Abstract

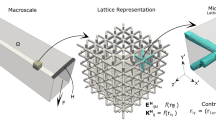

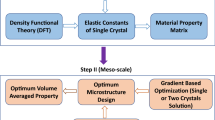

This paper introduces procedural generation of lattice structures inside predefined volumes for fatigue life enhancement of multiscale constructed structural components. Global optimization is applied to search the design space such that the mass and fatigue damage is minimized given the orientation of the microscopic lattice unit cells and the volume fraction of lattice material. A two-step optimization procedure is applied to avoid local minima. The macro-scale distribution of homogenized lattice material is first determined using a design search method. The second stage employs global optimization with surrogate modeling. Training data is initialized by hypercube sampling to fit a surrogate model so that a genetic algorithm can locate the global minima of the global design space using the lattice rotation and solid volume fraction. New results are applied to the procedural methods to create new testable models which optimize the microscale for minimum mass. New data points are used to enrich the surrogate model database and the model is rebuilt. The procedure iterates until a convergence criterion is met. A case study is presented to demonstrate the proposed methodology to which the mass was reduced by 87%, while fatigue performance was conserved for long life cycles of 106. A comparison between lattice modeled with linear beam elements versus lattice material as a three-dimensional solid is presented to validate the optimal solution. It is found that stresses were underestimated by at most a factor of four, while the difference in deflections was maintained within 8.1%.

Similar content being viewed by others

Availability of data and materials

The data presented in this study are available on request from the corresponding author.

Code availability

N/A.

References

Allaire G (1997) The homogenization method for topology and shape optimization. Springer, Vienna

Bendsøe MP, Sigmund O (1989) Optimal shape design as a material distribution problem. Struct Optimiz 1:193–202

Bendsoe MP, Sigmund O (1999) Topology optimization: theory, methods and applications. Springer, New York

Buhmann MD (2003) Radial basis functions: theory and implementations. The Press Syndicate of the University of Cambridge, Cambridge

Deb K, Pratap A, Agarwal S, Meyarivan T (2002) A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans Evol Comput 6(2):182–197

Fang Q (2018) Iso2Mesh. (MATLAB File Echange). Retrieved April 21, 2020, from https://www.mathworks.com/matlabcentral/fileexchange/68258-iso2mesh/

Hassani B, Hinton E (1999) Homogenization theory for media with periodic structure. In: Homogenization and structural topology optimization. Springer, London

Holmberg E, Torstenfelt B, Klarbring A (2013) Stress constrained topology optimization. Struct Multidiscip Optim 48(1):33–47

Horstemeyer MF (2009) Multiscale modeling: a review. Practical aspects of computational chemistry. Springer, New York, pp 87–135

Hussein A, Hao L, Yan C, Everson R, Young P (2013) Advanced lattice support structures for metal additive manufacturing. J Mater Process Technol 213(7):1019–1026

Huynh L, Rotella J, Sangrid MD (2016) Fatigue behavior of IN718 microtrusses produced via additive manufacturing. Mater Des 105:278–289

Kmiecik S, Gront D, Kolinski M, Wieteska L, Dawid AE, Kolinski A (2016) Coarse-grained protein models and their applications. Chem Rev 116(14):7898–7936

Krishna Dasari AS, Chaddad PA (2019) Random forest surrogate models to support design space exploration in aerospace use-case. In: Artificial intelligence applications and innovations (AIAI 2019), pp 532–544

Lebel LL, Therriault D (2011) Multiscale manufacturing of three-dimensional polymer-based nanocomposite structures. In: Advances in diverse industrial applications of nanocomposites, pp 409–428.

