with flow chemistry, which not only grants precise control over reaction parameters but also promotes sustainability and heightened reproducibility. Despite these promising advancements, the application of flow electrochemistry to steer asymmetric processes remains in its nascent stage. This perspective delves into the limited contributions to date, shedding light on critical challenges and presenting prospective solutions that are essential for fully unleashing the untapped potential of this field.

Graphical abstract

Similar content being viewed by others

Introduction

Organic electrochemistry owes its origins to Alessandro Volta's groundbreaking discovery of the electrochemical cell in 1800 [1]. This pivotal event paved the way for significant advancements in the field, such as the ones developed by Michael Faraday [2], Hermann Kolbe [3], and Fritz Haber [4], who applied electrochemical principles to organic reactions. These trailblazing contributions broadened the horizons of organic electrochemistry and opened new possibilities for employing electrochemical processes in the synthesis and manipulation of organic compounds.

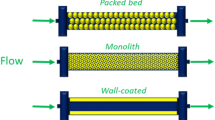

Currently, organic electrochemistry [5,6,7,8,9,10] is regarded as an invaluable tool for enabling redox neutral, reductive, or oxidative reactions in a manner that is mild and environmentally friendly [11]. A key advantage of this approach is the replacement of toxic and potentially hazardous oxidants and reducing agents with controlled electricity. By harnessing the power of electricity, organic electrochemistry not only enhances the safety and sustainability of organic synthesis but also enables the development of efficient and selective transformations. This paradigm shift towards electrochemical methodologies provides researchers with innovative strategies to minimize waste production and promote greener chemical processes [12]. However, the use of electrochemistry does come with certain challenges [13]. For instance, a notable drawback is the requirement of significant quantities of electrolyte to achieve a conductive solution. Additionally, the intrinsic heterogeneous nature of the electrochemical process places great importance on mass transfer phenomena. In some cases, these phenomena can even become rate-determining factors and, if not carefully considered, may lead to electrode surface modification or degradation [14]. Nonetheless, many of these issues can be effectively addressed by integrating electrosynthesis with flow chemistry [15,16,17,18,19]. This does not come as a surprise since flow chemistry [20, 21] has always been associated with improved mass and heat transfer, as well as a more precise control over the reaction conditions, reduced reaction times and enhanced scalability. Additionally, the increased proximity of electrodes in flow reactors often reduces the necessary amount of electrolyte for achieving good conductivity, further mitigating the issue. The synergistic power of electrochemistry and flow chemistry is exemplified by its successful application in industrial settings [22,23,24,25,26], such as the development of the new Monsanto process for adiponitrile production (up to 300.000 tons/year). Recently, there has been a significant surge of interest in utilizing organic electrochemistry to drive asymmetric transformations [27,28,29,30]. For example, electrochemistry has been successfully integrated with other catalytic systems, including organocatalysis [31], transition metal catalysis [32,33,34], and biocatalysis [35,36,37,38,39,40]. Additionally, alternative approaches (outside of the scope of this perspective) utilizing chiral electrodes, chiral solvents, or chiral electrolytes have been reported, further expanding the scope and potential of organic electrochemistry in achieving asymmetric synthesis.

Despite all these advancements, the development of asymmetric electrochemical transformations in flow is far from ideal, with a multitude of contributing factors. First of all, electroorganic synthesis and especially its merger with catalytic manifold is still in its infancy. For a long time, electrochemistry has been considered mostly part of the domain of physical chemistry, therefore organic electrochemistry has remained a niche approach [41]. Furthermore, there is a low abundance of reactors capable of performing electrochemical reactions in flow [15], especially if we compare it to the ones available for photoredox catalysis. As a matter of fact, the majority of these devices are built in-house and might pose problems of reproducibility.

The objective of this perspective is to focus on the major contributions within the realm of asymmetric organic electrochemistry in flow, highlighting the positive aspects, challenges, and milestones of coupling flow chemistry with electrochemical asymmetric synthesis. By doing so, the aim is to ignite increased enthusiasm for this field and expedite its advancement. To facilitate the discussion, the selected examples are categorized into four classes, based on whether the process is mediated/catalyzed or not by an organic molecule, a metal catalyst, or a biocatalyst. Finally, the future prospects and the advancements required to fully unlock the potential of this young interdisciplinary field will be discussed.