Lee J-Y, An J, Chua CK (2017) Fundamentals and applications of 3D printing for novel materials. Appl Mater Today 7:120–133

Li Z, Liu C, Wang B, Wang Z, Yang F, Gao C, Qin Y et al (2018) Heat treatment effect on the mechanical properties, roughness and bone ingrowth capacity of 3D printing porous titanium alloy. R Soc Chem 8:12471–12483

Li D, Dai N, Tang Y, Dong G, Zhao YF (2019) Design and optimization of graded cellular structures with triply periodic level surface-based topological shapes. J Mech Design. https://doi.org/10.1115/1.4042617

Lopes E, Cremasco A, Afonso C, Caram R (2011) Effects of double aging heat treatment on the microstructure, Vickers hardness and elastic modulus of Ti–Nb alloys. Mater Charact 62(7):673–680

Lucia A, DiMaggio PA (2004) Multi-scale optimization. Eur Symp Comput Aided Process Eng 14:1093–1098

Manu (2015) Patch Remesher. (MATLAB Central File Exhange). Retrieved April 21, 2020, from https://www.mathworks.com/matlabcentral/fileexchange/49691-patch-remesher

Moravec F, Roman S (2009) Numerical computing of elastic homogenized coefficients for periodic fibrous tissue. Appl Comput Mech 3:141–152

Pasini D, Moussa A, Rahimizadeh A (2018) Stress-constrained topology optimization for lattice materials. In: Altenbach H, Öchsner A (eds) Encyclopedia of Continuum Mechanics. Springer, Berlin, Heidelberg

Pincus M (1970) Letter to the Editor—A Monte Carlo method for the approximate solution of certain types of constrained optimization problems. Oper Res 18(6):1225–1228

Ruschau JJ, John R, Thompson SR, Nicholas T (1999) Fatigue crack nucleation and growth rate behavior of laser shock peened titanium. Int J Fatigue 21(1):S199–S209

Skala V (2016) A practical use of radial basis functions interpolation and approximation. Investig Oper 37(2):137–145

Spiga E, Degiacomi MT, Peraro MD (2014) Chapter Three—New strategies for integrative dynamic modeling of macromolecular assembly. Adv Protein Chem Struct Biol 96:77–111

Trudel E, ElSayed M (2021) Conformal wireframe nets for trimmed symmetric unit cells in functionally graded lattice materials. Appl Mech 2:81–107

Walker P, Malz S, Trudel E, ElSayed M, Kok L (2019) Effects of ultrasonic impact treatment on the stress-controlled fatigue performance of additively manufactured DMLS Ti-6Al-4V alloy. Appl Sci 9(22):4787

Wang Y, Xu H, Pasini D (2017) Multiscale isogeometric topology optimization for lattice materials. Comput Methods Appl Mech Eng 316:568–585

Wang C, Zhu J, Wu M, Hou J, Zhou H, Meng L, Zhang W et al (2021) Multi-scale design and optimization for solid-lattice hybrid structures and their application to aerospace vehicle components. Chin J Aeronaut 34(5):386–398

Xia L (2016) Multiscale structural topology optimization, 1st edn. ISTE Press-Elsevier, London

Yang X, Xie Y, Steven G, Querin O (1999) Bidirectional evolutionary method for stiffness optimization method. Struct Multidiscipl Optim 37:430–438

Yuan J, Li YM, Liu CL, Zha XF (2010) Leave-One-Out cross-validation based model selection for manifold regularization. In: Zhang L, Lu BL, Kwok J (eds) Advances in Neural Networks - ISNN 2010. ISNN 2010. Lecture Notes in Computer Science, vol 6063. Springer, Berlin, Heidelberg

Zeng Q, Yu A, Lu G (2008) Multiscale modeling and simulation of polymer nanocomposites. Prog Polym Sci 33(2):191–269

Zuo ZH, Huang X, Rong JH, Xie MY (2013) Multi-scale design of composite materials and structures for maximum natural frequencies. Mater Des 51:1023–1034

Acknowledgements

This work is carried out with the support from BOMBARDIER INC. Montreal, in collaboration with CARIC National Forum and MITACS Canada.

Funding

This research was funded by BOMBARDIER INC., in collaboration with CARIC National Forum, grant number MDO-1601 TRL4+ and MITACS Canada, Grant number IT07461.

Author information

Authors and Affiliations

Contributions

Conceptualization, MSAE; methodology, ET and MSAE; software, ET; validation, ET and MSAE; formal analysis, ET; investigation, ET; resources, MSAE; data curation, ET; writing—original draft preparation, ET; writing—review and editing, MSAE; visualization, ET; supervision, MSAE; project administration, MSAE; funding acquisition, MSAE.

Corresponding author

Ethics declarations

Conflict of interest

The authors hereby declare no conflicting interests.

Ethics approval

N/A.

Consent to participate

N/A.

Consent for publication

All authors have approved the content of this manuscript for submission and the manuscript is not under consideration for publication elsewhere.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix

A: Cubic lattice properties

Cubic lattice relative properties (Poisson ratio = 0.3) | ||||||

|---|---|---|---|---|---|---|

Density | Radius | D/L | 1st lame | 2nd lame | Poisson ratio | Modulus |

0.00E+ 00 | 0.00E+00 | 0.00E+00 | 0.00E+00 | 0.00E+00 | 1.53E+00 | 0.00E+00 |

4.67E−03 | 2.00E−02 | 4.00E−02 | 3.06E−05 | 4.11E−06 | 1.53E+00 | 4.61E−06 |

1.37E−02 | 4.00E−02 | 8.00E−02 | 1.66E−04 | 3.65E−05 | 1.45E+00 | 4.03E−05 |

3.55E−02 | 6.00E−02 | 1.20E−01 | 7.45E−04 | 2.58E−04 | 1.35E+00 | 2.79E−04 |

5.63E−02 | 8.00E−02 | 1.60E−01 | 1.62E−03 | 7.20E−04 | 1.29E+00 | 7.68E−04 |

8.44E−02 | 1.00E−01 | 2.00E−01 | 3.19E−03 | 1.79E−03 | 1.21E+00 | 1.87E−03 |

1.15E−01 | 1.20E−01 | 2.40E−01 | 5.47E−03 | 3.67E−03 | 1.15E+00 | 3.80E−03 |

1.55E−01 | 1.40E−01 | 2.80E−01 | 9.47E−03 | 7.61E−03 | 1.09E+00 | 7.76E−03 |

2.01E−01 | 1.60E−01 | 3.20E−01 | 1.51E−02 | 1.40E−02 | 1.03E+00 | 1.41E−02 |

2.40E−01 | 1.80E−01 | 3.60E−01 | 2.14E−02 | 2.22E−02 | 9.86E−01 | 2.21E−02 |

2.88E−01 | 2.00E−01 | 4.00E−01 | 3.05E−02 | 3.49E−02 | 9.46E−01 | 3.45E−02 |

3.38E−01 | 2.20E−01 | 4.40E−01 | 4.28E−02 | 5.34E−02 | 9.11E−01 | 5.23E−02 |

3.83E−01 | 2.40E−01 | 4.80E−01 | 5.65E−02 | 7.51E−02 | 8.84E−01 | 7.31E−02 |

4.44E−01 | 2.60E−01 | 5.20E−01 | 7.88E−02 | 1.11E−01 | 8.61E−01 | 1.07E−01 |

4.90E−01 | 2.80E−01 | 5.60E−01 | 1.01E−01 | 1.46E−01 | 8.49E−01 | 1.41E−01 |

5.48E−01 | 3.00E−01 | 6.00E−01 | 1.34E−01 | 1.96E−01 | 8.43E−01 | 1.89E−01 |

5.98E−01 | 3.20E−01 | 6.40E−01 | 1.72E−01 | 2.51E−01 | 8.44E−01 | 2.42E−01 |

6.47E−01 | 3.40E−01 | 6.80E−01 | 2.17E−01 | 3.12E−01 | 8.50E−01 | 3.01E−01 |

6.95E−01 | 3.60E−01 | 7.20E−01 | 2.71E−01 | 3.81E−01 | 8.61E−01 | 3.69E−01 |

7.35E−01 | 3.80E−01 | 7.60E−01 | 3.31E−01 | 4.51E−01 | 8.74E−01 | 4.38E−01 |

7.87E−01 | 4.00E−01 | 8.00E−01 | 4.16E−01 | 5.41E−01 | 8.93E−01 | 5.27E−01 |

8.27E−01 | 4.20E−01 | 8.40E−01 | 5.03E−01 | 6.25E−01 | 9.12E−01 | 6.12E−01 |

8.63E−01 | 4.40E−01 | 8.80E−01 | 5.88E−01 | 7.01E−01 | 9.29E−01 | 6.89E−01 |

8.93E−01 | 4.60E−01 | 9.20E−01 | 6.72E−01 | 7.71E−01 | 9.45E−01 | 7.61E−01 |

9.18E−01 | 4.80E−01 | 9.60E−01 | 7.48E−01 | 8.29E−01 | 9.59E−01 | 8.21E−01 |

9.43E−01 | 5.00E−01 | 1.00E+00 | 8.23E−01 | 8.83E−01 | 9.71E−01 | 8.78E−01 |

1.00E+00 | 5.40E−01 | 1.08E+00 | 1.00E+00 | 1.00E+00 | 1.00E+00 | 1.00E+00 |

Cubic lattice curve fitted effective stresses at yielding (Poisson ratio = 0.3) | |||||||

|---|---|---|---|---|---|---|---|

Density | \({\sigma }_{xx}^{y}\) | \({\sigma }_{yy}^{y}\) | \({\sigma }_{zz}^{y}\) | \({\sigma }_{xy}^{y}\) | \({\sigma }_{yz}^{y}\) | \({\sigma }_{xz}^{y}\) | \({\sigma }_{\mathrm{avg}}^{y}\) |