Non-mediated and non-catalytic processes

Electrochemistry is a powerful technique that offers unconventional synthetic solutions for the synthesis of complex molecules [42]. Opatz and colleagues have recently reported a noteworthy achievement in the total synthesis of ( −)-Oxycodone, a semisynthetic opioid produced commercially on a multi-ton scale [43]. In their synthetic route, the initial step involved a diastereoselective anodic oxidation of a Laudanosine derivative 1 (Scheme 1), leading to the formation of morphinandienone compound 2. This process, which relies on the electrochemical oxidative aryl-aryl coupling developed by Waldvogel [44,45,46], consists of a first electrochemical oxidation on the more electron-rich aromatic system, affording radical cation I. The judicious choice of the substituents on the aromatic rings completely drives the regioselectivity of the intramolecular recombination, generating intermediate III. Subsequently, III undergoes a second oxidation step, followed by deprotonation, leading to the formation of V. Hydrolysis of the latter furnishes the desired compound 2.

Total synthesis of ( −)-Oxycodone via anodic aryl–aryl coupling by Opatz and co-workers. Adapted with permission from reference [43]; copyright 2019, American Chemical Society. BDD: Boron Doped Diamond. IED: Interelectrode Distance

This protocol was carried out in an undivided electrochemical cell under galvanostatic conditions and could be performed either in batch (69% yield) or in flow (57% yield). Boron-doped diamond and platinum proved to be the optimal materials for the anode and cathode, respectively. Additionally, 4 equivalents of HBF4 were utilized as electrolyte and acid to prevent oxidation of the amine moiety, as well as proton source for the cathodic half-reaction, while a temperature of 0 °C and an interelectrode distance of 0.5 mm proved to be crucial to obtain the target molecule with good chemical efficiency.

Overall, this achievement showcases the successful application of electrochemistry in the total synthesis of ( −)-Oxycodone, demonstrating the potential of electrochemical methods for complex molecule construction in the pharmaceutical industry. The use of selective electrochemical transformations offers a promising strategy for the synthesis of valuable compounds with improved efficiency and sustainability.

The possibility to couple microfluidic reactors with inline techniques is an extremely advantageous feature of flow chemistry [47]. For instance, the reactor can be coupled with a sequential analysis to reduce the number of experiments needed for the optimization of the process and/or an analytical device, such as HPLC or NMR, to directly measure conversions and yields. This approach has also been applied within the field of asymmetric flow electrochemistry. The group of Wirth has detailed the development of a microfluidic electrochemical approach to yield enantioenriched N,O acetals by a “memory of chirality” approach (Scheme 2) [48]. In this strategy [49], pioneered by Seebach [50] and Fuji [51], the chirality of the starting material is translated to some extent to the corresponding product even though the reaction intermediate is planar, and no other permanently chiral element is present in the system. This electrochemical process relies on the oxidative decarboxylation of α-amino acid derivative 3, which leads to planar iminium ion intermediate VI that is ultimately trapped by methanol to yield compound 4. In this case, the presence of a sterically encumbering substituent at the nitrogen center is responsible for the facial discrimination of the iminium ion by the nucleophile, ultimately leading to the retention of the configuration of the stereocenter of the product as in the starting material. Notably, the authors coupled their microfluidic electrochemical setup, the commercially available Ion electrochemical reactor, with an online 2D-HPLC and used a Design of Experiment (DoE) [52] approach to carry on the optimization step. This combination enabled the intensive screening of several reaction parameters, such as electrode material, interelectrode distance, temperature, and flow rate, in a very short timeframe. Through this approach, product 4 was obtained in a 60% yield and 70% enantiomeric excess when employing glassy carbon as the anode, platinum as the cathode, NaOMe as base and electrolyte at -10 °C with an interelectrode distance of 0.5 mm in a galvanostatic approach.

Organo-mediated processes

Unlike biocatalysis and metal catalysis, enantioselective organocatalysis has not been extensively coupled with electrochemistry, despite this merger has been recognized as a possible prominent research area in this decade [53]. A significant obstacle in this endeavor might be represented by the inherent fragility of organic catalysts when compared to metallic counterparts, particularly in the challenging area of redox chemistry. As a testament to this issue, the only report where a chiral organic molecule is used to promote an enantioselective electrochemical transformation in flow makes use of hypervalent iodine [54], a class of compounds that closely emulates the behavior of transition-metal catalysts [55]. However, this process is not able to operate under a catalytic manifold. Indeed, the group of Wirth has reported the use of chiral iodoarene 5 (Scheme 3) to promote the enantioselective galvanostatic electrochemical lactonization of diketo acid derivative 6 [56]. Specifically, chiral iodoarene 5 is converted in situ into the pivotal iodine(III) intermediate VII by electrochemical oxidation at the anode of an undivided cell, replacing the use of stoichiometric oxidants like peroxycarboxylic acids. The hypervalent iodine compound is then responsible for driving the lactonization in an enantioselective fashion, affording compound 7. After an initial optimization in batch, platinum was selected as the best performing material as both anode and cathode, while nBu4NBF4 was selected as the optimal electrolyte and trifluoroacetic acid as a key additive to promote the lactonization in a satisfactory yield and selectivity. Furthermore, the authors used trifluoroethanol as solvent due to its ability to stabilize iodine(III) reagents under anodic environment [57]. Under these conditions, the scope of the process was evaluated in batch and subsequently translated into a microfluidic device, where the target lactone 7 was obtained with a 56% yield and 55% enantiomeric excess, with a tenfold decrease of the amount of the electrolyte required with respect to the batch setup but a decrease in terms of yield and enantioselectivity (70% yield and 71% enantiomeric excess under batch conditions). Unfortunately, when using the iodoarene in a catalytic amount, only traces of the product were observed.

Biocatalytic processes

Biocatalysis and electrochemistry have a long-standing history of integration, particularly within the domain of oxidoreductases [35,36,37,38,39,40, 58]. These remarkable enzymes play a crucial role in facilitating oxidation and reduction processes, involving the transfer of one or more electrons [59]. They are indispensable for numerous vital biological functions, including biosynthesis, energy production, and respiration, among others. To carry out their functions, these enzymes rely on a redox partner, such as cytochrome or flavoprotein, or a co-substrate like molecular oxygen or NAD(P)H, which helps balance the redox half-reaction. Electrochemistry has been employed either to substitute the electron-transfer partner or to provide a tool to replenish it, thereby enabling its use in a catalytic manner [60].

This approach has also been effectively implemented in flow systems [61]. In this context, utilizing an electrochemical flow cell for biocatalysis offers a dual advantage. Firstly, it expedites overall electrochemical cofactor regeneration. Secondly, it facilitates process scaling. Additionally, in the case of biocatalytic oxidations, it may even offer the opportunity to enhance the solubility of poorly soluble molecular oxygen by adjusting reactor pressure or increasing the interface between the liquid and gaseous phases.

The Schmid research group has introduced a microfluidic reactor comprising separate flow-through cathodic and anodic compartments, both constructed from reticulated vitreous carbon (RVC) [62]. This material provides a substantial active surface area for electrochemical reactions and a substantial void volume, making these electrodes ideal for scaling up processes without generating significant backpressure. This setup, operating in a recirculation mode, was employed for two distinct processes: the asymmetric reduction of 3-methylcyclohexanone [62] and the enantioselective epoxidation of styrene [63].

In the first process (Scheme 4a), the reaction is catalyzed by a thermophilic alcohol dehydrogenase from Thermus sp., which utilizes NADH as cofactor. The flow electrochemical setup was used to regenerate the cofactor, therefore enabling its use in a catalytic manner. However, NAD+ is known to undergo unspecific reduction at the electrode, leading to dimerization products and overall to an inactive cofactor species [64]. To tackle this issue, the authors used [Cp*Rh(bpy)(H2O)]2+, an efficient electrochemical mediator for the restoration of nicotinamide cofactors [65]. Under the optimized conditions, involving the use of a divided cell setup operating under potentiostatic conditions (-0.8 V vs Ag/AgCl), compound 8 was reacted in the cathodic compartment at 60 °C using a Bis–Tris buffer solution, 1 mol% of the redox mediator, 5 mol% of the cofactor and 0,002 mol% of the enzyme, yielding compound 9 in a 32% yield, full enantioselectivity and a diastereomeric excess of 96%. Furthermore, by increasing the concentration of 8, the authors were able to boost the productivity of the system from 0.06 to 0.13 g L−1 h−1.