0.00E+00 | 0.00E+00 | 0.00E+00 | 0.00E+00 | 0.00E+00 | 0.00E+00 | 0.00E+00 | 0.00E+00 |

4.67E−03 | 1.60E−03 | 1.60E−03 | 1.60E−03 | 1.10E−04 | 1.12E−04 | 1.11E−04 | 8.54E−04 |

1.37E−02 | 4.77E−03 | 4.77E−03 | 4.77E−03 | 3.19E−04 | 3.19E−04 | 3.20E−04 | 2.55E−03 |

3.55E−02 | 1.22E−02 | 1.22E−02 | 1.22E−02 | 1.23E−03 | 1.20E−03 | 1.20E−03 | 6.69E−03 |

5.63E−02 | 1.82E−02 | 1.82E−02 | 1.81E−02 | 1.87E−03 | 1.87E−03 | 1.88E−03 | 1.00E−02 |

8.44E−02 | 2.64E−02 | 2.64E−02 | 2.64E−02 | 3.15E−03 | 3.15E−03 | 3.15E−03 | 1.48E−02 |

1.15E−01 | 3.48E−02 | 3.49E−02 | 3.48E−02 | 4.69E−03 | 4.68E−03 | 4.67E−03 | 1.98E−02 |

1.55E−01 | 4.56E−02 | 4.57E−02 | 4.55E−02 | 7.55E−03 | 7.55E−03 | 7.53E−03 | 2.66E−02 |

2.01E−01 | 5.91E−02 | 5.94E−02 | 5.91E−02 | 1.12E−02 | 1.12E−02 | 1.11E−02 | 3.52E−02 |

2.40E−01 | 6.97E−02 | 7.00E−02 | 6.97E−02 | 1.46E−02 | 1.46E−02 | 1.46E−02 | 4.22E−02 |

2.88E−01 | 8.30E−02 | 8.32E−02 | 8.29E−02 | 1.96E−02 | 1.96E−02 | 1.96E−02 | 5.13E−02 |

3.38E−01 | 9.86E−02 | 9.88E−02 | 9.86E−02 | 2.64E−02 | 2.64E−02 | 2.64E−02 | 6.25E−02 |

3.83E−01 | 1.11E−01 | 1.12E−01 | 1.11E−01 | 3.28E−02 | 3.29E−02 | 3.28E−02 | 7.22E−02 |

4.44E−01 | 1.30E−01 | 1.30E−01 | 1.30E−01 | 4.40E−02 | 4.40E−02 | 4.40E−02 | 8.69E−02 |

4.90E−01 | 1.44E−01 | 1.45E−01 | 1.44E−01 | 5.38E−02 | 5.38E−02 | 5.38E−02 | 9.91E−02 |

5.48E−01 | 1.67E−01 | 1.67E−01 | 1.67E−01 | 6.93E−02 | 6.93E−02 | 6.93E−02 | 1.18E−01 |

5.98E−01 | 1.87E−01 | 1.87E−01 | 1.87E−01 | 8.52E−02 | 8.52E−02 | 8.52E−02 | 1.36E−01 |

6.47E−01 | 2.09E−01 | 2.09E−01 | 2.09E−01 | 1.03E−01 | 1.03E−01 | 1.03E−01 | 1.56E−01 |

6.95E−01 | 2.33E−01 | 2.33E−01 | 2.33E−01 | 1.26E−01 | 1.26E−01 | 1.26E−01 | 1.79E−01 |