The same reactor was then employed for the enantioselective epoxidation of styrene 10 (Scheme 4b) catalyzed by styrene monooxygenase (StyA), an enzyme reliant on molecular oxygen as oxidant and FADH2 to restore its catalytic activity. Previous findings from the group of Schmid had already outlined the potential use of FADH2 in catalytic amounts under an electrochemical regime [66]. However, such a system suffered from low cofactor regeneration rates compared to the native cycle, due to the inherent mass transfer issues related to the use of a batch-type electrochemical reactor and by the fast aerobic oxidation of the flavin. Nonetheless, by conducting this reaction in their flow-through electrochemical reactor, equipped with a RVC electrode serving also as a turbulence promoter, the authors were able to obtain the desired (S)-styrene oxide 11 with a 99.5% enantiomeric excess and 82% yield under the optimized reaction conditions in a potentiostatic regime (-0.75 V vs Ag/AgCl).

The group of Holtmann also devised a conceptually akin flow-through reactor to facilitate asymmetric biocatalytic reactions (Scheme 5) [67]. Specifically, this reactor is composed of a RVC packed bed anode, an iridium-based oxide plated titanium net as counter electrode separated by an ion exchange membrane and an Ag/AgCl reference electrode plugged into the catholyte chamber [68]. The authors developed a potentiostatic electrochemical approach to regenerate NADH within the asymmetric oxidation of meso-2,3-butanediol 12 to (R)-acetoin 13 catalyzed by an alcohol dehydrogenase (ADH-9). As previously discussed, NAD+ is not electrochemically stable, necessitating the use of a redox mediator to be restored to NADH. In this case, the authors used 2,2’-azino-bis-(3-ethylbenzothiazoline-6-sulphonic acid) (ABTS) as mediator. However, a previous study already highlighted that, under batch conditions, the mass transport of the oxidized form of ABTS from the electrode surface into the bulk solution significantly hampered the reaction rate and efficiency [69]. Crucially, by opting for an electrochemical flow cell instead of a batch one, the authors were able to obtain the desired compound at a potential of -0.8 V vs Ag/AgCl in a 65% yield, complete enantioselectivity and an average productivity of 5.7 mM h−1.

Enantioselective enzymatic synthesis of (R)-acetoin by Holtmann and co-workers. Adapted with permission from reference [68]; copyright 2014, Elsevier. GC: Glassy Carbon. τ: Residence Time. ADH-9: Alcohol Dehydrogenase 9. ABTS: 2,2’-azino-bis-(3-ethylbenzothiazoline-6-sulphonic acid)

Transition-metal catalyzed processes

Metal catalysis is an established tool in organic synthesis, encompassing an extremely rich and diverse reactivity, which is well understood and can be predicted [70]. Among the wide plethora of metal catalyzed processes, asymmetric hydrogenation [71, 72] is perhaps the most important from an industrial point of view [73, 74], superseding all other catalytic enantioselective methods for the manufacture of chiral compounds. As hydrogen can be easily obtained by electrochemical means (i.e. cathodic hydrogen evolution), it is not a surprise that transition-metal catalyzed hydrogenations and electrochemistry have been coupled [75]. Additionally, this strategy has been effectively performed under flow chemistry conditions. For instance, the group of Atobe has recently developed a galvanostatic electrochemical asymmetric hydrogenation of α,β-unsaturated carboxylic acids 14 (Scheme 6) in a microfluidic proton-exchange membrane (PEM) reactor [76]. This process relies on the cathodically in situ generation of hydrogen and the concomitant use of palladium as both cathode and catalyst of the reaction, while the enantioselectivity of the process originates from the use of cinchonidine 16 as chiral ligand. As detailed in Scheme 6, the PEM reactor consists of an ion-exchange membrane placed in between two catalyst/electrode layers composed of an ionomer, carbon black and platinum for the anode side and palladium for the cathode one. In their protocol, the authors introduced humidified hydrogen in the anodic chamber to be converted into protons on the Pt anode. It must be noted that the generation of H+ could also be achieved by other anodic reactions such as water oxidation. The electrochemically generated protons were transported through the membrane to the cathode to be reduced to monoatomic hydrogen species directly attached on the palladium catalyst surface and ultimately reacted with α,β-unsaturated carboxylic acids 14 to yield compounds 15. Furthermore, the authors have recently applied a similar reactor to promote the electrocatalytic diastereoselective hydrogenation of cyclic ketones [77].

Electrocatalytic asymmetric hydrogenation of α,β-unsaturated acids in a PEM reactor by Atobe and co-workers. Adapted with permission from reference [76]; copyright 2019, American Chemical Society. Yields refers to the current efficiencies

One of the key features of a metal catalyst is the wide range of oxidation states within reach, which are usually necessary for each elementary step in a catalytic cycle. In this sense, its coupling with electrochemistry is logical, to modulate the oxidation state of the metal catalyst at will, opening new reactivity venues while accessing often air-sensitive oxidation states directly in situ [32, 78]. The group of Ackermann has very recently disclosed an atroposelective cobaltaelectro-catalyzed C − H [79] annulation with allenes in both batch and flow environments, employing graphite felt as the anodic material and platinum as the cathodic one (Scheme 7) [80]. Notably, this transformation is the first enantioselective electrochemical organometallic C−H activation in continuous flow. The reaction, as suggested by a combination of kinetic analyses, stoichiometric experiments and cyclovoltammetric studies, involves a Co(III/I/II) catalytic cycle, proving the crucial role of electrochemistry in mediating the redox state of the metal catalyst by anodic means, while hydrogen evolution is taking place on the cathode. Under these galvanostatic conditions, the desired annulated products were obtained with outstanding yields and enantioselectivities (up to 86% yield and 99% enantiomeric excess), with slightly lower chemical efficiency when moving from batch to flow, but constant enantioselectivity. Furthermore, the use of a flow setup, the commercially available IKA ElectraSyn Flow, avoided the addition of electrolytes to the reaction mixture as well as enabling a decagram scale up.

Conclusions

Over the past few years, asymmetric synthesis, flow chemistry and electrochemistry have been audaciously merged to produce added-value molecules under mild conditions and, in the majority of cases, in a continuous fashion. This perspective has outlined how this was achieved within a total synthesis or how flow could enable the implementation of in-line monitoring techniques. Furthermore, this approach has been effectively applied to transition metal and biocatalysis, offering innovative solutions to address significant synthetic challenges, such as the modulation of the redox state of metal catalysts or regenerating cofactors in biocatalysis. Despite these trailblazing examples, the fields of asymmetric flow and even batch electrochemistry are still in their early stages, and there is plenty of room for further advancements. From an engineering perspective, the development of more standardized and accessible flow electrochemical reactors is essential. Additionally, as exemplified by the lack of reports in the area of organocatalysis and by the often non-optimal enantioselectivities, a future goal for the continued expansion of this field is the design of new asymmetric catalysts, taking into consideration also their electrochemical stability. Finally, as this process operates under mild conditions and can offer unique selectivity, applications in the area of late-stage functionalization can be expected in the upcoming future.

Given the promising results achieved thus far and the vast potential that lies ahead, the future of asymmetric flow electrochemistry holds great promise, excitement, and is undoubtedly electrifying.

References

Volta A (1832) On the electricity excited by the mere contact of conducting substances of different kinds. In a Letter from Mr. Alexander Volta, F. R. S. Professor of Natural Philosophy in the University of Pavia, to the Rt. Hon. Sir Joseph Banks, Bart. K. B. P. R. S. Proc R Soc Lond 1:27–29. https://doi.org/10.1098/rspl.1800.0016

Faraday M (1834) Siebente Reihe von Experimental-Untersuchungen über Elektricität. Ann Phys 109:433–451

Kolbe H (1847) Beobachtungen über die oxydirende Wirkung des Sauerstoffs, wenn derselbe mit Hülfe einer elektrischen Säule entwickelt wird. J Für Prakt Chem 41:137–139

Haber F (1898) Elektrolytische Darstellung von Phenyl-β-Hydroxylamin. Z Für Elektrotechnik Elektrochem 5:77–78

Wiebe A et al (2018) Electrifying organic synthesis. Angew Chem Int Ed 57:5594–5619

Minteer SD, Baran P (2020) Electrifying synthesis: recent advances in the methods, materials, and techniques for organic electrosynthesis. Acc Chem Res 53:545–546

Yan M, Kawamata Y, Baran PS (2017) Synthetic organic electrochemical methods since 2000: on the verge of a renaissance. Chem Rev 117:13230–13319

Schotten C et al (2020) Making electrochemistry easily accessible to the synthetic chemist. Green Chem 22:3358–3375