7.35E−01 | 2.56E−01 | 2.56E−01 | 2.56E−01 | 1.51E−01 | 1.51E−01 | 1.51E−01 | 2.03E−01 |

7.87E−01 | 2.87E−01 | 2.87E−01 | 2.87E−01 | 1.92E−01 | 1.92E−01 | 1.92E−01 | 2.39E−01 |

8.27E−01 | 3.21E−01 | 3.21E−01 | 3.21E−01 | 2.31E−01 | 2.31E−01 | 2.31E−01 | 2.76E−01 |

8.63E−01 | 3.85E−01 | 3.85E−01 | 3.85E−01 | 2.97E−01 | 2.97E−01 | 2.97E−01 | 3.41E−01 |

8.93E−01 | 4.58E−01 | 4.58E−01 | 4.58E−01 | 3.79E−01 | 3.79E−01 | 3.79E−01 | 4.18E−01 |

9.18E−01 | 5.35E−01 | 5.35E−01 | 5.35E−01 | 4.68E−01 | 4.68E−01 | 4.68E−01 | 5.02E−01 |

9.43E−01 | 6.42E−01 | 6.42E−01 | 6.42E−01 | 5.90E−01 | 5.90E−01 | 5.90E−01 | 6.16E−01 |

1.00E+00 | 1.00E+00 | 1.00E+00 | 1.00E+00 | 1.00E+00 | 1.00E+00 | 1.00E+00 | 1.00E+00 |

B: Pareto frontier values

Optimization | Log(damage) | Damage | Volume fraction | Distance to utopia |

|---|---|---|---|---|

A | − 1.53E+01 | 2.27E−07 | 9.98E−02 | 1.20E+01 |

B | − 2.20E+01 | 2.74E−10 | 2.00E−01 | 5.27E+00 |

C | − 2.50E+01 | 1.33E−11 | 3.00E−01 | 2.26E+00 |

D | − 2.61E+01 | 4.57E−12 | 4.00E−01 | 1.24E+00 |

E | − 2.68E+01 | 2.33E−12 | 5.00E−01 | 7.05E−01 |

F | − 2.70E+01 | 1.81E−12 | 6.00E−01 | 6.48E−01 |

G | − 2.71E+01 | 1.64E−12 | 7.00E−01 | 7.15E−01 |

H | − 2.73E+01 | 1.43E−12 | 8.00E−01 | 8.00E−01 |

I | − 2.73E+01 | 1.42E−12 | 8.99E−01 | 8.99E−01 |

Rights and permissions

About this article

Cite this article

Trudel, E., ElSayed, M.S.A. Global multiscale design optimization of procedural lattice structures for fatigue enhancement. Multiscale and Multidiscip. Model. Exp. and Des. 4, 145–167 (2021). https://doi.org/10.1007/s41939-021-00095-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41939-021-00095-5