Kingston C et al (2020) A survival guide for the “Electro-curious.” Acc Chem Res 53:72–83

Zhu C, Ang NWJ, Meyer TH, Qiu Y, Ackermann L (2021) Organic electrochemistry: molecular syntheses with potential. ACS Cent Sci 7:415–431

Horn EJ, Rosen BR, Baran PS (2016) Synthetic organic electrochemistry: an enabling and innately sustainable method. ACS Cent Sci 2:302–308

Schäfer HJ (2011) Contributions of organic electrosynthesis to green chemistry. Comptes Rendus Chim 14:745–765

Yuan Y, Lei A (2020) Is electrosynthesis always green and advantageous compared to traditional methods? Nat Commun 11:802

Heard DM, Lennox AJJ (2020) Electrode materials in modern organic electrochemistry. Angew Chem Int Ed 59:18866–18884

Noël T, Cao Y, Laudadio G (2019) The fundamentals behind the use of flow reactors in electrochemistry. Acc Chem Res 52:2858–2869

Pletcher D, Green RA, Brown RCD (2018) Flow electrolysis cells for the synthetic organic chemistry laboratory. Chem Rev 118:4573–4591

Nicholls TP, Schotten C, Willans CE (2020) Electrochemistry in continuous systems. Curr Opin Green Sustain Chem 26:100355

Atobe M, Tateno H, Matsumura Y (2018) Applications of flow microreactors in electrosynthetic processes. Chem Rev 118:4541–4572

Elsherbini M, Wirth T (2019) Electroorganic synthesis under flow conditions. Acc Chem Res 52:3287–3296

Plutschack MB, Pieber B, Gilmore K, Seeberger PH (2017) The Hitchhiker’s guide to flow chemistry. Chem Rev 117:11796–11893

Capaldo L, Wen Z, Noël T (2023) A field guide to flow chemistry for synthetic organic chemists. Chem Sci 14:4230–4247

Tanbouza N, Ollevier T, Lam K (2020) Bridging lab and industry with flow electrochemistry. iScience 23:101720

Walsh FC, Ponce De León C (2018) Progress in electrochemical flow reactors for laboratory and pilot scale processing. Electrochimica Acta 280:121–148

Leech MC, Garcia AD, Petti A, Dobbs AP, Lam K (2020) Organic electrosynthesis: from academia to industry. React Chem Eng 5:977–990

Botte GG (2014) Electrochemical manufacturing in the chemical industry. Interface Mag 23:49–55

Sequeira CAC, Santos DMF (2009) Electrochemical routes for industrial synthesis. J Braz Chem Soc 20:387–406

Chang X, Zhang Q, Guo C (2020) Asymmetric electrochemical transformations. Angew Chem 132:12712–12722

Ghosh M, Shinde VS, Rueping M (2019) A review of asymmetric synthetic organic electrochemistry and electrocatalysis: concepts, applications, recent developments and future directions. Beilstein J Org Chem 15:2710–2746

Lin Q, Li L, Luo S (2019) Asymmetric electrochemical catalysis. Chem.-Eur. J. 25:10033–10044

Jiao K-J et al (2022) The applications of electrochemical synthesis in asymmetric catalysis. Chem Catal 2:3019–3047

Ogawa KA, Boydston AJ (2015) Recent developments in organocatalyzed electroorganic chemistry. Chem Lett 44:10–16

Malapit CA et al (2022) Advances on the merger of electrochemistry and transition metal catalysis for organic synthesis. Chem Rev 122:3180–3218

Wang X, Xu X, Wang Z, Fang P, Mei T (2020) Advances in asymmetric organotransition metal-catalyzed electrochemistry. Chin J Org Chem 40:3738

Zheng W, Tao Y, Ma W, Lu Q (2023) Asymmetric organic electrochemistry catalyzed by transition metals. Synthesis 55:2896–2910

Arshi S, Nozari-Asbemarz M, Magner E (2020) Enzymatic bioreactors: an electrochemical perspective. Catalysts 10:1232

Harnisch F, Holtmann D (2019) Bioelectrosynthesis. Adv Biochem Eng Biotechnol, vol 167. Springer International Publishing. https://doi.org/10.1007/978-3-030-03299-9

Bernhardt PV (2006) Enzyme electrochemistry – biocatalysis on an electrode. Aust J Chem 59:233

Cadoux C, Milton RD (2020) Recent enzymatic electrochemistry for reductive reactions. ChemElectroChem 7:1974–1986

Wu R, Ma C, Zhu Z (2020) Enzymatic electrosynthesis as an emerging electrochemical synthesis platform. Curr Opin Electrochem 19:1–7

Chen H et al (2020) Fundamentals, applications, and future directions of bioelectrocatalysis. Chem Rev 120:12903–12993

Schröder U (2020) Electrochemistry: connector of sciences. J Solid State Electrochem 24:2179–2180

Sommer F et al (2022) Sustainable synthesis of noroxymorphone via a key electrochemical n-demethylation step. ACS Sustainable Chem Eng 10:8988–8996

Lipp A et al (2019) Total synthesis of (−)-oxycodone via anodic aryl-aryl coupling. Org Lett 21:1828–1831

Lipp A et al (2018) A Regio- and diastereoselective anodic aryl-aryl coupling in the biomimetic total synthesis of (−)-thebaine. Angew Chem Int Ed 57:11055–11059

Röckl JL, Pollok D, Franke R, Waldvogel SR (2020) A decade of electrochemical dehydrogenative C,C-coupling of aryls. Acc Chem Res 53:45–61

Waldvogel SR, Lips S, Selt M, Riehl B, Kampf CJ (2018) Electrochemical arylation reaction. Chem Rev 118:6706–6765

Rodriguez-Zubiri M, Felpin F-X (2022) Analytical tools integrated in continuous-flow reactors: which one for what? Org Process Res Dev 26:1766–1793

Santi M et al (2019) Memory of Chirality in Flow Electrochemistry: Fast Optimisation with DoE and Online 2D-HPLC. Chem - Eur J 25:16230–16235

Zhao G, Hsu DC, Carlier PR (2005) Memory of chirality: an emerging strategy for asymmetric synthesis. Synthesis:1–16. https://doi.org/10.1055/s-2004-834931

Seebach D, Wasmuth D (1981) Alkylation of amino acids without loss of optical activity:α- andβ-alkylation of an aspartic acid derivative. Angew Chem Int Ed Engl 20:971–971

Kawabata T, Yahiro K, Fuji K (1991) Memory of chirality: enantioselective alkylation reactions at an asymmetric carbon adjacent to a carbonyl group. J Am Chem Soc 113:9694–9696

Weissman SA, Anderson NG (2015) Design of experiments (DoE) and process optimization. A review of recent publications. Org. Process Res. Dev. 19:1605–1633

Lassaletta JM (2020) Spotting trends in organocatalysis for the next decade. Nat Commun 11:3787

Yoshimura A, Zhdankin VV (2016) Advances in synthetic applications of hypervalent iodine compounds. Chem Rev 116:3328–3435

Singh FV, Shetgaonkar SE, Krishnan M, Wirth T (2022) Progress in organocatalysis with hypervalent iodine catalysts. Chem Soc Rev 51:8102–8139

Gao W-C, Xiong Z-Y, Pirhaghani S, Wirth T (2019) Enantioselective electrochemical lactonization using chiral iodoarenes as mediators. Synthesis 51:276–284

Elsherbini M, Wirth T (2018) Hypervalent iodine reagents by anodic oxidation: a powerful green synthesis. Chem - Eur J 24:13399–13407

Kumar N, He J, Rusling JF (2023) Electrochemical transformations catalyzed by cytochrome P450s and peroxidases. Chem Soc Rev 52:5135–5171

Sellés Vidal L, Kelly CL, Mordaka PM, Heap JT (2018) Review of NAD(P)H-dependent oxidoreductases: properties, engineering and application. Biochim Biophys Acta BBA - Proteins Proteomics 1866:327–347

Wang X et al (2017) Cofactor NAD(P)H regeneration inspired by heterogeneous pathways. Chem 2:621–654

Yoon SK, Choban ER, Kane C, Tzedakis T, Kenis PJA (2005) Laminar flow-based electrochemical microreactor for efficient regeneration of nicotinamide cofactors for biocatalysis. J Am Chem Soc 127:10466–10467

Höllrigl V, Otto K, Schmid A (2007) Electroenzymatic asymmetric reduction of rac- 3-Methylcyclohexanone to (1 S,3 S )-3-methylcyclohexanol in organic/aqueous media catalyzed by a thermophilic alcohol dehydrogenase. Adv Synth Catal 349:1337–1340

Ruinatscha R, Dusny C, Buehler K, Schmid A (2009) Productive asymmetric styrene epoxidation based on a next generation electroenzymatic methodology. Adv Synth Catal 351:2505–2515

Jaegfeldt H (1981) A study of the products formed in the electrochemical reduction of nicotinamide-adenine-dinucleotide. J Electroanal Chem Interfacial Electrochem 128:355–370

Hollmann F, Witholt B, Schmid A (2002) [Cp∗Rh(bpy)(H2O)]2+: a versatile tool for efficient and non-enzymatic regeneration of nicotinamide and flavin coenzymes. J Mol Catal B Enzym 19–20:167–176

Hollmann F, Hofstetter K, Habicher T, Hauer B, Schmid A (2005) Direct electrochemical regeneration of monooxygenase subunits for biocatalytic asymmetric epoxidation. J Am Chem Soc 127:6540–6541

Kochius S et al (2014) Enantioselective enzymatic synthesis of the α-hydroxy ketone (R)-acetoin from meso-2,3-butanediol. J Mol Catal B Enzym 103:61–66

Kochius S et al (2014) Electrochemical regeneration of oxidised nicotinamide cofactors in a scalable reactor. J Mol Catal B Enzym 103:94–99

Schröder I, Steckhan E, Liese A (2003) In situ NAD+ regeneration using 2,2′-azinobis(3-ethylbenzothiazoline-6-sulfonate) as an electron transfer mediator. J Electroanal Chem 541:109–115

Hartwig JF (2010) Organotransition metal chemistry: from Bonding to Catalysis. Mill Valley, California. University Science Books

Behera P, Ramakrishna DS, Chandrasekhar MM, Kothakapu SR (2023) A concise review on recent advances in catalytic asymmetric hydrogenation. Chirality 35:477–497

Kraft S, Ryan K, Kargbo RB (2017) Recent Advances in Asymmetric Hydrogenation of Tetrasubstituted Olefins. J Am Chem Soc 139:11630–11641

Biosca M, Diéguez M, Zanotti-Gerosa A (2021) Chapter five - asymmetric hydrogenation in industry. In: Diéguez M, Pizzano A (eds) Metal-catalyzed Asymmetric Hydrogenation: Evolution and Prospect, vol 68. Academic Press, New York, pp 341–383. https://doi.org/10.1016/bs.acat.2021.08.005

Blaser H-U, Pugin B, Spindler F (2012) Asymmetric Hydrogenation. In: Blaser H, Beller M (eds) Organometallics as Catalysts in the Fine Chemical Industry. Heidelberg, Springer, Berlin, pp 65–102

Shi Z et al (2021) Recent advances in the electrochemical hydrogenation of unsaturated hydrocarbons. Curr Opin Electrochem 28:100713

Fukazawa A, Tanaka K, Hashimoto Y, Sato Y, Atobe M (2020) Electrocatalytic asymmetric hydrogenation of α, β-unsaturated acids in a PEM reactor with cinchona-modified palladium catalysts. Electrochem Commun 115:106734

Shimizu Y et al (2023) Diastereoselective electrocatalytic hydrogenation of cyclic ketones using a proton-exchange membrane reactor: a step toward the electrification of fine-chemical production. ACS Energy Lett 8:1010–1017

Lu J, Wang Y, McCallum T, Fu N (2020) Harnessing radical chemistry via electrochemical transition metal catalysis. iScience 23:101796

Sauermann N, Meyer TH, Ackermann L (2018) Electrochemical cobalt-catalyzed C−H activation. Chem - Eur J 24:16209–16217

Lin Y, Von Münchow T, Ackermann L (2023) Cobaltaelectro-catalyzed C-H annulation with allenes for atropochiral and P -stereogenic compounds: late-stage diversification and continuous flow scale-up. ACS Catal 13:9713–9723

Funding

Open access funding provided by Università degli Studi di Padova within the CRUI-CARE Agreement

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The author declares no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mazzarella, D. Asymmetric electrochemical synthesis in flow. J Flow Chem 14, 357–366 (2024). https://doi.org/10.1007/s41981-023-00293-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41981-023-00293-x